Documente Academic

Documente Profesional

Documente Cultură

1 s2.0 S0898122112000314 Main PDF

Încărcat de

Maroju Santosh KiranDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 s2.0 S0898122112000314 Main PDF

Încărcat de

Maroju Santosh KiranDrepturi de autor:

Formate disponibile

Computers and Mathematics with Applications 64 (2012) 102114

Contents lists available at SciVerse ScienceDirect

Computers and Mathematics with Applications

journal homepage: www.elsevier.com/locate/camwa

Indirect vector control of a squirrel cage induction generator

wind turbine

Jos Luis Domnguez-Garca a, , Oriol Gomis-Bellmunt a,b , Llus Trilla-Romero a ,

Adri Junyent-Ferr b

a

Catalonia Institute for Energy Research (IREC), Jardins de les Dones de Negre 1, 2a . 08930 Sant Adri de Bess, Barcelona, Spain

Centre dInnovaci Tecnolgica en Convertidors Esttics i Accionaments (CITCEA-UPC), Universitat Politcnica de Catalunya UPC, Av. Diagonal, 647, Pl. 2. 08028

Barcelona, Spain

article

info

Article history:

Received 9 March 2011

Received in revised form 9 January 2012

Accepted 9 January 2012

Keywords:

Back-to-back converter

Low voltage ride through

Squirrel cage induction generator (SCIG)

Torque regulation

Vector control

Wind power generation

abstract

The paper deals with a squirrel cage induction generator connected to the grid through

a back-to-back converter driven by vector control. The stator-side converter controls the

generator torque by means of an indirect vector control scheme. In order to reduce the

system dependance from the mechanical system behavior, a torque loop is used in the

current reference calculations. Moreover, a torque control is included in the stator-side

control in order to overcome a voltage dip fault. The grid-side converter controls the DC

bus voltage and the reactive power in order to accomplish the grid codes. The proposed

control strategy is evaluated by the simulation of different scenarios such as variable wind

R

speed and different levels of voltage sags by means of Matlab/Simulink

.

2012 Elsevier Ltd. All rights reserved.

1. Introduction

Wind power is one of the most promising renewable energy sources due to the progress experienced in the last decades.

The increasing penetration level of wind energy (Denmark 20%, Portugal 15%, Spain 14% and Germany 9% [1]) has led to the

establishment of grid codes. Among these requirements, voltage sag ride through capability is mandatory [25].

Wind farms can be composed of fixed-speed or variable-speed generators, and also by induction (doubly-fed and squirrelcage) or synchronous machines (permanent magnets and wound rotor). Squirrel cage induction generators (SCIG) have been

used as fixed-speed generators, or for micro-generation [6,7]. However, they can also be implemented as a variable-speed

generators, introducing full rate power converter between grid and generators [8]. The main advantages of using squirrel

cage generator topology are low cost, good reliability and robustness. Its main drawback compared to permanent magnets

synchronous generators (PMSG) is the difficulty to build a multipolar squirrel cage induction generator.

SCIG control can be implemented using different approaches: scalar or vector control, direct or indirect field orientation,

rotor or stator field orientation [911]. Scalar control [12] is simple to implement, but easily unstable. A better performance

is obtained with direct vector control, requiring sensed flux values to define and control the field orientation references.

This however means that it is necessary to use hall-effect sensors, which, in practise, is problematic, and expensive, [13,14].

The indirect field-orientation method is more sensitive to the machine parameters but removes the necessity of direct flux

sensing [15,16].

This paper proposes an indirect vector control strategy less sensitive from the machine parameters than the conventional

scheme [8]. Voltages are referred to a qd synchronous frame, aligned with the rotor flux vector, for the stator-side converter.

Corresponding author. Tel.: +34 933562615; fax: +34 933563802.

E-mail addresses: jldominguez@irec.cat, dominguez.garcia.joseluis@gmail.com (J.L. Domnguez-Garca).

0898-1221/$ see front matter 2012 Elsevier Ltd. All rights reserved.

doi:10.1016/j.camwa.2012.01.021

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

103

Nomenclature

Symbols

Flux linkage

Torque

Angle

Angular velocity

Slip

Resistance

Inductance

Mutual inductance

s

r

L

M

Superscripts

Set point

Synchronism reference

e

Subscript

s

l

z

d

q

Stator

Grid-side converter

Grid

d-axis

q-axis

The grid-side converter is controlled by means of vector control strategy decoupling active and reactive power. The article

also analyzes the response of the system during faults, where the fault ride through is achieved.

This paper is organized as follows. In Section 2, the studied global system under study is described and analyzed. The

control scheme is presented in Section 3. The torque regulation, in order to overcome the fault ride through, is explained in

Section 4. In Section 5, the proposed control is validated by means of different simulation. Conclusions are summarized in

Section 6.

2. Squirrel cage induction generator with full power converter

The system being analyzed can be seen in Fig. 1. It is important to point out that there are more elements, e.g. a

transformer and a wind farm grid, which are not included in the present paper.

The squirrel cage induction generator (SCIG) is attached to the wind turbine by means of a gearbox. The SCIG stator

windings are connected to a back to back full power converter.

The wind turbine is responsible for transforming wind power into kinetic energy. Wind Turbine power can be determined

by using,

1

cp A vw3 .

(1)

2

The gearbox provides speed and torque conversions from a rotating power source to another device, using gear ratios. In

the analyzed system, it is described by means of a one mass model which complies with:

Pw t =

d

dt

gen =

t =

g t

Jtot

(2)

Kgear

t = Kgear gen

where t and gen are the turbine and generator angular speeds, respectively.

For the machine equations, assuming that the stator and rotor windings are sinusoidal and symmetrical [17,18], the

relation between voltage and currents on a synchronous reference qd can be written as:

vsq

Ls

vsd 0

0 = M

0

Ls

0

M

M

0

Lr

0

0

isq

rs

M d isd Ls e

+

0 dt irq 0

Lr

ird

sM e

Ls e

rs

sM e

0

0

M e

rr

sLr e

M e

isq

0 isd

sLr e irq

rr

ird

(3)

104

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

Fig. 1. General system scheme.

Fig. 2. Back to back converter.

where e is the value of synchronous angular speed, which can be obtained by slip + r , where slip is the slip angular

speed, and r is the rotor angular speed (gen P), and P is the pole pair number.

Linkage fluxes can be written as

sq

Ls

sd 0

= M

rq

rd

0

0

Ls

0

M

M

0

Lr

0

0

isq

M isd

.

0 irq

Lr

ird

(4)

The torque can be expressed as:

3

P M (isq ird isd irq ).

2

The active and reactive power yields:

m =

Qs =

Ps =

3

2

3

vsq isd vsd isq

(5)

(6a)

vsq isq + vsd isd .

(6b)

2

The back to back converter is composed of the grid-side converter connected to the grid and the stator-side converter

connected to the stator windings (Fig. 2). Both sides are linked by a DC bus.

The DC bus voltage can be expressed as

E = E0 +

1

C

iDCE dt = E0 +

0

1

C

(iDCl iDCs )dt .

(7)

The grid system equations in a synchronous reference frame can be written as:

vzq

v

rl

lq =

vzd

vld

Ll e

Ll e

rl

ilq

L

+ l

ild

0

0

Ll

d

dt

ilq

.

ild

(8)

Active and reactive power, provided by the grid-side converter, can be expressed as:

Ql =

Pl =

3

2

3

2

vzq ild vzd ilq

vzq ilq + vzd ild .

(9a)

(9b)

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

105

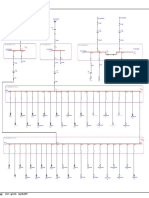

Fig. 3. General control scheme.

3. Control scheme

The electrical control of the converter can be achieved by using different kinds of current loops [19], for both sides of

the back to back converter, the references of the current loops through a vector control. As previously described, the power

converter can be treated separately, as two different converters (stator-side and grid-side).

For a stator-side converter, an indirect field oriented control is suggested. For the grid-side converter, vector control

[2022,6] is used.

The converter set points are established by the so-called high-level controller, as it appears drawn in Fig. 3. This uses the

wind speed and the grid reactive power requirements, in order to determine the optimum turbine pitch angle, the torque

and the reactive power set points referenced to the converter.

The stator-side converter controls the torque, while the grid-side converter controls the dc voltage and the grid-side

reactive power.

3.1. Stator-side converter

In the stator-side converter, the referenced torque and rotor flux determine the current references which determine the

voltages to be applied.

3.1.1. Reference calculation

By referencing the voltage to the qd synchronous frame aligned with the rotor flux vector, the q-component of the rotor

flux is zero (qr = 0).

Then, the d-component of the rotor flux is always at the maximum, it can be ensured that dtd dr and dtd qr are zero. These

hypotheses are important in order to relate reference values (torque and rotor flux) with the current references.

Satisfying the condition for proper orientation and knowing which are the reference values, the current references can

be calculated as follows:

rr M

ieds .

(10)

r r + Lr s

Both approaches allow the relation of the d-component of the rotor flux with the d-component of the stator current. For

simplification, calculations have been used for the first one. Then, the d-component of the stator current reference is found

through the d-component of the rotor flux reference.

edr = M ieds

edr .

(11)

M

The d-component of the rotor flux reference, which is the rotor flux reference, can be determined with the following

equation:

ieds =

edr =

Un

fn

(12)

where Un is the nominal voltage of the converter, which is limited by the DC bus voltage, and determined by the machine.

fn is the nominal frequency (50 Hz).

106

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

Fig. 4. Stator control scheme.

In order to determine the q-component of the stator current reference, instead of using a common calculation structure,

as appeared e.g in [23,24], a comparison between ideal and actual values of torque is implemented, and this error signal is

regulated by means of a PI controller. Its output is the q-component of the stator current reference. Thereby, the current

reference calculations are decoupled, allowing both current control loops to work independently.

The actual torque value is calculated by means of:

Te =

Ps

(13)

gen

where gen is the generator rotational speed and the stator active power (Ps ) can be calculated, on abc reference, as follows:

Ps = vsa isa + vsb isb + vsc isc .

(14)

The reference torque is determined as the optimum value that can be gained from the turbine [21].

Te =

Ps

(15)

gen

where Ps can be calculated as:

1

3

cpopt vw

(16)

ind .

2

This way of finding the reference torque gives more independence from the mechanical system (turbine, shaft and gearbox)

to the control.

The use of the equations introduced before in the d-axis rotor voltage equation can be shown as:

Ps =

vqr = rr iqr + qr (e r )dr .

dt

=0

(17)

=0

Substituting the chosen equation of (10) in (17) result in:

slip

= e r =

rr

Lr

ieqs

ieds

(18)

By integrating (18), the angle of rotation is determined, which will be used it to implement and reverse the Park

Transformation.

e =

e dt =

r + slip dt = r + slip .

(19)

Fig. 4 depicts the block diagram of the indirect rotor field-oriented control, which is based upon a torque loop,

(11) and (18).

3.1.2. Current loops

The current loop control can be implemented by means of the following stator voltage equations and by the assumption

of the hypothesis which were made before [23,18].

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

107

Rotor voltage equations can be written as:

vrq = rr irq + se rd +

vrd = rr ird + se rq +

d

dt

d

dt

rq

(20a)

rd .

(20b)

Considering the assumptions made, rq = 0, dtd rq = 0 and dtd rd = 0, and due to the fact that the generator is a squirrel

cage machine, rotor voltages are zero. Therefore, Eqs. (20a) and (20b) can be written as:

0 = rr irq + se rd

(21a)

0 = rr ird

(21b)

where it is clear that the d-component of the rotor current is zero (ird = 0).

In addition, as rq = 0 from the q-component rotor linkage flux equation (4), the following relationship can be obtained:

irq =

M

Lr

isq .

(22)

Hence, stator voltage equation (3) can be written as:

M2

d

vsq = rs isq + Ls e isd + Ls

isq

Lr

vsd = rs isd e Ls

M2

Lr

(23a)

dt

isq + Ls

d

dt

isd .

(23b)

Based on these equations, the state linearization feedback is described in order to study and analyze how to close the

current loop.

State linearization feedback.

The current control can also be implemented by means of a state linearization feedback of the Eq. (23), as it is shown in

the following equation:

vsq

vsd

vlq Ls e isd

M2

=

vsd Ls

e isq

(24)

Lr

where

vsq and

vsd are the voltage control values. The decoupling can be described as:

d

dt

isq

isd

rs

L M2

s

L

r

=

0

isq

L

s

rs isd

Ls

M

Lr

vsq .

vsd

1

(25)

Ls

The control loops are made by means of a comparison of the reference value and its real value. Their error signals are

regulated by a PI controller, the constants of which are tuned, using IMC, as described later.

3.2. Grid-side converter

The control of the electrical system of the grid is configured in order to control the DC bus voltage and the reactive power

which is consumed or supplied by the converter of the grid side. The DC bus voltage reference and the grid voltage level

are used to determine the current references which determine the voltages to be applied on the grid side. Fig. 5 depicts the

block diagram of grid side control.

3.2.1. Reference calculation

The q-axis may be aligned to the grid voltage, allowing active and reactive decoupled control.

In order to accomplish the reactive power delivery during voltage disturbances with the grid operator requirement, the

reactive output current is defined as function of the grid voltage level, i.e. when there is no voltage sag the reactive power

reference is set as zero.

The active power, which is responsible for the evolution of the dc bus, is controlled by the ilq . A linear controller is usually

designed to control the dc bus voltage and to keep it constant.

ilq =

2 PE

3 vzq

(26)

108

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

Fig. 5. Grid control scheme.

The DC link voltage behavior is defined by the Eq. (7), their current values iDCs and iDCl can be easily calculated

iDCs =

iDCl =

iabc

vsabc

s

(27a)

E

iabc

vlabc

l

E

(27b)

How to define the parameters of the PI controller for the Dc Bus control loop is explained in [21]. Then an active power

reference PE is defined as control loop output.

3.2.2. Current loops

The current control is implemented by the following state linearization feedback:

vlq

vlq + vzq Ll g ild

=

vld

vld + Ll g ilq

(28)

where

vlq and

vld are the voltage control values. The decoupling can be described as:

d

dt

ilq

ild

r

l

Ll

=

0

ilq

+ Ll

rl i

ld

Ll

vlq

.

1

vld

(29)

Ll

3.3. Current controller tuning

Controllers have been designed by using the so-called internal model control (IMC) [25]. The parameters of a PI controller,

with the aim to obtain a desired bandwidth , which appear due to a low-pass filter included by the IMC, are:

Kp = L x

Ki = r x

(30)

where the subscript x represents both stator and rotor.

4. Fault ride through

During a low voltage fault, the DC bus voltage tends to increase as the grid-side converter is not able to deliver all the

active power which comes from the stator-side converter. Therefore, in order to regulate and to control the DC bus voltage,

it is necessary to reduce the active power transferred by the generator. This can be done by means of a crowbar or a chopper

or by appropriately controlling the reference torque.

ref

= a opt

.

(31)

It is proposed to reduce the torque reference value, multiplying it by an a value, which is determined by the DC bus level, as

seen in (32).

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

Table 1

Mechanical parameters (S.I units).

Jgen

100

Jturb

5106

R

33

Kgear

98.625

Table 2

Electrical parameters (S.I units).

rs

1.1 103

rr

1.3 103

Ls

3.0636 103

Lr

3.0686 103

rl

0.01

Ll

5.35 104

C

15.3 103

P

2

M

2.9936 103

(a) Input wind speed variations.

(b) System torque evolution.

(c) Speed of the turbine.

(d) Active power system evolution.

Fig. 6. Representation of the turbine and stator-side converter variables during a wind speed variation.

109

110

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

(e) d-components of the stator current.

(f) q-components of the stator current.

Fig. 6. (continued)

This control presents a hybrid control strategy character since it mixes a discrete and a continuous component, where

the discrete part of the control, presented in (32), makes the decision and switches the control strategy, meanwhile the

continuous part works according to the new rules.

a=1

E Elim1

a=1

Elim2 Elim1

a=0

E Elim1

Elim1 < E < Elim2

Elim2 E

(32)

It is important to remark that the excess of power will be stored as kinetic energy in the rotating mass, this implies an

increase of the rotational turbine speed.

5. Simulation results

The presented model has been exposed to different scenarios, changing its simulation conditions as wind speed variations

and voltage sags.

The mechanical and the electrical parameters [26,27], can be seen in Tables 1 and 2.

5.1. Wind speed variation

During the first scenario, the system has been exposed to a real wind speed profile, in order to observe the behavior of

the SCIG and its control. These variations can be seen in the Fig. 6(a).

5.1.1. Stator-side converter

In Fig. 6(b) it is possible to observe how the system evolves guided by the reference value. It is important to observe how

the generator torque instantly follows the reference value. That means, it is possible to choose the operational point or follow

the wind variation. Thanks to this fast control, the mechanical system, mainly the turbine, is able to quickly reach a steady

state. However, as can be seen in Fig. 6(c), the turbine speed always decreases due to the wind speed variation, despite the

wind speed variation appearing filtered on the turbine by its own inertia. In Fig. 6(d), the Active Power value evolution is

represented, which presents almost the same shape (just a little damped) as the wind profile. This damping is due to the

multiplication of the mechanical rotation speed and the generator torque. As the generator torque almost mimics the wind

shape, the damping is due to the turbine speed and its inertia, as explained before. In Fig. 6(e) and (f), the components of the

stator current, the q-component and d-component, can be seen. The d-component remains constant because it is calculated

by means of a flux open loop, where the flux reference is set constant. The q-component, on the other hand, constantly

changes because of its dependence on the torque variation, as it searches for a steady state.

5.1.2. Grid-side converter

As can be observed in Fig. 7(a), the Dc bus voltage remains constant over the reference value. It is important to remark

that the error is lower than 0.001%. From Fig. 7(a) it can be concluded that the Dc bus is able to transfer all power delivered

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

111

(a) Dc bus voltage.

(b) d-components of the grid-side converter current.

(c) q-components of the grid-side converter current.

(d) Grid-side reactive power.

Fig. 7. Representation of the grid-side converter during a wind speed variation.

by the stator-side converter. In Fig. 7(b) and (c) it can be seen how the q-component varies, more or less, like the active

power transferred, and the d-component remains constantly zero, which implies zero reactive power, as can be found in

Fig. 7(d). The d-component is set zero because of the grid operator requirement.

5.2. Voltage sags

In this scenario, the system has been exposed to two different voltage sags in order to see the response of the control

to these new states. In this case, the wind speed has been assumed as a constant, because a voltage dip is shorter than 1 s.

At least this is the maximum time during which a wind mill should be kept connected to the grid when there is a voltage

fault. Therefore it is reasonable to make this assumption. The simulated voltage dips have a depth of 50% and 99% from the

normal voltage grid, respectively (Fig. 8(a)).

5.2.1. Grid-side converter

As it is shown in Fig. 8(b) and (c), it can be seen how the d-component is following its reference, which is determined by

the grid operator requirement of reactive power output. The q-component is increased until the current saturation of the

grid-side converter trying to deliver as much active power as is transferred by the stator-side converter. In Fig. 8(d), it can

112

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

(a) abc components grid voltage sag.

(b) q-component grid-side converter current.

(c) d-component grid-side converter current.

(d) Dc bus voltage.

(e) Grid-side reactive power delivery.

Fig. 8. Representation of the variables of the grid-side converter during voltage disturbances.

be observed how the bus voltage increases because the voltage sag has led to a current saturation. Then, the dc bus tries

to transfer all active power, and when it is not able to so, it raises its voltage value storing the excess of electrical power

into the dc link. When the voltage fault disappears, it can be seen how the dc bus is discharged and the transferred power

is optimal. In addition, it can be seen how the torque regulation, implemented to avoid bus saturation, works. This control

guides the bus voltage to a secure zone and holds the bus voltage there until the sag is over. Moreover, in Fig. 8(e) it can be

observed how the wind turbine is accomplishing the reactive power delivery ordered by grid codes.

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

113

(a) Active power during different voltage sags.

(b) Generator torque and Reference Torque during voltage sags.

(c) Evolution of the rotation speed of the turbine during the faults.

(d) d-component stator current.

(e) q-component stator current.

Fig. 9. Representation of the variables of the stator-side converter during voltage disturbances.

5.2.2. Stator-side converter

The active power has to be reduced due to the grid faults, as can be seen in Fig. 9(a), because the network is not able

to transfer all power that can be generated, and it is necessary protect the system. In Fig. 9(b) it can be observed how the

generator torque during the fault ride through changes to a lower value, and after the faults it is a little transient. The torque

controller guides the torque value to a new stable and safe operational point. In Fig. 9(c) it can be observed, how during the

114

J.L. Domnguez-Garca et al. / Computers and Mathematics with Applications 64 (2012) 102114

voltage dip, the turbine increases its speed in order to store the excess of obtained power, in Kinetic Energy. In Fig. 9(d) it can

be observed how the d-component is constantly following the reference, as explained before. This is due to the constant flux

value. In addition, in Fig. 9(e) the q-component shows some reductions, this fact implies that it follows its steady state. During

the voltage disturbances, the reduction of the q-component is produced due to the limitation of active power transferred to

the grid by the system.

6. Conclusion

This paper presents a control technique in order to deal with a SCIG connected to the grid through a full power converter.

Both stator-side and grid-side are taken into consideration. The control schemes used in each converter have been detailed.

The vector control scheme enables the system to control the stator-side converter without a flux sensor inside the machine.

This fact assures fewer mechanical problems during the lifetime of the machine. The indirect vector control proposed for the

stator-side converter is less dependant from machine parameters than the conventional indirect vector control, introducing

to the system a faster response. Moreover, the proposed scheme decouples the current reference calculations. In addition,

the inclusion of the torque regulator into the stator-side converter control, allows the eradication of an extra element of

the typical wind turbine, usually a chopper or a crowbar, in order to protect the machine. The control strategy has been

R

satisfactorily evaluated by means of Matlab/Simulink

simulations.

References

[1] WWEA, World Wind Energy Report 2009, Tech. Rep., World Wind Energy Association, 2010.

[2] M. Tsili, C. Patsiouras, S. Papathanassiou, Grid code requirements for large wind farms: a review of technical regulations and available wind turbine

technologies, in: European Wind Energy Conference & Exhibition, Brussels, 2008.

[3] M. de Industria Turismo y Comercio: Secretaria de Estado de Energa, Ch. Procedimientos de Operacin 12.3, vol. BOE num 254, 2006, pp. 3701737019.

[4] A.D. Hansen, G. Michalke, Fault ride-through capability of DFIG wind turbines, Renewable Energy 32 (9) (2007) 15941610.

doi:10.1016/j.renene.2006.10.008.

[5] A. Sumper, O. Gomis-Bellmunt, A. Sudri-Andreu, R. Villafafila-Robles, J. Rull-Duran, Response of fixed speed wind turbines to system frequency

disturbances, IEEE Transactions on Power Systems 24 (2009) 181192.

[6] R. Teodorescu, Flexible control of small wind turbines with grid failure detection operating in stand-alone and grid-connected mode, IEEE Transactions

on Power Electronics 19 (2004) 13231332.

[7] A. Sikorski, A. Kuzma, Cooperation of induction squirrel-cage generator with grid connected ac/dc/ac converter, Bulletin of the Polish Academy of

Sciences; Technical Sciences 57 (2009) 317322.

[8] N. Caliao, Dynamic modelling and control of fully rated converter wind turbines, Renewable Energy 36 (8) (2011) 22872297.

[9] M. Imecs, A survey of speed and flux control structures of squirrel-cage induction motor drives, Tech. Rep., Acta Universitatis Sapientiae Electrical and

Mechanical Engineering, 2009.

[10] J. Holtz, Sensorless control of induction motor drives, Proceedings of the IEEE 90 (2002) 13591394.

[11] M. Imecs, C. Szab, J.J. Incze, Stator-field-oriented control of the variable-excited synchronous motor: numerical simulation, in: 7th International

Symposium of Hungarian Researchers on Computational Intelligence, Budapest, Hungary, 2006.

[12] V. Vongmanee, Emulator of wind turbine generator using dual inverter controlled squirrel-cage induction motor, in: The Eighth International

Conference on Power Electronics and Drive Systems, Taipei, Taiwan, 2009.

[13] R. Leidhold, G. Garca, M.I. Valla, Field-oriented controlled induction generator with loss minimization, IEEE Transactions on Industrial Electronics 49

(2002) 147156.

[14] J. Faria, E. Margato, M. Resende, Self-excited induction generator for micro-hydro plants using water current turbines type, in: Proceedings INTELEC05,

2005, pp. 107112.

[15] C.-M. Ong, Dynamic Simulation of Electric Machinery using Matlab/Simulink, Prentice Hall, 1998.

[16] P.C. Krause, O. Wasynczuk, S.D. Sudhoff, Analysis of Electric Machinery and Drive Systems, second ed., IEEE Press, 2002.

[17] P.C. Krause, Analysis of Electric Machinery, McGraw-Hill, 1986.

[18] O. Gomis-Bellmunt, A. Junyent-Ferre, A. Sumper, J. Bergas-Jane, Ride-through control of a doubly fed induction generator under unbalanced voltage

sags, IEEE Transactions on Energy Conversion 23 (2008) 10361045.

[19] J. Bergas-Jane, Control del motor dinducci considerant els lmits del convertidor i del motor, Ph.D. Thesis, Universitat Politcnica de Catalunya, 2000.

[20] B.K. Bose, Modern Power Electronics and AC Drives, Prentice Hall PTR, 2001.

[21] A. Junyent-Ferr, Modelitzaci i control dun sistema de generaci elctrica de turbina de vent, Masters Thesis, ETSEIB-UPC, 2007.

[22] M. Molinas, B. Naess, W. Gullvik, T. Undeland, Cage induction generators for wind turbines with power electronics converters in the light of the new

grid codes, in: European Conference on Power Electronics and Applications, 2005.

[23] O. Anaya-Lara, N. Jenkins, J. Ekanayake, P. Cartwright, M. Hughes, Wind Energy Generation: Modelling and Control, Wiley, 2009.

[24] J.L. Domnguez-Garca, O. Gomis-Bellmunt, L. Trilla-Romero, A. Junyent-Ferr, Vector control of squirrel cage induction generator for wind power, in:

International Conference on Electrical Machines in Rome, 2010.

[25] L. Harnefors, H.-P. Nee, Model-based current control of ac machines using the internal model control method, IEEE Transactions on Industry

Applications 34 (1) (1998) 133141. doi:10.1109/28.658735.

[26] J.G. Slootweg, Reduced-order modelling of wind turbines, in: Wind Power in Power Systems, Wiley, 2005, pp. 555585.

[27] Y.X. Dafeng Fu, Study on linear dynamic model and analysis of operating characteristics of high-power vscf wind energy conversion system, in: World

Non-Grid-Connected Wind Power on Energy Conference.

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Bhartiya Pavithra Punya KshetraluDocument81 paginiBhartiya Pavithra Punya KshetraluMaroju Santosh KiranÎncă nu există evaluări

- Exercise PDFDocument17 paginiExercise PDFMaroju Santosh KiranÎncă nu există evaluări

- CH 13 PDFDocument4 paginiCH 13 PDFMaroju Santosh KiranÎncă nu există evaluări

- Credits Periods Exam Hrs. Exam Marks Total Marks Theory Tutorial LabDocument6 paginiCredits Periods Exam Hrs. Exam Marks Total Marks Theory Tutorial LabMaroju Santosh KiranÎncă nu există evaluări

- 2 PDFDocument324 pagini2 PDFMaroju Santosh KiranÎncă nu există evaluări

- 1 s2.0 S1876610213017268 Main PDFDocument10 pagini1 s2.0 S1876610213017268 Main PDFMaroju Santosh KiranÎncă nu există evaluări

- Electronic Instrumentation H S KalsiDocument652 paginiElectronic Instrumentation H S KalsiAjayChandrakar60% (10)

- Model-Based Predictive Direct Power Control of Doubly Fed Induction GeneratorsDocument11 paginiModel-Based Predictive Direct Power Control of Doubly Fed Induction GeneratorsMaroju Santosh KiranÎncă nu există evaluări

- 6448 3748 PDFDocument388 pagini6448 3748 PDFMaroju Santosh KiranÎncă nu există evaluări

- Sliding Mode Control For Second Order System PDFDocument9 paginiSliding Mode Control For Second Order System PDFMaroju Santosh KiranÎncă nu există evaluări

- 7 PDFDocument9 pagini7 PDFMaroju Santosh KiranÎncă nu există evaluări

- Rotor Voltage Dynamics in The Doubly Fed Induction Generator During Grid FaultsDocument13 paginiRotor Voltage Dynamics in The Doubly Fed Induction Generator During Grid FaultsMaroju Santosh KiranÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Introduction To Arduino PDFDocument13 paginiIntroduction To Arduino PDFAbhinav ChoudharyÎncă nu există evaluări

- ADC Eco Dry ES-50 COIN SpecificationsDocument2 paginiADC Eco Dry ES-50 COIN Specificationsmairimsp2003Încă nu există evaluări

- 5parameter ListDocument86 pagini5parameter ListIsradani MjÎncă nu există evaluări

- Tripping Report of Power PlantDocument3 paginiTripping Report of Power Plantmanohar kumarÎncă nu există evaluări

- 05-Fault Code List-WabcoDocument11 pagini05-Fault Code List-WabcoRaul GTÎncă nu există evaluări

- PRO Engines Instruction Manual ENGLISH V1 8 08 2019Document72 paginiPRO Engines Instruction Manual ENGLISH V1 8 08 2019jay biljanÎncă nu există evaluări

- GPSANT: GPS Antenna/Converter Unit: Key FeaturesDocument3 paginiGPSANT: GPS Antenna/Converter Unit: Key FeaturesShahrukh SaleemÎncă nu există evaluări

- Battery Sizing NicdDocument4 paginiBattery Sizing NicdMandip Pokharel0% (1)

- Module 3Document29 paginiModule 3Zaid AliÎncă nu există evaluări

- IRC5Document549 paginiIRC5HugoRamosÎncă nu există evaluări

- AmpLog Burr BrownDocument18 paginiAmpLog Burr Brownnapoleon_velasc3617Încă nu există evaluări

- TFM 94 SeriesDocument2 paginiTFM 94 Seriesluat1983Încă nu există evaluări

- JMUX Reference Manual Issue 4.0Document99 paginiJMUX Reference Manual Issue 4.0gradeli100% (2)

- UNIS OEM en 07-01Document8 paginiUNIS OEM en 07-01Razvan SasuÎncă nu există evaluări

- DRS2663B Amana Service ManualDocument72 paginiDRS2663B Amana Service ManualJohn TrippÎncă nu există evaluări

- NORDAC Compact Frequency Inverter: Operating InstructionsDocument38 paginiNORDAC Compact Frequency Inverter: Operating InstructionsNejra DedajićÎncă nu există evaluări

- Cat Switchgear - Eaton Consulting Application GuideDocument58 paginiCat Switchgear - Eaton Consulting Application GuideFélix VelascoÎncă nu există evaluări

- Voice Controlled SwitchDocument3 paginiVoice Controlled SwitchDarshan ThammaiahÎncă nu există evaluări

- View Topic - New VT Plus Series FX Loop - ValvetronixDocument5 paginiView Topic - New VT Plus Series FX Loop - ValvetronixStaticÎncă nu există evaluări

- Chapter - 1: Ece Department, AcoeDocument55 paginiChapter - 1: Ece Department, AcoeSana SriRamyaÎncă nu există evaluări

- Effect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IDocument6 paginiEffect of Shading On Photovoltaic Cell: Ekpenyong, E.E and Anyasi, F.IM VetriselviÎncă nu există evaluări

- Nibe GV HR110 Pliant 30 09 2013 enDocument4 paginiNibe GV HR110 Pliant 30 09 2013 envaliÎncă nu există evaluări

- Eee1001 Basic-Electrical-And-Electronics-Engineering Eth 1.0 37 Eee1001 PDFDocument2 paginiEee1001 Basic-Electrical-And-Electronics-Engineering Eth 1.0 37 Eee1001 PDFboomaÎncă nu există evaluări

- Transistor - Wikipedia, The Free EncyclopediaDocument16 paginiTransistor - Wikipedia, The Free EncyclopediaAlwyzz Happie RaamzzÎncă nu există evaluări

- LMV5 Tech Inst LV5-1000 Complete IndexedDocument374 paginiLMV5 Tech Inst LV5-1000 Complete Indexedjorge_people891931Încă nu există evaluări

- Vishay IRFP460APBF Datasheet PDFDocument8 paginiVishay IRFP460APBF Datasheet PDFkamel keddarÎncă nu există evaluări

- Mil HDBK 217F CN1Document37 paginiMil HDBK 217F CN1Bobby ChippingÎncă nu există evaluări

- NVIS 2040-80 20antennaDocument7 paginiNVIS 2040-80 20antennaChris VinceÎncă nu există evaluări

- One-Line Diagram - OLV1 (Short-Circuit Analysis)Document20 paginiOne-Line Diagram - OLV1 (Short-Circuit Analysis)Yogesh MittalÎncă nu există evaluări

- Analog DAN ModuelsDocument20 paginiAnalog DAN Moduelskzb003Încă nu există evaluări