Documente Academic

Documente Profesional

Documente Cultură

Icc Esr-1385 Kb3 Masonry

Încărcat de

xpertsteelDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Icc Esr-1385 Kb3 Masonry

Încărcat de

xpertsteelDrepturi de autor:

Formate disponibile

ICC-ES Evaluation Report

ESR-1385

Reissued February 1, 2012

This report is subject to renewal in two years.

www.icc-es.org | (800) 423-6587 | (562) 699-0543

DIVISION: 04 00 00MASONRY

Section: 04 05 19.16Masonry Anchors

REPORT HOLDER:

HILTI, INC.

5400 SOUTH 122ND EAST AVENUE

TULSA, OKLAHOMA 74146

(800) 879-8000

www.us.hilti.com

HiltiTechEng@us.hilti.com

EVALUATION SUBJECT:

KWIK BOLT 3 MASONRY ANCHORS

1.0 EVALUATION SCOPE

Compliance with the following codes:

2009 International Building Code (2009 IBC)

2009 International Residential Code (2009 IRC)

2006 International Building Code (2006 IBC)

2006 International Residential Code (2006 IRC)

Property evaluated:

Structural

2.0 USES

The Kwik Bolt 3 (KB3) Masonry Anchor is used to resist

static and transient seismic and wind tension and shear

loads in uncracked, grout-filled concrete masonry. The

anchor system is an alternative to cast-in-place anchors

described in Section 2107 (TMS 402/ACI 530/ASCE 5) of

the IBC. The anchor systems may also be used where an

engineered design is submitted in accordance with Section

R301.1.3 of the IRC.

A Subsidiary of the International Code Council

3 has a thread length equal to or less than three bolt

diameters, while the Long Thread Kwik Bolt 3 has a thread

length greater than three bolt diameters. The tapered

mandrel has an increasing diameter toward the anchor

base, and is enclosed by a three-section wedge that freely

moves around the mandrel. In the vertical direction, the

wedge movement is restrained by the mandrel taper at the

bottom and by a collar at the top of the mandrel. When the

anchor nut is tightened, the wedge is forced against the

wall of the predrilled hole to provide anchorage.

3.2 Grout-filled Concrete Masonry:

The masonry prism strength must be at least 1,500 psi

(10.3 MPa) at the time of anchor installation. Grout-filled

masonry must be constructed from the following materials:

3.2.1 Grout-filled Masonry Units: Grout-filled concrete

masonry walls must be constructed from minimum Type I,

Grade N, lightweight, medium-weight or normal-weight

concrete masonry units (CMUs) conforming to ASTM C 90

(IBC).

3.2.2 Grout: The masonry units must be fully grouted

with grout complying with Section 2103.12 of the IBC or

Section R609.1.1 of the IRC, and having a minimum

compressive strength as indicated in the tables at 28 days.

3.2.3 Mortar: Mortar must be Type N, S or M, prepared

in accordance with Section 2103.8 of the IBC or Section

R607 of the IRC.

4.0 DESIGN AND INSTALLATION

4.1 Design:

Minimum embedment depth, edge distance, and spacing

requirements are set forth in Table 2. Allowable stress

design tension and shear loads are as noted in Tables 2

and 3. Allowable loads for Kwik Bolt 3 anchors subjected to

combined shear and tension forces are determined by the

following equation:

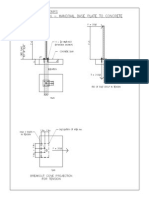

3.0 DESCRIPTION

3.1 Kwik Bolt 3:

The Kwik Bolt 3 expansion anchors consist of a stud,

wedge, nut, and washer. The stud is manufactured from

carbon material. The carbon steel Kwik Bolt 3 anchors

have a 5 m (0.0002 inch) zinc plating. The anchor is

illustrated in Figure 1 of this report.

The wedges for the carbon steel anchors are made from

1

carbon steel, except for all /4-inch (6.4 mm) lengths, which

have AISI 316 stainless steel wedges. All carbon steel

components are zinc-plated.The stud consists of a highstrength rod threaded at one end. The standard Kwik Bolt

(Ps/Pt)5/3 + (Vs/Vt)5/3 1

where:

Ps

Applied service tension load (lbf or N).

Pt

Allowable service tension load (lbf or N).

Vs

Applied service shear load (lbf or N).

Vt

Allowable service shear load (lbf or N).

4.2 Installation Requirements:

Kwik Bolt 3 must be installed in holes drilled into the base

material using carbide-tipped masonry drill bits complying

with ANSI B212.15-1994. The nominal drill bit diameter

ICC-ES Evaluation Reports are not to be construed as representing aesthetics or any other attributes not specifically addressed, nor are they to be construed

as an endorsement of the subject of the report or a recommendation for its use. There is no warranty by ICC Evaluation Service, LLC, express or implied, as

to any finding or other matter in this report, or as to any product covered by the report.

1000

Copyright 2011

Page 1 of 4

ESR-1385 | Most Widely Accepted and Trusted

must be equal to that of the anchor. The drilled hole must

exceed the depth of anchor embedment by at least one

anchor diameter to permit over-driving of anchors and to

provide a dust collection area. The anchor must be

hammered into the predrilled hole until at least six threads

are below the fixture surface. The nut must be tightened

against the washer until the torque values specified in

Table 1 are attained.

4.3 Special Inspection:

Special inspection must be provided in accordance with

Section 1704 of the IBC when design loads are based on

special inspections being provided during anchor

installation, as set forth in Tables 2 and 3. Special

inspection in accordance with Section 1704 of the IBC

must be provided under the IRC when special inspection is

specified in Tables 2 and 3. Under the IBC, additional

requirements as set forth in Sections 1705 and 1706 must

be observed, where applicable. The code official must

receive a report, from an approved special inspector, that

includes the following details:

1. Anchor description, including the anchor product name,

nominal anchor and bolt diameters, and anchor length.

2. Hole description, including verification of drill bit

compliance with ANSI B212.15-1994.

3. Installation description, including verification of

masonry compressive strength and verification of

anchor installation and location (spacing and edge

distance) in accordance with Hiltis published

installation instructions and this report.

5.0 CONDITIONS OF USE

The Kwik Bolt 3 Masonry Anchors described in this report

comply with, or are suitable alternatives to what is

specified in, those codes listed in Section 1.0 of this report,

subject to the following conditions:

5.1 Anchor sizes, dimensions, and installation must

comply with this report and Hiltis published

installation instructions.

5.2 Allowable tension and shear loads must be as noted

in Tables 2 and 3 of this report.

5.3 Calculations and details demonstrating compliance

with this report must be submitted to the code official

for approval.

5.4 The use of anchors must be limited to installation in

uncracked grout filled concrete masonry. Cracking

occurs when ft > fr due to service loads or

deformations.

5.5 Design of Kwik Bolt 3 Masonry Anchors installed in

grout-filled concrete masonry to resist dead, live, wind

and earthquake load applications must be in

accordance with Section 4.1.

Page 2 of 4

5.6 When using the basic load combinations in

accordance with IBC Section 1605.3.1, allowable

loads are not permitted to be increased for wind or

earthquake loading. When using the alternative basic

load combinations in IBC Section 1605.3.2 that

include wind or seismic loads, the allowable shear

and tension loads for anchors are permitted to be

1

increased by 33 /3 percent. Alternatively, the basic

load combinations may be reduced by a factor of 0.75

when using IBC Section 1605.3.2.

5.7 Where not otherwise prohibited in the applicable

code, anchors are permitted for use with fireresistance-rated construction provided that at least

one of the following conditions is fulfilled:

Anchors are used to resist wind or seismic forces

only.

Anchors

that

support

fire-resistance-rated

construction or gravity loadbearing structural

elements are within a fire-resistance-rated envelope

or a fire-resistance-rated membrane, are protected

by approved fire-resistance-rated materials, or have

been evaluated for resistance to fire exposure in

accordance with recognized standards.

Anchors are

elements.

used

to

support

nonstructural

5.8 Use of carbon steel Kwik Bolt 3 anchors must be

limited to dry, interior locations.

5.9 Special inspection must be provided in accordance

with Section 4.3 of this report when required by

Tables 2 and 3.

5.10 Anchors

are

manufactured

by

Hilti,

Inc.,

Feldkircherstrasse 100, Schaan, Liechtenstein; and

Hilti Operaciones de Mexico S.A., Matamoros,

Tamaulipas, Mexico, under a quality control program

with inspections conducted by Underwriters

Laboratories Inc. (AA-668).

6.0 EVIDENCE SUBMITTED

Data in accordance with the ICC-ES Acceptance Criteria

for Expansion Anchors in Masonry Elements (AC01), dated

December 2009, including seismic tests, reduced spacing

tests and reduced edge distance tests.

7.0 IDENTIFICATION

The anchors must be identified in the field by dimensional

characteristics and packaging. The packaging label

indicates the manufacturers name (Hilti, Inc.) and address,

the size and type of anchor, the name of the inspection

agency (Underwriters Laboratories Inc.), and the ICC-ES

report number (ESR-1385). A length identification code

letter is stamped on the threaded end of the bolt. The

length identification system is described in Table 4.

ESR-1385 | Most Widely Accepted and Trusted

Page 3 of 4

1

TABLE 1INSTALLATION SPECIFICATIONS

SETTING DETAILS

ANCHOR SIZE

1

/4 inch

/8 inch

/2 inch

/8 inch

/4 inch

Drill bit size = anchor diameter (inches)

/4

/8

/2

Wedge clearance hole (inches)

/16

/16

/16

11

13

Anchor length (min./max.) (inches)

1 /4

Thread length std./long thread length (inches)

Installation:

Torque guide values Carbon steel: Min. Embedment

Carbon steel: Std. Embedment

(ft-lb) in

concrete masonry

Min. base material thickness (inches)

4 /2

/4

2 /8

7

/8

/4

/16

/16

2 /4

3 /2

10

12

1 /4

4 /4

1 /2

1 /2

5 /8

15

15

4

4

/8

120

120

65

65

25

25

3 inches or 1.5 embedment depth, whichever is greater

For SI: 1 inch = 25.4 mm, 1 ft-lbf = 1.356 N-m.

1

Installation torques are applicable for all anchors installations unless noted otherwise in this report.

TABLE 2ALLOWABLE TENSION AND SHEAR VALUES FOR HILTI KWIK BOLT 3 CARBON STEEL ANCHORS

1,2,3,4

INSTALLED IN THE FACE SHELLS OF GROUT-FILLED CONCRETE MASONRY WALLS (in pounds)

ANCHOR

DIAMETER

(inch)

EMBEDMENT

5

DEPTH

(inches)

1 /8

1

/4

2

5

1 /8

3

/8

1

2 /2

1

2 /4

1

/2

1

3 /2

3

2 /4

5

/8

4

1

3 /4

3

/4

3

4 /8

MINIMUM

DISTANCE

FROM EDGE

6

OF WALL

(inches)

TENSION

SHEAR

IBC/IRC

IBC/IRC

121

304

12

121

304

432

342

12

432

342

257

589

12

273

751

626

764

12

626

1,054

502

664

12

533

1,171

724

840

12

724

1,853

651

710

12

692

1,732

994

743

12

1,035

2,123

829

627

12

829

2,508

1,316

657

12

1,368

2,627

For SI: 1 inch = 25.4 mm, 1 lb = 4.45 N.

1

Values valid for anchors installed in face shells of Type 1, Grade N, lightweight, medium-weight, or normal-weight concrete masonry units

conforming to ASTM C 90. The masonry units must be fully grouted with coarse grout conforming to IBC 2103.12. Mortar must comply with

IBC Section 2103.8. Masonry prism strength must be at least 1,500 psi at the time of anchor installation when tested in accordance with IBC

Section 2105.2.2.2.

2

3

Anchors must be installed a minimum of 1 /8 inches from any vertical mortar joint in accordance with Figure 2.

3

Anchor locations are limited to one per masonry cell with a minimum spacing of 8 inches on center.

4

Allowable loads or applied loads may be modified in accordance with Section 5.6 of this report due to short-term wind or seismic loads.

5

Embedment depth must be measured from the outside face of the concrete masonry unit.

6

For intermediate edge distances, allowable loads may be determined by linearly interpolating between the allowable loads at the two

tabulated edge distances.

7

These tension values are only applicable when anchors are installed with special inspection in accordance with Section 4.3 of this report.

ESR-1385 | Most Widely Accepted and Trusted

Page 4 of 4

TABLE 3ALLOWABLE TENSION AND SHEAR VALUES FOR HILTI KWIK BOLT 3 CARBON STEEL ANCHORS

1,2,3,4

INSTALLED IN TOP OF GROUT-FILLED CONCRETE MASONRY WALLS (in pounds)

EMBEDMENT

5

DEPTH

(inches)

TENSION

3 /2

ANCHOR

DIAMETER

(inch)

/2

/8

SHEAR

Perpendicular to Wall

Parallel to Wall

IBC/IRC

IBC/IRC

IBC/IRC

517

249

491

682

249

491

For SI: 1 inch = 25.4 mm, 1 lb = 4.45 N.

1

Values valid for anchors installed into top cells of Type 1, Grade N, lightweight, medium-weight, or normal-weight concrete masonry units

conforming to ASTM C 90. The masonry units must be fully grouted with coarse grout conforming to IBC 2103.12. Mortar must comply with

IBC Section 2103.8. Masonry prism strength must be at leasst 1,500 psi at the time of anchor installation when tested in accordance with IBC

Section 2105.2.2.2.

2

3

Anchors must be installed a minimum of 1 /4 inches from edge of the block.

3

Anchor locations must be limited to one per masonry cell with a minimum spacing of 8 inches on center.

4

Allowable loads or applied loads may be modified in accordance with Section 5.6 of this report due to short-term wind or seismic loads.

5

Embedment depth is measured from the top edge of the concrete masonry unit.

6

These tension values are only applicable when anchors are installed with special inspection in accordance with Section 4.3 of this report.

TABLE 4LENGTH IDENTIFICATION CODES

STAMP ON ANCHOR

From

A

1

C

1

E

1

G

1

I

1

K

1

M

1

O

1

Q

1

1 /2 2 2 /2 3 3 /2 4 4 /2 5 5 /2 6 6 /2 7 7 /2 8 8 /2 9 9 /2 10 11 12 13 14 15 16 17 18

Length of

Anchor Up to but not

1

1

1

1

1

1

1

1

2 2 /2 3 3 /2 4 4 /2 5 5 /2 6 6 /2 7 7 /2 8 8 /2 9 9 /2 10 11 12 13 14 15 16 17 18 18

(inches)

including

For SI: 1 inch = 25.4 mm.

S-ar putea să vă placă și

- 4514 Power FastDocument11 pagini4514 Power Fastgreg_mercurio_1Încă nu există evaluări

- ESR 1056 Titen HeadDocument6 paginiESR 1056 Titen HeadSandeepÎncă nu există evaluări

- Submittal Re500 EpoxyDocument13 paginiSubmittal Re500 EpoxyErnest NavarroÎncă nu există evaluări

- Icc Esr-1967 Hit-Hy 150 MasonryDocument8 paginiIcc Esr-1967 Hit-Hy 150 MasonryxpertsteelÎncă nu există evaluări

- Simspon at Epoxy Anchor - ICC ER-0263Document19 paginiSimspon at Epoxy Anchor - ICC ER-0263pandavision76Încă nu există evaluări

- B.4.4 - STD Spec For Steel StacksDocument6 paginiB.4.4 - STD Spec For Steel StacksHernan RodriguezÎncă nu există evaluări

- Data Techlib Docs Approvals-Listings-Reports Icbo ESR2678Document5 paginiData Techlib Docs Approvals-Listings-Reports Icbo ESR2678superpiojooÎncă nu există evaluări

- DocAnclaje Esr1056Document11 paginiDocAnclaje Esr1056Cesar CeronÎncă nu există evaluări

- B.4.4 - STD Spec For Steel StacksDocument6 paginiB.4.4 - STD Spec For Steel StacksEkta SanguleÎncă nu există evaluări

- ICBO Evaluation Service, IncDocument7 paginiICBO Evaluation Service, InczarafshinÎncă nu există evaluări

- EnsayosAlSikadur AnchorFix-4Document8 paginiEnsayosAlSikadur AnchorFix-4dadvaÎncă nu există evaluări

- Simpson XT Anchor ICBO CertDocument16 paginiSimpson XT Anchor ICBO CertjarnebergÎncă nu există evaluări

- ICC-ES Evaluation Report ESR-3051Document14 paginiICC-ES Evaluation Report ESR-3051moamenmahmoud84Încă nu există evaluări

- Esr 1227Document26 paginiEsr 1227murdicksÎncă nu există evaluări

- Screw Strength DocumentDocument3 paginiScrew Strength Documentmsiddiq1Încă nu există evaluări

- Legacy Report: ICC Evaluation Service, IncDocument2 paginiLegacy Report: ICC Evaluation Service, Incjmcc2Încă nu există evaluări

- ICBOEvaluation Report 5064Document3 paginiICBOEvaluation Report 5064Vicki Levy WillifordÎncă nu există evaluări

- Esr 2583Document19 paginiEsr 2583VaniaCuevaSotoÎncă nu există evaluări

- Tieback Anchors - 1.24.11Document7 paginiTieback Anchors - 1.24.11xcvÎncă nu există evaluări

- Kwik Hus Ez1 AnchorDocument8 paginiKwik Hus Ez1 Anchorsas999333Încă nu există evaluări

- Bridge Technical NoteDocument5 paginiBridge Technical Noteপ্রিয়দীপ প্রিয়মÎncă nu există evaluări

- Icc-Es Esr-1917Document15 paginiIcc-Es Esr-1917kmccrapmailÎncă nu există evaluări

- IjoistDocument8 paginiIjoistvergopiÎncă nu există evaluări

- Particular Specification For Rock-Socketed Steel H-PiwefwlesDocument15 paginiParticular Specification For Rock-Socketed Steel H-PiwefwlesLee Tin YanÎncă nu există evaluări

- 03 30 00 Cast in Place Concrete ChristensonDocument9 pagini03 30 00 Cast in Place Concrete ChristensonHendra Rikardo TobingÎncă nu există evaluări

- BS 1139 4 1982 - Metal Scaffolding Specs For Splitheads and TrestlesDocument12 paginiBS 1139 4 1982 - Metal Scaffolding Specs For Splitheads and TrestlesPradeep Nair100% (1)

- AcceptanceCriteriaforPrecastStoneVeneer Ac51 PDFDocument5 paginiAcceptanceCriteriaforPrecastStoneVeneer Ac51 PDFjaykmseÎncă nu există evaluări

- ICC-ES Evaluation Report ESR-3372 : - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilDocument16 paginiICC-ES Evaluation Report ESR-3372 : - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilpabinupcÎncă nu există evaluări

- API Storage Tank Job SpecificationDocument15 paginiAPI Storage Tank Job Specificationhuynhthanhtamga1981Încă nu există evaluări

- SCI - P324 - The Use of Tension Control Bolts Grade SIOT in Friction Grip ConnectionsDocument84 paginiSCI - P324 - The Use of Tension Control Bolts Grade SIOT in Friction Grip ConnectionsLathesh JanarthananÎncă nu există evaluări

- SteelDocument19 paginiSteelJohneey DeepÎncă nu există evaluări

- Disc Fitting 45 KN (T&C) TypeDocument4 paginiDisc Fitting 45 KN (T&C) TypePasupuleti007Încă nu există evaluări

- SECTION 03230 Post-Tensioned TendonsDocument11 paginiSECTION 03230 Post-Tensioned TendonsMohammed Misbahuddin AsifÎncă nu există evaluări

- Technical Criteria of QR:: Details of Meg (Material Enlistment Group) 1.0 MEG No. 2.0 MEG DescriptionDocument9 paginiTechnical Criteria of QR:: Details of Meg (Material Enlistment Group) 1.0 MEG No. 2.0 MEG DescriptionnicolasÎncă nu există evaluări

- KBIIDocument13 paginiKBIInetozx100% (1)

- Asset Doc Loc 34 Apc RawDocument41 paginiAsset Doc Loc 34 Apc RawlaurenjiaÎncă nu există evaluări

- Disc Fitting Spec for 70kN OHLDocument4 paginiDisc Fitting Spec for 70kN OHLPasupuleti007Încă nu există evaluări

- Icc Esr-2302 Kb3 ConcreteDocument11 paginiIcc Esr-2302 Kb3 ConcretexpertsteelÎncă nu există evaluări

- GRATINGS Rev.1Document7 paginiGRATINGS Rev.1mohdÎncă nu există evaluări

- BS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFDocument28 paginiBS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFambition1340cn100% (2)

- GTTPL Technical Specifications Full EpcDocument10 paginiGTTPL Technical Specifications Full EpcPinku MaitiÎncă nu există evaluări

- Bored Cast in Situ Method LogyDocument77 paginiBored Cast in Situ Method LogySujan RajkumarÎncă nu există evaluări

- Highway SpecificationDocument85 paginiHighway SpecificationAkaninyeneÎncă nu există evaluări

- Is 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocument10 paginiIs 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDebajani DekabaruahÎncă nu există evaluări

- BS 1876 (1990) PDFDocument11 paginiBS 1876 (1990) PDFAdesina AlabiÎncă nu există evaluări

- Scope of Supply and Work SpecificationsDocument23 paginiScope of Supply and Work SpecificationsmoodydoodyÎncă nu există evaluări

- Specifications PDFDocument30 paginiSpecifications PDFRivaiÎncă nu există evaluări

- Transmission Construction Standard: Saudi ElectricitycompanyDocument12 paginiTransmission Construction Standard: Saudi ElectricitycompanyTori Small0% (1)

- Expansion Joint Technical Specification and Data Sheet1Document9 paginiExpansion Joint Technical Specification and Data Sheet1RAPHAEL suzartÎncă nu există evaluări

- Api 650Document4 paginiApi 650arif99pak100% (1)

- Binder1 1600077763 8Document1 paginăBinder1 1600077763 8SHIVAJIÎncă nu există evaluări

- Tie Back Anchors For Soldier Pile N Lagging Wall - Iowa-DOT - SP-150358aDocument19 paginiTie Back Anchors For Soldier Pile N Lagging Wall - Iowa-DOT - SP-150358aRakesh KapoorÎncă nu există evaluări

- 3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanDocument8 pagini3550-8310-SP-0006 Rev D2.pdf MARKED-c.vanPhuong ThaoÎncă nu există evaluări

- Technical Specification Section StructureDocument10 paginiTechnical Specification Section StructurePremBhushanÎncă nu există evaluări

- Technical Specification Section: StructureDocument10 paginiTechnical Specification Section: StructurePremBhushanÎncă nu există evaluări

- SCI - P324-Secure (Tension Control Bolts, Grade S10T, in Friction Grip Connections)Document86 paginiSCI - P324-Secure (Tension Control Bolts, Grade S10T, in Friction Grip Connections)haharamesh100% (1)

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Brittle Fracture in Steel StructuresDe la EverandBrittle Fracture in Steel StructuresG.M. BoydÎncă nu există evaluări

- Spot Welding Interview Success: An Introduction to Spot WeldingDe la EverandSpot Welding Interview Success: An Introduction to Spot WeldingÎncă nu există evaluări

- ASCE 7-05 Diaphragm Design ForcesDocument2 paginiASCE 7-05 Diaphragm Design ForcesxpertsteelÎncă nu există evaluări

- Broadway StairsDocument1 paginăBroadway StairsxpertsteelÎncă nu există evaluări

- Custom Component EditingDocument89 paginiCustom Component EditingAugustin LaiÎncă nu există evaluări

- Hilti - Seismic Brochure en W4039Document12 paginiHilti - Seismic Brochure en W4039xpertsteelÎncă nu există evaluări

- Hilti 2011 Anchor Fastening Technical Guide B25981 PDFDocument389 paginiHilti 2011 Anchor Fastening Technical Guide B25981 PDFChristian D. OrbeÎncă nu există evaluări

- Anchoring in Cracked ConcreteDocument11 paginiAnchoring in Cracked Concretekjpatel2Încă nu există evaluări

- Simpson - CrackingtheConcreteAnchorCodesDocument54 paginiSimpson - CrackingtheConcreteAnchorCodesxpertsteelÎncă nu există evaluări

- Icc Esr-3013 Hit-Hy 150 Max-Sd ConcreteDocument30 paginiIcc Esr-3013 Hit-Hy 150 Max-Sd ConcretexpertsteelÎncă nu există evaluări

- Icc Esr-2302 Kb3 ConcreteDocument11 paginiIcc Esr-2302 Kb3 ConcretexpertsteelÎncă nu există evaluări

- HILTI Technical Guide Volume 1Document175 paginiHILTI Technical Guide Volume 1xpertsteelÎncă nu există evaluări

- Hilti 2011 Anchor Fastening Technical Guide B25981 PDFDocument389 paginiHilti 2011 Anchor Fastening Technical Guide B25981 PDFChristian D. OrbeÎncă nu există evaluări

- Broadway Ledger AnglesDocument8 paginiBroadway Ledger AnglesxpertsteelÎncă nu există evaluări

- Broadway Hilti - Handrail BaseDocument4 paginiBroadway Hilti - Handrail Basexpertsteel100% (1)

- Gage Chart EquivalentsDocument2 paginiGage Chart EquivalentsxpertsteelÎncă nu există evaluări

- Canby Stairs DesignDocument1 paginăCanby Stairs DesignxpertsteelÎncă nu există evaluări

- Gary Chaffee Alternate Rhythmic PlacementsDocument1 paginăGary Chaffee Alternate Rhythmic Placementsxpertsteel100% (1)

- Getting The Most From Your Machines and FoundationsDocument5 paginiGetting The Most From Your Machines and FoundationsxpertsteelÎncă nu există evaluări

- Structural Dynamics LectureDocument29 paginiStructural Dynamics Lecturexpertsteel100% (2)

- Totten CatalogDocument19 paginiTotten CatalogxpertsteelÎncă nu există evaluări

- Evolution of UBC and IBC Static Lateral ForceDocument5 paginiEvolution of UBC and IBC Static Lateral ForcexpertsteelÎncă nu există evaluări

- Problem2 A 3Document1 paginăProblem2 A 3xpertsteelÎncă nu există evaluări

- Conversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessDocument21 paginiConversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessJaqueline SilvaÎncă nu există evaluări

- What To Do When Service Is Needed: C Cu Ua An ND Do o N Ne Ec Ce Es Siitta A S Se Errv Viic Ciio oDocument48 paginiWhat To Do When Service Is Needed: C Cu Ua An ND Do o N Ne Ec Ce Es Siitta A S Se Errv Viic Ciio oJAÎncă nu există evaluări

- AMMIE 2023 Conference on Advanced Materials and ManufacturingDocument9 paginiAMMIE 2023 Conference on Advanced Materials and ManufacturingrjÎncă nu există evaluări

- Consolidated 1811 SeriesDocument16 paginiConsolidated 1811 Seriesivan_fuenzalida_1Încă nu există evaluări

- Sony Dsc-w630 Ver1.1 Level2Document25 paginiSony Dsc-w630 Ver1.1 Level2Alberto MorenoÎncă nu există evaluări

- Cable Impedance Calculations - Open ElectricalDocument4 paginiCable Impedance Calculations - Open Electricaludayakumart100% (1)

- Fluid Mechanics-I Lab ManualDocument28 paginiFluid Mechanics-I Lab Manualउमेश गावंडेÎncă nu există evaluări

- Contents Centrifugal Oil CleanersDocument12 paginiContents Centrifugal Oil Cleanersg33sp0tÎncă nu există evaluări

- Latching Assignment PLC Ladder LogicDocument4 paginiLatching Assignment PLC Ladder LogicsalonyÎncă nu există evaluări

- Raven 2350 Ultra Carbon Black Technical Data SheetDocument2 paginiRaven 2350 Ultra Carbon Black Technical Data SheetCoopertiva PlastcooperÎncă nu există evaluări

- Volvo EC160Document25 paginiVolvo EC160superbludnik100% (3)

- Civil Engineering Materials UOL Lahore: ConcreteDocument119 paginiCivil Engineering Materials UOL Lahore: ConcreteNawab Zada ManekaÎncă nu există evaluări

- Ministry of Steel Presentatation On MSFDocument27 paginiMinistry of Steel Presentatation On MSFDebashis SarkarÎncă nu există evaluări

- Chemsheets GCSE 1069 Allotropes of CarbonDocument1 paginăChemsheets GCSE 1069 Allotropes of CarbonNoah KellerÎncă nu există evaluări

- Design of Steel ISMC 300 Member for Axial and Bending LoadsDocument1 paginăDesign of Steel ISMC 300 Member for Axial and Bending LoadsAnand.5Încă nu există evaluări

- 12 18 13polyaspartic Webinar CommercialDocument48 pagini12 18 13polyaspartic Webinar CommercialAelya SanÎncă nu există evaluări

- History of Flexible Pavement Design in IRC 37 GuidelinesDocument41 paginiHistory of Flexible Pavement Design in IRC 37 GuidelinesUday KumarÎncă nu există evaluări

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocument146 paginiBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadÎncă nu există evaluări

- API 653 Tank Inspection StandardsDocument7 paginiAPI 653 Tank Inspection StandardsEngr Shahid AliÎncă nu există evaluări

- 496-2032-Gates Drive BeltComponents Catalogue November 2009Document324 pagini496-2032-Gates Drive BeltComponents Catalogue November 2009tttyyyuuu12350% (2)

- Workplace Housekeeping: Training Slides OnDocument42 paginiWorkplace Housekeeping: Training Slides OnAsad AwanÎncă nu există evaluări

- Rolling Friction FundamentalsDocument19 paginiRolling Friction FundamentalsMuhammad AliÎncă nu există evaluări

- Storing and Sanitation TechniquesDocument27 paginiStoring and Sanitation TechniquesMarjory Alga Omale100% (1)

- Iron Cast Iron Wrought IronDocument18 paginiIron Cast Iron Wrought IronvelavansuÎncă nu există evaluări

- User Manual RCU Universal Rev01Document48 paginiUser Manual RCU Universal Rev01Anonymous FGY7goÎncă nu există evaluări

- ProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Document1 paginăProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Araujo Felipe AndrésÎncă nu există evaluări

- Improving Packed Tower PerformanceDocument3 paginiImproving Packed Tower PerformanceManish542Încă nu există evaluări

- Introduction To Wastewater ManagementDocument18 paginiIntroduction To Wastewater ManagementMuhammad IqmalÎncă nu există evaluări

- Aama 501.2-83Document3 paginiAama 501.2-83Abdul Raqeeb67% (3)

- Chlorine Dioxide Generator Systems: Capacity OverviewDocument2 paginiChlorine Dioxide Generator Systems: Capacity OverviewOchoa Para La BandaÎncă nu există evaluări