Documente Academic

Documente Profesional

Documente Cultură

Uht-56 Asme Viii Div 1 2010

Încărcat de

Germán Lobo Clavijo100%(1)100% au considerat acest document util (1 vot)

207 vizualizări1 paginătratamiento termico

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documenttratamiento termico

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

207 vizualizări1 paginăUht-56 Asme Viii Div 1 2010

Încărcat de

Germán Lobo Clavijotratamiento termico

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

2010 SECTION VIII DIVISION 1

by the rules of UG-33, using the applicable external pressure charts referenced in Table 1A of Section II, Part D

and given in Subpart 3 of Section II, Part D.

UHT-34

attachment of the head or shell [see UHT-56(b) and (c)].

(e) When material of SA-333 Grade 8, SA-334 Grade

8, SA-353, SA-522, SA-553, and SA-645, Grade A are

postweld heat treated, the complete vessel or vessel component being so heat treated shall be maintained within the

permissible temperature range defined in Table UHT-56.

HEMISPHERICAL HEADS

When hemispherical heads are used, the head-to-shell

transition of Fig. UW-13.1 sketch (j) or Fig. UW-13.1

sketch (l) shall be used. When the weld is in or adjacent

to the tapered section, it shall be finished in a manner that

will maintain the required uniform slope for the full length

of the tapered section.

UHT-40

UHT-57

(a) Radiography. Radiographic examination for the

complete length of weld in accordance with the requirements of UW-51 is required for all welded joints of Type

No. (1) of Table UW-12. The required radiographic examination shall be made after any corrosion-resistant alloy

cover weld has been deposited.

(b) Nozzle Attachment Welds. Nozzle attachment welds

as provided for in UHT-18, Figs. UHT-18.1 and UHT-18.2

shall be radiographically examined in accordance with the

requirements of UW-51, except that Fig. UHT-18.2 type

nozzles having an inside diameter of 2 in. (50 mm) or less

shall be examined by a magnetic particle or liquid penetrant

method. For nozzle attachments illustrated as sketches (a),

(b), and (f) of Fig. UHT-18.2, the exposed cross section

of the vessel wall at the opening shall be included in the

examination.

(c) All corrosion resistant overlay weld deposits shall

be examined by the liquid penetrant method.

(d) Magnetic Particle Method. All welds, including

welds for attaching nonpressure parts to heat treated steels

covered by this Part, shall be examined by the magnetic

particle method after the hydrostatic test, except that those

surfaces not accessible after the hydrostatic test shall be

examined by the magnetic particle method at the last feasible stage of vessel fabrication. A magnetization method

shall be used that will avoid arc strikes. Cracks shall be

repaired or removed.

(e) Liquid Penetrant Method. As an acceptable alternative to magnetic particle examination or when magnetic

particle methods are not feasible because of the nonmagnetic character of the weld deposits, a liquid penetrant

method shall be used. For vessels constructed of SA-333

Grade 8, SA-334 Grade 8, SA-353, SA-522, SA-553

Grades A and B, and SA-645 materials, welds not examined radiographically shall be examined by the liquid penetrant method either before or after the hydrotest. Cracks are

unacceptable and shall be repaired or removed. Relevant

indications are those which result from imperfections. Linear indications are those indications in which the length

is more than three times the width. Any relevant linear

indications greater than 116 in. (1.5 mm) shall be repaired

or removed.

MATERIALS HAVING DIFFERENT

COEFFICIENTS OF EXPANSION

When welding materials with austenitic electrodes, the

differences between the coefficients of expansion and the

strengths of the base material and the weld metal should

be carefully considered, particularly for applications

involving cyclic stresses.

(10)

UHT-56

EXAMINATION

POSTWELD HEAT TREATMENT

(a) Before applying the detailed requirements and

exemptions in these paragraphs, satisfactory weld procedure qualifications of the procedures to be used shall be

performed in accordance with all of the variables in Section

IX including conditions of postweld heat treatment or lack

of postweld heat treatment and including restrictions listed

below. When determining the thickness requiring postweld

treatment in Table UHT-56 for clad or weld deposit overlayed vessels or parts of vessels, the total thickness of the

material, including the clad and weld deposit overlay, shall

be employed.

(b) Vessels or vessel parts constructed of steels listed

in Table UHT-23 shall be postweld heat treated when

required in Table UHT-56, except that postweld heat treatment shall be required for all thicknesses when joining the

materials with the inertia and continuous drive friction

welding processes.

(c) Postweld heat treatment shall be performed in accordance with UCS-56 as modified by the requirements of

Table UHT-56. In no case shall the PWHT temperature

exceed the tempering temperature. PWHT and tempering

may be accomplished concurrently. The maximum cooling

rate established in UCS-56(e)(5) need not apply. Where

accelerated cooling from the tempering temperature is

required by the material specification, the same minimum

cooling rate shall apply to PWHT.

(d) All welding of connections and attachments shall be

postweld heat treated whenever required by Table UHT-56

based on the greatest thickness of material at the point of

238

S-ar putea să vă placă și

- Tubos de Aço - Dimensões Normalizadas: MM MM cm2 cm2 m2/m Linear cm4 cm3 M/M LinearDocument8 paginiTubos de Aço - Dimensões Normalizadas: MM MM cm2 cm2 m2/m Linear cm4 cm3 M/M LinearJunior RodriguesÎncă nu există evaluări

- Pipe Fittings Equivalent LengthDocument3 paginiPipe Fittings Equivalent LengthRashel Hasan100% (1)

- Saudi Arabian Oil Company: Instrument Specification Sheet Differential Type Level InstrumentsDocument1 paginăSaudi Arabian Oil Company: Instrument Specification Sheet Differential Type Level Instrumentsgayu87Încă nu există evaluări

- Asme B16.36 Int PDFDocument3 paginiAsme B16.36 Int PDFRuben Dario Mamani ArellanoÎncă nu există evaluări

- Sockolet, Threadolet Weight Chart (Unit in KG)Document1 paginăSockolet, Threadolet Weight Chart (Unit in KG)gobiÎncă nu există evaluări

- Estandar de SoporteriaDocument74 paginiEstandar de SoporteriaRuth Tecsi TCÎncă nu există evaluări

- M-2006 Weld KGDocument8 paginiM-2006 Weld KGDinesh ShahÎncă nu există evaluări

- Swaging Machine OPDocument40 paginiSwaging Machine OPOsvaldo Urzua Castillo100% (1)

- Pipe Dimensions Imperial/MetricDocument3 paginiPipe Dimensions Imperial/MetricmtbecerrapÎncă nu există evaluări

- 031 DG Pi05 0301 0Document28 pagini031 DG Pi05 0301 0powerclean ctgÎncă nu există evaluări

- Anexo I - Típicos de Soportes Metálicos PDFDocument174 paginiAnexo I - Típicos de Soportes Metálicos PDFAngely CanalesÎncă nu există evaluări

- ASME B31.3 & Expansion JointsDocument2 paginiASME B31.3 & Expansion JointsHomer SilvaÎncă nu există evaluări

- API 12B - Bolted Tanks TableDocument1 paginăAPI 12B - Bolted Tanks TableED SA CAÎncă nu există evaluări

- Welding Electrodes SelectionDocument19 paginiWelding Electrodes SelectionjerickÎncă nu există evaluări

- Asme Sec Viii D1 C PT UhtDocument14 paginiAsme Sec Viii D1 C PT Uhtkcp1986Încă nu există evaluări

- Special Pipe SupportsDocument293 paginiSpecial Pipe Supportsbkm dizaynÎncă nu există evaluări

- Listado Normas PFIDocument2 paginiListado Normas PFIIsidoro LópezÎncă nu există evaluări

- ASME B16.5 - 3 InchDocument1 paginăASME B16.5 - 3 InchRanjan KumarÎncă nu există evaluări

- Intercambiadores - Ejercicios MaterialDocument62 paginiIntercambiadores - Ejercicios MaterialLuiz Gustavo YamamotoÎncă nu există evaluări

- Subsea Pipeline Technology: Radial Flow TeeDocument1 paginăSubsea Pipeline Technology: Radial Flow TeeJuan Roberto López BetanzosÎncă nu există evaluări

- Odin Elastopipe Eng Oct 2019 PDFDocument2 paginiOdin Elastopipe Eng Oct 2019 PDFHafidzManaf100% (1)

- Vertical Compress DrawingDocument1 paginăVertical Compress DrawingFaull JackmanÎncă nu există evaluări

- Process Industry Practices Coatings: PIP CTCE1000 External Coating System Selection CriteriaDocument27 paginiProcess Industry Practices Coatings: PIP CTCE1000 External Coating System Selection CriteriaCarlos Maldonado SalazarÎncă nu există evaluări

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 paginăCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelÎncă nu există evaluări

- Content of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesDocument24 paginiContent of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesJuan Ayala ValdebenitoÎncă nu există evaluări

- Bill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Document5 paginiBill of Material For Mechnical & Structure For Hot Water Skid Rev.0 - 3Vu TranÎncă nu există evaluări

- JCM Split Tee and Weld On Outlets For Industrial ServiceDocument1 paginăJCM Split Tee and Weld On Outlets For Industrial ServiceochableÎncă nu există evaluări

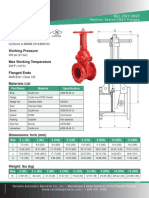

- OS&Y Gate Valve PDFDocument1 paginăOS&Y Gate Valve PDFAhmed Mohamed Abd Elhakam100% (1)

- Gasket Paking ListDocument1 paginăGasket Paking ListIrwansyah MuchtarÎncă nu există evaluări

- Denso Protal 7200Document2 paginiDenso Protal 7200min_one447065Încă nu există evaluări

- Dic Pps Weld StrengthDocument1 paginăDic Pps Weld StrengthWoong KimÎncă nu există evaluări

- Lecture 8fDocument38 paginiLecture 8fhiteshÎncă nu există evaluări

- Hidrante Seco Mod F0733Document1 paginăHidrante Seco Mod F0733Julio FloresÎncă nu există evaluări

- 1.alignment of PipeDocument2 pagini1.alignment of Pipevuong100% (1)

- SHORTSTOPP 300D Split Tees With Guide BarsDocument3 paginiSHORTSTOPP 300D Split Tees With Guide BarsMartin AndradeÎncă nu există evaluări

- Folder Grobblech Heads Cones 1608Document28 paginiFolder Grobblech Heads Cones 1608Filip StojkovskiÎncă nu există evaluări

- ASME Steam Blowing Acceptance CriteriaDocument3 paginiASME Steam Blowing Acceptance CriteriaMuhammad AlfattahÎncă nu există evaluări

- 761-V-103 (Vessel With Demister), PDFDocument1 pagină761-V-103 (Vessel With Demister), PDFAlvin SmithÎncă nu există evaluări

- Cost API 650 Vs API 620Document3 paginiCost API 650 Vs API 620johnÎncă nu există evaluări

- AstmDocument6 paginiAstmMasih BelajarÎncă nu există evaluări

- QT 16Cr PDFDocument1 paginăQT 16Cr PDFYaroslav RuizÎncă nu există evaluări

- Pipe - Line Bevel MachineDocument24 paginiPipe - Line Bevel MachineSun SunÎncă nu există evaluări

- SP3D Piping Isometrics Practice Labs PDFDocument97 paginiSP3D Piping Isometrics Practice Labs PDFKukuh KurniadiÎncă nu există evaluări

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pagini177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Intercambiadores - Tablas y GráficosDocument62 paginiIntercambiadores - Tablas y GráficosLuiz Gustavo YamamotoÎncă nu există evaluări

- 1824 000 PI SPC 0003 - 7 - IFP - CleanedDocument22 pagini1824 000 PI SPC 0003 - 7 - IFP - CleanedJudith HidalgoÎncă nu există evaluări

- Catalogo SchulzDocument61 paginiCatalogo SchulzIsabel PulidoÎncă nu există evaluări

- SBC (Safety Break-Away Couplings) v140630Document16 paginiSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Manhole. API 650-2021Document3 paginiManhole. API 650-2021jose luisÎncă nu există evaluări

- Copia de EPCDocument32 paginiCopia de EPCPeter RodriguezÎncă nu există evaluări

- Clase Bridas y Válvulas 2016Document43 paginiClase Bridas y Válvulas 2016cuervusjcÎncă nu există evaluări

- Douglas Chero Catalogue Valve 6-2003Document89 paginiDouglas Chero Catalogue Valve 6-2003Yurizki LhzÎncă nu există evaluări

- Astm A 234 A234m-15Document9 paginiAstm A 234 A234m-15Mohammed AliÎncă nu există evaluări

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 paginiUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiÎncă nu există evaluări

- Asme Sec Viii Ucs PWHTDocument35 paginiAsme Sec Viii Ucs PWHTMahesh KumarÎncă nu există evaluări

- SecVIII Div1 UW40Document2 paginiSecVIII Div1 UW40arianaseriÎncă nu există evaluări

- 4 Heat TreatmentokDocument22 pagini4 Heat TreatmentokPramod AthiyarathuÎncă nu există evaluări

- Asme Viii Div 1 2013 Cri-1Document4 paginiAsme Viii Div 1 2013 Cri-1vivicastedoÎncă nu există evaluări

- Pressure Vessels Lectures 69Document1 paginăPressure Vessels Lectures 69Adeel NizamiÎncă nu există evaluări

- 2007 Section ViiiDocument3 pagini2007 Section ViiiMiriam LopezÎncă nu există evaluări

- Consideraciones Sa 517 GR B Tanques Transportables Asme Viii Div 1-2013Document4 paginiConsideraciones Sa 517 GR B Tanques Transportables Asme Viii Div 1-2013Germán Lobo ClavijoÎncă nu există evaluări

- Asme Iia-2013-Sa 240 Tipo 304l Dureza MaximaDocument1 paginăAsme Iia-2013-Sa 240 Tipo 304l Dureza MaximaGermán Lobo ClavijoÎncă nu există evaluări

- ASME II-A-2013-Vol-1 198Document1 paginăASME II-A-2013-Vol-1 198Germán Lobo ClavijoÎncă nu există evaluări

- Guia para Instalar El PipelinestudioDocument3 paginiGuia para Instalar El PipelinestudioGermán Lobo ClavijoÎncă nu există evaluări

- Specification For Consumable InsertsDocument18 paginiSpecification For Consumable InsertsSarvesh MishraÎncă nu există evaluări

- GREASe Process ReportDocument110 paginiGREASe Process Reportrazamalik01Încă nu există evaluări

- Compressor BearingsDocument55 paginiCompressor BearingsAnonymous OFP2ygPId100% (1)

- United Insulation DocumentsDocument168 paginiUnited Insulation Documentsjsherrer1Încă nu există evaluări

- Asme Sa 106 Grade A PipesDocument1 paginăAsme Sa 106 Grade A PipesFerroPipEÎncă nu există evaluări

- Checklist Steam BlowingDocument2 paginiChecklist Steam Blowingyushveer002Încă nu există evaluări

- Basic CorrosionDocument11 paginiBasic CorrosionmohdluthfiÎncă nu există evaluări

- Apron FeederDocument10 paginiApron FeederKenny Ruiz100% (1)

- A4 Catalogo TX - 12111Document29 paginiA4 Catalogo TX - 12111msajanjÎncă nu există evaluări

- 1200 PDFDocument9 pagini1200 PDFeidelsayedÎncă nu există evaluări

- The Cyanide Process of Gold Extraction 1000740146 PDFDocument260 paginiThe Cyanide Process of Gold Extraction 1000740146 PDFAnonymous rBcspMzPÎncă nu există evaluări

- BURNDY 2002 Master Catalog PDFDocument688 paginiBURNDY 2002 Master Catalog PDFLuis CabimasÎncă nu există evaluări

- Metal Enclosed Non-Segregated Bus Duct: GE Industrial SolutionsDocument2 paginiMetal Enclosed Non-Segregated Bus Duct: GE Industrial SolutionsMadhu BTÎncă nu există evaluări

- 736 623Document2 pagini736 623slymnÎncă nu există evaluări

- DM PlantDocument21 paginiDM PlantAbdulSalamath100% (10)

- Approved Civil Material VendorsDocument14 paginiApproved Civil Material VendorsOmer SyedÎncă nu există evaluări

- Boiler PlateDocument2 paginiBoiler PlateshazanÎncă nu există evaluări

- Full Range Stress Strain Curves For Stainless Steel PDFDocument15 paginiFull Range Stress Strain Curves For Stainless Steel PDFEvgeny ShavelzonÎncă nu există evaluări

- A181A181MDocument3 paginiA181A181Mrgi178Încă nu există evaluări

- 2 TS SS STR R8 030309 060213Document16 pagini2 TS SS STR R8 030309 060213dkshtdkÎncă nu există evaluări

- Alcoa Ultralloy® 6020-T8 Aluminum: Metal, Nonferrous Metal, Aluminum Alloy, 6000 Series Aluminum AlloyDocument2 paginiAlcoa Ultralloy® 6020-T8 Aluminum: Metal, Nonferrous Metal, Aluminum Alloy, 6000 Series Aluminum AlloyChristina Christina ChristinaÎncă nu există evaluări

- NPS GB PresentationDocument13 paginiNPS GB PresentationSofiDanielaCruzÎncă nu există evaluări

- Value-In-Use Model From Iron Ore Through Direct-Reduced Iron and Electric Arc FurnaceDocument11 paginiValue-In-Use Model From Iron Ore Through Direct-Reduced Iron and Electric Arc FurnaceGladman MundingiÎncă nu există evaluări

- Pohon Industri Baja NasionalDocument1 paginăPohon Industri Baja NasionalrossajnrÎncă nu există evaluări

- QCP For Control of Welding ConsumablesDocument9 paginiQCP For Control of Welding ConsumablesUmair Awan100% (1)

- PGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri5Document1 paginăPGDD KPE 1403 09 EEL MT 002 MTO For Electrical Bulk Material Duri5wibowo wibowoÎncă nu există evaluări

- Rochelle Q2 Report 2009Document299 paginiRochelle Q2 Report 2009drchobbesÎncă nu există evaluări

- Torque in OrthodonticsDocument115 paginiTorque in OrthodonticsRohini TondaÎncă nu există evaluări