Documente Academic

Documente Profesional

Documente Cultură

Ginevri OGB PolyCare 3 Incubator - Service Manual

Încărcat de

Sveto SlDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ginevri OGB PolyCare 3 Incubator - Service Manual

Încărcat de

Sveto SlDrepturi de autor:

Formate disponibile

Rev.

04

OGB Poly Care 3 - Service Manual

THIS MANUAL HAS BEEN REALIZED

RESPECTING THE ENFORCED NORMS

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

INDICE

1 PRESENTATION................................................................................................................................... 5

2 EC CERTIFICATE ............................................................................................................................ 6

3. CALIBRATION CHECK ..................................................................................................................... 7

3.1 TEMPERATURE PROBES CALIBRATION...................................................................................................................8

3.2 HUMIDITY PROBE CALIBRATION..............................................................................................................................9

3.3 OXYGEN PROBE CALIBRATION .................................................................................................................................9

3.4 HUMIDIFICATOR SYSTEM CALIBRATION. ............................................................................................................10

4. ELECTRICAL INTERCONNECTION DIAGRAM....................................................................... 12

5. SPARE PART ...................................................................................................................................... 16

5.1 INCUBATOR POLY 3...........................................................................................................................................................16

5.2 ASSEMBLED BODY INCUBATOR ........................................................................................................................................18

5.3 ASSEMBLED CONTROL PANEL ...........................................................................................................................................20

5.4 ASSEMBLED WATER BOX .................................................................................................................................................22

5.7 LOCKED POWER CONTROL PANEL ....................................................................................................................................27

5.8 CONTROL PANEL KEYBOARD ............................................................................................................................................29

5.9 ASSEMBLED HOOD DOOR .................................................................................................................................................31

6. MAINTENANCE SERVICE .............................................................................................................. 32

7. PROGRAMMED AND PREVENTIVE MAINTENANCE............................................................. 33

8. FINAL CHECK ................................................................................................................................... 34

9. TECHNICAL DATA........................................................................................................................... 35

10 COMPLIES WITH FOLLOWING STANDARD ........................................................................... 36

Ginevri s.r.l.

7669bmt

Novembre 2009

Rev.04

OGB Poly Care 3 - Service Manual

WHITE PAGE

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

1 PRESENTATION

Dear customer,

we would like to thank you for choosing our Incubator OGB Polycare 3.

Ginevris quality, long experience, safety and easy maintenance will prove to be

the best reward for your continuous interest in our products line.

Giorgio Ginevri

GINEVRI s.r.l. Registered office

Via Giacomo Boni - 00162 Roma

Warning

Before using the device, all personnel, who will be working with the unit, should read

and thoroughly understand this manual.

This manual provides instructions for calibration and operator maintenance. Ginevri cannot be

responsible for the performance of the Incubator OGB Polycare 3 if the user does not operate the

unit in accordance with the instructions, fails to follow the maintenance recommendations in this

manual, or effect any repairs with unauthorized components.

Calibration and repair should be performed only by qualified service personnel. Technical

information is available through your local distributor.

If there is anything you do not understand, please contact your Ginevris representative for further

information.

GINEVRI srl - Servizio Assistenza Clienti

Via Cancelliera 25/B 00041 Cecchina (Roma) - ITALY

Tel. ++39 06 93459331

Fax ++39 06 93459393

E-mail: export@ginevri.com

www.ginevri.com

This manual refers to the enclosed equipment:

Incubator OGB Polycare 3

S/N

Ginevri s.r.l.

7669bmt

Novembre 2009

Rev.04

OGB Poly Care 3 - Service Manual

2 EC CERTIFICATE

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

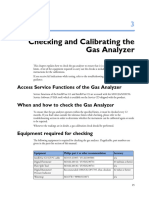

3. CALIBRATION CHECK

Every three months check the Temperature, Humidity and Oxygen probes correct operation.

To check the probes reading use the optional Ginevri Reference Simulator P/N 10487A60.

To check the reading of the probes perform the following steps:

Temperature probes

a) Switch off the equipment and disconnect it from the mains

b) Disconnect from the control panel the probe assembly connector and replace it

with the Reference Simulator

c) Connect the equipment to the mains and switch it on

d) Select on the Reference Simulator:

PROBES

on AIR 1

TEMP C

on 25C

SELECT

on MUTE

The AIR LED display should show the selected reading with a 0.2C tolerance

for temperatures lower then 30C and with a 0.1C tolerance for temperatures

higher then 30C.

Repeat this step for the temperature settings

e) Check the AIR2 and SKIN Temperature probes selecting AIR2 first and then

SKIN on the simulator dial and performing the same operations of the preceding

step

f) Select on the Reference Simulator:

PROBES

MAX TEMP

TEMP C

on 39.8C

SELECT

on H.T.

check that the MAX TEMP alarm does not activate.

Select on the Reference Simulator: TEMP C on 40.1C And check that the

MAX TEMP alarm activates.

Humidity Probe

a)

Switch off the equipment and disconnect it from the mains

b)

Disconnect from the control panel the probe assembly connector and

replace it with the Reference Simulator

c)

Connect the equipment to the mains and switch it on

d)

Select on the Reference Simulator:

PROBES

on HUM

Hum %

on 30%

SELECT

on MUTE

e)

The HUM LED display should show the selected reading

f)

Repeat this step for all Hum %settings .

Oxygen probe

a)

Switch off the equipment and disconnect it from the mains

b)

Disconnect from the control panel the probe assembly connector and

replace it with the Reference Simulator

c)

Connect the equipment to the mains and switch it on

d)

Select on the Reference Simulator:

PROBES

on OXY

Oxy %

on 21%

SELECT

on MUTE

e)

The OXY LED display should show the selected reading

f)

Repeat this step for all the OXY %settings

If the readings of the probes are not correct, within the specified tolerances, the probes should

be calibrated. The calibration is performed by means of the reference simulator as described in

the following chapters.

Ginevri s.r.l.

7669bmt

Novembre 2009

Rev.04

OGB Poly Care 3 - Service Manual

3.1 TEMPERATURE PROBES CALIBRATION

ATTENTION: Unless otherwise stated, the temperature probes calibration is performed

on the microprocessor board ( P/N 10359A15).

To calibrate the temperature probes perform the following steps:

AIR 1

a) Switch off the equipment

b) Remove the four screws securing the control panel and open it to have free

access to the boards

c) Disconnect from the control panel the probe assembly connector and replace it

with the Reference Simulator

d) Connect the equipment to the mains and switch on, if an alarm goes off mute it.

e) Select on the Reference Simulator:

PROBES

on AIR 1

TEMP C

on 25C

SELECT 1 on MUTE

f) connect the negative lead of the multimetr to PIN 2 of J5, connect the positive lead

of the multimeter to TP1

g) Adjust the trimmer R29 to read 1060 mV 1 on the multimeter

h) Select on the Reference Simulator:

TEMP C

su 36C

i) Disconnect the multimeter

j) Adjust the trimmer R 28 to read 36C 0.1 on the AIR display of the control panel

k) Check the calibration selecting on the Reference Simulator dial all the settable

values, with the exception of 0C and MAX TEMP, verifying that the set value is

displayed on the AIR display (to obtain a correct reading each set temperature

value should be kept stable for at least 10 seconds) the reading should be

between the following tolerances

< 30C

0.2C

> 30C

0.1C

AIR 2

PROBES

su AIR 2

TEMP C

su 36C

m)Adjust the trimmer R31 to read 36C 0.1 on the AIR display of the control panel.

Follow the instructions of step k) setting the PROBES dial of the Reference

Simulator first on AIR1 and then on AIR2

SKIN

n) Select on the Reference Simulator:

MAX TEMP

l) Select on the Reference Simulator:

PROBES

on SKIN

TEMP C

on 36.5C

o) Adjust the trimmer trimmer R30 to read 36.5C 0.1 on the SKIN display of the

control panel. . Follow the instructions of step k) setting the PROBES dial of the

reference simulator first on AIR1, AIR2 And then on SKIN

p) Select on the Reference Simulator:

PROBES

TEMP C

SELECT

on MAX TEMP

on 40C

on H.T.

The alarm should be inactive

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

q) Adjust the trimmer PT 5 placed on display board to reach half-way between alarm

activated and not activated. Adjust the trimmer PT 101 to have the MAX TEMP

alarm activated.

r) Select on the Reference Simulator VAR condition and adjust the potentiometer

placed in the simulator to have the MAX TEMP alarm activated. Select on the

Reference Simulator AIR 1 and verify that it is possible to read on incubator air

display a value of 40.0C 0.1C , if necessary repeat the q) point.

s) Repeat steps p) and q) to check the MAX TEMP calibration.

3.2 HUMIDITY PROBE CALIBRATION

ATTENTION: Unless otherwise stated, the humidity probe calibration is performed on

the microprocessor board ( P/N 10359A15)

a) Switch off the equipment

b) Remove the four screws securing the control panel and open it to have free access to

the boards

c) Disconnect from the control panel the probe assembly connector and replace it with

the Reference Simulator

d) Connect the equipment to the mains and switch on, if an alarm activates mute it by

MUTE push button.

e) Select on the Reference Simulator:

PROBES

on HUM

HUM %

on 0% (short circuit)

f) On the MICROPROCESSOR BOARD connect the negative lead of a multimeter to

PIN 2 of J5 (black lead) and the positive lead to PIN 5 of U12. Adjust trimmer PT2 on

the DISPLAY BOARD to read 0 mV 2

g) Select on the reference simulator HUM % on 90%

h) Adjust PT1 to read 90% on the display HUM of the control panel

i) Check the calibration Selecting on the Reference Simulator dial all the settable values,

with the exception of IN, verifying that the set value is displayed on the HUM. For a

further check of the humidity level in the incubator use a wet bulb Hygrometer.

3.3 OXYGEN PROBE CALIBRATION

ATTENTION: Unless other stated, the oxigen probe calibration is performed on the

display board

a) Switch off the equipment

b) Remove the four screws securing the control panel and open it to have free access to

the boards

c) Disconnect from the control panel the O2 probe connector and replace it with the

Reference Simulator

d) Connect the equipment to the mains and switch on, if an alarm goes off mute it.

e) Select on the Reference Simulator:

PROBES

on OXY

OXY % on 0% (short circuit)

f) On the MICROPROCESSOR BOARD connect the negative lead of a multimeter to

PIN 2 of J5 (black lead), connect the positive lead PIN 6 of U 12. Adjust the trimmer

PT 4 on the DISPLAY BOARD to read 0 mV 2 . If it is necessary adjust before PT3.

Ginevri s.r.l.

7669bmt

Novembre 2009

9

Rev.04

OGB Poly Care 3 - Service Manual

g) Select OXY % on 21%.

h) Adjust trimmer PT3 to read 980 mV 5 on the multimeter

i) Select OXI% on CAL and check that the oxi display on the control panel is showing

21%, ( calibration operation ,indicated with CA, takes about 30 sec.).

j) Select OXI % on 98% and adjust PT3 trimmer to obtain the reading of 98% on the oxi

display.

k) Select OXI% on 21% and verify the reading of 21% on the oxi display. If necessary

repeat the previous points i), j) and k).

3.4 HUMIDIFICATOR SYSTEM CALIBRATION.

ATTENTION:

Unless specified, the humidificator calibration system is performed on the

power board.

a) Switch off the equipment

b) Remove the four screws securing the control panel and open it to have free

access to the boards

c) Disconnect from the control panel the probe assembly connector and replace it

with the Reference Simulator

d) Connect the equipment to the mains and switch on, if an alarm goes off mute it.

e) Select on the Reference Simulator:

PROBES

on HUM

HUM %

on

0% (short circuit)

f) Disconnect the J5 from Power Board.

g) Verify that D14 led lights on.

h) Connect the negative lead of multimeter to the ground test-point placed near to R31

resistor.

i) Connect the positive lead of multimeter to the pin 3 of U6 and adjust the

trimmer RV1 to 3.83 Vdc.

j) Verify that the leds status does not change.

k) Connect the positive lead of multimeter to the pin 9 of U5 and adjust the

trimmer RV2 to 11 Vdc.

l) Verify that the leds status does not change.

m)Connect the positive lead of multimeter to the pin 6 of U5 and adjust the

trimmer RV5 to 3.8 Vdc.

n) Verify that the leds status does not change.

o) Connect the J5 connector to the Power Board.

p) Verify that D14 led lights off.

q) Select on Reference Simulator HUM = 30%

r) Adjust the HUM SET point value to 66%.

10

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

s) Verify that the D19 led lights on.

t) Connect the positive lead of multimeter to pin 3 ( red wire ) of J5 connector

of the power board.

u) Adjust the trimmer RV3 to 3.3Vdc value.

v) Select on Reference Simulator HUM= 66%.

w) Verify that the D19 led lights off.

x) Connect the positive lead of multimeter to pin 3 ( red wire ) of J5 connector

of the power board.

y) Adjust the trimmer RV4 to 2.5Vdc value.

Ginevri s.r.l.

7669bmt

Novembre 2009

11

Rev.04

OGB Poly Care 3 - Service Manual

4. ELECTRICAL INTERCONNECTION DIAGRAM

12

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Ginevri s.r.l.

7669bmt

Rev.04

Novembre 2009

13

Rev.04

14

OGB Poly Care 3 - Service Manual

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Ginevri s.r.l.

7669bmt

Rev.04

Novembre 2009

15

Rev.04

OGB Poly Care 3 - Service Manual

5. SPARE PART

5.1 Incubator Poly 3

16

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Item

1

2

10

3

12

6

Code

10226A72

10239A72

11885A72

10262A72

10180A72

10388A72

Ginevri s.r.l.

Rev.04

Description

ASSEMBLED BODY INCUBATOR

ASSEMBLED WATER BOX

POWER CABLE SCHUKO - IEC

OXYGEN PROBE HOLDER

ASSEMBLED CONTROL PANEL

HOLDER CALIBRATION OXY SENSOR

7669bmt

Novembre 2009

Q.ty

NR

NR

NR.

NR

NR

NR

1

1

1

1

1

1

17

Rev.04

OGB Poly Care 3 - Service Manual

5.2 Assembled Body Incubator

18

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Item

1

2

5

4

7

Code

10106A72

11315A72

6100A72

7320A72

11835A72

Ginevri s.r.l.

Rev.04

Description

COMPLETED BASEMENT

MICROFILTER COVER

PATIENT TRAY

AIR CONVEYOR

ASSEMBLED HOOD

7669bmt

Novembre 2009

Q.ty

NR.

NR.

NR.

NR.

NR.

1

1

1

1

19

Rev.04

OGB Poly Care 3 - Service Manual

5.3 ASsembled Control Panel

20

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Item

1

2

7

6

Code

10181A72

10182A72

10183A72

10185A72

Ginevri s.r.l.

Rev.04

Description

BLOCK POWER CONTROL PANEL

BLOCK KEYBOARD CONTROL PANEL

KNURLED KNOB

KNURLED KNOB

7669bmt

Novembre 2009

Q.ty

NR.

NR.

NR.

NR.

1

1

2

2

21

Rev.04

OGB Poly Care 3 - Service Manual

5.4 Assembled Water Box

22

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Item

1

5

6

2

3

4

Code

5847A72

5849A72

5927A72

5928A72

5929A72

5930A72

Ginevri s.r.l.

Rev.04

Description

WATER BOX

INFERIOR HALF-COVER

SUPERIOR HALF-COVER.

POLE WITH DEFLECTOR

PIVOT PIN

LOCK FOR PIVOT PIN

7669bmt

Novembre 2009

Q.ty

NR.

NR.

NR.

NR.

NR.

NR.

1

1

1

1

1

1

23

Rev.04

OGB Poly Care 3 - Service Manual

5.5 Assembled Hood

Item

1

2

3

4

5

6

7

24

Code

Description

Q.ty

10231B72

11745A72

11750A72

2592A72

7460A72

12029A73

11725A73

HOOD DOOR PANEL OVAL PORT ASSEMBLY

OGB INCUBATOR OVAL PORTHOLE

PUSH OPENERS FOR ACCESS PORTS

TRIANGLE FOR OGB

OGB INCUBATOR HOOD LEXAN N/MOD

RUBBER SEAL FOR THE HOOD (ROUND HOLES)

SLEEVE FOR PORTHOLE

7669bmt

Novembre 2009

2

6

2

1

6

12

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

5.6 Assembled Basament

Ginevri s.r.l.

7669bmt

Novembre 2009

25

Rev.04

Item

6

7

8

9

11

12

14

17

18

19

22

26

OGB Poly Care 3 - Service Manual

Code

10107A72

10108A72

10244A72

10245A72

10744A72

10745A72

1660A72

453A72

5846A72

5932A72

7702A72

Description

TRAY POSITIONING LEVER LEFT

TRAY POSITIONING LEVER RIGHT

SMOOTH TILT LEFT

SMOOTH TILT RIGHT

SMOOTH-TILT KNOB CASE

SMOOTH TILT KNOB PASSING BEARING

KNOB M6X25

HOLED LONGERON X OGB

BASE OGB LEXAN

ORIFICE PLATE OGB/2000 LEXAN

KNOB D50 X SHAFT D8

7669bmt

Novembre 2009

Q.ty

NR

NR

NR

NR

NR

NR

NR

NR

NR

NR

NR

1

1

1

1

2

2

4

2

1

1

2

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

5.7 Locked Power Control Panel

Ginevri s.r.l.

7669bmt

Novembre 2009

27

Rev.04

OGB Poly Care 3 - Service Manual

Item

8

16

9

1

7

10

28

Code

11233A72

11134B72

4906A72

5848A72

6912A72

11882A72

Description

ASSEMBLED ENGINE GROUP

SECURITY THERMOSTAT

FAN

INTERNAL BODY CONTROL PANEL

FAN FAILURE SENSOR

RESISTANCE 280W 220V X OGB POLY

7669bmt

Novembre 2009

NR

NR

NR

NR

NR

NR

Q.ty

1,0000

1,0000

1,0000

1,0000

1,0000

1,0000

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

5.8 Control Panel Keyboard

Ginevri s.r.l.

7669bmt

Novembre 2009

29

Rev.04

Item

22

24

21

12

27

2

25

1

14

15

7

30

OGB Poly Care 3 - Service Manual

Code

10663A72

10935A72

10531A72

11888A72

10197A72

10461A72

11215A72

122A72

6422A72

11219A72

10467A72

Description

LABEL SIDE SX CONTROL PANEL

LABEL SIDE DX CONTROL PANEL

SWITCH PROTECTION 30x24

PLUG IEC 2A

EPROM

KEYBOARD

POWER CARD

FRONTAL CONTROL PANEL.

GREEN SWITCH ON/OFF

MICROPROCESSOR BOARD

CONTROL BOARD

7669bmt

Novembre 2009

Q.ty

NR

NR.

NR

NR

NR.

NR

NR.

NR

NR

NR.

NR.

1

1

1

1

1

1

1

1

1

1

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

5.9 Assembled Hood Door

Rif.

Code

1

2

3

4

5

11744A72

11745A72

11750A72

11721A73

11725A73

Ginevri s.r.l.

Q.ty

Description

OGB INCUB.DOOR WITH OVAL PORTS

OVAL ACCESS PORTS OGB INCUB.

PUSH OPENERS FOR ACCESS PORTS

RUBBER SEAL FOR DOORS WITH OVAL PORTHOLES

SLEEVE FOR PORTHOLE

7669bmt

Novembre 2009

1

2

6

6

12

31

Rev.04

OGB Poly Care 3 - Service Manual

6. MAINTENANCE SERVICE

Ginevri representative in your country can stipulate, within one month before warranty period expiry,

various kinds of maintenance contract.

For any inquiry please contact us:

Ginevri s.r.l.

Via Cancelliera, 25/B

00041 Cecchina (Roma)

Italy

Tel. +39 06 93459331

Fax. +39 06 93459393

E-mail: mail@ginevri.com

The device is manufactured in compliance with the standards CEI 62.5 (file 1445 of 01/91) and EN 60

601-1 and related IEC 601-2-50. Moreover the device is provided with an EMC (electromagnetic

compatibility) anti-jamming device.

If servicing/maintenance after warranty period is performed by other companies not qualified/authorized

by us, all fixed parts have to be marked by the repairer. The repairer has to verify and guarantee in

writing the perfect functioning of the device. Any modification of the device must comply with the

Medical Devices Normative law 93/42/CEE and approved by Ginevri s.r.l.

For maintenance service original materials must be used.

.

32

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

7. PROGRAMMED AND PREVENTIVE MAINTENANCE

All electromedical devices must be maintained regularly, as for the normative law (CEI 1276 G).

The aim of preventive and programmed maintenance is to minimise the need of faults repairing and to

obtain:

Correct functioning;

Safety for the patient, the operator and the surrounding environment;

Maximum availability of the device.

Preventive maintenance consists in controls performed by the operator and periodical maintenance.

Written programs should be defined regarding every kind of device, based on laws, technical standards

and suggestions of the manufacturer. These programs must include controls performed by the operators

and periodical maintenance.

Ginevri s.r.l.

7669bmt

Novembre 2009

33

Rev.04

OGB Poly Care 3 - Service Manual

8. FINAL CHECK

If all test operations are successfully completed, sign and stamp the Functional-Check field and

tick the Setting field of the label attached to the device, as shown in the following picture.

If test operations are not successfully completed, state whether the OGB Polycare Infant Incubator

has to be repaired or replaced. In case it has to be repaired, this can be done immediately (urgent

cases) or afterwards. If the maintenance can be performed afterwards, place a red mark on the

device and leave it in the area dedicated to materials waiting for maintenance for a further service.

Write down the anomalies in the Notes field on the back of the label.

If the OGB Polycare Infant Incubator has to be replaced, fill in the non-conformity statement,

according to PO-10.

34

7669bmt

Novembre 2009

Ginevri s.r.l.

OGB Poly Care 3 - Service Manual

Rev.04

9. TECHNICAL DATA

FRAME

POLYCARBONATE

POWER SUPPLY

220V 50/60 HZ

POWER DRAIN

330W (540W HOT SPOT )

SAFETY CLASS

CATEGORY

GROUND DISPERSION CURRENT

70 A

ELECTRICAL PROTECTION

2 FUSES 5X20MM 3.15 AMP F

POWER FAILURE ALARM BATTERY

INCLUSA

SKIN TEMPERATURE DISPLAY

0.1C RESOLUTION, 0.3C MAX ERROR

AIR TEMPERATURE DISPLAY

0.1C RESOLUTION, 0.6C MAX ERROR

HIGH TEMPERATURE ALARM

(only Automatic mode) ACOUSTIC/VISUAL

AUTOMATIC (+1C with respect to SET

TEMP)

ENVIRONMENT OPTIMUM TEMPERATURE

21C /26C

STORAGE TEMPERATURE

-10C/+50C

MAXIMUM WHEIGHT ON PATIENT BED

10 KG

MAXIMUM DIMENSIONS

83x59x68 Cm

WHEIGHT

51 kg

Ginevri s.r.l.

7669bmt

Novembre 2009

35

Rev.02

OGB Poly Care 3 Service Manual

10 COMPLIES WITH FOLLOWING STANDARD

:

IEC

IEC

EN

EN

EN

EN

EN

EN

601.1

601.2.19

55011

61000-4-2

61000-4-3

61000-4-4

61000-4-5

61000-4-11

(CEI 62.5)

MEDICAL DEVICE 93/42/CEE

CLASS IIb

UNI EN ISO 9000:2000 CERTIFIED QUALITY

SYSTEM BY IQNET No. CERT IT-37100

UNI CEI ISO 13485 PARTICULAR

REQUIREMENTS FOR MEDICAL DEVICES

Ginevri s.r.l.

7669BMT

Marzo 99

36

S-ar putea să vă placă și

- Instruction Pages (GA-171) 083111Document14 paginiInstruction Pages (GA-171) 083111claudiumacÎncă nu există evaluări

- Galaxy R Service Manual PDFDocument58 paginiGalaxy R Service Manual PDFPedro Bortot56% (9)

- CO2CELL 170 - en - Ns 0301 - MMM - V1.0Document22 paginiCO2CELL 170 - en - Ns 0301 - MMM - V1.0gigel1980Încă nu există evaluări

- Combustible Gas Leak Detector: Instruction ManualDocument16 paginiCombustible Gas Leak Detector: Instruction ManualjosselinefÎncă nu există evaluări

- 123 Manual CO2 Inergen R1Document13 pagini123 Manual CO2 Inergen R1MomoMaroufÎncă nu există evaluări

- 4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The ComplexDocument5 pagini4.30 PM / Calibration Procedure For Fire & Gas Detection System Installed at Different Plant Location Across The Complexkirandevi1981Încă nu există evaluări

- GFG Instrumentation 4021Document16 paginiGFG Instrumentation 4021Tony NavaÎncă nu există evaluări

- Portable Exhaust Gas Analyzer Operators ManualDocument24 paginiPortable Exhaust Gas Analyzer Operators Manualمحمد مصرىÎncă nu există evaluări

- Accutrend GCDocument58 paginiAccutrend GCAnonymous DytNol3Încă nu există evaluări

- NHA-500 ManualDocument28 paginiNHA-500 ManualJuan Morales EstradaÎncă nu există evaluări

- Inspector EXPPlus Operation Manual EnglishDocument29 paginiInspector EXPPlus Operation Manual EnglishAhmad AliÎncă nu există evaluări

- Royal Enfield Bullet Service Manual by P. SnidalDocument4 paginiRoyal Enfield Bullet Service Manual by P. SnidalRafiÎncă nu există evaluări

- Calibration Procedure For Calibration of External Micrometer PDFDocument8 paginiCalibration Procedure For Calibration of External Micrometer PDFscopeldelimaÎncă nu există evaluări

- p0420 Catalyst ErrorDocument7 paginip0420 Catalyst Errordion132100% (2)

- 15PPM Bilge Alarm (Gba-155) Manual (Rev5)Document16 pagini15PPM Bilge Alarm (Gba-155) Manual (Rev5)Raúl Oscar Ledesma100% (1)

- AfiMilk MPC Calibration Manual June 2019Document24 paginiAfiMilk MPC Calibration Manual June 2019Mustkim DhukkaÎncă nu există evaluări

- OMC 1108 ManualDocument8 paginiOMC 1108 ManualmrkbsmÎncă nu există evaluări

- Snooper MiniSNOOPER MiniDocument28 paginiSnooper MiniSNOOPER MiniViorel VaidaÎncă nu există evaluări

- Philips M1013-M1019A CheckOutProcedureDocument13 paginiPhilips M1013-M1019A CheckOutProcedureraviÎncă nu există evaluări

- Proportional Reducing Valve Sweep - Test: Pruebas y AjustesDocument2 paginiProportional Reducing Valve Sweep - Test: Pruebas y AjustesAugusto BellezaÎncă nu există evaluări

- Algometer Type Ii Manual English Sbmedic 170718Document15 paginiAlgometer Type Ii Manual English Sbmedic 170718Brigiditt BethancourttÎncă nu există evaluări

- Form Euro.326 Rev.2 - Echo Preventive MaintenanceDocument6 paginiForm Euro.326 Rev.2 - Echo Preventive MaintenancesanazÎncă nu există evaluări

- Greenstar He Plus Combi Service Booklet For EngineersDocument56 paginiGreenstar He Plus Combi Service Booklet For EngineersMladen StuparÎncă nu există evaluări

- Greenstar CDi Classic Engineer Service BookletDocument40 paginiGreenstar CDi Classic Engineer Service BookletsagmonaÎncă nu există evaluări

- Ppbrae Plus: Parts Per Billion Voc Monitor Pgm-7240Document19 paginiPpbrae Plus: Parts Per Billion Voc Monitor Pgm-7240umair2kplus492Încă nu există evaluări

- Manual Flujometro Gpi Hby-007 PDFDocument35 paginiManual Flujometro Gpi Hby-007 PDFvicthor2Încă nu există evaluări

- Evita 2 CAP - C02 - MEASURMENT - ENGDocument30 paginiEvita 2 CAP - C02 - MEASURMENT - ENGПётр ТрашкунÎncă nu există evaluări

- Calibration Procedure Oxygen Analyzer (Furnace Stack)Document9 paginiCalibration Procedure Oxygen Analyzer (Furnace Stack)ArdvarkÎncă nu există evaluări

- Hach Portable Meter ManualDocument116 paginiHach Portable Meter ManualLuz Del Alba JimenezÎncă nu există evaluări

- Philips 109b7Document90 paginiPhilips 109b7Charly HirschÎncă nu există evaluări

- Chapter 5 Test and Material List 5.1 Test Procedure 5.1.1 Connection and CheckingDocument9 paginiChapter 5 Test and Material List 5.1 Test Procedure 5.1.1 Connection and CheckingJean Carlos FlorianoÎncă nu există evaluări

- Manual For TC CO2 IncubatorDocument42 paginiManual For TC CO2 IncubatorperlitacantoÎncă nu există evaluări

- Inspector Alert Manual PDFDocument32 paginiInspector Alert Manual PDFnagatopein6Încă nu există evaluări

- Philips MicroDose-L30-full CalibrationDocument12 paginiPhilips MicroDose-L30-full CalibrationTony Kututo100% (1)

- Sensor CODocument24 paginiSensor COcristianÎncă nu există evaluări

- Detector de Co Bx170Document8 paginiDetector de Co Bx170oscarÎncă nu există evaluări

- Xplorer: Operating ManualDocument130 paginiXplorer: Operating ManualDaniel ArmasÎncă nu există evaluări

- Calibration Procedure For Calibration of External MicrometerDocument11 paginiCalibration Procedure For Calibration of External MicrometerDiganta Hatibaruah100% (1)

- PH Transmit ErDocument34 paginiPH Transmit ErMiguel SandoyaÎncă nu există evaluări

- 51098680Document15 pagini51098680ศิลป์ ไชยวุฒิÎncă nu există evaluări

- Manual PH Hanna 211 PDFDocument40 paginiManual PH Hanna 211 PDFTito El CidÎncă nu există evaluări

- JUD410349-B9000 60-160kVA-TestProcedDocument26 paginiJUD410349-B9000 60-160kVA-TestProcedalexFillÎncă nu există evaluări

- Furuno SC-50 - 110Document30 paginiFuruno SC-50 - 110etchegarayf100% (1)

- Ethos 24c Maintenance ManualDocument29 paginiEthos 24c Maintenance Manualdanielteo2008Încă nu există evaluări

- Manual Nuvair Pro - CO - Manual - Rev - 10 17Document24 paginiManual Nuvair Pro - CO - Manual - Rev - 10 17Reynaldo FiremedÎncă nu există evaluări

- Calibration Procedure For BFP-T Turbine Rotor Expansion SensorDocument9 paginiCalibration Procedure For BFP-T Turbine Rotor Expansion Sensornaresh977977Încă nu există evaluări

- RENR1998 RDDDocument4 paginiRENR1998 RDDAfzal AhmadÎncă nu există evaluări

- Boeing Bond and Ground Job AidDocument8 paginiBoeing Bond and Ground Job AidEdwin ValenciaÎncă nu există evaluări

- MB ManualDocument47 paginiMB ManualdangthanhlinhÎncă nu există evaluări

- Itrans - Rev 16.0 - EN (77023554-1) - 0 PDFDocument88 paginiItrans - Rev 16.0 - EN (77023554-1) - 0 PDFaepriyadiÎncă nu există evaluări

- Labconco 974321installDocument5 paginiLabconco 974321installenticoÎncă nu există evaluări

- Kane Km900 Combustion Flue Gas Analyzer Product ManualDocument39 paginiKane Km900 Combustion Flue Gas Analyzer Product ManualdesanchezeÎncă nu există evaluări

- Mid 039 - Cid - FMI 05: TroubleshootingDocument3 paginiMid 039 - Cid - FMI 05: TroubleshootinganiroÎncă nu există evaluări

- MFX User ManualDocument11 paginiMFX User ManualLuisM_CRÎncă nu există evaluări

- Calibration Procedure For Oscilloscope, Agilent Models Dso3062a and Dso3202a - Tb-9-6625-2409-24Document17 paginiCalibration Procedure For Oscilloscope, Agilent Models Dso3062a and Dso3202a - Tb-9-6625-2409-24luroguitaÎncă nu există evaluări

- Digital Lux Meter: Instructions ManualDocument34 paginiDigital Lux Meter: Instructions Manualjadson_vianaÎncă nu există evaluări

- HTO Sensor Air Humidity and Temp SensorDocument8 paginiHTO Sensor Air Humidity and Temp SensorZill RafiÎncă nu există evaluări

- Automotive Air Conditioning and Climate Control SystemsDe la EverandAutomotive Air Conditioning and Climate Control SystemsEvaluare: 4 din 5 stele4/5 (6)

- Microcontroller-Based Temperature Monitoring and ControlDe la EverandMicrocontroller-Based Temperature Monitoring and ControlEvaluare: 3.5 din 5 stele3.5/5 (2)

- Nikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsDe la EverandNikon D500: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsÎncă nu există evaluări

- NST User's Guide Rev 06-11-2015Document43 paginiNST User's Guide Rev 06-11-2015Sveto SlÎncă nu există evaluări

- Motorola A8 Two Way Radio ManualDocument62 paginiMotorola A8 Two Way Radio ManualSveto SlÎncă nu există evaluări

- Solar Energy For You and MeDocument24 paginiSolar Energy For You and MeVipinÎncă nu există evaluări

- 20170329005124BT-S2 User ManualDocument10 pagini20170329005124BT-S2 User ManualJhon Alvaro Cardona WilliamsÎncă nu există evaluări

- Gzg1de1 PDFDocument130 paginiGzg1de1 PDFGhanshyam VajpayeeÎncă nu există evaluări

- Medison Sonoace 8000seDocument160 paginiMedison Sonoace 8000seSveto Sl100% (4)

- Airsep VisionAire Concentrator - Service Manual PDFDocument46 paginiAirsep VisionAire Concentrator - Service Manual PDFBoyke WinterbergÎncă nu există evaluări

- (Science in The Real World) Richard Hantula-How Do Solar Panels Work - Chelsea Clubhouse (2009) PDFDocument33 pagini(Science in The Real World) Richard Hantula-How Do Solar Panels Work - Chelsea Clubhouse (2009) PDFKan ChoraÎncă nu există evaluări

- Control by A Triac For An Inductive LoadDocument15 paginiControl by A Triac For An Inductive LoadmitrosÎncă nu există evaluări

- Dijeta 1200 Kcal LipidiDocument4 paginiDijeta 1200 Kcal LipidiSveto SlÎncă nu există evaluări

- Laser Diode HL40085G - R0Document4 paginiLaser Diode HL40085G - R0Sveto SlÎncă nu există evaluări

- SERVICE MANUAL Sony KDL-32 40 46S2510 KD PDFDocument103 paginiSERVICE MANUAL Sony KDL-32 40 46S2510 KD PDFSveto SlÎncă nu există evaluări

- 2005 Hill Laser Diode Presentation PDFDocument17 pagini2005 Hill Laser Diode Presentation PDFManu MathewÎncă nu există evaluări

- SK54 N0939 Rev.Document5 paginiSK54 N0939 Rev.csclzÎncă nu există evaluări

- PL2303 Windows Driver User Manual v1.19.0 PDFDocument14 paginiPL2303 Windows Driver User Manual v1.19.0 PDFjairo becerra perezÎncă nu există evaluări

- TOSHIBA ECCOCCEE Ssa340a PDFDocument103 paginiTOSHIBA ECCOCCEE Ssa340a PDFVremedSoluCionesÎncă nu există evaluări

- Angelo Po ENUDocument305 paginiAngelo Po ENUSveto Sl100% (1)

- Depanage AG Autogas SystemsDocument47 paginiDepanage AG Autogas Systemsmolotc50% (2)

- CT Dose Profiler - Users Manual - English-6.2A PDFDocument62 paginiCT Dose Profiler - Users Manual - English-6.2A PDFSveto SlÎncă nu există evaluări

- Datasheet 5A 180Khz 36V Buck DC To DC Converter Xl4015 Features General DescriptionDocument10 paginiDatasheet 5A 180Khz 36V Buck DC To DC Converter Xl4015 Features General DescriptionShaheer DurraniÎncă nu există evaluări

- AVR-4 Alternator Voltage Regulator: Description FeaturesDocument2 paginiAVR-4 Alternator Voltage Regulator: Description FeaturesSveto SlÎncă nu există evaluări

- Oximeter Data Manager User Manual (Software V5.4.0.1) - V1.9Document54 paginiOximeter Data Manager User Manual (Software V5.4.0.1) - V1.9Sveto SlÎncă nu există evaluări

- Central Superficie Amron Amcom I Manual enDocument45 paginiCentral Superficie Amron Amcom I Manual enSveto SlÎncă nu există evaluări

- Medison Sonoace 8000seDocument160 paginiMedison Sonoace 8000seSveto Sl100% (4)

- Manual C28 Plus enDocument28 paginiManual C28 Plus enSveto SlÎncă nu există evaluări

- Nihon Kohden 9010K Service Manual PDFDocument130 paginiNihon Kohden 9010K Service Manual PDFJumbo JamesÎncă nu există evaluări

- Dream Station Service Manual PDFDocument135 paginiDream Station Service Manual PDFSveto Sl100% (2)

- Medison Sonoace 8000seDocument160 paginiMedison Sonoace 8000seSveto Sl100% (4)

- Nihon Kohden 9010K Service Manual PDFDocument130 paginiNihon Kohden 9010K Service Manual PDFJumbo JamesÎncă nu există evaluări

- Midas Rex Legend: Pneumatic High-Speed SystemDocument48 paginiMidas Rex Legend: Pneumatic High-Speed SystemSveto SlÎncă nu există evaluări

- Ascii To Pdu Converter Convert Ascii To Pdu and Vice VersaDocument3 paginiAscii To Pdu Converter Convert Ascii To Pdu and Vice Versaelviz6000Încă nu există evaluări

- ONTAP 9 NDMP Configuration Express GuideDocument22 paginiONTAP 9 NDMP Configuration Express Guidestreet_carpÎncă nu există evaluări

- ASTM E824 Light Meter CalibrationDocument6 paginiASTM E824 Light Meter CalibrationreiazhÎncă nu există evaluări

- 010 Evac Ejector UnitsDocument6 pagini010 Evac Ejector UnitsMichael CorderoÎncă nu există evaluări

- 8155 Is An Integrated RamDocument22 pagini8155 Is An Integrated RamVipan SharmaÎncă nu există evaluări

- CSB Ups12460 9ah 12vDocument2 paginiCSB Ups12460 9ah 12vMichalis AltousÎncă nu există evaluări

- BS en Iso 4287-98 A1-09Document36 paginiBS en Iso 4287-98 A1-09fernando salvatierra100% (2)

- DumpDocument7 paginiDumpKusuma SaddalaÎncă nu există evaluări

- RAN18.1 Capacity Monitoring Guide (BSC6910-Based) (02) (PDF) - EN PDFDocument78 paginiRAN18.1 Capacity Monitoring Guide (BSC6910-Based) (02) (PDF) - EN PDFUmar MirÎncă nu există evaluări

- SCADADocument45 paginiSCADAalexlakimikapestaÎncă nu există evaluări

- Programming in C++ 2 MarksDocument24 paginiProgramming in C++ 2 MarksSudersan BalajiÎncă nu există evaluări

- BS 2562 Cable Boxes For Transformers and ReactorsDocument70 paginiBS 2562 Cable Boxes For Transformers and ReactorsMohamed987100% (1)

- Jsec 17.aDocument2 paginiJsec 17.aRizwan Ahmed AnsariÎncă nu există evaluări

- Blue Ribbon CommitteeDocument15 paginiBlue Ribbon CommitteeMadhav KesarÎncă nu există evaluări

- SJ-20120802162214-007-ZXA10 C300 (V1.2.3) Optical Access Convergence Equipment Configuration Manual (CLI)Document209 paginiSJ-20120802162214-007-ZXA10 C300 (V1.2.3) Optical Access Convergence Equipment Configuration Manual (CLI)sethzinho0% (1)

- Fab Idia Baru PDFDocument7 paginiFab Idia Baru PDFQudsiPradyanÎncă nu există evaluări

- MQX Rtos PDFDocument23 paginiMQX Rtos PDFcadornetti100% (1)

- 664 Publist 2014 DecemberDocument15 pagini664 Publist 2014 DecemberJ Salvador Calderón BarrancosÎncă nu există evaluări

- PC Case ModDocument42 paginiPC Case ModMihai IavorschiÎncă nu există evaluări

- NT 664Y6400 B E-Tech-S ENDocument24 paginiNT 664Y6400 B E-Tech-S ENHugo CarvalhoÎncă nu există evaluări

- 793D Off Higway Truck FDBDocument28 pagini793D Off Higway Truck FDBMelissa TorresÎncă nu există evaluări

- 数字电视解码芯片及整机厂方案Document21 pagini数字电视解码芯片及整机厂方案api-3725890100% (1)

- Civil Engineer Interview QuestionsDocument7 paginiCivil Engineer Interview QuestionsVirgil Sorcaru100% (1)

- R002u2u2 Med Warning PDFDocument173 paginiR002u2u2 Med Warning PDFmuamer1Încă nu există evaluări

- Delta Checklist ISO 9001-2015Document10 paginiDelta Checklist ISO 9001-2015FendiÎncă nu există evaluări

- 2006 CSTE CBOK Skill Category 7Document23 pagini2006 CSTE CBOK Skill Category 7api-3733726Încă nu există evaluări

- 2750 514-23 en Rev BDocument4 pagini2750 514-23 en Rev BGuitART TVÎncă nu există evaluări

- Set 05Document13 paginiSet 05Wak TunÎncă nu există evaluări

- P400 PX400 Adv MTL Eom 12Document64 paginiP400 PX400 Adv MTL Eom 12VictorÎncă nu există evaluări

- Catálogo FlowserveDocument23 paginiCatálogo Flowserveanderson8657Încă nu există evaluări