Documente Academic

Documente Profesional

Documente Cultură

Specification Writing

Încărcat de

Tharaka KodippilyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Specification Writing

Încărcat de

Tharaka KodippilyDrepturi de autor:

Formate disponibile

BE 3103

Specification Writing

Course Work

Specifications for Partitioning and Air Conditioning/

Ventilation System

Student Name(s)

Reg. No.

Asmone A.S.

Kodippily T.T.

092404N

092647K

Saranga N.B.

Satharasinghe N.R.P.

Senarathna W.D.D.A.

Wijekoon K.A.D.N.C.

092457D

082460V

092687G

092451E

Lecturers Name

: Prof. Archt. Lalith De Silva

: Miss. Harshini Mallawarachchi

Date of Assignment : 16th May 2012

Date of Submissions : 11th June 2012

Department of Building Economics

University of Moratuwa

Course Work Brief and Feedback Form

Degree programme title

Module number and title

Lecturer(s) name(s)

Honours Degree of Bachelor of Science in Quantity Surveying and

Honours Degree of Bachelor of Science in Facilities Management

BE 3103 Specification Writing

Prof. Arch. Lalith De Silva

Ms. Harshini Mallawarachchi

Moderator(s) name(s)

Specifications for Partitioning and Air Conditioning/

Course work title

Set date

Ventilation System

.

Moderated date

Date of assignment

16th May 2012

Dates of submissions

11th June 2012

Student declaration

I / We confirm that the works submitted for this assignment are my /our own work

Students names / Signatures

Asmone A.S.

Satharasinghe N.R.P.

Kodippily T.T.

Senarathna W.D.D.A.

Saranga N.B.

Wijekoon K.A.D..N.C.

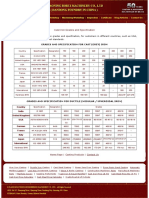

Report Evaluation

Maximum marks

Student(s) names(s) / Reg. No.

Asmone A.S.

Saranga N.B.

Satharasinghe N.R.P.

Senarathna W.D.D.A.

Wijekoon K.A.D.N.C.

10

with provisions of appropriateNew design of work place

Kodippily T.T.

structure of reportPreparation/ organization and

15

types of partitioning and A/C Identifications of different

20

formats and clausesIdentification of specification

10

35

Conclusion

specification for each itemCorrect writing of

Group Basis

Total

Stamp for date receipt of the assignment

Assessment Criteria

Report Feedback Sheet

10

100

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

Table of Conten

1. Introduction.....................................................................................................................................................3

2. New Design of the Work Place........................................................................................................................4

3. Selection of a Specification Writing Method and Language...........................................................................5

4. Selection of a Partitioning System for Floor Locations..................................................................................6

4.1 Board Room..............................................................................................................................................7

4.2 Specification Board Room Partitioning.................................................................................................8

4.3 Cubicle of Staff/ Research Room/ Computer Room.................................................................................9

4.4 Specification Cubicles of Staff/ Research Room/ Computer Room....................................................10

4.5 Documentation Room..............................................................................................................................11

4.6 Specification Documentation Room....................................................................................................12

5. Selection of a Air Conditioning System and Accessories.............................................................................13

5.1 General Notes..........................................................................................................................................13

6. Specification - Installation of Air Conditioning Units and Accessories........................................................15

6.1General Specification...............................................................................................................................15

6.2 Compressor Specification........................................................................................................................15

6.3 Air Condition Unit Enclosure..................................................................................................................16

6.4 Room Conditions.....................................................................................................................................17

6.5 Installation, Testing and Commissioning................................................................................................17

6.6 Maintenance Period.................................................................................................................................18

6.7 Technical Literature.................................................................................................................................18

6.7 Special Specifications..............................................................................................................................19

7. Conclusion.....................................................................................................................................................20

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

References.........................................................................................................................................................21

Annexure...........................................................................................................................................................22

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

Introduction

Specification can be defined as a detailed, exact statement of particulars, specially a statement prescribing

materials, dimensions, and quality of work for something to be built, installed, or manufactured. In the eye of

a professional in the construction industry or built environments, specifications are found as an integral

element of project information.

Common Arrangement of Work Sections (CAWS) is a working convention designed to promote

standardization of, and detailed coordination between, bills of quantities and specifications. It is part of the

industry wide coordinated projects information (CPI) initiative and has been used for the arrangement of the

national Building Specification. With the coordination given by CAWS between drawings, specifications and

bills of quantities and flexibility to the contractor in dividing the project information into work packages. But

here in this report we have used the traditional method of specification writing instead of CAWS method

because Sri Lankan construction industry is not used to use it. And usage of CAWS will make the bidders

ambiguous about the specification.

Given above is the basic introduction to specifications and the scope of specification related in this study. The

understanding of writing and understanding specification is quite important to quantity surveyors as well as

facilities managers who will have to deal with specifications of all sorts and means, day-in and day-out.

Therefore the coursework for this module BE 3103 Specification Writing, Specifications for partitioning and

air conditioning systems has proven to be of utmost interest and significant to the undergraduates.

In this course work report where a scenario is given for them to redesign the space plan of the department of

Building Economics and to prepare a proper air circulation and conditioning system, the specifications for all

these proposals are given in detailed manner following international standards and methods.

The report unveils with the first chapter where we identify an appropriate method of specification writing for

the selected systems, then we have selected suitable partitioning systems for office spaces with different

functional requirements. Afterwards we have selected a suitable air conditioning system and developed a

specification.

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

2. New Design of the Work Place

The existing premise of the Department of Building Economics is located at the 3 rd floor of sumanadasa

building. Interior of it is bit congested because they have to accommodate several functions within a limited

floor area. Workplace environment quality makes a big impact on employee productivity and efficiency and

the Department of Building Economics is not exempt. We have understood certain negative aspects of the

existing layout and partitioning system/ air conditioning system and suggested alterations as mentioned

below. For existing layout of premises, proposed partitioned layout and air conditioning system layout please

refer annex 1, 2 and 3.

Drawbacks of Existing System

Proposed Suggestions

Partitioning System and Layout

Partition layout does not allow space for future

Install demountable partitioning system at eastern

expansion

side of the premises rather than around the perimeter.

Tenants can merge with existing class room and

The strength of existing system is not sufficient

Existing layout limits visual privacy because the

make space for future expansion.

Use 75mm powder coated aluminum frame partition

Place the cubicles at the rear and make separate

cubicles are arranged around the passage

The partitioning at the documentation area is not fire

access to them

Use 120 minutes fire rated partitioning system

rated, this is a critical drawback

Space for data cabling, electricity wire cabling is

Use a partitioning system that have insulation of at

insufficient

least 40mm wide

Air Conditioning System and Layout

Current layout does not allow proper air flow to

Arrange the cubicles in stacked form to allow

some cubicles

moderate flow of air

3. Selection of a Specification Writing Method and Language

When selecting an appropriate method of specification writing, we have considered that partitioning system

requires a specification that identifies both performance as well as aesthetical appearance. Because of that we

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

have selected a combination of descriptive-performance specification writing method. When scrutinizing on

the specification writing methods practiced in the Sri Lankan industry we have understood that it is more

meaningful and bidders will get a good idea on what the design intents.

While we have recognized that the specification of air conditioning system should be based on performance

of the selected service. That allows the bidder to use suitable air conditioning system to cater the need and

detach the client or consultant from the responsibility of selecting a system. Hence when writing

specification for air conditioning system we have used performance specification method after carrying out a

technical analysis.

To be effective, writing needs to be clear and unambiguous, it should be technically correct and correct

grammatically. Moreover it shall be concise so the bidders get the information they need with least amount of

effort. We have avoided using dead words and broad statements when writing the specification, and have

written the attribute of the specification first followed by a colon and then the details. Examples are

mentioned below;

i. Attribute: Details of specification

ii. Fire resistance: To BS 476, 30 minutes

iii. Cavity filling: 45mm thick mineral fibre wool to density of 60kgm-3

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

4. Selection of a Partitioning System for Floor Locations

A partition wall can be considered as a wall or division made up of bricks, studs, timber, plasterboard, glass

or other such material and provided for the purpose of dividing one space from another. Generally partition

walls are designed as non-load bearing walls and may come from folding, collapsible or fixed types.

Selection of a partition system depends on several factors such as

Required level of acoustics

Required level of fire resistance

Required level of thermal insulation

Structural criteria (dead load, imposed loads)

Services, fixtures to be installed

Budget available

Nature of the environment and occupants

Material, technology and craftsmen availability

The department of building economic premises is the space that is needed to be partitioned, the spaces of the

department accommodate several functions. Based on those functional requirements, the type of partition can

be varied. We have identified the spaces and categorized them as follows,

i.

ii.

iii.

iv.

v.

vi.

Board room

Cubicles of academic/ non academic staff

Toilet

Kitchen/ lunch room

Documentation room/ research room

Computer room

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

4.1 Board Room

Requirement Considered

Details

Acoustics

Acoustical control is critical in virtually every office space but it is of

paramount importance when it comes to partitioning a board room. The

partition at a board room shall absorb internal sounds so that it will not reflect

and cause resonance, secondly it should keep sound from outside coming in and

sound of inside not reflecting to out. Hence we have determined that the

selected partition shall have following characteristics

Fire resistance

Noise Reduction Coefficient (NRC) > = 0.70

Sound Transmission Class (STC) > = 0.45 as per BS 2750-3:1995

The selected space is not subjected to a higher level of fire hazard. Hence we

assumed that there is no requirement of using a partition with superior fire

resistant characteristics.

Thermal insulation

Fire resistance shall be 30 minutes

The board room is air conditioned with a separate split type air conditioner. The

important factor we have to consider is that one adjacent side of the room is the

proposed kitchen area. But since that side is covered by existing block wall,

Structural characteristics

there is no need of consideration on that matter.

The structural characteristics considered are the horizontal imposed loads

(crowd pressure) and vertically imposed loads. Since there are no imposed

Services to be installed

horizontal loads, we have reflected on horizontally imposed forces only.

There may be a requirement to install service lines such as audio system and

electricity lines. But because there are existing block wall partitions on 3 sides

of the space, we assumed necessary service line will be fixed on them. We have

Selected partitioning

suggested a dry wall lining to the existing block walls.

We have suggested a dry wall lining to the existing block walls.

system

4.2 Specification Board Room Partitioning

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

Performance Criteria

Fire resistance: To BS 476, 30 minutes

Noise reduction coefficient: Equal or exceed 0.70

Sound Transmission Class (STC): Equal or exceeding 0.45 as per BS 2750-3-1995

Strength: Shall be capable of withstanding a nominal horizontal concentrated force of 700N acting

nominal to the wall surface over an area of 0.1 m x 0.1 m at any point

Cavity insulation: With mineral fiber confirm to BS 2750 part 3 of 1995

Materials

Studs: Single frame of 50mm CStuds at 700mm centers and 50mm UChannel for the head/base track

Lining: 15mm thick acoustic panel

Cavity filling: 45mm thick mineral fibre wool to density of 60kgm-3

Finishing: 20mm width, 2mm thick aluminum beading

Glazing: With 4mm thick toughened clear glass

Fixing and installation

Studs: Fixed to inner side of existing wall with 50mm stainless steel screws, CStuds at 700mm centers

and UChannel for the head/base track at 1000mm centers

Cavity filling: Install 45mm thick mineral fibre cavity filling, cut neatly between studs to ensure no gaps

or excessive filling

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

4.3 Cubicle of Staff/ Research Room/ Computer Room

Requirement Considered

Details

Acoustics

Acoustical control is not the major factor when it comes to partitioning the

cubicles.

Fire resistance

Sound Transmission Class (STC) > = 0.25 as per BS 2750-3:1995

The selected space is not subjected to a higher level of fire hazard. Hence we

assumed that there is no requirement of using a partition with superior fire

resistant characteristics.

Thermal insulation

Fire resistance shall be 30 minutes

The cubicles of staff are air conditioned. Since there arent dedicated air

conditioners or air supply ducts, it is important to install cubicles in such a way

that air flow will be maintained at an acceptable level. To allow moderate air

flow within cubicles, it is assumed that fully covered partitioning is not

Structural characteristics

supportive.

The structural characteristic considered was the dead load of the partitioning

system. Since there is a large area to be partitioned the weight of the cubicles

Services to be installed

might be considerable.

There may be a requirement to install service lines such as internet cables and

Selected partitioning

electricity lines.

We have concluded that an aluminum framed composite partitioning system

system

with plasterboard lining is appropriate for cubicles.

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

4.4 Specification Cubicles of Staff/ Research Room/ Computer Room

Performance Criteria

Fire resistance: To BS 476, 60 minutes

Sound Transmission Class (STC): Equal or exceeding 0.25 as per BS 2750-3-1995

Strength: Shall be capable of withstanding a nominal horizontal concentrated force of 500N acting

nominal to the wall surface over an area of 0.1 m x 0.1 m at any point

Cavity insulation: With extruded polystyrene foam confirm to BS 2750 part 3 of 1995

Materials

Frame: Single frame of 75mm powder coated aluminum at 700mm centers and 100mm powder coated

head and base rails

Covering: 10mm thick plasterboards on both sides fitted with 25mm screw bolts

Cavity filling: 55mm thick mineral fibre wool to density of 60kgm-3

Finishing: 20mm width, 2mm thick aluminum beading

Fixing and installation

Studs: Base rail fixed to floor with 50mm stainless steel screws, vertical braces at 700mm centers fixed to

base rail and head rail

Cavity filling: Install 55mm thick mineral fibre cavity filling, cut neatly between studs to ensure no gaps

or excessive filling.

Covering shall be upto 1.20m height on both sides

Glazing from 1.20 level to ceiling level with single 4mm thick clear glass

Contractor shall calibrate with electrical contractor in providing space for cables inside the cavity

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

4.5 Documentation Room

Requirement Considered

Details

Acoustics

Acoustical control is not the major factor when it comes to partitioning the

documentation room since it is not used by occupants that often, hence it is

Fire resistance

acceptable to use partitioning with lower STC value

The selected space is not subjected to a higher level of fire hazard. But the

protection of the documents is of utmost importance. Hence we assumed that

there is a considerable requirement of using a partition with superior fire

resistant characteristics.

Fire resistance shall be 120 minutes

Thermal insulation

As previously stated this area is not used by occupants commonly, hence

Structural characteristics

thermal insulation is not considered.

This area is subjected to loading and unloading of documents in bulk. Due to

that reason the partition system shall have sufficient strength to bear heavy

Services to be installed

forces.

Requirement of service cabling or lighting on partitions is minimal. It is not

Selected partitioning

considered when selecting a partitioning system.

We have concluded that a steel framed and steel covered partition system is

system

appropriate for documentation area.

Department of Building Economics

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

4.6 Specification Documentation Room

Performance Criteria

Fire resistance: To BS 476, 120 minutes

Strength: Shall be capable of withstanding a nominal horizontal concentrated force of 1000N acting

nominal to the wall surface over an area of 0.1 m x 0.1 m at any point

Materials

Frame: Double frame of 100mm powder coated aluminum at 700mm centers and 100mm powder coated

head and base rails

Covering: 10mm thick plasterboards on both sides fitted with 25mm screw bolts

Cavity filling: 90mm thick mineral fibre wool to density of 60kgm-3

Finishing: 20mm width, 2mm thick aluminum beading

Fixing and installation

Studs: Base rail fixed to floor with 50mm stainless steel screws, vertical braces at 700mm centers fixed to

base rail and head rail

Cavity filling: Install 90mm thick mineral fibre cavity filling, cut neatly between studs to ensure no gaps

or excessive filling.

Covering shall be upto ceiling height on both sides

Contractor shall calibrate with electrical contractor in providing space for cables inside the cavity

Department of Building Economics

10

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

5. Selection of a Air Conditioning System and Accessories

5.1 General Notes

Nature of Bid

The Contractor shall carefully study the drawings mentioned under scope of work and fill in the price in the

attached bill of quantities. It is to be distinctly understood that the total quantity Bided for is to be complete

and comprehensive of all minor deficiencies if any, in the brief description. No variation or extras will be

allowed except in respect of alterations, which are specially authorized in writing. No alterations shall be

made without the written permission of the Engineer.

Surplus Stock

No compensation shall be paid by the Board on completion of the work for any surplus stock of pipes,

specials, fittings etc. and materials obtained for the purpose of this Contract. However, on completion of the

Contract, the Engineer may retain any surplus stock, which would be useful for the maintenance of the above

Air Conditioning Unit and pay at prices agreed upon at that time by the Engineer and the Contractor.

Power Supply

The necessary 230 V, single phase and neutral 50Hz electric power will be made available at the power

distribution panel of the floor. The power required for the distribution panel for air conditioning units shall be

from the aforementioned electrical power distribution point and all cabling and accessories shall be provided

and fixed by the Contractor. All electrical equipment and wiring shall conform to the standards set by the

I.E.E., (UK) as well as Sri Lanka regulations and be acceptable to the Ceylon Electricity Board, Sri Lanka.

Calibration of Instrument & Meters

All instruments and meters shall be calibrated in the Metric Units as follows;

(a)

Pressure shall be indicated in kg/ cm

(b) Temperature in C

(c) Voltage in V

(d) Time shall be indicated in Hours

Department of Building Economics

11

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

(e) Amperage shall be indicated in Amperes

(f) Relative humidity in RH % with dry bulb temperature

Literature On Equipment And Materials

The Bidder shall supply detailed literature and specifications from the manufacturers in respect of all

equipment and materials included in his offer and give the names of all such manufacturers and the countries

of origin of the materials and equipment.

Installation, Testing And Commissioning

Refer the specific specifications for split type Air conditioning units and Accessories.

Calculation of Operational Cost

In the evaluation of bidders of the capacity more than 18,000 Btu / hr Air Conditioning units with the

capacity present worth of operational cost will be considered and followings will be used in calculation of

operational cost.

a) Overall efficiency of the Air conditioning unit / COP

b) Economic life of equipment - 07 years

c) Annual operational hours of each unit (As per the specific specifications for Air Conditioning units

and Accessories)

d) Cost of Electrical Energy Rs. 19.40 per kWh

e) Discounting Rate - 12%

Warranty Period

The supplier should provide a warranty period of minimum 05 years for trouble free operation of the

Compressor and one year trouble free warranty for all equipment and accessories supplied under this

contract. During first year of warranty period all the works describe under the maintenance period have to be

attended. This should include at least six free services within warranty period. The contractor should provide

required materials, labour and spare parts during the warranty period without any charged to the Department

of Building Economics. The warranty period commences from the completion date as per the completion

Department of Building Economics

12

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

certificate. The contractor has to assure that he is equipped with sufficient resources to attend any

maintenance or major breakdowns immediately after informed by Department of Building Economics.

Department of Building Economics

13

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

6. Specification - Installation of Air Conditioning Units and Accessories

6.1General Specification

The Air Conditioning Units shall be of the split type suitable for indoor installation unit with wall brackets

which are necessary in the upper floors of the building, power connection, condensate water drain piping

using suitable PVC piping to the nearest common drain line. The product shall be ASHREA Energy

efficiency Class A with COP not less than 4.4.

The outdoor unit shall be housed in a Galvanized steel fabricated box with acoustic, heat insulation and

vibration protected painted with corrosion resistive paints suitable for Tropical climate. The indoor unit shall

be architecturally designed and made in elegant appearance with sound and noise protections, piping and

auto, remote controls. This installation shall facilitate in such a way to permit the removal of the units when

the repairs to be carried out.

a. The unit shall be with fully hermitic compressor,

b. Operate on a Refrigerant free of halocarbons.

c. Condenser with inbuilt fan.

d. Evaporator with Squirrel Cage Fan,

e. Air throws control facility with facility for control for efficient operation.

f. Remote Control device.

Original performance curves of the Air Conditioning units certified by the manufacturer should be provided

and photocopies will be accepted which are duly certified by the local agent. A dimensioned drawing of the

Air Conditioning Units complete with materials of manufacture shall be provided with the Bid. The brand of

the Compressor shall be provided with performance efficiency, power supply and capacity details.

6.2 Compressor Specification

The Compressor shall be energy efficient fully hermitically sealed type rotary / reciprocating, 230 V + / - 10

%, 01 Phase, 50Hz. Operating on Refrigerant R134A.

Department of Building Economics

14

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

The compressor Motor shall be suitably protected against overloading using a removable suitably sized over

load protection. These shall be mounted on resilient mountings for quite operation. It shall be with low

vibration and noise less than 60dB(A) at 3 m distance.

6.3 Air Condition Unit Enclosure

General

The control panels shall be completely designed, fabricated, assembled, wired, checked and tested at the

factory as per standards and per descriptions given below. Modern architectural design arrangement and

finish suitable for luxury living environment shall be elegant and workmanship shall be of a high order with

flushed and concealed type front cover. The unit shall be wall mounted and locked on to the steel enclosure

made out of Galvanized steel with protective paints suitable for tropical climate. Earthing of the enclosure

shall be ensured. The units and all electrical components should be suitable for the operation on 230 volts +

10% 01 phase 02 wire, 50Hz, AC power Supply.

Construction

The panels shall be of sheet metal, wall mounted as per the specification. The design shall be totally

enclosed, dust and rain splash-proof as per IP 55 of IEC publication 34-5. The housing of the panel shall be

fabricated of 14 SWG. The outer and inner surface of the panels shall be primed and painted with corrosive

resist PVC, Epoxy or plastic, marine grade special coating, colour as specified. Access to all equipment

mounted inside shall be from the front. Switch gears and earth, main connections and auxiliary wiring shall

be arranged and marked in general compliance with relevant British standards.

Earthing

A suitable earth terminal should be provided to facilitate the connection of the main earth. Earthing

arrangement should be complies with BS 7430 and earth resistance of the main earth should not be exceed 5

.

Wiring

Control wiring shall be concealed by taking through neatly arranged PVC Spiral wire protectors and all

control wires shall be terminated with cable lugs or compression type terminals. All Current carrying bolts

and nuts shall be of high conducting material.

Department of Building Economics

15

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

Control Panel Equipment, Remote Controls and Protections

The equipment to be mounted on the control panel / Remote controller of Air Conditioning Unit shall consist

of the following and starting method as per the specification.

Direct on-line (DOL) starting of the Compressor

a. Over Load protection for the all Motor.

b. Thermostatic expansion and flow control of the refrigerant

c. Room temperature sensor

d. Fan speed control, three minimum speeds.

e. Compressor loading control, high / low and economical

f. Remote controller with LCD display shall be provided with one on / off timer, selecting fan

speed (three speeds) and setup of temperature.

6.4 Room Conditions

Please refer the room layout and the locations suggested for the installation of the Air Conditioning units.

Room without Air conditioning Temperature shall be limited to 40 C with Relative humidity at 90%.

6.5 Installation, Testing and Commissioning

All installation work shall be carried out in accordance with relevant International Standards and CIBSE code

of practice. When all installation work is satisfactorily completed, the contractor shall inform the Engineer in

writing that equipment are ready for handing over and the Engineer shall then fix a date for taking over. At

the taking over all equipment shall be tested for a period as per the application to determine the following.

a. Power consumption

Department of Building Economics

16

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

b. Room Temperature and Relative Humidity at full load as given

c. Vibration and Noise

If the Engineer is not satisfied with the performance of the equipment or other installation, he may refuse to

take over the equipment until necessary improvements are effected. Any time necessary for this additional

work will be considered as contractors delay.

6.6 Maintenance Period

The Air Conditioning units and other equipment shall be satisfactorily maintained for a period of 24 months

from the date of taken over. During the maintenance period, the contractor should attend to;

a. All periodical service

b. Maintain a maintenance record

c. Attending to all the repairs and replacements to avoid any failure of the system with in a time period

not less than 03 working days from the date the contractor has been notified

d. In addition to the equipment which fails, the equipment that do not give satisfactory performance

during the period of maintenance shall be replaced by the contractor within 3 weeks from the date the

contractor has been notified

e. In order to cut down the downtime in the event of any major failure of unit the supplier should

provide the spare unit till such time the unit is replaced after repairs

The expenses involved in this connection shall be met by the contractor who should take this in to

consideration when biding. If the contractor is not attended to the repair within the time specified as above,

the engineer has the right to rectify the fault and claim the cost thus incurred from the contractor.

6.7 Technical Literature

The following technical literature for the Air conditioning units, Remote Controls, and accessories, shall be

forwarded along with offer.

Department of Building Economics

17

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

Technical Specification of the Air conditioning units (Features, dimensions, cross Sectional drawing of the

Air Conditioning Units showing materials, etc.).

Department of Building Economics

18

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

6.7 Special Specifications

The Air conditioning units shall be providing the following room conditions and requirement.

Number of Occupants

: 25

Number of Air changes per hour not less than 6 Nos.

Floor Area - 500m and room height 3m

2

Walls Brick / thickness

: 225mm

Type of Ceiling / Floor Slab

: Suspended Aluminum Grid Ceiling

Number of Windows

: 20 nr covering 50m2 area primarily facing north

Electrical Equipment inside the Room and the heat out put

Room Lighting

: With 60 nr of 65 Watt liner fluorescent lamps

Computers

: 25 nr

Printers

: 5 nr

Photo copiers

: 3 nr

Any other heat sources

: Oven, gas cooker, refrigerator and water heater

Note

Room after Air Conditioning shall be 23C with Relative Humidity 65%

Noise level at full load condition shall be less than 55dB (A)

Department of Building Economics

19

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

7. Conclusion

In construction sector, it is vital for suppliers, purchases, and users of materials, products, or services in-order

to understand and agree upon all requirements. A specification is a type of a standard, which is open

reference by a contract with providing the necessary details about the specific requirements. The importance

of giving crystal clear details on quality, standard, and workmanship arises when there is a discrepancy

between the specifications and the drawings, the actual intent made explicit in the contract between the

Owner and the Contractor is given the priority to the specifications.

Compared to the past practices specification has gained the attention of both contractor and client as a major

project information with the development of construction industry. The main feature of specifications which

is the capacity of driving the cost of construction has dragged the attention of all interested parties. What is

more, specifications build up a common language which any party who is in the field could understand. This

becomes more important with the current trend of absorbing specialized skills with sub contracting.

In general specification of any construction project can be divided into two major parts namely; structural

specifications and services specifications. Having two separate specifications with as build drawings are

much helpful for maintenance, renovations and re-designing of a facility. Moving further to redesigning

aspect specifications should be prepared to minimize additional cost while making maximum use of current

assets, materials and designs. Therefore, the effectiveness of specifications as a cost controller will always

depend on the propose design for the project.

Moreover, Common Arrangement of Work Sections (CWAS) is a framework introduced to make the

specification writing a less burden in project management. It is an accepted structure followed by many

professionals to make effective specifications for their construction project. CWAS can be used as reference

without writing in detail specifications for each individual project. Also, it will guide almost for all

constructions do a better specification document without neglecting any element to be described. But in Sri

Lankan sector it is rarely used, knowledge of the bidders on that is minimal, hence traditional specification

writing methods are continued to be used.

In a word, specification is a tool which explains the unexplained of the drawings and drives the economic

aspects of a construction project. Even it is prepared in the inception stage of the building life cycle, it is used

throughout its life span as a reference. Therefore, it is an important document comes under bidding document

Department of Building Economics

20

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

which can be influence by both QS and FM professionals at different stages in diverse manner of the building

life span.

References

Kalms, B., 1995. Guide to Specification Writing, Australian Government Publishing Service,

Canberra.

Willis, A., Willis, A.J., Willis, C.J., 1997. Specification Writing for Architects and Surveyors, John

Wiley and Sons, London.

American Society for Testing and Materials, 2012 [online] Available from

http://www.astm.org/Standards/C423.htm, [Accessed 28th May 2012].

International Organization for Standardization, 2012 [online] Available from

http://www.iso.org/iso/iso_catalogue/catalogue_ics/catalogue_ics_browse.htm?

ICS1=91&ICS2=120&ICS3=20, [Accessed 29th May 2012].

Department of Building Economics

21

BE 3103 - Specification Writing

Specifications for Partitioning and Air Conditioning/ Ventilation System

Annexure

Department of Building Economics

22

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Remedies For BreachDocument18 paginiRemedies For BreachTharaka Kodippily0% (1)

- Introduction To Linear Algebra 6th Edition and A CR - 05Document14 paginiIntroduction To Linear Algebra 6th Edition and A CR - 05maviarena44% (9)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- HRM 3703 Exam Prep ALL Chapters - CarolineDocument60 paginiHRM 3703 Exam Prep ALL Chapters - CarolineTessa Mkhomole100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Application of Public Private Partnership (PPP) in Hong KongDocument10 paginiApplication of Public Private Partnership (PPP) in Hong KongTharaka KodippilyÎncă nu există evaluări

- Back-UPS RS 550 Installation & Operation: Inventory SafetyDocument7 paginiBack-UPS RS 550 Installation & Operation: Inventory SafetyAndrej VukalovicÎncă nu există evaluări

- FIDIC & ICTAD Formula DifferencesDocument5 paginiFIDIC & ICTAD Formula DifferencesTharaka Kodippily67% (3)

- Time and Money Claim Provisions FIDICDocument9 paginiTime and Money Claim Provisions FIDICTharaka Kodippily100% (7)

- Quantity Surveying BookDocument79 paginiQuantity Surveying BookHarold Jackson Mtyana100% (3)

- Odyssey RB3 Radio WiringDocument38 paginiOdyssey RB3 Radio WiringLevisrabak Rabak100% (1)

- Heat Exchangers Hydrostatic Test ProcedureDocument1 paginăHeat Exchangers Hydrostatic Test Procedureqaisarabbas900288% (17)

- Procurement Routes and Contracts - Construction Information For Contracts - Isurv PDFDocument1 paginăProcurement Routes and Contracts - Construction Information For Contracts - Isurv PDFTharaka KodippilyÎncă nu există evaluări

- Grade 10 Math Q2 FULL Week 1 - WatermarkDocument28 paginiGrade 10 Math Q2 FULL Week 1 - WatermarkSophia Junelle100% (1)

- Cast Iron Grades and SpecificationDocument1 paginăCast Iron Grades and SpecificationRajagopal100% (1)

- Rics Guidance Note The Role of The Commercial Manager in Infrastructure 1st Edition 2017Document25 paginiRics Guidance Note The Role of The Commercial Manager in Infrastructure 1st Edition 2017Tharaka Kodippily100% (1)

- On A/C All: Reference Qty DesignationDocument21 paginiOn A/C All: Reference Qty DesignationRalph FernandesÎncă nu există evaluări

- GreenBiz Baseline Survey 2023Document6 paginiGreenBiz Baseline Survey 2023Maina KanyottuÎncă nu există evaluări

- 2004 How To Properly Demonstrate Delays in A P3 Schedule To Support A Delay ClaimDocument42 pagini2004 How To Properly Demonstrate Delays in A P3 Schedule To Support A Delay ClaimbappanaduÎncă nu există evaluări

- 31-40 Contract Selection Vol 4Document10 pagini31-40 Contract Selection Vol 4Tharaka KodippilyÎncă nu există evaluări

- 3 Two Stage Tendering GuidanceDocument4 pagini3 Two Stage Tendering Guidancelinkdanu100% (1)

- Study Guide: CBCN4103 Introduction To NetworkingDocument271 paginiStudy Guide: CBCN4103 Introduction To NetworkingHuy HAÎncă nu există evaluări

- Risk & Value ManagementDocument31 paginiRisk & Value ManagementTharaka KodippilyÎncă nu există evaluări

- 41-61 Contract Selection Vol 5Document21 pagini41-61 Contract Selection Vol 5Tharaka KodippilyÎncă nu există evaluări

- 11-20 Contract Selection Vol 2Document10 pagini11-20 Contract Selection Vol 2Tharaka KodippilyÎncă nu există evaluări

- 21-30 Contract Selection Vol 3Document10 pagini21-30 Contract Selection Vol 3Tharaka KodippilyÎncă nu există evaluări

- 1-10 Contract Selection Vol 1Document10 pagini1-10 Contract Selection Vol 1Tharaka KodippilyÎncă nu există evaluări

- Construction Supply Chain Payment Charter Factsheet: 1. Is It Mandatory?Document3 paginiConstruction Supply Chain Payment Charter Factsheet: 1. Is It Mandatory?Tharaka KodippilyÎncă nu există evaluări

- Robert Gordon University Terms and Conditions of AdmissionDocument8 paginiRobert Gordon University Terms and Conditions of AdmissionTharaka KodippilyÎncă nu există evaluări

- Skilled Migration Assessment Policy 08112019Document13 paginiSkilled Migration Assessment Policy 08112019krishnashankar9_3743Încă nu există evaluări

- Gulf Talent Employee and Salary PDFDocument14 paginiGulf Talent Employee and Salary PDFAnonymous PkAjjOZBÎncă nu există evaluări

- Pre Contract PW1Document8 paginiPre Contract PW1Tharaka KodippilyÎncă nu există evaluări

- NBS National BIM Report 2018Document27 paginiNBS National BIM Report 2018Tharaka KodippilyÎncă nu există evaluări

- Fidic 87-99Document1 paginăFidic 87-99Tharaka KodippilyÎncă nu există evaluări

- Ethical DilemmaDocument15 paginiEthical DilemmaTharaka KodippilyÎncă nu există evaluări

- Q-01 Importance of Having Specification As A Separate Document in Construction Project or A Service IndustryDocument2 paginiQ-01 Importance of Having Specification As A Separate Document in Construction Project or A Service IndustryTharaka KodippilyÎncă nu există evaluări

- The Gap in FIDIC 1999 Sub Clause 20.7 by DR Nael Bunni Presented by Dr. Kamal MALASDocument15 paginiThe Gap in FIDIC 1999 Sub Clause 20.7 by DR Nael Bunni Presented by Dr. Kamal MALASTharaka KodippilyÎncă nu există evaluări

- Survey ReportDocument19 paginiSurvey ReportTharaka KodippilyÎncă nu există evaluări

- Industrial Training Report Guideline (Built Environment)Document35 paginiIndustrial Training Report Guideline (Built Environment)keganiÎncă nu există evaluări

- Exploring The Types of Construction Cost Modelling For Industrialised Building System (Ibs) Projects in MalaysiaDocument21 paginiExploring The Types of Construction Cost Modelling For Industrialised Building System (Ibs) Projects in MalaysiaTharaka KodippilyÎncă nu există evaluări

- Introduction To LinuxDocument17 paginiIntroduction To Linuxسليمان الشمريÎncă nu există evaluări

- Global Business Environment: Lessons From The Businesses That Have Failed in The Global MarketDocument15 paginiGlobal Business Environment: Lessons From The Businesses That Have Failed in The Global MarketKeshav ChaudharyÎncă nu există evaluări

- Mr. Vinayak Hanchate - CV BIM PDFDocument3 paginiMr. Vinayak Hanchate - CV BIM PDFYassem MalikÎncă nu există evaluări

- FL518 FL776 FL1036 SparepartDocument8 paginiFL518 FL776 FL1036 Sparepartphantomboyz_aipÎncă nu există evaluări

- Lecture Notes - Week 2Document13 paginiLecture Notes - Week 2Nathaniel LucasÎncă nu există evaluări

- Logrolling A ClientDocument1 paginăLogrolling A ClientJanice LucasÎncă nu există evaluări

- CDS BIG OMEGA ® 20in. 133lb-ft K55 API Drift 18.543in.Document1 paginăCDS BIG OMEGA ® 20in. 133lb-ft K55 API Drift 18.543in.ThierryÎncă nu există evaluări

- 19me411 QR With AnsDocument43 pagini19me411 QR With AnsAravind KumarÎncă nu există evaluări

- Saonon Datasheet-50Hz (Cummins) - S415CC (S)Document4 paginiSaonon Datasheet-50Hz (Cummins) - S415CC (S)Wai YanÎncă nu există evaluări

- User Manual: PV Analyzer Z100Document37 paginiUser Manual: PV Analyzer Z100Duyệt Đinh XuânÎncă nu există evaluări

- Deutz Fahr Agrolux 55e Test ReportDocument12 paginiDeutz Fahr Agrolux 55e Test ReportMamta RaybageÎncă nu există evaluări

- Computer Science Paper Scheme (Marks Distribution)Document4 paginiComputer Science Paper Scheme (Marks Distribution)Honey BunnyÎncă nu există evaluări

- Computer ArchitectureDocument21 paginiComputer ArchitectureAsad JavedÎncă nu există evaluări

- Nil Report EP LabDocument6 paginiNil Report EP LabCHANDRAPRAKASHÎncă nu există evaluări

- PVTsimHelp 20Document197 paginiPVTsimHelp 20JesseÎncă nu există evaluări

- Fact-Sheet gsx-300 en OriginalDocument3 paginiFact-Sheet gsx-300 en Originaldream2bdjÎncă nu există evaluări

- Lecture 2Document98 paginiLecture 2pushpendra singhÎncă nu există evaluări

- Machine Learning Model For Green Building Design PredictionDocument10 paginiMachine Learning Model For Green Building Design PredictionIAES IJAIÎncă nu există evaluări

- (Diane) Discord Moderator Contract - SignedDocument2 pagini(Diane) Discord Moderator Contract - Signed39B ALYSA Alysa YaoÎncă nu există evaluări

- Let Us Discover: Quarter: 4 Week: 4 ELC: Perform Testing, Documentation, and Pre DeploymentDocument3 paginiLet Us Discover: Quarter: 4 Week: 4 ELC: Perform Testing, Documentation, and Pre Deploymentrianeprogod3600Încă nu există evaluări