Documente Academic

Documente Profesional

Documente Cultură

Hinge Plate PDF

Încărcat de

rentfarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hinge Plate PDF

Încărcat de

rentfarDrepturi de autor:

Formate disponibile

Experimental Investigation on Steel Bracing Connection through Hinge Plate

Abstract

Bracing elements and their connections have played a key role in the steel bracing frame energy

dissipation through yielding and buckling. Whereas it is normally expected that gusset plates yield

and buckle after that of bracing elements. Moreover, bracing elements buckling go with the plastic

hinge formation in gusset plates. However, the geometry requirement to provide plastic hinge

formation leads to larger and consequently thicker gusset plate. This article is a research concerning

steel bracing connection detail. In this proposed steel bracing connection, Hinge Plate manages the

formation of the plastic hinge in the bracing connections. To verify the proposed new idea a

monotonic compression test was conducted on a bracing element that was detailed with Hinge Plate.

As a primary observational goal of the test, buckling mode of bracing element was depicted to be

well managed by Hinge Plate. In addition, it was observed that the hierarchy of yielding in bracing

element and then in Hinge Plate coincided with expected energy dissipation requirement in bracing

frame.

Keywords: bracing connection; gusset plate; plastic hinge; in-plane buckling.

1.

Introduction

Bracing elements in concentrically steel braced frame (CSBF) are designed to provide lateral load

resistance and energy dissipation through yielding and buckling due to tension and compression

respectively. The expected proper energy dissipation pattern is specified in two important

characteristics. Firstly, the bracing section yields in tension before its connection in gusset plate

yields. Secondly, the detailing in gusset plate allows the bracing element to buckle in compression

before any local or global buckling in gusset plate. In a way, yielding and buckling of gusset plate,

before that of bracing element, provide unpleasant failure.

In this regard, design codes [1] express three clauses for gusset plate design limitation. First, the

minimum required tensile strength of gusset plate has to conform to expected yield strength of,

RYFYAg where; RY= 1.1 to 1.5, FY= yield stress and Ag= bracing section area. Second, it has to

provide at least 1.1 times of the expected brace compression strength. Finally, the gusset plate has to

satisfy the plastic hinge formation with the brace terminating before the line of restraint.

The importance of plastic hinges formation in appropriate bracing element function is emphasised.

Development of plastic hinge formation on bracing elements is narrowed down by Astaneh-Asl et al.

[2]. This study is now considered as one of the basic reference in American Institute of Steel

Construction (AISC) [3]. To meet this requirement, gusset plates become larger and consequently

thicker [4]. Many researchers have considered this outcome and tried to develop alternative theory

to reduce gusset plate size resulted from plastic hinge formation. In Fig.1 elliptical clearance band

pattern is used for plastic hinge formation [5]. Another research has presented the three line pattern

for plastic hinge [6]. These researches [5, 6] assumes that gusset plate perform a twofold function of

load transferring and plastic hinge formation. Similar assumptions are also used by other

researchers [2, 4]. Indeed, it is desirable to utilize one structural element for two demanding

functions, if their criterion satisfactions are not in opposite direction. At location where the plastic

hinge formation line is not likely to happen, then the gusset plate dimensions become smaller.

a)AISC pattern

b)Elliptical clearance band theory

Fig.1 plastic hinge patterns

The purpose of this paper is to present an alternative proposal of steel bracing connection through

hinge plate. Accordingly an experimental study is designed and conducted to examine the proposed

bracing connection detail.

S-ar putea să vă placă și

- Buckling and Ultimate Strength of Ship and Ship-like Floating StructuresDe la EverandBuckling and Ultimate Strength of Ship and Ship-like Floating StructuresEvaluare: 4 din 5 stele4/5 (4)

- A New Method For Improving Ductility in Existing RC Ordinary Moment Resisting Frames Using FrpsDocument15 paginiA New Method For Improving Ductility in Existing RC Ordinary Moment Resisting Frames Using Frpsrachellej_436066654Încă nu există evaluări

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsDe la EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoÎncă nu există evaluări

- Bauer 1997 Plastic Modulus AiscDocument16 paginiBauer 1997 Plastic Modulus Aiscatman chanaÎncă nu există evaluări

- Behavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesDe la EverandBehavior and Design of Trapezoidally Corrugated Web Girders for Bridge Construction: Recent AdvancesÎncă nu există evaluări

- An Update On Eccentric Seismic Bracing: Design of A Shear LinkDocument2 paginiAn Update On Eccentric Seismic Bracing: Design of A Shear Linkx620Încă nu există evaluări

- Finite Element Analysis of Bolted Column Base Connection Without and With StiffenersDocument3 paginiFinite Element Analysis of Bolted Column Base Connection Without and With StiffenersJohnson SambranoÎncă nu există evaluări

- Thin-Walled Structures: Xiao-Gang Liu, Jian-Sheng Fan, Yu-Fei Liu, Ming-Zhao Zheng, Jian-Guo NieDocument16 paginiThin-Walled Structures: Xiao-Gang Liu, Jian-Sheng Fan, Yu-Fei Liu, Ming-Zhao Zheng, Jian-Guo NieJhon Smit Gonzales UscataÎncă nu există evaluări

- An Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFDocument21 paginiAn Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFM. Murat ErginÎncă nu există evaluări

- Modelling of The Hysteretic Behaviour of Buckling Restrained BracesDocument8 paginiModelling of The Hysteretic Behaviour of Buckling Restrained BracesCristian Camilo Martinez JimenezÎncă nu există evaluări

- SteelwiseDocument3 paginiSteelwiseAnonymous 7MdZQn1Încă nu există evaluări

- 2021 ShenLiTizani SeisPerRCIntJointNovelReinf EngStruct AsSubmittedDocument22 pagini2021 ShenLiTizani SeisPerRCIntJointNovelReinf EngStruct AsSubmittedQurrain MirÎncă nu există evaluări

- 2022 ShenLiChenTizani RelocatingPlasticHingesRCmechAnc STENG 251 AsSubDocument42 pagini2022 ShenLiChenTizani RelocatingPlasticHingesRCmechAnc STENG 251 AsSubIbrahim BadhushaÎncă nu există evaluări

- Crash Energy-Absorption Structure Design Based On An Innovated Leightweight TechnologyDocument16 paginiCrash Energy-Absorption Structure Design Based On An Innovated Leightweight TechnologySMITIÎncă nu există evaluări

- Plastic Hinge Length of Reinforced Concrete Columns.Document8 paginiPlastic Hinge Length of Reinforced Concrete Columns.nvnrevÎncă nu există evaluări

- Beam Column Joint ThesisDocument5 paginiBeam Column Joint Thesiskarriegarcianorthlasvegas100% (2)

- Choi 2008 Engineering-StructuresDocument10 paginiChoi 2008 Engineering-StructuresAndreea NanÎncă nu există evaluări

- 10 3390@app10010094 PDFDocument21 pagini10 3390@app10010094 PDFabadittadesseÎncă nu există evaluări

- 1 s2.0 S0143974X04001750 Main PDFDocument22 pagini1 s2.0 S0143974X04001750 Main PDFGayanÎncă nu există evaluări

- Cyclic Tests of Four Two-Story Narrow Steel Plate Shear Walls - Part 1: Analytical Studies and Specimen DesignDocument25 paginiCyclic Tests of Four Two-Story Narrow Steel Plate Shear Walls - Part 1: Analytical Studies and Specimen DesignMarimuthu KaliyamoorthyÎncă nu există evaluări

- (5hdo $%HG/QHN DQG (0ludpehooDocument8 pagini(5hdo $%HG/QHN DQG (0ludpehooRaquel CarmonaÎncă nu există evaluări

- Analytical Investigation and The Design of The Compressive Strength of Steel Gusset Plate ConnectionsDocument21 paginiAnalytical Investigation and The Design of The Compressive Strength of Steel Gusset Plate ConnectionsNaomi PratiwiÎncă nu există evaluări

- Practical Compactness and Bracing Provisions For The Design of Single Angle BeamsDocument7 paginiPractical Compactness and Bracing Provisions For The Design of Single Angle Beamsbruno_alqÎncă nu există evaluări

- Review of AISI Design Guide For Cold-Formed Steel Purlin Roof FraDocument17 paginiReview of AISI Design Guide For Cold-Formed Steel Purlin Roof FraguillermoÎncă nu există evaluări

- A Literature Review On Beam Column Joints With Different Loading Condition and Methods of StrengtheningDocument8 paginiA Literature Review On Beam Column Joints With Different Loading Condition and Methods of StrengtheningIJRASETPublicationsÎncă nu există evaluări

- Experiments On Castellated Steel BeamsDocument14 paginiExperiments On Castellated Steel BeamsLuiz Flávio Vieira Brant100% (1)

- Gholami 2012Document11 paginiGholami 2012Jairo MasaÎncă nu există evaluări

- Nonlinear Finite Element Modeling of Concrete Confined by Fiber Composites. Amir M. Elsevier 2000Document18 paginiNonlinear Finite Element Modeling of Concrete Confined by Fiber Composites. Amir M. Elsevier 2000FELIX C.GÎncă nu există evaluări

- International Journal of EngineeringDocument10 paginiInternational Journal of Engineeringparth daxiniÎncă nu există evaluări

- Size Effects in Plastic Hinges of Reinforced Concrete MembersDocument24 paginiSize Effects in Plastic Hinges of Reinforced Concrete MembersakreitÎncă nu există evaluări

- Copy First Phase Report MSDocument39 paginiCopy First Phase Report MSSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inÎncă nu există evaluări

- Editor'S Note: Sashi K. KunnathDocument5 paginiEditor'S Note: Sashi K. KunnathPriyanka BasuÎncă nu există evaluări

- Prediction of Residual Strength and Curvilinear Crack Growth in Aircraft FuselagesDocument9 paginiPrediction of Residual Strength and Curvilinear Crack Growth in Aircraft FuselagesnagpalanishÎncă nu există evaluări

- Lateral Displacement of Different Types of Steel Sleepers On Ballasted TrackDocument8 paginiLateral Displacement of Different Types of Steel Sleepers On Ballasted TrackpeymanÎncă nu există evaluări

- Performance of Reduced Beam Section in Castellated Beam Subjected To Cyclic LoadingDocument11 paginiPerformance of Reduced Beam Section in Castellated Beam Subjected To Cyclic LoadingniniÎncă nu există evaluări

- Global Buckling Prevention Condition of All-Steel Buckling Restrained BracesDocument12 paginiGlobal Buckling Prevention Condition of All-Steel Buckling Restrained BracesCihuy RahmatÎncă nu există evaluări

- Tension Field ActionDocument19 paginiTension Field ActionKam LauÎncă nu există evaluări

- 04 CanneyDocument12 pagini04 CanneyJeffrox ReboldilaÎncă nu există evaluări

- Effect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorDocument21 paginiEffect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorEliyaHeninÎncă nu există evaluări

- Seismic Behavior of Steel Beam and Reinforced Concrete Column ConnectionsDocument20 paginiSeismic Behavior of Steel Beam and Reinforced Concrete Column Connectionsjuan carlosÎncă nu există evaluări

- Local Flange Bending and Local Web Yielding Limit States in Steel Moment-Resisting ConnectionsDocument11 paginiLocal Flange Bending and Local Web Yielding Limit States in Steel Moment-Resisting ConnectionsMuhammad irfan javaidÎncă nu există evaluări

- Wcee2017 1276Document12 paginiWcee2017 1276gopa dasÎncă nu există evaluări

- Micropile Bearing Plates PDFDocument11 paginiMicropile Bearing Plates PDFrowatersÎncă nu există evaluări

- Bracing of Steel Beams in Bridges - Joseph YuraDocument96 paginiBracing of Steel Beams in Bridges - Joseph YuraMáryuri CriadoÎncă nu există evaluări

- Chen Noda Wahab Akaishi Sano Takase Fekete 64 PDFDocument19 paginiChen Noda Wahab Akaishi Sano Takase Fekete 64 PDFGusztav FeketeÎncă nu există evaluări

- Hybrid FrameDocument11 paginiHybrid FramesenthilcivilÎncă nu există evaluări

- Sand 4Document17 paginiSand 4Pavan MÎncă nu există evaluări

- Literature ReviewDocument8 paginiLiterature ReviewAkhil RajagopalÎncă nu există evaluări

- Applied Sciences: Lateral Torsional Buckling of Steel Beams Elastically Restrained at The Support NodesDocument17 paginiApplied Sciences: Lateral Torsional Buckling of Steel Beams Elastically Restrained at The Support NodesАлександар Але СтојановићÎncă nu există evaluări

- 1963 - Bresler Scordelis - Shear Strength of RC Beams PDFDocument24 pagini1963 - Bresler Scordelis - Shear Strength of RC Beams PDFKaio César Arnaud DeonÎncă nu există evaluări

- Failure Modes and Failure Mechanisms of Fiber Reinforced Polymer Composite Bridge DecksDocument10 paginiFailure Modes and Failure Mechanisms of Fiber Reinforced Polymer Composite Bridge Decksalemteka97Încă nu există evaluări

- Earthquake-Resistance Design of Double-Angle BracingsDocument15 paginiEarthquake-Resistance Design of Double-Angle BracingsJoseph Cristhian Lipa FloresÎncă nu există evaluări

- What Do We Know About Confinement in Reinforced Concrete Columns-Sakai-SheikhDocument16 paginiWhat Do We Know About Confinement in Reinforced Concrete Columns-Sakai-SheikhAlberto Ezequiel León TamayoÎncă nu există evaluări

- Analyzing The Buckling Strength of Stiffened Steel Plates With Longitudinal Stiffeners Subjected To Uniaxial CompressionDocument5 paginiAnalyzing The Buckling Strength of Stiffened Steel Plates With Longitudinal Stiffeners Subjected To Uniaxial CompressionOraib AljaafrehÎncă nu există evaluări

- Engineering For Steel ConstructionDocument2 paginiEngineering For Steel ConstructionBiju Muttathukatil0% (1)

- Applied Sciences: Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject To Cyclic LoadingDocument20 paginiApplied Sciences: Damage Analyses of Replaceable Links in Eccentrically Braced Frame (EBF) Subject To Cyclic LoadingAndres Riffo VillagranÎncă nu există evaluări

- Evaluation and Modeling of Ultimate Bond Strength of Corroded Reinforcement in Reinforced Concrete ElementsDocument21 paginiEvaluation and Modeling of Ultimate Bond Strength of Corroded Reinforcement in Reinforced Concrete ElementsEng mohammadÎncă nu există evaluări

- Deformation and Failure of Hybrid Composite Sandwich Beams With A MetalDocument52 paginiDeformation and Failure of Hybrid Composite Sandwich Beams With A MetalSorina gÎncă nu există evaluări

- Experimental Analysis and Modelling of Bolted T-Stubs Under Cyclic LoadsDocument15 paginiExperimental Analysis and Modelling of Bolted T-Stubs Under Cyclic LoadsSam SamouraÎncă nu există evaluări

- Simplified and Detailed Finite Element Models of Steel Plate Shear WallsDocument13 paginiSimplified and Detailed Finite Element Models of Steel Plate Shear WallsponjoveÎncă nu există evaluări

- Con 1Document1 paginăCon 1rentfarÎncă nu există evaluări

- Feh 9Document1 paginăFeh 9rentfarÎncă nu există evaluări

- ContentDocument11 paginiContentrentfarÎncă nu există evaluări

- Feh 6Document1 paginăFeh 6rentfarÎncă nu există evaluări

- Feh 1Document1 paginăFeh 1rentfarÎncă nu există evaluări

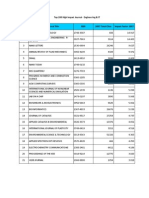

- Top 200 High Impact Journal - Engineering & ITDocument9 paginiTop 200 High Impact Journal - Engineering & ITrentfarÎncă nu există evaluări

- Feh 4Document1 paginăFeh 4rentfarÎncă nu există evaluări

- GDDocument18 paginiGDSnehashis PatnaikÎncă nu există evaluări

- Passive Fire Protection Testing & CertificationDocument9 paginiPassive Fire Protection Testing & CertificationVikas Kumar Pathak100% (1)

- Sewing Room in Apparel IndustryDocument46 paginiSewing Room in Apparel IndustryP. Lakshmanakanth100% (3)

- Fusion TaxDocument308 paginiFusion Taxupender100% (2)

- اعطال وتشريح s6SM-G920 and s6 edge SM-G925 PDFDocument8 paginiاعطال وتشريح s6SM-G920 and s6 edge SM-G925 PDFÉp Kính Phú QuốcÎncă nu există evaluări

- Specification 715 Rev. 0 - Electric Motor Operated Valve Actuator PDFDocument10 paginiSpecification 715 Rev. 0 - Electric Motor Operated Valve Actuator PDFzazaÎncă nu există evaluări

- Recruitment For Supervisor (Technical) at S-1 Level PDFDocument2 paginiRecruitment For Supervisor (Technical) at S-1 Level PDFbk yÎncă nu există evaluări

- BigFix API Reference GuideDocument110 paginiBigFix API Reference GuideJose Antonio Hernandez VelazquezÎncă nu există evaluări

- Guidelines For Vehicle Fitness TestingDocument50 paginiGuidelines For Vehicle Fitness TestingGaurav GuptaÎncă nu există evaluări

- SCCPCH Concept & ImplementationDocument11 paginiSCCPCH Concept & ImplementationSwandito HaryoyudantoÎncă nu există evaluări

- Technical Specification: STC/HFXJG-01-2005 2000ADocument32 paginiTechnical Specification: STC/HFXJG-01-2005 2000AJatindra AndiaÎncă nu există evaluări

- Sz15rr - Cfao Motors - enDocument1 paginăSz15rr - Cfao Motors - enJimJiangÎncă nu există evaluări

- 4.3.3.4 Lab - Configure HSRPDocument7 pagini4.3.3.4 Lab - Configure HSRPjb100% (1)

- DatasheetDocument4 paginiDatasheetSoud FarhanÎncă nu există evaluări

- Global Recycled Standard v3 PDFDocument29 paginiGlobal Recycled Standard v3 PDFJuice GuavaÎncă nu există evaluări

- Sunil BhandariDocument3 paginiSunil Bhandarisbhandari1974100% (2)

- CS610 Quiz Solved by Smiling BoyDocument4 paginiCS610 Quiz Solved by Smiling BoychiÎncă nu există evaluări

- 15 Inch PV755A Optoma PanoView PV755A MonitorDocument3 pagini15 Inch PV755A Optoma PanoView PV755A MonitorVictor Tito C GÎncă nu există evaluări

- General Technical Requirement For Mechanical - Piping (D 13Document18 paginiGeneral Technical Requirement For Mechanical - Piping (D 13Elias EliasÎncă nu există evaluări

- Safety Data Sheet: Aspirin PowderDocument3 paginiSafety Data Sheet: Aspirin Powdervetma1Încă nu există evaluări

- Surge AnalysisDocument39 paginiSurge AnalysisAneeq Sh100% (1)

- Rinnai 26e Service Manual PDFDocument68 paginiRinnai 26e Service Manual PDFteddiprintÎncă nu există evaluări

- Glasvezel RouterDocument2 paginiGlasvezel RoutercraponzelÎncă nu există evaluări

- Lab Report 251013Document5 paginiLab Report 251013Agrobacterium Tumefaciens67% (9)

- Qualcomm QPSTDocument7 paginiQualcomm QPSTJeremy TourvilleÎncă nu există evaluări

- SEN Plus Brochure English Ed06!13!680808Document20 paginiSEN Plus Brochure English Ed06!13!680808Hamad GulÎncă nu există evaluări

- Aisi S200-12&aisis200-12-C Version1 e SDocument47 paginiAisi S200-12&aisis200-12-C Version1 e SEricaÎncă nu există evaluări

- Fts Lifebook Ah552 User ManualDocument78 paginiFts Lifebook Ah552 User Manualanders_brjÎncă nu există evaluări

- Pipe BendingDocument26 paginiPipe Bendinghabib100% (1)

- Rocket Boomer E3-C18 EspecificacionesDocument4 paginiRocket Boomer E3-C18 EspecificacionesDiego CarrilloÎncă nu există evaluări

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!De la EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Evaluare: 4 din 5 stele4/5 (3)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- Onshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesDe la EverandOnshore Structural Design Calculations: Power Plant and Energy Processing FacilitiesEvaluare: 4.5 din 5 stele4.5/5 (13)

- Piping Engineering Leadership for Process Plant ProjectsDe la EverandPiping Engineering Leadership for Process Plant ProjectsEvaluare: 5 din 5 stele5/5 (1)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- A Welder’s Handbook to Robotic ProgrammingDe la EverandA Welder’s Handbook to Robotic ProgrammingEvaluare: 5 din 5 stele5/5 (3)

- DIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesDe la EverandDIY Drones for the Evil Genius: Design, Build, and Customize Your Own DronesEvaluare: 3.5 din 5 stele3.5/5 (3)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsDe la EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsÎncă nu există evaluări

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDe la EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureEvaluare: 4.5 din 5 stele4.5/5 (2)

- Working Guide to Pump and Pumping Stations: Calculations and SimulationsDe la EverandWorking Guide to Pump and Pumping Stations: Calculations and SimulationsEvaluare: 5 din 5 stele5/5 (3)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!De la EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Evaluare: 3 din 5 stele3/5 (1)

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildDe la EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildEvaluare: 5 din 5 stele5/5 (5)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.De la EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Evaluare: 4 din 5 stele4/5 (5)

- AI Unraveled: A Comprehensive Guide to Machine Learning and Deep LearningDe la EverandAI Unraveled: A Comprehensive Guide to Machine Learning and Deep LearningÎncă nu există evaluări

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- Medical and Healthcare Robotics: New Paradigms and Recent AdvancesDe la EverandMedical and Healthcare Robotics: New Paradigms and Recent AdvancesOlfa BoubakerÎncă nu există evaluări