Documente Academic

Documente Profesional

Documente Cultură

Mold Check List

Încărcat de

ctansariDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mold Check List

Încărcat de

ctansariDrepturi de autor:

Formate disponibile

Mold Check List

= Complete

_______ Information to be filled in: Y = Yes, N = No, NA = Not Applicable

C

u

to

u

ta

n

dc

o

p

y

Date Job Placed_________________________

Part Name ____________________________

Purchase order #_________________________

Part Number ___________________________

Material Vendor__________________________

Initial revision level_______________________

Material Type___________________________

Final revision level________________________

Material Part Number_____________________

Customer Contact _______________________

Customer Name_________________________

Est. Date for Capability Run________________

Est. Date for Tryout_______________________

Customer Phone_________________________

Est. Date in-plant for first production _________

Customer Fax___________________________

Est. Date Ready for Texture/plating __________

Customer e-mail_________________________

Date for Capability Run ___________________

In-house Contact_________________________

Date for Tryout __________________________

Date RFQ out___________________________

Date in-plant for first production _____________

Date Quote Returned_____________________

Date Ready for Texture/plating _____________

Dimensions __ Inches ____ mm

Part Design

_____Computer simulation of cooling Y/N

_____Computer simulation of part Y/N

_____Computer simulation of runners Y/N

_____Core/Cavity Concentricity ___________

_____Core/Cavity mismatch _____________

_____Design approved

_____Draft____________________________

_____Engineering Level_________________

_____Fillets and Radii __________________

_____Front side ejector side determined Y/N

_____Gate size, Location________________

_____Molded in Threads ________________

_____Parting Line established Y/N

_____Polish __________________________

_____Tolerances_______________________

_____Wall intersections _________________

_____Other (see below)

_____

_____

Molded Part

_____Assembly Jigs/fixtures Y/N

_____Check dimensions (See Below)

_____Clearance for inserts ______________

_____Cosmetic Requirements____________

_____Dimensional Tolerances____________

_____Flatness/Warpage _______________

Molded Part (cont)

_____Functional Requirements ___________

_____Gate location defined Y/N

_____Inspection gages Y/N

_____Other (see below)

_____

_____

Mold/Machine Fit

___________Length/width of mold

___________Machine Tie bar spacing

___________Molding Machine Type

_____Clamp slots on all four sides Y/N

_____Clamp Tonnage

_____Front/Rear Ejection? Y/N

_____Locator Ring diameter

_____Machine ejection stroke

_____Machine knockout pattern

_____Machine locator hole size

_____Mold ejection stroke

_____Mold full open

_____Mold knockout pattern

_____Mold stack height

_____Molding Machine Max Daylight

_____Molding Machine Nozzle length

_____Molding Machine Nozzle radius

_____Molding Machine Shut height

_____Shot required (20-60% of Shot)

_____Shot size

_____Sprue Bushing distance from back

_____Sprue Bushing radius

_____Other (see below)

_____

_____

Copyright WJT

Associates 2003

Part Number _____________ Mold Number _____________

Mold Check List

= Complete

_______ Information to be filled in: Y = Yes, N = No, NA = Not Applicable

Gates

_____# of gates/cavity

_____Diaphragm Y/N

_____Edge Y/N

_____Fan Y/N

_____Gate Sizes ____________________

_____Hot Edge Y/N

_____Hot tip Y/N

_____Pin Y/N

_____Sprue Y/N

_____Sub Y/N

_____Tab Y/N

_____Valve Y/N

_____Other (see below)

_____

_____

Waterlines

Mold - basic

_____Blind Pockets Y/N

_____Cavity hardness (Rc)

_____Cavity steel Specification

_____Cavity vents joined to main vents Y/N

_____Die locks Y/N

_____Eyebolts provided Y/N

_____Gate inserts Y/N

_____Guide pins length and size

_____Handling holes for each plate Y/N

_____Hot runner sketch Y/N

_____I.D. on each plate Y/N

_____Mold base hardness (Rc)

_____Mold Design approved ________ Date

_____Mold Design Complete ________ Date

_____Mold ID plates Y/N

_____Plating specification Y/N

_____Pry slots on all plates Y/N

_____RED non-removable Safety strap Y/N

_____Robot end of arm tooling Y/N

_____Robot programmed Y/N

_____Rough Edges, Sharp Corners Y/N

_____Spare Gate Inserts Y/N

_____Stop buttons for ejector system Y/N

_____Water line isometric sketch Y/N

_____Preload standoff area from cavities Y/N

_____Machine nozzle provided? Y/N

_____Sprue/nozzle orifice compatible? Y/N

_____ Other (see below)

C

u

to

u

ta

n

dc

o

p

y

C

u

to

u

ta

n

dc

o

p

y

Mold description

_____Cavities/block steel type(s)

_____Class Mold (SPI, WJT, In-house)

_____Cold Runner? Y/N

_____Family mold? Y/N

_____Hot Runner # of Drops

_____Hot Runner cavity/drop

_____Hot Runner/cold runner combo?

_____Hot Runner?

_____Insulated runner Y/N

_____Mold steel Specification

_____Number of Cavities

_____Number of Molds

_____Rotary mold? Y/N

_____Shrinkage ___________________ in/in

_____Stack mold? Y/N

_____Three Plate? Y/N

_____Transfer mold? Y/N

_____Two Plate? Y/N

_____Other (see below)

_____

_____

_____Blocked circuits? Y/N

_____Certified hosing provided Y/N

_____Countersunk clearance for fingers Y/N

_____Each Circuit Pressure Tested Y/N

_____Fittings provided Y/N

_____H2O on side of mold Y/N

_____Male inlets countersunk Y/N

_____Manifold pressure tested Y/N

_____Manifold pressure tested Y/N

_____Manifolds provided Y/N

_____Threaded holes Y/N_______

_____Waterline Size

_____Waterline Thread size/type

_____Nipples provided Y/N

_____ Other (see below)

_____

Air Circuits

_____Blocked circuits? Y/N

_____Certified hosing provided Y/N

_____Circuit Size

_____Each Circuit Pressure Tested Y/N

_____Fittings provided Y/N

_____Hosing length Y/N

_____Manifold pressure tested Y/N

_____Manifolds provided Y/N

_____Smooth movements? Y/N

_____Thread size

_____Threaded holes

_____Max working pressure

_____Cylinder(s)size (see below)

_____Cylinder floating? __ Mounted? __

_____ Air fittings provided Y/N

_____ Other (see below)

Hydraulics

_____Air bled from circuits? Y/N

Copyright WJT

Associates 2003

Part Number _____________ Mold Number _____________

Mold Check List

= Complete

_______ Information to be filled in: Y = Yes, N = No, NA = Not Applicable

_____Blocked circuits? Y/N

_____Certified hosing provided Y/N

_____Circuit Size

_____Each Circuit Pressure Tested Y/N

_____Fittings provided Y/N

_____Hosing length

_____Male forward, Female Back? Y/N

_____Manifold pressure tested Y/N

_____Manifold tested Y/N

_____Manifolds provided Y/N

_____Smooth movements? Y/N

_____Teflon Sealed? Y/N

_____Thread Size

_____Threaded holes

_____Cylinder(s)size (see below)

_____Cylinder floating? __ Mounted? __

_____ Other (see below)

_____

_____

Mechanisms

_____Air Cylinders Y/N (see below)

_____Angle Pins Y/N

_____Cams Y/N

_____Front and back locking positions? Y/N

_____Hardened core pins Y/N

_____Hydraulic Cylinders Y/N (see below)

_____Locking mechanisms Y/N

_____Preload of mechanisms Y/N (see

below)

_____Self lubricating wear plates Y/N

_____Slides Y/N

_____Slides with inserts Y/N

_____Smooth movement? Y/N

_____Spare mechanisms Y/N

_____Springs Y/N

_____Other (Specify below)

_____

_____

Cavity Blocks

_____All vents checked? Y/N

_____Cavity ID Y/N

_____Engraving Y/N

_____Core Polish Y/N

_____Cavity What SPI finish?

_____Preload ______ Y/N

_____Sharp corners Y/N

_____Spare cavity sets? Y/N

Cavity Blocks

_____Surface Hardness Treatments Y/N

_____Texturing Y/N (see below)

_____Vent Depth

_____Vent Land size

_____Vent Width

_____Vented to main vents Y/N

_____Cavity insert blocks drafted Y/N

_____Other (see below)

_____

_____

Ejection

_____# of pullback pins______

_____Air Blow-off Ejection Y/N

_____Blades Y/N

_____Ejection Distance____

_____Guided ejection Y/N

_____Hydraulic return Y/N (see below)

_____Pins Y/N

_____Proper max. loading on springs Y/N

_____Proper preloading on Springs Y/N

_____Proper sized return springs

_____Pull back thread size

_____Reverse Ejection

_____Screw-in machine return

_____Sleeve Y/N

_____Smooth movement? Y/N

_____Stacked ejection Y/N

_____Standard ejection Y/N

_____Stripper plates Y/N

_____Unscrewing Y/N

_____Knock out Pattern (see below)

_____ Ejector Rods provided Y/N

_____ Other (see below)

_____

Electrical

_____Electric connections on top of mold Y/N

_____Hot Runner Block Y/N

_____Waterproof connections/plug-ins? Y/N

_____Power connector type (see below)

_____Voltage for electricals

_____Terminal box Y/N

_____Thermocouples (see below)

_____Heater wattage

_____Total Amperage per mold

_____# of zones required for controller

_____ Controller included with mold

purchase? Y/N (see below)

_____ Other (see below)

_____

_____

Copyright WJT

Associates 2003

Part Number _____________ Mold Number _____________

Vendors

Name/part number /address/contact info

Hot manifold ______________________________________________________________________

Hydraulic Cylinders and nipple sizes ____________________________________________________

Air Cylinders and nipple sizes _________________________________________________________

Mold base ________________________________________________________________________

Thermocouples ____________________________________________________________________

Transducers ______________________________________________________________________

C

u

to

u

ta

n

dc

o

p

y

Heaters, probes, nozzles ____________________________________________________________

Electrical controllers ________________________________________________________________

Valve Gate Manufacturer ____________________________________________________________

Knock Out pattern on mold from centerline_________________________________________

Cylinder Dimensions ___________________________________ Single __ Double __Rod end

Other: - With off shore suppliers Have you sent all applicable SPI Standards?____

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

.________________________________________________________________________________

S-ar putea să vă placă și

- Mold ChecklistDocument5 paginiMold ChecklistSelvaraj BalasundramÎncă nu există evaluări

- Mold Spec Guidelines Jun 08revisedDocument27 paginiMold Spec Guidelines Jun 08revisedDirk HenningÎncă nu există evaluări

- Program Name: CE's APQP and Product Launch System (APLS)Document2 paginiProgram Name: CE's APQP and Product Launch System (APLS)Janaka MangalaÎncă nu există evaluări

- CV Cipet Production NewDocument4 paginiCV Cipet Production NewKamlesh KumarÎncă nu există evaluări

- Mold Flow AnalysisDocument30 paginiMold Flow AnalysisArun PrasadÎncă nu există evaluări

- MOULD MAINTENANCE GUIDEDocument40 paginiMOULD MAINTENANCE GUIDEprashanthÎncă nu există evaluări

- Mold Maintenance StepDocument0 paginiMold Maintenance StepMonica JoynerÎncă nu există evaluări

- Mold Check ListDocument10 paginiMold Check Listapk11Încă nu există evaluări

- Mold Maintenance ProgramDocument6 paginiMold Maintenance Programमनोज चौधरी100% (1)

- The Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SDocument6 paginiThe Process of Injection Mold Price Estimation:: The Tool Is Using This Formula: Weight L/1000 W/1000 T SSanjay KumarÎncă nu există evaluări

- Die Design ChecklistDocument3 paginiDie Design ChecklistLương TuấnÎncă nu există evaluări

- Tata Motors Ltd.Document44 paginiTata Motors Ltd.Arjun BhardwajÎncă nu există evaluări

- Mold Cost EstimationDocument5 paginiMold Cost EstimationPenjahit TedyÎncă nu există evaluări

- Mold Design Spec SheetDocument1 paginăMold Design Spec Sheetomerscheen0% (1)

- Injection Molding Cost CalculatorDocument111 paginiInjection Molding Cost CalculatorvenkithankamÎncă nu există evaluări

- 03 - SIPOC Diagram - 2009-06-11Document1 pagină03 - SIPOC Diagram - 2009-06-11Anand RajaÎncă nu există evaluări

- Molding Parameter Record RevDocument26 paginiMolding Parameter Record Revapi-37326090% (1)

- MANUF PROCESS - Troubleshooting App. Defects in Automotive Plastic Injection Molding DCC 2007Document54 paginiMANUF PROCESS - Troubleshooting App. Defects in Automotive Plastic Injection Molding DCC 2007dcajr687253Încă nu există evaluări

- PT Vs SOP 17 Tooling RepairDocument7 paginiPT Vs SOP 17 Tooling RepairRidwanÎncă nu există evaluări

- Minsa Trial Report Molde SC194Document2 paginiMinsa Trial Report Molde SC194daniel ortiz fuentesÎncă nu există evaluări

- Injection Molding Scrap ReductionDocument57 paginiInjection Molding Scrap ReductionkggganiÎncă nu există evaluări

- Moulding TroubleshootingDocument22 paginiMoulding TroubleshootingPiousPatialaÎncă nu există evaluări

- Developing A Project Scope For An Injection MoldDocument3 paginiDeveloping A Project Scope For An Injection MoldnadoÎncă nu există evaluări

- Form Tooling List Approval Tooling (002) Rev 4Document3 paginiForm Tooling List Approval Tooling (002) Rev 4Kalista BettiÎncă nu există evaluări

- Setting Process ConditionDocument11 paginiSetting Process Conditioneitan-dalia4971Încă nu există evaluări

- Mold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationDocument3 paginiMold Repair Form: Repair Request Information Request By: Req Category: Mold Defect InformationUmang Srivastava100% (1)

- Plastic injection moulding lubrication for reduced costsDocument2 paginiPlastic injection moulding lubrication for reduced costsJako MishyÎncă nu există evaluări

- Molding condition sheet settingsDocument1 paginăMolding condition sheet settingsNur AmiraÎncă nu există evaluări

- Analysis To Optimizing Inventory Management in Dies-Mold Making Factory by Partial Least Square (PLS) Case Study: ABC CompanyDocument3 paginiAnalysis To Optimizing Inventory Management in Dies-Mold Making Factory by Partial Least Square (PLS) Case Study: ABC CompanyInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- 8 Optimizing The Molding ParametersDocument54 pagini8 Optimizing The Molding ParametersEdith Chavez LindosÎncă nu există evaluări

- Moulding Check ListDocument2 paginiMoulding Check Listapi-3732609Încă nu există evaluări

- Autocar Ppap Requirements Rev 5Document17 paginiAutocar Ppap Requirements Rev 5man hoÎncă nu există evaluări

- Setting Molding ConditionsDocument21 paginiSetting Molding Conditionssuwithy04Încă nu există evaluări

- Industrial Machine Operation GuideDocument11 paginiIndustrial Machine Operation GuideLongfvn100% (1)

- CTM Mold Design Standards PDFDocument43 paginiCTM Mold Design Standards PDFDini ViruÎncă nu există evaluări

- Mould Change, Storage and Maintenance ProcedureDocument10 paginiMould Change, Storage and Maintenance ProcedureTechnicians SIM100% (1)

- Performance Appraisal Form AnalysisDocument5 paginiPerformance Appraisal Form AnalysisShami KantÎncă nu există evaluări

- Injection Molding Defect OzDocument12 paginiInjection Molding Defect Oztopkaya100% (1)

- Inj Mold CalculateDocument9 paginiInj Mold CalculateGiap NguyenÎncă nu există evaluări

- Defects in Injection MouldingDocument14 paginiDefects in Injection Mouldinghajarpaiman100% (1)

- Hot Runner System: Training ManualDocument21 paginiHot Runner System: Training ManualHồng HoàngÎncă nu există evaluări

- Compression Mould.Document26 paginiCompression Mould.Aadi AdarshÎncă nu există evaluări

- Maintenance of Plastic Processing MachinesDocument37 paginiMaintenance of Plastic Processing Machinesnishantbhore6830100% (1)

- Routsis Injection Molding ReferenceDocument176 paginiRoutsis Injection Molding ReferenceRupesh PillaiÎncă nu există evaluări

- Mold Making & Injection Molding - Bluestar Mould Group 2015Document59 paginiMold Making & Injection Molding - Bluestar Mould Group 2015Huy Bui VanÎncă nu există evaluări

- D10369520ADocument4 paginiD10369520AQUALITY ControlÎncă nu există evaluări

- Optimization of a fanuc mould process sheetDocument1 paginăOptimization of a fanuc mould process sheetx engineeringÎncă nu există evaluări

- Injection Molding LabDocument2 paginiInjection Molding LabZulhusni Abdul JamanÎncă nu există evaluări

- Mold SpecificationDocument1 paginăMold SpecificationVictor Villouta LunaÎncă nu există evaluări

- NPI WebDocument50 paginiNPI WebfutpemataÎncă nu există evaluări

- Injection Moulding - Quality Molded PartsDocument28 paginiInjection Moulding - Quality Molded PartsQuản Lê Đình100% (3)

- Mold Maintenance ProgramDocument14 paginiMold Maintenance ProgramLordsonÎncă nu există evaluări

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 paginiMould Check List / Trial Record: FG Control Tube FG H-ToprajeshÎncă nu există evaluări

- Design and Fabrication of Injection Moulding Machine-Mechanical ProjectDocument4 paginiDesign and Fabrication of Injection Moulding Machine-Mechanical ProjectUr FriendÎncă nu există evaluări

- Mould Maintenance A.kumarDocument40 paginiMould Maintenance A.kumarShankar Hindgavkar100% (2)

- ADDICKS MOLD SPECIFICATION SHEETDocument1 paginăADDICKS MOLD SPECIFICATION SHEETRakesh Junnur100% (1)

- Injection Mold Standards 80 Eng D 20Document21 paginiInjection Mold Standards 80 Eng D 20Deep ShahÎncă nu există evaluări

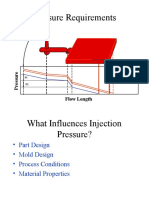

- Pressure Requirements: Flow LengthDocument43 paginiPressure Requirements: Flow Lengthanirudha_jewalikar1100% (2)

- Assembly Process A Complete Guide - 2020 EditionDe la EverandAssembly Process A Complete Guide - 2020 EditionÎncă nu există evaluări

- Working Capital of Plastic IndustryDocument59 paginiWorking Capital of Plastic Industryctansari50% (2)

- Iso 9001 2008 Checklist Sample Rev 2-20-09usDocument8 paginiIso 9001 2008 Checklist Sample Rev 2-20-09usRonaldSincheÎncă nu există evaluări

- What Are The Different Types of Maintenance David Albrice PDFDocument4 paginiWhat Are The Different Types of Maintenance David Albrice PDFmorisÎncă nu există evaluări

- Anilox Cleaning and CareDocument7 paginiAnilox Cleaning and CarectansariÎncă nu există evaluări

- Injection Mold Design ChecklistDocument4 paginiInjection Mold Design Checklistctansari0% (1)

- WLB PDFDocument156 paginiWLB PDFctansariÎncă nu există evaluări

- WLB PDFDocument156 paginiWLB PDFctansariÎncă nu există evaluări

- WLB PDFDocument156 paginiWLB PDFctansariÎncă nu există evaluări

- Iso 9001 2008 FaqDocument4 paginiIso 9001 2008 FaqSUBODHHÎncă nu există evaluări

- Secrets of Pulse ExcerptDocument17 paginiSecrets of Pulse ExcerptctansariÎncă nu există evaluări

- Log Price SeriesDocument2 paginiLog Price SeriesctansariÎncă nu există evaluări

- Industry Performance in 2014Document13 paginiIndustry Performance in 2014ctansariÎncă nu există evaluări

- Collection of Job Interview Questions and The AnswersDocument46 paginiCollection of Job Interview Questions and The AnswersctansariÎncă nu există evaluări

- 03 Baking Powder, Jelly Crystal & Custard PowderDocument8 pagini03 Baking Powder, Jelly Crystal & Custard PowderctansariÎncă nu există evaluări

- Ginger Garlic Processing - MOFPIDocument9 paginiGinger Garlic Processing - MOFPINirmal SharmaÎncă nu există evaluări

- Machine AuditsDocument2 paginiMachine AuditsctansariÎncă nu există evaluări

- TNPSC Group 4 Model Question Paper 2Document20 paginiTNPSC Group 4 Model Question Paper 2training2jobs100% (1)

- Application For Registration of Marriage: at Private ResidenceDocument1 paginăApplication For Registration of Marriage: at Private ResidencectansariÎncă nu există evaluări

- I Sots 16949Document5 paginiI Sots 16949ctansariÎncă nu există evaluări

- 0122 PDFDocument2 pagini0122 PDFkaviatchennaiÎncă nu există evaluări

- How To Make A Folding Carton SMLDocument17 paginiHow To Make A Folding Carton SMLctansari100% (1)

- Corrugated Box Plant Business PlanDocument17 paginiCorrugated Box Plant Business Planctansari25% (4)

- Simulated Robot Football Team Uses Neural Networks to LearnDocument8 paginiSimulated Robot Football Team Uses Neural Networks to LearnKishore MuthukulathuÎncă nu există evaluări

- Leica CS10 CS15 GSSensors QG v3.0.1 en PDFDocument16 paginiLeica CS10 CS15 GSSensors QG v3.0.1 en PDFMohammad Saiful AzamÎncă nu există evaluări

- Health Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4Document7 paginiHealth Optimizing Physical Education: Learning Activity Sheet (LAS) Quarter 4John Wilfred PegranÎncă nu există evaluări

- Serto Up To Date 33Document7 paginiSerto Up To Date 33Teesing BVÎncă nu există evaluări

- Amna Hameed: ObjectiveDocument2 paginiAmna Hameed: ObjectiveSabrina GandapurÎncă nu există evaluări

- Sexual & Reproductive Health of AdolocentsDocument8 paginiSexual & Reproductive Health of AdolocentsSourav HossenÎncă nu există evaluări

- Barry Wylant: Design Thinking and The Experience of InnovationDocument13 paginiBarry Wylant: Design Thinking and The Experience of InnovationVanesa JuarezÎncă nu există evaluări

- Tower Light Inspection ChecklistDocument19 paginiTower Light Inspection ChecklistMOHAMMED RIYAN TÎncă nu există evaluări

- Arts9 q4 Mod1 Theatricalforms v5Document30 paginiArts9 q4 Mod1 Theatricalforms v5Harold RicafortÎncă nu există evaluări

- FeatureSelectionAccepted IEEE Review PDFDocument20 paginiFeatureSelectionAccepted IEEE Review PDFrvsamy80Încă nu există evaluări

- Kara&Suoglu ProjectreportDocument4 paginiKara&Suoglu ProjectreportRicard Comas xacnóÎncă nu există evaluări

- Fictional Narrative: The Case of Alan and His FamilyDocument4 paginiFictional Narrative: The Case of Alan and His Familydominique babisÎncă nu există evaluări

- Stmma-Fd: Zhejiang Castchem New Material Co.,Ltd&Castchem (Hangzhou), IncDocument2 paginiStmma-Fd: Zhejiang Castchem New Material Co.,Ltd&Castchem (Hangzhou), IncYash RaoÎncă nu există evaluări

- Kanavos Pharmaceutical Distribution Chain 2007 PDFDocument121 paginiKanavos Pharmaceutical Distribution Chain 2007 PDFJoao N Da SilvaÎncă nu există evaluări

- Philippine Politics Concepts ExplainedDocument3 paginiPhilippine Politics Concepts ExplainedAngel Lyn A Lacerna100% (1)

- Active Disturbance Rejection Control For Nonlinear SystemsDocument8 paginiActive Disturbance Rejection Control For Nonlinear SystemsTrần Việt CườngÎncă nu există evaluări

- Rethinking Classification and Localization For Object DetectionDocument13 paginiRethinking Classification and Localization For Object DetectionShah Nawaz KhanÎncă nu există evaluări

- Ultimate Guide To Construction SubmittalsDocument10 paginiUltimate Guide To Construction SubmittalsDavid ConroyÎncă nu există evaluări

- How To Install Windows XP From Pen Drive Step by Step GuideDocument3 paginiHow To Install Windows XP From Pen Drive Step by Step GuideJithendra Kumar MÎncă nu există evaluări

- 7 Tools for Continuous ImprovementDocument202 pagini7 Tools for Continuous Improvementvivekanand bhartiÎncă nu există evaluări

- Reading in Philippine History (Chapter 3)Document14 paginiReading in Philippine History (Chapter 3)AKIO HIROKIÎncă nu există evaluări

- Psalms Magick of The Old Testament PDFDocument129 paginiPsalms Magick of The Old Testament PDFirrrs100% (1)

- Youre The Inspiration CRDDocument3 paginiYoure The Inspiration CRDjonjammyÎncă nu există evaluări

- 09 Chapter TeyyamDocument48 pagini09 Chapter TeyyamABÎncă nu există evaluări

- MB0042-MBA-1st Sem 2011 Assignment Managerial EconomicsDocument11 paginiMB0042-MBA-1st Sem 2011 Assignment Managerial EconomicsAli Asharaf Khan100% (3)

- Sight Reduction Tables For Marine Navigation: B, R - D, D. SDocument12 paginiSight Reduction Tables For Marine Navigation: B, R - D, D. SGeani MihaiÎncă nu există evaluări

- Cat TSDDocument55 paginiCat TSDvarsha sharmaÎncă nu există evaluări

- How To Calibrate OscilloscopeDocument2 paginiHow To Calibrate OscilloscopeninoÎncă nu există evaluări

- User Manual LCD Signature Pad Signotec SigmaDocument15 paginiUser Manual LCD Signature Pad Signotec SigmaGael OmgbaÎncă nu există evaluări

- Ex 2 6 FSC Part2 Ver3Document16 paginiEx 2 6 FSC Part2 Ver3Usama TariqÎncă nu există evaluări