Documente Academic

Documente Profesional

Documente Cultură

Flushing Oil Flooded Rotary Screw Air Compressors Procedure en

Încărcat de

SergiSerrano100%(1)100% au considerat acest document util (1 vot)

253 vizualizări2 paginiFlushing oil

Titlu original

Flushing Oil Flooded Rotary Screw Air Compressors Procedure En

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentFlushing oil

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(1)100% au considerat acest document util (1 vot)

253 vizualizări2 paginiFlushing Oil Flooded Rotary Screw Air Compressors Procedure en

Încărcat de

SergiSerranoFlushing oil

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Technical Topic

Procedure for Flushing Oil Flooded Rotary

Screw Air Compressors

Switching to Mobil SHC Cibus Series Products

Lubricants used in oil flooded rotary screw air compressors come

in many different base fluids and additive technologies. The typical

base fluids used in air compressor lubricants may be mineral or

synthetic. Synthetic base fluids could be Polyalphaolefins (PAO)

or Polyalkylene Glycol (PAG) or Silicones or Esters. These lubricants

may not be compatible, therefore we recommend flushing when

converting your oil flooded rotary screw air compressor to Mobil

SHC Cibus Series lubricants.

This procedure can be used for flushing any type of air compr essor

lubricant.

1. Start compressor and allow running up to normal temperatur es

(185F/85C) for approximately 1 hour.

2. Shut down compressor.

3. Drain and clean the lubrication system:

a. Drain sump tank of as much of the existing pr oduct

as possible

b. Carefully blow out the low system spots or potential oil

"traps" in the compressor using compressed air

c. If deposits are present, clean (hand) the reservoir, accessible

lubrication system parts, bearings, and gears. Dismantle

and clean the strainers and filter units

d. Blow down and drain air receiver

4. Change oil filter and gravity drain oil out of the fibr ous materials

of the air/oil separator.

5. Fill compressor sump to normal oil levels with a Mobil synthetic

diester product (Mobil Rarus 800 Series - choose corr ect

viscosity). The use of diester product is needed for

proper flushing.

6. Start compressor and allow discharge oil temperature to reach

a typical temperature of 185F/85C. Operate compressor for

a minimum of 4 hours. Compressor does not need to be

loaded, but must run long enough and at the appr opriate

temperatures to allow for the thermostat to open.

a. Sample and check the lubricant with a r egular (10 micron)

Millipore membrane filter pad to assist in monitoring the

efficiency of the flushing. The filter pad is a visual aid on the

relative cleanliness of the compressor.

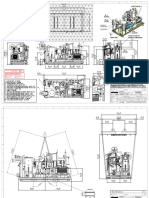

Flow Diagram for Oil-Flooded Rotary Screw Air Compressor

7. Shut down compressor.

8. Drain compressor of the Mobil Rarus 800 Series flush

lubricant, including coolers, sump, tank, and strainers.

Disconnect lines as required to drain oil trapped in low ar eas.

Drain the flushing charge (Mobil Rarus 800 Series lubricant)

preferably when the fluid is warm (120F/49C - 140F/60C).

9. Clean strainers; replace air/oil separator and all oil filters that

are not permanent. Check inlet filter for signs of oil coating of

contaminated fluid and replace as required.

10. Fill compressor with synthetic PAO product (Mobil SHC

Cibus Series - choose correct viscosity) and operate

compressor as usual.

11.Circulate the new charge of Mobil SHC Cibus Series

lubricant for 4 - 12 hours. Check the oil filters and air/oil

separator for cleanliness and deposit free. If not clean and

deposit free repeat flushing procedure.

12. Drain off the Mobil SHC Cibus Series lubricant from the circuit.

(Note: This oil may be re-used for flushing other air compressors,

if its inspection characteristics are judged satisfactory.)

13. Refill the installation with fresh Mobil SHC Cibus Series

lubricant (choose correct viscosity) and resume normal operation.

Note: Foaming of the lubricant can be caused by high discharge

applications

velocities (140+ mph) of the air in oil flooded r otary screw compressors

Advantages and Benefits: NSF H1 registered lubricants;

into the air/oil separator. However, foam should dissipate quickly in

provides safety and performance for food-related applications

the separator.

It is also recommended that the Mobil SHC Cibus Series lubricant

Advantages and Benefits: Designed for longer oil life and to

to get the most out of the pr oduct in service. Signum Oil Analysis

resist deposit formation; reduces maintenance costs as

can be used for this service.

compared to mineral oil products

Advantages and Benefits: Improved operational reliability;

are specially formulated for high performance in a wide variety

than mineral oils. These are just a few of our synthetic lubricants

for air compressors:

Mobil SHC 600 Series synthetic gear, bearing, and

circulating oils

Mobil SHC scientifically engineered supreme performance oils

of extreme applications staying on the job significantly longer

Mobil Rarus SHC 1020 Series synthetic rotary screw

compressor oils

is analyzed on a periodic basis to ensur e proper performance and

How our synthetic lubricants help keep your air

compressor operating in top form.

Mobil SHC Cibus Series synthetic lubricants for food-grade

extended oil life compared to mineral oil products

Mobilith SHC 100 and Mobil Polyrex EM electric

motor-bearing greases

Advantages and Benefits: Helps extend bearing life

to improve electric motor reliability compared to

mineral oil products

www.mobilindustrial.com

2010 Exxon Mobil Corporation

Mobil, Rarus and the Pegasus design ar e registered trademarks of Exxon Mobil Corporation or one of its subsidiaries.

SYN201001

S-ar putea să vă placă și

- Xrvs 1000 ServiceDocument10 paginiXrvs 1000 ServiceAbbas AhmedÎncă nu există evaluări

- Boge Screw UsaDocument40 paginiBoge Screw UsaAir Repair, LLC100% (1)

- Centrifugal Vs Reciprocating Compressor - Turbomachinery Magazine PDFDocument2 paginiCentrifugal Vs Reciprocating Compressor - Turbomachinery Magazine PDFReyes SanchezÎncă nu există evaluări

- Air Compressors (MOD)Document72 paginiAir Compressors (MOD)ROSHAN100% (1)

- Ingersol-Rand-Air-Compressor PHE Booster Eng DataDocument46 paginiIngersol-Rand-Air-Compressor PHE Booster Eng Datadevilsharma100% (1)

- Maintenance/clearance Area: Dimensions Could Be Change +/-5 MMDocument2 paginiMaintenance/clearance Area: Dimensions Could Be Change +/-5 MMZander MctrevorÎncă nu există evaluări

- WP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataDocument2 paginiWP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataMarcos AssialdiÎncă nu există evaluări

- Twin Screw Compressor PLC Operation Manual (PDFDrive)Document158 paginiTwin Screw Compressor PLC Operation Manual (PDFDrive)sola sidoÎncă nu există evaluări

- Aux Mach 1 Air CompressorDocument86 paginiAux Mach 1 Air CompressorConrado Sta Ines100% (1)

- Screw Compressor GH-series Instruction Manual: GH250S/L, GH320SDocument111 paginiScrew Compressor GH-series Instruction Manual: GH250S/L, GH320SManh PhamÎncă nu există evaluări

- Tuthill Blower Spec - 02Document8 paginiTuthill Blower Spec - 02Kari ConwayÎncă nu există evaluări

- Heatless Regenerative Dessicant DryersDocument20 paginiHeatless Regenerative Dessicant DryersfructoraÎncă nu există evaluări

- Boge Energy Efficient Air Compressor or Master ControllersDocument12 paginiBoge Energy Efficient Air Compressor or Master ControllersAir Repair, LLCÎncă nu există evaluări

- Manual FM160 CompressorDocument61 paginiManual FM160 CompressorSeekPTÎncă nu există evaluări

- Service Air CompresorDocument75 paginiService Air CompresorDamitha100% (2)

- Operation Manual For Oxygen CompressorDocument18 paginiOperation Manual For Oxygen CompressorAshutosh SinghÎncă nu există evaluări

- CENTAC 2CC Inspection and Storage ProceduresDocument13 paginiCENTAC 2CC Inspection and Storage ProceduresLusi ArsenalÎncă nu există evaluări

- Manual Aircel Ahld-750Document44 paginiManual Aircel Ahld-750Robert Cid de Leon0% (1)

- Cameron CCDocument6 paginiCameron CCYogesh Badhe100% (1)

- Compressor ABC vs. B&M ComparisonDocument3 paginiCompressor ABC vs. B&M ComparisonsoekirmanÎncă nu există evaluări

- LPG Compressors: Sales CatalogDocument40 paginiLPG Compressors: Sales CatalogAn IkhrandiÎncă nu există evaluări

- Hertz Piston Type Compressor ManuelDocument31 paginiHertz Piston Type Compressor Manueligor_sandulenkoÎncă nu există evaluări

- 090 R01Document72 pagini090 R0118085012Încă nu există evaluări

- Kirloskar Oil Free Reciprocating Air Compressors: Service and SupportDocument2 paginiKirloskar Oil Free Reciprocating Air Compressors: Service and SupportSuresh NathÎncă nu există evaluări

- Howden - FFP Free Floating Piston Lowres PDFDocument4 paginiHowden - FFP Free Floating Piston Lowres PDFdigecaÎncă nu există evaluări

- Ingersoll RandDocument2 paginiIngersoll Randvijayps.mech0% (1)

- Dresser RandDocument4 paginiDresser RandBams ArifinÎncă nu există evaluări

- Desiccant Type Air DryersDocument60 paginiDesiccant Type Air DryersOrlando R. LopezÎncă nu există evaluări

- FD Dryers CatalogDocument13 paginiFD Dryers CatalogmasrooorÎncă nu există evaluări

- ZR-ZT55-90 VSD-FFDocument22 paginiZR-ZT55-90 VSD-FFrodrigodiazsilvaÎncă nu există evaluări

- 3225 C Instruction Manual: Compound 2-Stage Screw CompressorDocument182 pagini3225 C Instruction Manual: Compound 2-Stage Screw CompressorAlexÎncă nu există evaluări

- China Screw Air Compressor Market Situation and The Pattern of BrandDocument2 paginiChina Screw Air Compressor Market Situation and The Pattern of BrandFahad QaiserÎncă nu există evaluări

- Compressor Size CalulatorDocument2 paginiCompressor Size CalulatorŞef Utas Awij100% (1)

- Manual de Operacion Secadores Ra 100 y Ra 125Document76 paginiManual de Operacion Secadores Ra 100 y Ra 125Ricardo López BernalÎncă nu există evaluări

- ScrewCompressors XRV204 SpecSheet DigitalDocument1 paginăScrewCompressors XRV204 SpecSheet DigitalBarros Arias EnriqueÎncă nu există evaluări

- Cryostar Process Machinery PDFDocument0 paginiCryostar Process Machinery PDFJavad AmnianÎncă nu există evaluări

- Manual Champion Pl70Document32 paginiManual Champion Pl70De Luna BraulioÎncă nu există evaluări

- P300Document6 paginiP300abbas_mehdeÎncă nu există evaluări

- For Screw Compressor Minimum Pressure Valve Type MPVL65FH and MPVL65FHS PDFDocument2 paginiFor Screw Compressor Minimum Pressure Valve Type MPVL65FH and MPVL65FHS PDFСергей КолесниковÎncă nu există evaluări

- Unloader Valve in Reciprocating Compressor Capacity ControlDocument8 paginiUnloader Valve in Reciprocating Compressor Capacity Controlfri_13th100% (1)

- GHH PDFDocument14 paginiGHH PDFpricopdanielÎncă nu există evaluări

- Rotina de Inspeção em ManutençãoDocument11 paginiRotina de Inspeção em ManutençãoBrender VictorÎncă nu există evaluări

- Брошюра - Осушители BdDocument12 paginiБрошюра - Осушители Bdairpart100% (1)

- Engineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsDocument126 paginiEngineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsAfzaalUmair100% (1)

- 11 Compressor Terms Acronyms Units of MeasureDocument8 pagini11 Compressor Terms Acronyms Units of MeasureLe Anh DangÎncă nu există evaluări

- Hankison - Secador Adsorcion HPD 300-3200 SCFM - EsDocument8 paginiHankison - Secador Adsorcion HPD 300-3200 SCFM - EsrobertohugosanchezÎncă nu există evaluări

- HOS (Heavy Oilfield Separable Compressor) BrochureDocument6 paginiHOS (Heavy Oilfield Separable Compressor) BrochureakamalapuriÎncă nu există evaluări

- Centac: C1000 Planning & Installation ManualDocument35 paginiCentac: C1000 Planning & Installation ManualDam SztÎncă nu există evaluări

- HOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesDocument8 paginiHOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesJose Luis RattiaÎncă nu există evaluări

- Zeks Compressed Air SolutionsDocument39 paginiZeks Compressed Air SolutionsChristian MabayaÎncă nu există evaluări

- Nuovo Pignone Reciprocating Compressor ManualDocument18 paginiNuovo Pignone Reciprocating Compressor ManualVICTOR HUGO ORTIZ MOSCOSO50% (2)

- Design Features of The Boge Air Compressor S-SeriesDocument9 paginiDesign Features of The Boge Air Compressor S-SeriesAir Repair, LLC100% (1)

- ZR - ZT 110-900 BrochureDocument24 paginiZR - ZT 110-900 BrochureSreenivasÎncă nu există evaluări

- Centrifugal Aftermarket Solutions BrochureDocument8 paginiCentrifugal Aftermarket Solutions BrochureJose Renato MendesÎncă nu există evaluări

- Oil Free Centrifugal CompressorDocument24 paginiOil Free Centrifugal CompressorAnonymous zMWvcT0% (1)

- A-VIP Compressor BrochureDocument6 paginiA-VIP Compressor BrochureAvrinFakherniaÎncă nu există evaluări

- 1 1Document9 pagini1 1Ankush SehgalÎncă nu există evaluări

- Design and Analysis of Centrifugal CompressorsDe la EverandDesign and Analysis of Centrifugal CompressorsÎncă nu există evaluări

- Reciprocating Compressors:: Operation and MaintenanceDe la EverandReciprocating Compressors:: Operation and MaintenanceEvaluare: 4 din 5 stele4/5 (7)

- Technical Topic Procedure For Flushing Oil-Flooded Rotary Screw Air CompressorsDocument2 paginiTechnical Topic Procedure For Flushing Oil-Flooded Rotary Screw Air Compressorsdhavit wijayantoÎncă nu există evaluări

- Ingersoll Rand TS10-TS3000 PDFDocument65 paginiIngersoll Rand TS10-TS3000 PDFSergiSerrano100% (2)

- DXR75 1000 June 1996Document2 paginiDXR75 1000 June 1996SergiSerranoÎncă nu există evaluări

- RBS 85Document1 paginăRBS 85SergiSerranoÎncă nu există evaluări

- L90RS-L132RS Variable Speed Rotary Screw Compressor BrochureDocument2 paginiL90RS-L132RS Variable Speed Rotary Screw Compressor BrochureSergiSerranoÎncă nu există evaluări

- AtlasDocument318 paginiAtlasFArras FakhiraÎncă nu există evaluări

- Operators Manual - 80447097Document36 paginiOperators Manual - 80447097SergiSerranoÎncă nu există evaluări

- 3304 and 3306 Industrial and Generator Engine Set Sebu5779-02Document63 pagini3304 and 3306 Industrial and Generator Engine Set Sebu5779-02SergiSerrano100% (2)

- Modular Drive Spares May 2014Document3 paginiModular Drive Spares May 2014SergiSerrano100% (1)

- GD Credit Application 2012 PDFDocument1 paginăGD Credit Application 2012 PDFSergiSerranoÎncă nu există evaluări

- Open Conductor Bar PDFDocument48 paginiOpen Conductor Bar PDFSergiSerranoÎncă nu există evaluări

- Compair Hydrovane hv30-45 PDFDocument34 paginiCompair Hydrovane hv30-45 PDFSergiSerranoÎncă nu există evaluări

- US Seal MFG Catalog 2012Document236 paginiUS Seal MFG Catalog 2012hufuents-1Încă nu există evaluări

- PaosclDocument3 paginiPaosclSergiSerranoÎncă nu există evaluări

- Airotronics-050 TGMLDocument2 paginiAirotronics-050 TGMLSergiSerranoÎncă nu există evaluări

- LRS90 - 000 LRS 07 22Document12 paginiLRS90 - 000 LRS 07 22SergiSerranoÎncă nu există evaluări

- Aeon 9000spDocument2 paginiAeon 9000spSergiSerranoÎncă nu există evaluări

- Filters: General Purpose Particulate / Coalescing Filter - Grade Ig High Efficiency Coalescing Filter - Grade IhDocument1 paginăFilters: General Purpose Particulate / Coalescing Filter - Grade Ig High Efficiency Coalescing Filter - Grade IhSergiSerranoÎncă nu există evaluări

- Electrical Diagnostic Check ListDocument1 paginăElectrical Diagnostic Check ListSergiSerranoÎncă nu există evaluări

- 2013CatalogCompressed PDFDocument408 pagini2013CatalogCompressed PDFSergiSerranoÎncă nu există evaluări

- Danfoss Temperature Pressure SwitchesDocument48 paginiDanfoss Temperature Pressure SwitchesSergiSerranoÎncă nu există evaluări

- Cat PHBRCHVDocument20 paginiCat PHBRCHVlacrimosa881021Încă nu există evaluări

- Cable Size Calculations SpreadsheetDocument4 paginiCable Size Calculations Spreadsheetbhavin24uÎncă nu există evaluări

- Newvhdl Syllabus (It&Cse)Document2 paginiNewvhdl Syllabus (It&Cse)Mude Kishore NaikÎncă nu există evaluări

- Machine Fault Detection Using Vibration Signal Peak DetectorDocument31 paginiMachine Fault Detection Using Vibration Signal Peak Detectordavison coyÎncă nu există evaluări

- Best Approach: Compound AngleDocument8 paginiBest Approach: Compound AngleAbhiyanshu KumarÎncă nu există evaluări

- Asme Ix Test 1Document8 paginiAsme Ix Test 1RedzuanÎncă nu există evaluări

- C V RamanDocument8 paginiC V RamanJayesh KomalwarÎncă nu există evaluări

- Mit BBM (Ib), Ipm-Session 2.4Document32 paginiMit BBM (Ib), Ipm-Session 2.4Yogesh AdhateÎncă nu există evaluări

- Lecture - 11 Analysis and Design of Two-Way Slab Systems (Two-Way Slab With Beams & Two Way Joist Slabs) PDFDocument64 paginiLecture - 11 Analysis and Design of Two-Way Slab Systems (Two-Way Slab With Beams & Two Way Joist Slabs) PDFNafees KhanÎncă nu există evaluări

- Task 4 Finite Element MethodDocument7 paginiTask 4 Finite Element MethodMohd Azizee Bin SukorÎncă nu există evaluări

- Design of Water Supply System-High Rise BLDGDocument108 paginiDesign of Water Supply System-High Rise BLDGcris bunagÎncă nu există evaluări

- High Pressure Jet Grouting in TunnelsDocument8 paginiHigh Pressure Jet Grouting in TunnelsSandeep AggarwalÎncă nu există evaluări

- PTP Symmetric Om FNLDocument8 paginiPTP Symmetric Om FNLn888nÎncă nu există evaluări

- Measures of Central Tendency: Mean Median ModeDocument20 paginiMeasures of Central Tendency: Mean Median ModeRia BarisoÎncă nu există evaluări

- Unit 6 - EarthingDocument26 paginiUnit 6 - Earthinggautam100% (1)

- Gantt ChartDocument4 paginiGantt ChartSyed FaridÎncă nu există evaluări

- Ruby On Rails 3 Cheat SheetDocument7 paginiRuby On Rails 3 Cheat SheetJarosław MedwidÎncă nu există evaluări

- Demag KBK Alu Enclosed Track SystemDocument2 paginiDemag KBK Alu Enclosed Track SystemMAGSTÎncă nu există evaluări

- Basic Use of Datum Plane in Creo ParametricDocument8 paginiBasic Use of Datum Plane in Creo ParametricKartik BhararaÎncă nu există evaluări

- Analiza Procesa Ocenjivanja Na Časovima Matematike - BaucalDocument22 paginiAnaliza Procesa Ocenjivanja Na Časovima Matematike - BaucalНевенка ЈовановићÎncă nu există evaluări

- Awards Gold Medals Grade VIDocument11 paginiAwards Gold Medals Grade VIBernadeth Escosora DolorÎncă nu există evaluări

- 15Document20 pagini15Allen Rey YeclaÎncă nu există evaluări

- Ap Unit 1 NotesDocument42 paginiAp Unit 1 NotesDhruv GoyalÎncă nu există evaluări

- Form in MusicDocument8 paginiForm in MusicAndri KurniawanÎncă nu există evaluări

- Physics Sample Question PaperDocument9 paginiPhysics Sample Question PaperVarsha SharmaÎncă nu există evaluări

- Robot Sensors and TransducersDocument176 paginiRobot Sensors and TransducerssakthivelÎncă nu există evaluări

- Hydrocarbon RecoveryDocument29 paginiHydrocarbon RecoveryAlekhya BandaruÎncă nu există evaluări

- Organic Chemistry - Some Basic Principles and Techniques-1Document195 paginiOrganic Chemistry - Some Basic Principles and Techniques-1aditya kumar Agarwal100% (1)

- TM1 Rules White Paper Best Practice RulesDocument22 paginiTM1 Rules White Paper Best Practice RulesMax ChenÎncă nu există evaluări

- SOFARSOLAR ModBus-RTU Communication ProtocolDocument22 paginiSOFARSOLAR ModBus-RTU Communication ProtocolВячеслав ЛарионовÎncă nu există evaluări

- MMMDocument34 paginiMMMVaibhav Vithoba NaikÎncă nu există evaluări