Documente Academic

Documente Profesional

Documente Cultură

Art:10.1007/s12205 013 0236 X PDF

Încărcat de

Alhaz UddinDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Art:10.1007/s12205 013 0236 X PDF

Încărcat de

Alhaz UddinDrepturi de autor:

Formate disponibile

KSCE Journal of Civil Engineering (2013) 17(4):789-796

DOI 10.1007/s12205-013-0236-x

Structural Engineering

www.springer.com/12205

Experimental Study on Strength Gaining Characteristics

of Concrete using Portland Composite Cement

Md. Alhaz Uddin*, Mohammed Jameel**, Habibur Rahman Sobuz***,

Md. Shahinul Islam****, and Noor Md. Sadiqul Hasan*****

Received May 13, 2012/Revised July 11, 2012/Accepted August 19, 2012

Abstract

This study deals with experimental investigation of strength gaining characteristics of concrete made with Portland Composite

Cement (PCC) and Ordinary Portland Cement (OPC). Compressive strength of concrete is often considered as a measure to

determine the rate of strength gain of concrete with age and different cement composition. Strength developments of five concrete

types have been investigated in terms of cement content and curing duration. Experimental observations on 495 specimens reveal

that the early age strength of PCC concrete is lower than that of OPC concrete. Based on the test results, lack of proper pozzolanic

reaction in the presence of fly ash in PCC concrete strength is lower at early age. The pozzolanic activity of fly ash also contributes to

the strength gain at later stages of continuous curing. This study also concludes that drying ambient conditions reduce the strength

potential of PCC concrete as the secondary (pozzolanic) reaction fails to contribute to the development of strength.

Keywords: strength gain, cement composition, curing time, compressive strength, pozzolanic reaction

1. Introduction

The strength of concrete is one of the most important engineering

properties of construction materials. There are many factors

affecting the rate of strength gain of concrete. Concrete is composed

of cement as well as other cementitious materials such as fly ash,

slag, coarse aggregate, fine aggregate, water, and chemical

admixtures. In building construction sector, there is a common

complain that concrete does not gain target strength within specified

period (28 days). A decision should be taken at the time (28 days) to

remove formwork depend on the rate of strength gain of the concrete

considering safety, economy and quality. Freiesleben and Pedersen

(1977) reported that the rate of strength gain of concrete depends on

temperature. In view of Saul (1951) and Kim et al. (1998)

investigation, the strength gain of concrete is subjected to combined

effect of curing time and temperature during hardening process.

They found that the concrete gain strength at early-age subjected to a

high temperature. In an experimental study, Price (1951) and

Zhutovsky and Kovler (2012) pointed out that due to the first 2 hrs

of curing at high temperature concrete gain a higher strength at early

stage. Strength development in concrete at early stage due to effect

of curing temperature was reported by Klieger (1958) and Toe et al.

(2010). Strength at any given age and rate of strength gain of mortars

and concretes containing fly ash will depend on the pozzolanic

reactivity of the fly ash (Jansen et al., 2012; Wongkeo et al., 2012),

the richness of the mix, the character and grading of the aggregate,

the water content of the mix and the curing conditions (Brue et al.,

2012; El-Nemr, 2011; Hobbs, 1983). Sometimes dying ambient

disorders significantly reduce the strength potential of concrete

made with PCC for secondary (pozzolanic) reaction fails to

contribute to gain of strength (Mahasneh and Shawabkeh, 2004;

Razak and Sajedi, 2011; Sata et al., 2012).

Incorporation of fly ash in concrete improves workability and

thereby reduces the water requirement with respect to the

conventional concrete. Among numerous other beneficial

effects are reduced bleeding, reduced segregation, reduced

permeability, increased plasticity, lowered heat of hydration

(Shafiq 2011), and increased setting times (ACI, 1987;

Mahasneh and Shawabkeh, 2004). A critical drawback of the

use of fly ash in concrete is that the rate of strength gain of fly

*Ph.D. Candidate, School of Civil, Environmental and Mining Engineering, University of Adelaide, Adelaide, South Australia, 5005, Australia (Corresponding Author, E-mail: mauce52@siswa.um.edu.my)

**Senior Lecturer, Dept. of Civil Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia (E-mail: jameel@um.edu.my)

***Ph.D. Candidate, School of Civil, Environmental and Mining Engineering, University of Adelaide, Adelaide, South Australia, 5005, Australia (E-mail:

habibkuet@gmail.com)

****Researcher, Dept. of Civil Engineering, Bangladesh University of Engineering and Technology, Bangladesh (E-mail: shahinul02@gmail.com)

*****Lecturer, School of Civil Engineering, Linton University College, Legenda Education Group, 71700 Mantin, Malaysia (E-mail: noorhasan@legendagroup.edu.my)

789

Md. Alhaz Uddin, Mohammed Jameel, Habibur Rahman Sobuz, Md. Shahinul Islam, and Noor Md. Sadiqul Hasan

ash concrete is slower but it is sustained for longer periods than

the rate of the strength increase of Portland cement concrete

(Chindaprasirt et al., 2005; Hwang et al., 2004). Kaosar (2006)

has made a study on brick aggregate concrete with varying

amount of fly ash content where fly ash were added directly at

the time of mixing. Then compressive strength and two types

of durability test such as chloride resistance (Florea and

Brouwers, 2012) and sulfate resistance tests have been

performed to evaluate the effects of fly ash on strength and

durability of brick aggregate concrete (Ahmadi and Shekarchi,

2010; Golestanifar and Ahangari, 2011). Cement manufacturing

companies of Bangladesh have been using fly ash in cement to

minimize the rising production cost of cement. These fly ash

containing cement are available in the market named as

Portland Composite Cement. It is observed that the

proportions of different ingredients of PCCs are varied among

the different cement manufacturing companies. Thus, it is

necessary to investigate the strength gaining property of

concrete made with PCC both at early and later ages.

In this study, strength development of five different composition

cement types has been investigated in terms of different

curing condition. In the framework of experimental study

during 365 days; mortars have been prepared with different

composition cement such as clinker, fly ash, gypsum, slag

and limestone which kept at two different curing conditions.

It is found that PCC concrete has shown lower early age

strength than OPC whereas, at later ages both of the concrete

is providing approximately similar strength characteristics

due to continuous curing conditions and well performed

pozzolanic reaction activities.

2. Materials and Methods

This experimental study represents a general scenario of the

strength gain characteristics of concrete made with PCC and

OPC both at earlier and later ages. All properties of concrete

ingredients are kept constant and cement type is varying with

different composition. The work is performed using locally

available materials such as stone chips, sand (Coarse Sand) and

cement (Portland composite and ordinary Portland). The

concrete have been cured in two different ways, one set of

concrete specimens have been cured continuously until they are

tested while the other set of concrete specimens have been cured

only 14 days under water to know effect of continuous curing

over 14 days curing (Zhao et al., 2012).

Table 1. Physical Properties of Fine and Coarse Aggregate

Properties

Maximum aggregate size (mm)

Bulk Specific gravity

Absorption capacity (%)

Unit weight (kg/m3)

Fineness modulus

Local sand

2.36

2.56

1.21

2.73

Crushed stone

19

2.71

0.45

1556

6.74

Fig. 1. Sieve Analysis of Fine and Coarse Aggregate

also shown in Table 1.

The gradations of fine and coarse aggregates have been

obtained by sieve analysis (Fig. 1), according to standard ASTM

C 136. A suitable gradation of an aggregate in PCC and OPC

mixture is important in order to secure strength gain of the

concrete mix (Celik et al., 2008; Sharifi, 2012). The fineness

modulus of fine and coarse aggregate are obtained from sieve

analysis is 2.73 and 6.74 respectively.

2.1.2 Properties of Cement

Cement is a cementitious material in concrete mixture. The

properties of concrete ingredients (coarse aggregate, fine aggregate,

water) have been kept constant, only the cement type has been

changed. In this project PCC of four different types and one

Ordinary (ASTM Type I) Portland Cement (OPC) have been

used in making concrete. Specific gravity of OPC is 3.15. The

chemical compositions and cement ingredient of different type

2.1 Materials Properties

2.1.1 Properties of Aggregate

Aggregate act as an inert filler in concrete providing improved

volume stability. Locally available coarse sand has been used for

this project as fine aggregate. The physical properties of fine

aggregate are shown in Table 1. Crushed stone has been used in

this project as coarse aggregate whose physical properties are

790

Table 2. Chemical Composition of PCC and OPC

Constituent

SiO2

Al2O3

Fe2O3

CaO

MgO

SO3

Na2O

K2O

LOI

PCC

20.60

4.74

3.28

64.82

1.84

2.4

0.21

0.38

1.73

OPC

19.24

4.78

2.90

64.05

1.65

3.36

0.25

0.81

2.96

KSCE Journal of Civil Engineering

Experimental Study on Strength Gaining Characteristics of Concrete using Portland Composite Cement

Table 3. Proportions of Ingredients in Cements

PCC

Ingredient

Type-A (%)

66.4

3.36

30.24

Clinker

Gypsum

Slag, Fly Ash, Limestone

Type-B (%)

74.53

3.21

22.26

Type-C (%)

72.32

2.90

24.78

Type-D (%)

87.56

1.77

10.67

OPC

Type-E (%)

96.47

3.53

-

Table 4. Amount of Ingredients Required for Making Concrete

Target strength (MPa)

17.24

27.58

41.37

Slump (mm)

(76-101)

(25-51)

(25-51)

Cement (Kg/m3)

476.74

581.55

807.95

Water (Kg/m3)

357.46

331.21

331.21

vibrating table (Fig. 2). After that, leaving the molded concrete

specimens in place of hardening for a period of 24 h, and then demolded. The total 495 numbers of concrete specimens have been

prepared according to different curing condition (continuously

curing and only 14 days curing). In this project PCC of four different

compositions and one OPC have been used in making concrete for

target strength of 17.24 MPa, 27.58 MPa and 41.37 MPa.

Table 5. w/c Ratio of Concrete Mixtures

28 day compressive

strength (MPa)

17.24

27.58

41.37

Non air

Entrained

0.75

0.57

0.41

Fine aggregate (Kg/m3) Coarse aggregate (Kg/m3)

1460.53

1798.11

1442.77

1798.11

1255.94

1798.11

Air

Entrained

0.67

0.48

---

are shown in Table 2 and Table 3, respectively.

2.2.2 Curing of Specimens

Concrete specimens have been cured in two different ways,

2.2 Mixture Compositions

According to ACI mix design method, the required quantity of

cement, sand, fine aggregate and coarse aggregate have been

mixed for target strength of 17.24 MPa, 27.58 MPa and 41.37

MPa (Table 4). Concrete mixtures have been proportioned using

w/c ratios (Table 5) in air entrained and non-air entrained

condition. Slump value of mixtures was different according to

target strength as shown in Table 4.

2.2.1 Preparation of Test Specimens

Concrete specimen have been casted for the target strength of

17.24 MPa, 27.58 MPa and 41.37 MPa using PCC of four

different types and one OPC. The steel molds (cylindrical in

shape with 100 mm diameter and 200 mm height) have been

used for casting of all specimens and then, compacted using a

Fig. 3. Placing of Concrete Specimens into the Curing Tank

Fig. 2. Preparing of Concrete Specimens: (a) Casting, (b) Compacting on Vibration Table

Vol. 17, No. 4 / May 2013

791

Md. Alhaz Uddin, Mohammed Jameel, Habibur Rahman Sobuz, Md. Shahinul Islam, and Noor Md. Sadiqul Hasan

Fig. 4. Compressive Strength Test: (a) Applying Load on the Concrete Cylinder by Compression Test Machine, (b) Failure Surface of the

Crushed Concrete Cylinder

one set of concrete specimens have been cured continuously until

testing while the other set of concrete specimens have been cured

only 14 days under water in the laboratory. These 14 days cured

specimens have been kept in air until testing. A curing tank has

been constructed for curing the concrete specimens properly

(Fig. 3). The temperature of the curing water varies from 20 to

25oC and relative humidity 55 to 75%.

2.3 Testing Procedure

The rate of strength gain with age of concrete is determined in

accordance with ASTM C39 (1996). Compressive strength is one of

the most important and useful properties of concrete. It usually gives

an overall picture of the quality of concrete because it is directly

related to the structure of the hardened cement paste (Ozturk and

Baradan, 2011; Woo et al., 2011). Compressive strength test (Fig. 4)

of moist cured concrete specimens has been carried out after removal

from moist storage. The compressive strength of concrete cylinders

has been tested at 3, 7, 14, 28, 90, 180, 365 days of concrete.

Fig. 6. Comparison of Compressive Strength Gain with Age of

Concrete made with Various Cement for 27.58 MPa

3. Test Results and Discussion

3.1 Relative Strength Gain

PCC and OPC concrete shows different characteristics in

strength development at early and later ages. Figs. 5-7 shows the

Fig. 7. Comparison of Compressive Strength Gain with Age of

Concrete made with Various Cement for 41.37 MPa

Fig. 5. Comparison of Compressive Strength Gain with Age of

Concrete made with Various Cement for 17.24 MPa

variation of strength gain characteristics of concrete at early and

later ages with cement type at continuous curing condition that

have been designed for target strengths of 17.24 MPa, 27.58

MPa and 41.37 MPa, respectively.

It can be seen from Fig. 5 that the relative strength gain of PCC

and OPC concrete for target strength of 17.24 MPa. As seen

from Fig. 5, the compressive strength increases in all specimens

with time. The percentage of target compressive strength gain at

early ages (3 days, 7 days, 14 days) of PCC concrete is lower

than that of OPC concrete but at later ages (180 days) is almost

792

KSCE Journal of Civil Engineering

Experimental Study on Strength Gaining Characteristics of Concrete using Portland Composite Cement

same. The only exception is found in case of cement type-D

where the percentage of target compressive strength gain of

concrete at early age (3 days) is higher than other kinds (type-A,

type-B, type-C), since type-D contains highest percentage of

clinker 87.56% thus lower percentage of fly ash whereas cement

type A and C contain 66.4% and 72.32% clinker respectively

and type-B contains 74.53% clinker. Fig. 5 also shows that the

strength gain curve fitting for all cement composition of target

strength 17.24 MPa. The best cement composition is:

fc (OPC)E = 0.0322Ln(t) + 14.372 with R2 = 0.6191

(1)

and worst cement composition is:

fc (PCC)B = 0.0421Ln(t) + 10.617 with R2 = 0.706

(2)

where fc is compressive strength in MPa, t is age of specimen in

days, and R2 is the coefficient of correlation.

The relative strength gain of concrete for target strength of 27.58

MPa for PCC and OPC which is shown in Fig. 6. It can be seen from

Fig. 6 that PCC concrete have gained 15 percent less strength at 14

days of age than that of OPC conrete. But at the later age, they have

gained similar percentage of target strength at continuous curing

condition. The only exception is found in case of cement type-D

where the percentage of target compressive strength gain of concrete

at early age (3 days) is higher than PCC concrete of cement types

(type-A, type-B, type-C) since type-D contains higher percentage of

clinker thus lower percentage of fly ash. Fig. 6 also shows that the

strength gain curve fitting for all cement composition of target

strength 27.58 MPa. The best cement composition is:

fc (OPC)E = 0.0448Ln(t) + 19.406 with R2 = 0.5551

(3)

Fig. 8. Variation of Target Strength at 7 and 28 days with Cement

type for 17.24 MPa Target Strength

Fig. 9. Variation of Target Strength at 7 and 28 days with Cement

type for 27.58 MPa Target Strength

and worst cement composition is:

fc (PCC)C = 0.0542Ln(t) + 16.005 with R2 = 0.6267

(4)

where fc is compressive strength in MPa, t is age of specimen in

days, and R2 is the coefficient of correlation.

The relative strength gain of PCC and OPC concrete for target

strength of 41.37 MPa is shown in Fig. 7. It is found that PCC

concrete gains 15 to 20 percent less strength at early ages (3

days, 7 days, 14 days) than OPC concrete. But at later ages (180

days), PCC have gained only 5 percent less strength than of OPC

concrete at continuous curing condition. Fig. 7 also shows that

the strength gain curve fitting for all cement composition of

target strength 41.37 MPa. The best cement composition is:

fc (OPC)E = 0.0383Ln(t) + 32.657 with R2 = 0.5288

(5)

Fig. 10. Variation of Target Strength at 7 and 28 days with Cement

type for 41.37 MPa Target Strength

and worst cement composition is:

fc (PCC)B = 0.0573Ln(t) + 25.057 with R2 = 0.6242

(6)

where fc is compressive strength in MPa, t is age of specimen in

days, and R2 is the coefficient of correlation.

3.2 Development of Compressive Strength of Concrete at

Early Ages

Figure 8 shows that PCC concrete type A, B, C and D for

Vol. 17, No. 4 / May 2013

target strength of 17.24 MPa has gained 55 to 60 percent and 80

to 85 percent of target strength at 7 days and 28 days of age at

continuous curing condition. At 14 days curing condition, it has

gained 80 percent of its target strength at 28 days of age. On the

other hand, OPC concrete type E has gained 75 percent and 100

percent of the target strength at 7 days and 28 days of age of

concrete at continuous curing condition and 95 percent of target

793

Md. Alhaz Uddin, Mohammed Jameel, Habibur Rahman Sobuz, Md. Shahinul Islam, and Noor Md. Sadiqul Hasan

strength at 28 days of age at 14 days curing condition.

Figure 9 shows that PCC concrete type A, B, C and D for

target strength of 27.58 MPa has gained 50 to 60 percent and

80 percent of target strength at 7 days and 28 days of age at

continuous curing condition. At 14 days curing condition, it

has gained 75 to 80 percent of its target strength at 28 days of

age. On the other hand, OPC concrete type E has gained 60

percent and 95 percent of the target strength at 7 days and 28

days of age of concrete at continuous curing condition and 90

percent of target strength at 28 days of age at 14 days curing

condition.

Figure 10 shows that PCC concrete type A, B, C and D for

target strength of 41.37 MPa has gained 55 to 60 percent and 80

percent of target strength at 7 days and 28 days of age at

continuous curing condition. At 14 days curing condition, it has

gained 75 to 80 percent of its target strength at 28 days of age.

On the other hand, OPC concrete type E has gained 70 percent

and 95 percent of the target strength at 7 and 28 days of age of

concrete at continuous curing condition and 90 percent of target

strength at 28 days of age at 14 days curing condition.

3.3 Time Required to Gain Full Target Strength

The time required to gain the full target strength of PCC and OPC

concrete have been estimated when they are cured at continuous

curing condition. Fig. 11 shows the time required by concrete made

Fig. 11. Time Required for Gaining Full Target Strength at Different

Cement Type at Continuous Curing Condition

with PCC relative to OPC to gain full target strengths of 17.24

MPa, 27.58 MPa and 41.37 MPa respectively. It is found that PCC

concrete for target strengths of 17.24 MPa, 27.58 MPa and 41.37

MPa required 50 to 70 days, 80 to 100 days and 180 to 200 days

respectively to gain full target strength. At the same condition, OPC

concrete for target strengths of 17.24 MPa, 27.58 MPa and 41.37

MPa required 30 days, 40 days and 90 days respectively to gain full

target strength.

3.4 Effect of Curing on Strength Development of Concrete

Concrete properties are significantly influenced by curing

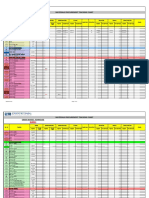

Table 6. Compressive Strength Gain with Age of Concrete for 17.24 MPa

Cement Type

A(PCC)

B(PCC)

C(PCC)

D(PCC)

E(OPC)

Curing condition

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

28 days

084.72

087.56

083.56

084.96

084.68

090.84

087.64

092.04

101

102.72

% of Compressive strength

90 days

180 days

101.04

113.6

102.92

121.32

104.76

113.72

105.28

123.84

108.96

117.92

111.92

127.48

110.2

118.2

110.48

126.44

115.92

122.08

119.8

132.36

365 days

119.52

132.4

119.2

135.56

124.28

137.88

123.2

137.04

126.72

138.12

Table 7. Compressive Strength Gain with Age of Concrete for 27.58 MPa

Cement Type

A(PCC)

B(PCC)

C(PCC)

D(PCC)

E(OPC)

Curing condition

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

% of Compressive strength

28 days

78.175

79.575

74.15

76.65

79.65

81.9

83.55

84.65

94.4

95.85

794

90 days

087.625

098.825

090.35

096.95

096.325

099.7

096.7

102.925

101.2

105.175

180 days

090.675

103.075

097.225

111.125

101.55

108.075

103.55

113.675

107.125

112.725

365 days

092.85

107.025

098.7

117.175

104.1

115.6

105.55

121.35

109.8

117.075

KSCE Journal of Civil Engineering

Experimental Study on Strength Gaining Characteristics of Concrete using Portland Composite Cement

Table 8. Compressive Strength Gain with Age of Concrete for 41.37 MPa

Cement Type

A(PCC)

B(PCC)

C(PCC)

D(PCC)

E(OPC)

Curing condition

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

14 days curing

Continuous curing

28 days

82.37

83.20

75.12

77.37

80.27

80.78

85.48

86.42

91.00

93.23

since it greatly effects the hydration of cement. A proper curing

maintains a suitably warm and moist environment for the

development of hydration products and thus reduces the porosity in

hydrated cement paste and increases the density of microstructure

in concrete.

Table 6 shows that PCC concrete specimens have gained full

target strength (17.24 MPa) within 90 days at 14 days curing

condition. Concrete specimens have gained 120 to 140 percent

of target strength after 365 days for 14 days curing and

continuous curing condition. OPC concrete have gained 140

percent and 125 percent of target strength at continuous curing

and 14 days curing condition respectively after 365 days.

Table 7 shows that PCC concrete specimens have gained full

target strength (27.58 MPa) within 180 days at 14 days curing

condition. Concrete specimens have gained 110 to 120 percent

and 95 to 105 percent of target strength after 365 days at

continuous curing and 14 days curing condition respectively.

OPC concrete have gained 120 percent and 110 percent of target

strength at continuous curing and 14 days curing condition

respectively after 365 days.

Table 8 shows that PCC concrete specimens have failed to gain

full target strength (41.37 MPa) within 365 days at 14 days

curing condition. Concrete specimens have gained 100 percent

and 90 percent of target strength after 365 days at continuous

curing and 14 days curing condition respectively. OPC concrete

have gained 105 percent and 95 percent of target strength at

continuous curing and 14 days curing condition respectively

after 365 days. It is suggested that adequate curing at early ages

as well as later ages is essential to continue the pozzolanic

reaction in concrete which contribute to the development of

strength of concrete made with PCC.

4. Conclusions

This experimental study has investigated the strength gain

characteristics of five different composition cement types in

terms of different curing conditions. The compressive strength

gain at early ages of Portland cement concrete is lower than that

of ordinary Portland cement concrete. Lack of proper Pozzolanic

Vol. 17, No. 4 / May 2013

% of Compressive strength

90 days

180 days

088.58

090.63

091.63

096.93

085.02

089.08

090.22

095.92

090.48

092.88

093.97

099.17

092.02

094.05

095.83

100.13

094.43

097.10

100.97

103.38

365 days

089.75

101.87

090.87

101.05

094.35

104.30

095.20

102.62

097.92

104.92

reaction in the presence of fly ash in PCC concrete strength is

lower at early age. The pozzolanic activity of fly ash also

contributes to the strength gain at later stages of continuous

curing. But at later ages, the strength of PCC concrete and OPC

is almost same to continuous curing. At continuous curing

condition, PCC concrete for the target strengths of 17.24 MPa,

27.58 MPa, and 41.37 MPa requires 50 to 70 days, 80 to 100

days and 180 to 200 days respectively to gain full target strength

and at 14 days curing condition, it requires 90 days and 180 days

to gain the target strength of 17.24 MPa and 27.58 MPa

respectively. But it fails to gain the target strength of 41.37 MPa

in 365days at 14 days curing condition. The compressive

strength of five different compositions cement increased with

increasing curing time. Adequate curing at early ages as well as

at later ages is essential in the strength development of PCC

concrete. It can be concluded that drying ambient conditions

reduce the strength potential of PCC concrete as the secondary

(pozzolanic) reaction fails to contribute to the development of

strength. This characteristics of strength development can

significantly increase the use of PCC in construction of mass

concrete to be used in water related structure.

Acknowledgements

The authors gratefully acknowledge Civil Engineering Department

of Bangladesh University of Engineering & Technology and the

grant RG093-10AET provided by University of Malaya.

References

ACI Committee (1987). Use of fly ash in concrete. American

Concrete Institute Materials J., pp. 381-409.

Ahmadi, B. and Shekarchi, M. (2010). Use of natural zeolite as a

supplementary cementitious material. Cem. Concr. Comp., Vol. 32,

No. 2, pp. 134-141.

Brue, F., Davy, C. A., Skoczylas, F., Burlion, N., and Bourbon, X.

(2012). Effect of temperature on the water retention properties of

two high performance concretes. Cem. Concr. Res., Vol. 42, No. 2,

pp. 384-396.

Celik, O., Damci, E., and Piskin, S. (2008). Characterization of fly ash

795

Md. Alhaz Uddin, Mohammed Jameel, Habibur Rahman Sobuz, Md. Shahinul Islam, and Noor Md. Sadiqul Hasan

and it effect on the compressive strength properties of Portland

cement. Indian J. of Eng. & Materials Sci., Vol. 15, No. 5, pp. 433440.

Chindaprasirt, P., Jaturapitakkul, C. H., and Sinsiri, T. (2005). Effect of

fly fineness on compressive strength and pore size of blended

cement paste. Cem. Concr. Comp., Vol. 27, No. 4, pp. 425-428.

El-Nemr, K. F. (2011). Effect of different curing systems on the

mechanical and physico-chemical properties of acrylonitrile butadiene

rubber vulcanizates. Materials & Design, Vol. 32, No. 6, pp. 33613369.

Florea, M. V. A. and Brouwers, H. J. H. (2012). Chloride binding

related to hydration products Part I: Ordinary Portland cement.

Cem. Concr. Res., Vol. 42, No. 2, pp. 282-290.

Freiesleben, H. P. and Pedersen, E. J. (1977). Maturity computer for

controlled curing and hardening of concrete. Nordisk Betong, Vol.

No. 1, pp. 21-25.

Golestanifar, M. and Ahangari, K. (2011). Decision on coarse aggregates

borrow sources of concrete. KSCE J. Civ. Eng., Vol. 15, No. 6, pp.

965-973.

Hobbs, D. W. (1983). Influence of fly ash upon the workability and

early strength of concrete. Presented at Proceedings of the

CANMET/ACI First International Conference on the Use of Fly

Ash, Silica Fume, Slag and Other Mineral by-products in Concrete,

Vol. 79, pp. 289-306.

Hwang, K., Noguchi, T., and Tomosawa, F. (2004). Prediction model

of compressive strength development of fly-ash concrete. Cem.

Concr. Res., Vol. 34, No. 12, pp. 2269-2276.

Jansen, D., Neubauer, J., Goetz-Neunhoeffer, F., Haerzschel, R., and

Hergeth, W.-D. (2012). Change in reaction kinetics of a portland

cement caused by a superplasticizer Calculation of heat flow

curves from XRD data. Cem. Concr. Res., Vol. 42, No. 2, pp. 327

332.

Kaoser, A. R. (2006). Study on strength and durability of brick aggregate

concrete with fly ash, PhD Thesis, Bangladesh University of

Engineering and Technology, Dhaka.

Kim, J. K., Moon, Y. H., and Eo, S. H. (1998). Compressive strength

development of concrete with different curing time and temperature.

Cem.Concr. Res., Vol. 28, No. 12, pp. 1761-1773.

Klieger, P. (1958). Effect of mixing and curing temperatures on

concrete strength. ACI J. Proc., Vol. 54, No. 12, pp. 1063-1081.

Mahasneh, B. Z. and Shawabkeh, R. A. (2004). Compressive strength

and permeability of sand-cement-clay composite and application for

heavy metals stabilization. American J. of Applied Sci., Vol. 1, No.

4, pp. 01-04.

Ozturk, A. U. and Baradan, B. (2011). Effects of admixture type and

dosage on microstructural and mechanical properties of cement

mortars. KSCE J. Civ. Eng., Vol. 15, No. 7, pp. 1237-1243.

Price, W. H. (1951). Factors affecting concrrete strength. J. American

Concrete Institute, Vol. 47, pp. 417-432.

Razak, H. A. and Sajedi, F. (2011). The effect of heat treatment on the

compressive strength of cement-slag mortars. Materials & Design,

Vol. 32, Nos. 8-9, pp. 4618-4628.

Sata, V., Tangpagasit, J., Jaturapitakkul, C., and Chindaprasirt, P. (2012).

Effect of W/B ratios on pozzolanic reaction of biomass ashes in

Portland cement matrix. Cem. Concr. Comp., Vol. 34, No. 1, pp.

94-100.

Saul, A. G. A. (1951). Principles underlying the steam curing of

concrete at atmospheric pressure. Magazine of Conc. Res., Vol. 2,

No. 6, pp. 127-140.

Shafiq, N. (2011). Degree of hydration and compressive strength of

conditioned samples made of normal and blended cement system.

KSCE J. Civ. Eng., Vol. 15, No. 7, pp. 1253-1257.

Sharifi, Y. (2012). Structural performance of self-consolidating concrete

used in reinforced concrete beams. KSCE J. Civ. Eng., Vol. 16, No.

4, pp. 618-626.

Teo, D. C. L., Mannan, M. A., and Kurian, V. J. (2010). Durability of

lightweight concrete OPS concrete under different curing conditions.

Materials and Structures, Vol. 43, pp. 1-13.

Wongkeo, W., Thongsanitgarn, P., and Chaipanich, A. (2012). Compressive

strength and drying shrinkage of fly ash-bottom ash-silica fume

multi-blended cement mortars. Materials & Design, Vol. 36, pp.

655-662.

Woo, S. K., Song, Y. C., and Won, J.-P. (2011). Enhanced durability

performance of face slab concrete in Concrete-Faced Rock-filled

Dam using fly ash and PVA fibre. KSCE J. Civ. Eng., Vol. 15, No.

5, pp. 875-882.

Zhao, H., Sun, W., Wu, X., and Gao, B. (2012). Effect of initial watercuring period and curing condition on the properties of selfcompacting concrete. Materials & Design, Vol. 35, pp. 194-200.

Zhutovsky, S. and Kovler, K. (2012). Effect of internal curing on

durability-related properties of high performance concrete. Cem.

Concr. Res., Vol. 42, No. 1, pp. 20-26.

796

KSCE Journal of Civil Engineering

S-ar putea să vă placă și

- Institutional Summary: 1. The InstitutionDocument1 paginăInstitutional Summary: 1. The InstitutionAlhaz UddinÎncă nu există evaluări

- Plan 07.dwg-Model - PDF 01Document1 paginăPlan 07.dwg-Model - PDF 01Alhaz UddinÎncă nu există evaluări

- Assignments 2 1st 2019 20Document3 paginiAssignments 2 1st 2019 20Alhaz UddinÎncă nu există evaluări

- Design of Beam ShearDocument34 paginiDesign of Beam ShearAlhaz UddinÎncă nu există evaluări

- Sumon Vi Savar Floor Plan-Model - pdf-1 (15!08!2017)Document1 paginăSumon Vi Savar Floor Plan-Model - pdf-1 (15!08!2017)Alhaz UddinÎncă nu există evaluări

- Seismic Analysis To UBC 97 Sample 2 PDFDocument12 paginiSeismic Analysis To UBC 97 Sample 2 PDFAlhaz UddinÎncă nu există evaluări

- Final Sedimentation TankDocument12 paginiFinal Sedimentation TankAlhaz UddinÎncă nu există evaluări

- A044 2019 20 Readiness Review Template For EAC 3-12-2018 FinalDocument25 paginiA044 2019 20 Readiness Review Template For EAC 3-12-2018 FinalAlhaz UddinÎncă nu există evaluări

- PTE Describe ImageDocument13 paginiPTE Describe ImageAlhaz UddinÎncă nu există evaluări

- MDT Geotech Manual Covers Roadway Slope and Embankment DesignDocument40 paginiMDT Geotech Manual Covers Roadway Slope and Embankment DesignAlhaz UddinÎncă nu există evaluări

- Pile Load TestDocument10 paginiPile Load TestAlhaz Uddin100% (1)

- Abstract - ICCS18Document2 paginiAbstract - ICCS18Alhaz UddinÎncă nu există evaluări

- Main structure list for wastewater treatment plantDocument3 paginiMain structure list for wastewater treatment plantAlhaz Uddin100% (1)

- Asce 7-10Document20 paginiAsce 7-10Julio OrozcoÎncă nu există evaluări

- WorkDocument4 paginiWorkAlhaz UddinÎncă nu există evaluări

- MDT Geotech Manual Covers Roadway Slope and Embankment DesignDocument40 paginiMDT Geotech Manual Covers Roadway Slope and Embankment DesignAlhaz UddinÎncă nu există evaluări

- Structural mechanics course detailsDocument54 paginiStructural mechanics course detailsAlhaz UddinÎncă nu există evaluări

- MECHCOMP2014: An Improved Modelling of Steel-Concrete Composite Beams Based On A Higher Order TheoryDocument18 paginiMECHCOMP2014: An Improved Modelling of Steel-Concrete Composite Beams Based On A Higher Order TheoryAlhaz UddinÎncă nu există evaluări

- MECHCOMP2014: An Improved Modelling of Steel-Concrete Composite Beams Based On A Higher Order TheoryDocument18 paginiMECHCOMP2014: An Improved Modelling of Steel-Concrete Composite Beams Based On A Higher Order TheoryAlhaz UddinÎncă nu există evaluări

- Structural Mechanics Tutoring Sheet No.1 Dates: 6.3.2014,7.3.2014Document1 paginăStructural Mechanics Tutoring Sheet No.1 Dates: 6.3.2014,7.3.2014Alhaz UddinÎncă nu există evaluări

- G. FloorDocument1 paginăG. FloorAlhaz UddinÎncă nu există evaluări

- MECHCOMP2014: An Improved Modelling of Steel-Concrete Composite Beams Based On A Higher Order TheoryDocument18 paginiMECHCOMP2014: An Improved Modelling of Steel-Concrete Composite Beams Based On A Higher Order TheoryAlhaz UddinÎncă nu există evaluări

- Thermal Stresses in A Multilayered Anisotropic MediumDocument7 paginiThermal Stresses in A Multilayered Anisotropic MediumAlhaz UddinÎncă nu există evaluări

- Steel Concrete Composite Beam Using A Higher Order Beam TheoryDocument4 paginiSteel Concrete Composite Beam Using A Higher Order Beam TheoryAlhaz UddinÎncă nu există evaluări

- Please Make Ensure Burner Totally Off: Your Uses Plate & Mug Keep Inside The DishwasherDocument4 paginiPlease Make Ensure Burner Totally Off: Your Uses Plate & Mug Keep Inside The DishwasherAlhaz UddinÎncă nu există evaluări

- Week Meeting Report of HabibuRahman - 20!03!13Document1 paginăWeek Meeting Report of HabibuRahman - 20!03!13Alhaz UddinÎncă nu există evaluări

- Annotation AlhazDocument1 paginăAnnotation AlhazAlhaz UddinÎncă nu există evaluări

- Mathieuinstability of A Spar Platform With Mooring and RisersDocument34 paginiMathieuinstability of A Spar Platform With Mooring and RisersAlhaz UddinÎncă nu există evaluări

- Steel Concrete Composite Beam Using A Higher Order Beam TheoryDocument4 paginiSteel Concrete Composite Beam Using A Higher Order Beam TheoryAlhaz UddinÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Cement ManufacturingDocument30 paginiCement ManufacturingHARISH RANIWAL100% (7)

- PRE - Model Exit Exam - Civil Engineering DepartmentDocument31 paginiPRE - Model Exit Exam - Civil Engineering DepartmentTadesse MegersaÎncă nu există evaluări

- Applications of Chemistry in EngineeringDocument14 paginiApplications of Chemistry in EngineeringDr. M. Rukmangathan, Dean AcademicsÎncă nu există evaluări

- BS EN196-21pdf PDFDocument26 paginiBS EN196-21pdf PDFahsan abbasÎncă nu există evaluări

- SCM 310 Logistic and Transportation Section:2 Prepared For: Meshbaul Hasan ChowdhuryDocument24 paginiSCM 310 Logistic and Transportation Section:2 Prepared For: Meshbaul Hasan ChowdhuryShamima AkterÎncă nu există evaluări

- DSR ProjectDocument17 paginiDSR ProjectPankaj Zudpe87% (15)

- DAY1 - DA - 10 Rules For Clinker QualitiesDocument30 paginiDAY1 - DA - 10 Rules For Clinker Qualitiestricky77792% (12)

- BOQ TemplateDocument5 paginiBOQ Templatenitish JhaÎncă nu există evaluări

- Gashaw Final T BiTDocument126 paginiGashaw Final T BiTSadam GudetoÎncă nu există evaluări

- Fosroc Conplast WP400: Constructive SolutionsDocument2 paginiFosroc Conplast WP400: Constructive SolutionsVincent JavateÎncă nu există evaluări

- Quality For Road and Engineer Hand BookDocument255 paginiQuality For Road and Engineer Hand BookvenkyÎncă nu există evaluări

- Culverts, Trafficsigns, FoundationDocument308 paginiCulverts, Trafficsigns, FoundationsrinivasparasaÎncă nu există evaluări

- 1627-Article Text-4517-4-10-20220703Document10 pagini1627-Article Text-4517-4-10-20220703bakhtiar Al-BarzinjiÎncă nu există evaluări

- Conmix SP1: High Range Water Reducing SuperplasticiserDocument2 paginiConmix SP1: High Range Water Reducing SuperplasticiserEsmaelDawudÎncă nu există evaluări

- Pengaruh Komposisi Gypsum Terhadap Setting Time Pada Proses Produksi Semen PCCDocument7 paginiPengaruh Komposisi Gypsum Terhadap Setting Time Pada Proses Produksi Semen PCCNabil FahmiÎncă nu există evaluări

- CementProject PlanDocument54 paginiCementProject PlanDilnesa EjiguÎncă nu există evaluări

- Millennium Product DataDocument15 paginiMillennium Product DataAnonymous ZizCrNlQkpÎncă nu există evaluări

- QC10-H-043 M03 Cement Mortar Lining-Rev2Document25 paginiQC10-H-043 M03 Cement Mortar Lining-Rev2GousePeerzadeÎncă nu există evaluări

- Procurement Tracking ChartDocument5 paginiProcurement Tracking ChartjayÎncă nu există evaluări

- Section 321313 - Concrete Paving: Part 1 - GeneralDocument13 paginiSection 321313 - Concrete Paving: Part 1 - Generalery achjariÎncă nu există evaluări

- BRE Digest 330 pt3 Alkali-Silica Reaction in ConcreteDocument8 paginiBRE Digest 330 pt3 Alkali-Silica Reaction in ConcretehemendraengÎncă nu există evaluări

- TDS - Conbextra VG 1Document3 paginiTDS - Conbextra VG 1Albert NajjarÎncă nu există evaluări

- Mix Design of Concrete (ACI 211) : Plain & Reinforced Concrete Ii (Lab)Document17 paginiMix Design of Concrete (ACI 211) : Plain & Reinforced Concrete Ii (Lab)Eman ArshadÎncă nu există evaluări

- Road Bed ConstructionDocument34 paginiRoad Bed ConstructionJek Yuson Junio100% (1)

- Best Practices in Energy Efficiency in Cement SectorDocument32 paginiBest Practices in Energy Efficiency in Cement SectorChandra SekarÎncă nu există evaluări

- KUWS&DBoard SR 2018-19Document63 paginiKUWS&DBoard SR 2018-19Radhakrishna KPÎncă nu există evaluări

- New QC MPR Format, Oct.22,09.11.2022Document14 paginiNew QC MPR Format, Oct.22,09.11.2022Devendra SinghÎncă nu există evaluări

- Financial Project Report ON Ultratech Cement India LTDDocument11 paginiFinancial Project Report ON Ultratech Cement India LTDDinesh AilaniÎncă nu există evaluări

- Portland Cement Recap AggregatesDocument127 paginiPortland Cement Recap AggregatesshayndellÎncă nu există evaluări

- The influence of mineral filler on aggregate-bitumen adhesionDocument6 paginiThe influence of mineral filler on aggregate-bitumen adhesionCatalinaLixandruÎncă nu există evaluări