Documente Academic

Documente Profesional

Documente Cultură

GU-379 Pipeline Emergency Repair Manual

Încărcat de

happale2002Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GU-379 Pipeline Emergency Repair Manual

Încărcat de

happale2002Drepturi de autor:

Formate disponibile

GU-379 Pipeline Emergency Repair Manual

Authorised For Issue --/--/----

Signed:........................................................................................

M. Zadjali, UIP

CFDH Pipelines

The following is a brief summary of the 5 most recent revisions to this document. Details of all revisions

prior to these are held on file by the issuing department.

Version No.

Rev. 4.0

Rev. 3.2

Date

Nov 2004

April 2001

Feb. 2001

Author

UEL/1

R Harris

OIP/31

UEL/1

Scope/ Remarks

GRP pipeline section added. Document re-formatted.

Electronic copy of Emergency Materials List (Appendix 13)

added.

Designed as BCD Guideline. Minor textual changes to adapt to

GU- format and reference updated. Technical content not

reviewed.

Rev. 3.1

Rev. 3

June 1999

OIP/4

Updated to reflect changes in responsibilities due to asset based

organisation and reformatted to new template.

Rev. 2

Mar 1995

AEF/631

Page 2 of 76

GU-379 Pipeline Emergency Repair Manual

Table Of Content

Authorised For Issue --/--/----.........................................................................................2

1.0

Introduction.....................................................................................................................

1.1

Objective.................................................................................................................5

1.2

Scope.......................................................................................................................5

1.3

Applicable Standards..............................................................................................6

1.4

Definitions and Abbreviations................................................................................6

1.5

Distribution/Target Audience..................................................................................7

1.6

Document Structure................................................................................................7

1.7

Review & Improvement..........................................................................................8

2.0

Emergency Repairs for Carbon Steel Pipelines...........................................................

2.1

Scope.......................................................................................................................9

2.2

Types of defects and its causes................................................................................9

2.3

Causes of Emergency Defects...............................................................................10

2.4

Types of Level I Emergency Defects....................................................................10

2.5

Level-I Emergency Defects...................................................................................11

2.6

Composite Repair: An Alternative Repair Method...............................................29

2.7

Level II Emergency Defects- Injurious non leaking defects.................................30

2.8

Repair organisation...............................................................................................30

3.0

Emergency Repairs for Glass Reinforced Plastic (GRP) Pipelines.........................

3.1

General..................................................................................................................31

3.2

Scope.....................................................................................................................31

3.3

Causes of defects in an operating GRP pipeline system.......................................31

3.4

Defects due to over pressurisation........................................................................31

3.5

Defect categorisation.............................................................................................31

3.6

Repair of Level-I Emergency Defects...................................................................32

3.7

Emergency Repair Procedure Qualification..........................................................36

3.8

Quality Programme during Repair........................................................................36

3.9

Emergency Repair Kit...........................................................................................36

4.0

Emergency Repair of Subsea Carbon Steel Pipelines..............................................

4.1

General..................................................................................................................38

4.2

Scope.....................................................................................................................38

4.3

Causes of Defects..................................................................................................39

4.4

Level I Emergency Defects...............................................................................39

4.5

Resources..............................................................................................................41

5.0

Emergency Stock Materials.........................................................................................

5.1

Philosophy.............................................................................................................42

5.2

Loaction and Quantities of Emergency Stock Materials.......................................42

6.0

Safety..............................................................................................................................

6.1

Safety requirements during repair of emergency defects......................................43

6.2

Accidental releases................................................................................................44

7.0

References......................................................................................................................

Page 3 of 76

GU-379 Pipeline Emergency Repair Manual

Appendix-1

Appendix-2

Appendix-3

Appendix-4

Appendix 5

Appendix 6

Appendix-7

Appendix-8

Appendix-9

Appendix-10

Page 4 of 76

Mechanical methods to be used in installation of sleeves

Plidco Split + Sleeve

Plidco Smith + Clamp

Plidco Weld + Cap

Fixing arrangements for Plidco Weld + End

Plidco Flange + Repair Ring

Plidco Flange Repair + Split Sleeve

List of Emergency Material

Manufacturer Instructions

User Comment Form

GU-379 Pipeline Emergency Repair Manual

1.0 Introduction

1.1

Objective

The objective of this manual is to provide a structured approach for emergency repairs

to Carbon steel pipelines, GRP off-plot pipelines and subsea pipelines.

The main purpose of an emergency repair is to restore the structural integrity of the

pipeline in the most efficient manner, to avoid further damage to health, safety and the

environment and to resume the operation without any further loss in production. In

this regard expediency is a more important factor than achieving the cheapest capital

cost of the repair itself, particularly as the time saved due to fast repair will lead to

lower losses in production throughput of the pipeline.

An emergency repair differs from a planned repair in that the time available for

assessment of the best course of action, material supply and execution time are

limited by the need for resumption of production.

The main purpose of the manual is to define the guidelines and requirements for

emergency repairs in order to reduce the execution time in the assessment of the

emergency scenario and deciding the best course of action. The manual gives

practical repair and maintenance solutions to various potential emergency situations.

The manual provides the user with information to select and execute a suitable repair

method for a given pipeline damage scenario. It is not possible to foresee every

condition that may arise in the event of a pipeline requiring repairs and, therefore, the

exact course of action to be taken must be decided upon by the engineer in charge of

the repair.

In the event of an emergency situation, reference shall be made to the PDO

Emergency Procedures. These procedures provide information essential to the

Emergency Controller when making decisions and formulating an action plan to

control and rectify a wide range of emergency situations.

1.2

Scope

This document covers the emergency repairs of off-plot pipelines. The

recommendations covered pertain to both aboveground and underground Carbon steel

and GRP pipelines. Repair of subsea carbon steel pipelines is briefly covered in this

document. The repair methods specified in this manual can be used for repair of all

classes of pipelines as defined in section 3.2.5 of SP-1211. However, the emergency

material is stocked for class-I pipelines only.

This document covers emergency scenarios for the off-plot portion of a pipeline

outside the plant boundary. On plot emergency repairs including those related to

scraper traps, bypass lines and other related on plot facilities are excluded. These

latter repairs shall form part of the plant repair/shutdown manual.

The document covers emergency repairs for internally and externally coated/lined

pipelines but repairs to cathodic protection systems are excluded.

Page 5 of 76

GU-379 Pipeline Emergency Repair Manual

Only leakage emergency scenarios are covered in this manual. For non-leaking

injurious defects, reference is made to requisite DEP/PDO standards. The scope of the

manual is taken from the point where the leak has been identified and located. It also

briefly covers the aspect of detection or identification of the defects by reference to

the relevant DEP / Standards.

1.3

Applicable Standards

The list of applicable standards, specifications, codes, guidelines and procedures are

indicated in section 6.0 of this document.

1.4

1.4.1

Definitions and Abbreviations

General Definitions

Contractor - The party that has a contract with the Company for providing work

(including emergency repairs), equipment, material, services (including consulting

services) and manpower. Contractor shall be read to also include sub-contractor

and parties providing support to contractors and sub-contractors. The company may

undertake all or part of the duties of the contractor.

Company - is Petroleum Development of Oman LLC. The company may include an

agent or consultant authorised to act on behalf of the company.

Shall - indicates a requirement.

Should - indicates a recommendation.

May - indicates a possible course of action.

1.4.2

Specific Definitions

Defect: - a flaw which may have a deleterious effect on the structural integrity of the

pipeline.

Emergency: - a critical condition that may endanger life, environment and/or assets.

Injurious defect: - a defect which requires removal, repair or derating of the pipeline.

Permanent repair: - a repair that makes a pipeline safe for continuous service for the

remaining period of its design life at its maximum allowable operating pressure or at a

reduced pressure.

Temporary repair: - a repair that makes a pipeline safe for service for a limited

period of minimum 3 months.

Leaking cracks: - Stress induced separation of the pipe material, which, without any

other influence, is insufficient in extent to cause complete rupture. The cracks usually

occur due to excessive straining during the initial mechanical formation of the pipe or

as a result of micro-structural sensitivity to certain environments, which are often high

in hydrogen or sulphur content, in combination with tensile stresses. Cracks may be

found in the girth welds, seam welds or in the pipe body.

Page 6 of 76

GU-379 Pipeline Emergency Repair Manual

Prompt action: Consists of dispatching qualified personnel without delay for

evaluating and, where necessary, abating the existing or probable hazard.

1.4.3

1.5

Abbreviations

API

American Petroleum Institute.

ANSI

American National Standards Institute

ASME

American Society of Mechanical Engineers

DEP

Design and Engineering Practice (SHELL documents)

HIC

Hydrogen Induced Cracking

MPI

Magnetic Particle Inspection

NPS

Nominal Pipe Size

SCC

Stress Corrosion Cracking

UT

Ultrasonic Testing

Distribution/Target Audience

The document is intended for use by PDO and all other parties involved in the

pipeline maintenance and emergency repairs as a basic guideline for the emergency

repair of pipelines. Typical parties include operators, design consultants, construction

contractors, inspection, repair and maintenance contractors, certifying agencies and

authorities.

1.6

Document Structure

The document comprises of the following sections:

1.

Introduction

2.

Emergency repairs for Carbon steel pipelines

3.

Emergency repairs for GRP pipelines

4.

Emergency repairs for Subsea CS pipelines

5.

Safety

6.

References

The sections will be further sub-divided to cover the relevant technical / safety

considerations, procedures and planning required to meet the objectives of the

manual. References at the back of the manual will include relevant reference material.

The document is intended for use by PDO and all other parties involved in the

pipeline maintenance and emergency repairs as a basic guideline for the emergency

repair of pipelines. Typical parties include operators, design consultants, construction

contractors, inspection, repair and maintenance contractors, certifying agencies and

authorities.

Page 7 of 76

GU-379 Pipeline Emergency Repair Manual

1.7

Review & Improvement

These Guidelines will be reviewed and updated once every three years. The review

authority will be CFDH Pipelines. No changes will be made without the approval of

the Custodian (CFDH Pipelines).

Page 8 of 76

GU-379 Pipeline Emergency Repair Manual

2.0 Emergency Repairs for Carbon Steel Pipelines

2.1

Scope

This part of the document defines emergency repair requirements for carbon steel

pipelines. The pipelines covered are for diameters ranging from 4 to 48, wall

thickness ranging from 4.8mm to 20.06mm and steel grades conforming to API 5L up

to Grade X-70. It excludes the repair details for other metallic pipelines e.g. ductile

iron, duplex material etc.

The subjects addressed in this part of the document contain information regarding

assessment of an emergency defect, inspection, repair methods and the safety

requirements to be followed during repair.

2.2

Types of defects and its causes

The possible repair methods are, to a large extent, dictated by the type of the defect.

The various types of defects in a pipeline system can be classified on the basis of

availability of time required for repair, the resources required to deal with the repair

and the consequences. These are classified in the following two main types: Emergency defects:- a defect in the pipeline that has a deleterious effect on the

health, safety, environment and/or production. Such defects in a pipeline system are

those, which require immediate and prompt action and also need specialised

procedures, equipment, manpower and supplies to protect the public safety or

property from an existing or potential hazard.

Emergency defects can be further categorised Level 1 and Level 2.

Level I emergency defects: - All leaking defects in Class I pipelines are classified

as Level I emergency defects. These Level I emergency defects pose an

immediate threat to the health, safety, environment and production and therefore

needs to be rectified on an immediate basis with prompt action. The period

between reporting of a defect and the repair shall be kept as short as practicable.

Level II emergency defects: - All non-leaking injurious defects as defined in SP1235 in Class I pipelines are defined as Level II emergency defects. These

defects do not pose an immediate threat to health, safety, environment and

production. However, the extent of damage to the pipeline system is such that

these defects can at any time become leaking defects. Therefore the time

available for carrying out repairs for such defects is more than the time available

in Level I emergency defects, but is less than the time available for nonemergency defects.

Non-Emergency defects: - a defect which, in its present state, does not have any

immediate impact on the health, safety, environment and/or production. However,

such defects can if not rectified, have the potential to become emergency defects and

thereof need planned repair. The time available for carrying out repairs for such

defects is more than the time available in cases of emergency defects. Therefore, no

specialised procedures and resources are required.

Page 9 of 76

GU-379 Pipeline Emergency Repair Manual

Such defects can be repaired in a planned manner, but must also be rectified in a

timely manner to ensure that do not become emergency defects.

P i p e l in e D e f e c t s

E m e rg e n c y D e fe c ts

M in o r L e ak

N o n -E m e rg e n c y D e fe c ts

L e v e l-I

L e v e l - II

L e a k in g In ju r io u s D e fe c ts

N o n L e a k in g In ju r io u s D e fe c ts

(A s p e r S P -1 2 3 5 )

M a jo r L e a k

R u p tu re

P i p e M i ll D e f e c t s

G i r t h W e l d D e f e c ts

D e n ts

C r a c k s /A r c B u r n s

S p a llin g , G o u g e s , G r o o v e s

G e n e r a l /L o c a l M e t a l L o s s

Fig. 1: Summary of pipeline defects

2.3

Causes of Emergency Defects

The occurrence of emergency defects in the pipeline system can be attributed to one

or a combination of the following causes: 1. Third party interference

2. Manufacturing/construction/design/material defects

3. Excessive operational loads/errors

4. Geo-technical forces

5. Corrosion/sensitivity to environment

The most common reasons for pipeline failures are third party interference or

corrosion.

2.4

Types of Level I Emergency Defects

Level I emergency defects can be further categorised based on the type of leaks into: Minor Leak

A leak (also called a pinhole leak), where the largest dimension of

the leaking hole is < 3mm.

Major Leak

A leak, where the largest dimension of the leak hole is > 3mm but

less than 60% of the outer diameter of the line pipe

Rupture

A rupture is a defect where the largest dimension of the leak hole

is >60% of the outer diameter of the line pipe. In these cases, the

pressure in the pipeline system is drastically reduced and also, the

leakage rate from the defect is high.

Page 10 of 76

GU-379 Pipeline Emergency Repair Manual

In addition to the above, leaks occurring from flanges/ flanged fittings, valves etc.,

shall also be considered as Level I emergency defects.

Repair methods adopted for Level I emergency defects will depend on the nature of

the leak and location at which the leak occurs. Leaks occurring in pipeline systems in

the vicinity of road and wadi crossings shall require different repair methods than the

leaks reported from other areas.

2.5

Level-I Emergency Defects

The events/activities related to Level I emergency defects can be categorised under

following four main headings: 1. Detection of defect/leak

2. Perform damage/leak assessment survey

3. Analyse damage assessment survey and decide upon repair options

4. Mobilise emergency repair equipment/contractors and commence repair works as

per procedures outlined in this manual.

Note: This manual places greater emphasis points 3 & 4 above. Points 1 & 2 have only been covered in

brief.

2.5.1

Detection/identification of leak

Timely detection/identification of leaks is essential to prevent catastrophic effects of

the leak. For detailed guidelines on the leak detection, reference shall be made to DEP

31.40.60.11 and PR-1066 (Clause 2.3.9 and 2.3.10).

Identification of suspected leaks, unless it has been sighted and reported by 3 rd party/

PDO surveillance team or in the absence of a suitable leak detection technique, will

involve patrolling (walking, driving or flying) the pipeline to identify evidence of one

or more of the following:

1. Vegetation disturbances - visual observation to detect abnormal or unusual

indications in vegetation, e.g. an area of dead vegetation or a build up of frost on

the ground

2. Visual identification of fluid spillage

3. A loud whistling sound associated with a leak in a high pressure pipeline system

4. Smell of the fluid being transported in the leaking pipeline

5. Possible shortness of breath in the area of a leak

6. Fire near a pipeline facility

Other essential warnings signs of a leak include a reduction in the pressure or

discharge flow rate in the pipeline system, which cannot be explained by the analysis

of the regular operating conditions. A drastic reduction in pressure normally indicates

the presence of rupture in the pipeline and requires an immediate shut down of the

system. The extent of pressure reduction in the system is nominal in cases of major

leaks whereas it may be unnoticeable for cases of minor leaks.

Page 11 of 76

GU-379 Pipeline Emergency Repair Manual

Once a suspected leak is confirmed, identification of the exact location of the leak

involves mobilisation of crews with leak detection equipment such as gas detectors,

ultrasonic leak detection tools etc. This phase will also involve exposing the pipeline

at probable locations of a leak to ascertain the exact location. All necessary safety

measures as required and specified in the later parts of this document shall be adopted

during the operation.

For leakage survey procedures, leakage pinpointing, equipment and test methods for

gas leakage, reference shall be made to appendix-M of ASME B 31.8-2003.

2.5.2

Defect/Leak Assessment/Inspection

Once the leak has been detected and located it should be accessed and categorised in

accordance with Section 2.4 of this manual. Assessment and categorisation is essential

in deciding on the repair procedure and safety methods to be adopted during the

repair.

In the absence of readily available inspection tools or due to the lack of time, leak

assessment/inspection for buried pipeline is normally done by digging at the location

of the leak and reaching the leak position on the pipeline. The probable locations of

the leaks are identified in the previous phase of leak detection. Suitable safety

measures as detailed in Section 5.0 shall be implemented before start of digging.

Excavation for live pipelines shall be done as per ERD 38-11. Excavation at the

damaged portion of pipeline shall be carried out with due regard to trench stability

and safe egress.

In cases where the leak has been detected by inspection tools, no digging may be

required at this stage as the results produced from the inspection tests normally detail

the type, size and assessment of the defect/leak. These inspection results shall be

further interpreted/assessed by trained personnel to classify the leak into major, minor

or rupture, the reason for leak and to propose the strategy to be followed in the repair

of these defects.

On reaching the location of the leak, further visual inspection shall be done to assess

and categorise the damage. All loose wrapping shall be removed and the damaged

area shall be cleaned of all traces of mud and extraneous matter.

2.5.3

Shut down and pressure reduction

Under normal circumstances, no shutdown is required for cases of minor leaks as the

repair can be done on a running pipeline except in cases of pipelines transporting

excessively sour or hazardous fluid and passing through areas of higher location

classes (class 3 and 4 as per SP-1211). Shutting down or pressure reduction during

minor leaks becomes essential in the following cases: 1. Risk of growth of the defect at locations with stresses other than those due to

internal pressure only e.g. at locations of soil movement or settlement or

inadequate pipe support conditions etc.

2. Presence of defect (leak) in critical location

3. Use of hot work for the repair (may require decommissioning of the pipeline)

Page 12 of 76

GU-379 Pipeline Emergency Repair Manual

4. The leak, although minor, will still result in unacceptable safety situation or an

environmental impact.

However it is essential that the operating pressure of the system be reduced for all

cases of minor leaks to a maximum of 80% of the operating pressure at the time of

defect reporting to ensure safe repair operations. Specific care shall be exercised for

cases of downhills of a liquid line where the required pressure reduction of more than

80% due to static head of the liquid. The criteria and extent of the pressure reduction

shall be verified by the engineer-in-charge. Settings of safeguarding instruments shall

be adjusted to maintain the pressure reduction during repair period.

Note: The pressure reduction recommended above is the reduction required at the time of repair. The

pressures at which the pipeline system shall be operated after accomplishment of repair shall be

decided by the engineer-in-charge in its close out report. For down hill sections where the 80%

reduction criteria could not be met due to static head, the engineer in charge shall decide the

operating pressure during repair period.

In cases involving hazardous major leaks, it is recommended to shutdown the system

to avoid any disastrous consequences during the repair works, to prevent any growth

in the defect and to prevent any increase in threat to health, safety or the environment.

The decision for shutting down the pipeline shall be taken by the local emergency

coordinator who must carefully assess the risk and consequences involved and the

loss in production on account of a shutdown.

In cases involving rupture, the pipeline system will incur a serious pressure drop in

the area of the rupture resulting in excessive loss of product. In these situations,

shutting down the system should be carried out immediately to avoid further damage,

control the risk and avoid further loss of product. Repairs in these cases normally

require sectional replacement.

If the pipeline has been shut down, repressurising for testing after the repair should be

done with extreme caution. Repressurising should be accomplished slowly and

steadily without surges to avoid vibration of the pipeline and fittings. No personnel

should be allowed near the repair until the test has been completed. Other safety

measures as detailed in the later parts of this document shall be adopted during such

repairs.

2.5.4

Repair options

The preferred option for a permanent repair is to completely decommission the

pipeline, then cut out and replace the section of pipe containing the defect. However,

this option is rarely used due to the time constraints.

The preferred repair options for Level I emergency defects can be classified into: Temporary repair options: - These provide temporary relief to the defects in the

pipeline system but have to be removed and replaced with more permanent

alternatives during a planned shutdown or as soon as practically possible. Such

methods are employed to reduce the down time of the pipeline. A temporary repair is

recommended only when the loss of production caused by the time needed to execute

a permanent repair is such that it justifies the cost involved in both the temporary

repair and the subsequent planned permanent repair.

Page 13 of 76

GU-379 Pipeline Emergency Repair Manual

Permanent repair options: - These provide permanent relief to the defects, enabling

the normal operating pressure of the system to be maintained for the remaining design

life. A temporary repair should be replaced with a permanent repair method within a

period of 3 months (as per SP 1210). Any further extension beyond 3 months shall be

subject to demonstration of performance with confidence and written approval from

competent authority (CFDH pipelines).

Once the defect has been categorised and located the following repair options are

recommended depending upon the type of defect. (Refer Table 1).

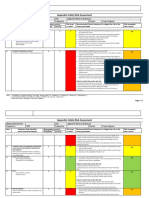

Table - 1: Selection of emergency repair options - CS pipelines

Type of defect

Minor leak

Temporary repair option

Permanent repair option

Plidco Smith+Clamp,

Plidco Split + Sleeve or similar

Composite Repair****

Plidco Smith+Clamp+

Plidco Weld+Cap

Plidco Split + Sleeve (duly

welded) or similar

Sectional replacement*

Composite Repair****

Major leak

Plidco Split + Sleeve or similar Plidco Split + Sleeve (duly

Composite Repair****

welded) or similar

Sectional replacement

Composite Repair****

Leaking cracks

Plidco Split+Sleeve** or similar Sectional replacement

Rupture

NIL

Sectional replacement

Leakage through flange Plidco Flange + Repair-Ring

Sectional replacement

Plidco Flange-Repair + SplitSleeve*** or similar

Leakage through valve Nil

Valve replacement/repair as per

manufacturers recommendation

Leaks in road crossings

See Section 2.5.6

Leaks in wadi

crossings

Note: Plidco brand repair materials are indicated in the table for reference purpose only. All Plidco

equivalent PDO approved brand repair materials can also be used for emergency repair.

*

**

***

****

Page 14 of 76

Sectional replacement can also be achieved using Plidco weld+end couplings.

Refer to details given below in Section 2.5.8.3.

The length of split sleeve shall be suitable for the length of crack. The welded

split sleeve cannot be considered as a permanent repair due to possible

propagation of crack during the service.

Not applicable for valve flanges

Composite repair can be used with in the limits of qualification in accordance

to ASME Code. Please Refer Section 2.6.

GU-379 Pipeline Emergency Repair Manual

2.5.5

Repair of internal PE lined pipelines

The PE lined pipelines may develop leaks either due to 3 rd party interference to such

an extent that the liner is also damaged or in-service failure of liner and subsequent

corrosion of the pipeline. The leaks in these lines shall be temporarily repaired using

Plidco split sleeves or mechanical clamp in an emergency situation.

The temporarily repaired sections of these internal PE lined pipelines shall be

replaced by a permanent alternative method within 3 months period as per section

2.4.5.3 of SP-1210. The flange-to-flange sectional replacement including replacement

of damaged liner is the only recommended permanent method of repair for PE lined

pipelines.

2.5.6

Repair options for leaks at areas of road and wadi crossings

The repair options specified in Section 2.5.4 are applicable for pipeline leaks at road

crossings subject to the condition that open cut repair is feasible for such roads, e.g.

traffic diversion during the repair works should not lead to any major disruption.

Temporary repair options for leaks in these areas are not recommended due to the

following associated disadvantages:1. The temporary repair options do not enable the complete structural integrity of the

pipeline to be restored. This is more critical in areas of road crossings.

2. Temporary repairs are short term and will ultimately have to be replaced with

more permanent repairs which will require further closure of the road for open

cutting.

For roads where open cut is not possible, e.g. on a major road, the repair works shall

be done using boring/drilling to avoid disrupting the traffic movement. In such cases a

casing pipe, along with the sectional spool piece, shall be laid using thrust/auger

boring. The sectional pipe shall be joined to the main line using Pildco Weld + End

Couplings or welding as shown in Figure-2 .

Page 15 of 76

GU-379 Pipeline Emergency Repair Manual

Figure 2: Sectional replacement of defective pipeline at road crossings

Leaks in pipelines at wadi crossings are more critical as the leaking oil/gas is likely to

spread to a larger area through the flood water (during rainy seasons).

During non-rainy seasons, if the wadi does not contain water, normal methods as

described in Section 2.5.4 can be used to carry out repairs. For wadi types B and C,

the concrete coating over the pipeline shall be removed and the necessary repair

carried out. After completion of the repair works, the complete sectional spool along

with the associated sleeves shall be recoated with concrete in-situ. The concrete

coating shall be done in such a way that the sleeves do not get damaged due to

presence of gabions over them.

In case if the pipeline leak occurs in a live wadi (for example during rainy season),

arrangements should be made to divert the wadi stream and evacuation of remaining

water in wadi prior to starting the repair activity. Following diversion, evacuation of

wadi, the repair shall be similar to that of dry wadi region explained above.

Continuous evacuation of water using vacuum trucks might be required during repair

activity, in case if continuous oozing of water is noticed.

Temporary repair options are not recommended for leaks in wadi crossings.

Page 16 of 76

GU-379 Pipeline Emergency Repair Manual

2.5.7

Repair activity procedures

The activities detailed below shall form part of the overall repair works and shall be

applied in conjunction with the procedure for carrying out the specific repairs detailed

in Section 2.5.8.

2.5.7.1 Procedure for cleaning of the defect area

The surface of the defective area of the pipeline shall be cleaned to enable repair,

welding, UT inspection etc. The cleaning shall achieve removal of scale, rust,

coatings and vegetation by the use of wire brushes, chipping tools or grit blasting. The

grit blasting shall be permitted only when remaining wall thickness of the pipe is

more than 2 mm. Reference shall be made to SP-1246 for this purpose.

2.5.7.2 Confirmation of suitability of live pipeline for permanent repair welding

The following checks shall be done to confirm the suitability of the live pipeline for

the purpose of welding:1. Before assembling the repair fittings to line pipe an ultrasonic inspection shall be

conducted to cover a zone extending a minimum of 100mm on the either side of

each weld area to confirm a minimum wall thickness (refer point no. 2 below) and

to check for the laminations. Laminar defects exceeding 6mm in any direction and

any lamination not parallel to the pipe surface shall be unacceptable. Ultrasonic

test techniques shall be in accordance with ASME V article 5 as supplemented by

SP-1176.

Levels of indications requiring investigations are as follows:- all reflectors giving an indication in excess of 20% DAC shall be investigated

and evaluated in accordance with the acceptance standard (DAC = Distance

Amplitude Correction).

- all reflectors giving an indication in excess of 50% DAC shall be evaluated and

reported.

- all reflectors exceeding 100% DAC shall be cause for rejection.

2. Before carrying out any kind of weld repair on a live pipeline, it shall be ensured

that during the welding operation the material in the region of the weld pool has

sufficient strength to contain safely the internal pressure and avoid a blow out.

The risk of blow out is dependent upon a complex interaction of welding

conditions, pipe material, pipe thickness, pipe temperature and hoop stress. For

material of yield strength not greater than 448 MPa (Grade X-65 as per API 5L),

operating at temperatures of not greater than 350 deg.C with a hoop stress not

greater than 72% of the specified minimum yield stress, blow out can be

prevented during welding provided the minimum thickness is not less than 4.8mm

(reference shall be made to Appendix-2 and 3 of DEP 31.38.60.10). The actual

minimum wall thickness shall be determined by ultrasonic testing as specified in

point no. 1 above. For other materials or conditions, a minimum pipe thickness

shall be determined, based on either specific previous experience and/or data from

trials.

Page 17 of 76

GU-379 Pipeline Emergency Repair Manual

3. Welding on live pipelines is prohibited for the following cases:- Mixtures of gases or vapours within their flammable range or which may

become flammable as a result of heat input in welding operations.

- Oxygen enriched atmospheres in the presence of hydrocarbons which may be

present either in the atmosphere or in the deposits on the inside surface of the

pipe.

- No welding shall be performed on lined, clad or internally coated pipes

4. Attention shall be paid to controlling the pipe wall temperature during the welding

to avoid deterioration of the microstructure of the pipe material due to excessive

heat input resulting in excessive metal temperature. Reference shall be made to

Clause 3.3.2 of DEP 31.38.60.10.

5. The pressure in the pipeline system shall be verified to confirm that it does not

exceed the maximum allowable operating pressure during welding operations.

This shall be based on the derated pressure conditions necessary whilst the

material is at elevated temperature whilst welding. It is also essential to prevent

any propagation of any unstable cracks. The maximum allowable operating

pressure during welding shall be determined as per Clause 3.3.3 of DEP

31.38.60.10.

6. Welding on a live pipeline under no-flow or intermittent flow conditions shall not

be attempted unless it has been confirmed that no explosive or flammable mixture

will develop during welding operations. In this respect it shall be confirmed that

no ingress of oxygen in the line is possible. In cases where this requirement

cannot be met, nitrogen purging (de-commissioning) shall be done using a

minimum purge velocity of 0.4m/s.

7. A high liquid flow usually causes rapid cooling of the weld area which results in

hard material zones, which are susceptible to cracking. Under these circumstances

the minimum inter pass temperatures may not be attainable, resulting in undesired

material properties. A suggested maximum velocity for liquid flow during welding

is 1.75m/s. There is no restriction on maximum velocity for gas lines, subject to

the attainment of acceptable inter pass temperatures.

Note:- For wall thickness between 6.4mm and 12.7mm, flow also increases the weld cooling rate

and hence the risk of cracking. Minimizing the flow rate reduces the risk of cracking and of burn

through. For metal thickness greater than 12.7mm, the effect of flow on both weld cooling rates

and burn through are less significant.

2.5.7.3 Procedure for welding/inspection for emergency defect rectification

All emergency repair welding and inspection of welds on pressurised pipeline

systems, including the welding of sleeves, clamps shall be done as per SP-1167 and

DEP 31.38.60.10 and selected approved welding procedure. Other precautions needed

during welding include:1. Careful control of the size and shape of the circumferential fillet welds. The size

of the fillet weld should be at least 1.4 times the wall thickness of the pipe at the

weld area.

Page 18 of 76

GU-379 Pipeline Emergency Repair Manual

2. Maintenance of a concave faced fillet weld with streamlined blending into both

members. The smoother and more streamlined the weld profile, the greater the

resistance to fatigue failure.

3. Avoiding notches and undercuts during welding.

4. Use of welding consumables as indicated in approved WPS.

5. Use of temperature crayons or probe thermometers, to monitor heat generated

during welding or preheating operations, particularly near the areas of the soft

seals. If the heat generated approaches the temperature limit of the seal material,

which is indicated on the label, welding should be discontinued to allow the

affected area to cool.

6. Ensuring that welding does not overheat the seals. The welding should be

sequenced so that the heat is not concentrated in one area. It may be necessary to

re-torque the stud bolts and nuts periodically during field welding because weld

contraction causes them to loosen.

7. Avoiding burn through during the root run. First weld pass for pipelines with a

wall thickness less than 6.4mm thick should be achieved by using 2.4mm or

smaller diameter welding electrode to limit heat input.

8. For pipelines with wall thickness more than 12.7mm, where burn through is not a

primary concern, care should be taken by avoiding the use of excessive welding

current.

PDO pre-qualified welding procedures and welders (PR-1276, SP-1177) shall be used

for welding on live pipelines to avoid delay due to pre-qualification. However, in

some scenarios, in order to carry out weld repairs without the delay the following

deviations are permitted from SP-1177:1. If no records are available, the defective line pipe shall be assumed to be API 5L

Grade B, which shall be used for the new replacement pipe if no material

specification records are available.

2. The pipeline engineer shall decide the WPS and PQR to be followed in

consultation with repair contractor and welding engineer. Welding conditions and

relevant parameters shall be noted and test pieces shall be prepared once the job is

complete.

3. 100% radiography, UT and MPI shall be done on all emergency repair welds.

4. All records and test piece results shall be reviewed after the repair, to determine if

the method meets the requirements of the application. If deemed necessary,

cutting out and replacement of unacceptable weld repairs shall be planned and

executed as per SP-1177.

2.5.7.4 Procedure for recoating/painting of the defect area

After completion of the repairs, the defective area shall be recoated / repainted as per

SP-1246.

Page 19 of 76

GU-379 Pipeline Emergency Repair Manual

2.5.7.5 Procedure for sand padding and backfilling of the trench

1. Screened soft sand, free of rock and foreign matter, shall be used for sand

padding. The minimum depth of padding below the pipe shall be 300 mm.

2. Hand shovel and wooden hand-ramming device shall be used for the placement

of sand under the pipe.

3. Sand shall be lowered into the trench with a mechanical shovel and hand spread

uniformly around the pipe. The depth of the sand padding over the top of the

pipe shall be at least 300 mm. Sand on top of the pipe shall be shaped to the

natural angle of repose.

4. Screened excavated material from the location shall be used (after the removal

of any rock and boulders) on top of the sand. In order not to damage the sand

padding, the initial layers of final fill shall be carefully lowered into the trench

from each side by mechanical shovel ensuring that the backfill material is

deposited carefully to avoid disturbing the sand padding.

5. The mechanical excavator shall maintain the following minimum safe distances

(which shall be clearly marked by a line of bunting) from the edge of the trench:

-

Rock: distance from edge of trench shall be 1.0 metre

Compacted ground: distance from battered edge of trench shall be 1.5

metre

Soft sand with trench sides battered to a minimum slope of 2:1:

distance shall be 2 metres.

6. After completion of the initial backfill layer, the remaining backfill shall be

finished to a level slightly above the natural grade and shall be thoroughly

compacted by means of a compacting vibrator.

7. Windrow shall be reinstated, including the section used for temporary crossings.

Where the excavation crosses wadis or ditches with lined or otherwise improved

surfaces, these shall be reinstated to their original contour and condition.

Reference should also be made to ERD 38-11 and SP-1208 for details on

reinstatement.

2.5.7.6 Procedure for de-commissioning, isolation and draining/venting of the pipeline

for defect repair

Venting/Draining of the pipeline

Complete draining and venting of the pipeline is essential in cases of sectional

replacement of a defective portion of the pipeline. For pipelines with block valve

stations draining can be limited to the section between the block valves. Where there

are no block valves, the entire length of the pipeline shall be drained.

For pipelines without block valve stations: For such pipelines, most of the fluid is

drained from the pipeline during the depressurisation process by shutting down the

flow and opening the valves at the receiving end station. The remaining fluid can be

drained by opening the drain and vent valves at each end. The drained fluid shall be

disposed of safely to prevent any hazard to life or the environment. For any residual

Page 20 of 76

GU-379 Pipeline Emergency Repair Manual

fluid trapped in the pipeline such as in areas of lower elevations, the engineer-incharge shall study the need for further draining/venting. This can be accomplished as

follows:1. For liquid lines, the ruptured or leaking portion of the pipeline shall be covered

temporarily either by a sleeve or composite reinforcing sleeve and pigging with

soft pigs carried out, driven with compressed nitrogen or water, to displace the

remaining liquid.

Alternatively, the trapped liquid can be removed using suction pumps. The suction

hose shall be inserted into the pipeline either through drain valves or through the

leaking portion and the liquid transferred to a tanker. The use of suction pumps is

limited depending upon the capacity of the pump available and the length/terrain

of the pipeline and is only recommended for small lengths. Another method of

draining the liquid line is by flushing with water (for general details refer to PR1074)

2. For gas pipelines, any remaining trapped gas can be vented by purging with inert

gas from one or both ends of the pipeline. Venting of any hazardous gases shall

only be allowed only through the designated vents and shall be suitably flared in

accordance with standard safety procedures.

For pipelines with block valve stations: For these pipelines, only the portion

between the block valves needs to be drained and vented. This shall be done as

follows:1. For liquid lines, the trapped liquid shall be drained out through the drain valves at

the block valve stations. Any remaining liquid can be removed using suction

pumps. The suction hose shall be connected to the drain lines at the block valve

stations. The capacity of the suction pump should be sufficient to drain

approximately 32 km of pipeline being the maximum length between two block

valve stations. Flushing with water can also be undertaken to remove the

hydrocarbon liquid as specified above.

2. For the handling non-sour gases, controlled venting can be done to atmosphere

through the vents provided at the BV stations. Any remaining trapped gas can be

vented out by inert gas purging from one or both stations. Venting of any

hazardous gases shall only be allowed through designated vents and shall be flared

in accordance with standard safety procedures either through temporary mobile

flare or as directed by the PDO Safety Officer.

Note: It is also feasible to drain and vent the pipeline by installing a hot tap through which the pipeline

contents can be drained, vented or flared.

Isolation of the pipeline

If deemed necessary, even after isolating and draining the defective section at the

block valve stations, further localised isolation by use of specific pipeline isolation

plugs such as PE Grip Lock Pipe Plugs, air plugs, mud/freeze plugs or Hi friction pigs

is recommended.

Page 21 of 76

GU-379 Pipeline Emergency Repair Manual

For smaller lengths where no block valve stations exist, the pipeline shall be first

decommissioned and then the defective segment is isolated using air/mechanical

plugs/stopples. Isolation of a defective portion of a pipeline without block valves is

essential to prevent the possibility of trapped fluid draining from other areas whilst

repairs are in progress and also to prevent transfer of welding fumes to other segments

of the pipeline. The requirement of isolation for these pipelines shall be verified by

Operations personnel and done in accordance with PR-1076.

Note:- Hot tapping the line to provide a means of inserting the plugs/stopples to isolate the defective

line section may affect a safe repair. Considerations should be given to the factors such as

product characteristics, pipe condition, temperatures and required differential pressures to

ensure that the proper type of plugs are used and that their holding capacity can adequately

resist the pressure to be encountered. Various types of plugs that can be possibly used for

isolation include mud plugs, freeze plugs and mechanical/air plugs.

2.5.7.7 Emergency repair close out report

The purpose of the close out report is to capture all the relevant actions taken to

identify the cause of damage, the repair methods used and to serve as feedback to

correct any deficiency and make future improvements. The recommended table of

contents shall be as follows:1. Pipeline service and details (fluid transported, flow, operating pressure, diameter,

wall thickness, year built etc.)

2. Type of defect, cause and assessment of damage (safety, environment and loss of

production)

3. Repair method (advantages and disadvantages)

4. As built drawings revisions.

5. Conclusions and lateral recommendations, including the requirement to derate the

pipeline after completion of repair if necessary.

6. Feedback to pipeline emergency repair manual.

7. Any other additional checks or tests found necessary to verify the integrity of the

pipeline.

This report shall be in addition to any other requirements specified in the PDO

emergency procedures and HSE 97-01/PR-1060.

Page 22 of 76

GU-379 Pipeline Emergency Repair Manual

2.5.8

Emergency repair methods CS pipelines

The following sections cover the various emergency repair methods for CS pipelines.

For ease of reference the Plidco Smith brand of repair materials have been quoted in

this manual. However, equivalent products available from other manufacturers can

also be used provided they are an approved vendor listed in the AVME.

2.5.8.1 Plidco Smith + Clamp + Weld + Cap

Plidco Smith + Clamp is a temporary repair solution for minor leaks. The point of the

cone is centred exactly on the hole, and force applied using the force screw to shut off

the leak. The draw bolts at the bottom of the fitting are used to hold the clamp in

place. The use of a welded Plidco Weld + Cap when used in conjunction with the

Plidco Smith + Clamp makes the repair permanent. Reference shall be made to

Appendix 3 and 4 for details.

Applications : 1. Plidco Smith + Clamps are available in standard sizes from 1.5 to 48

2. The standard pressure rating for Plidco Smith + Clamp and Plidco Weld + Cap is

2000 psig (~138 barg).

3. Plidco Weld + Cap are available in standard sizes from 4 to 48

4. Welding of the Weld + Cap is required for permanent repair

5. Can tolerate only minor surface irregularities up to + 1/32

Procedure for installation on live pipelines: For temporary repair:

1.

2.

3.

4.

5.

Verify the pipeline as per Section 2.5.3

Ensure all safety precautions as per Section 5.0

Clean the defect area as per Section 2.5.7.1

Install Plidco Smith + Clamp as per manufacturers procedure

Prepare detailed report as per Section 2.5.7.7

For permanent repair continue as follows:

6. Verify and confirm the suitability of the pipeline for welding as per Section

2.5.7.2

7. Install Plidco Weld + Cap as per manufacturers procedure

8. Weld the Cap and inspect the weld as per Section 2.5.7.3.

9. Recoat/paint the system as per Section 2.5.7.4

10. Sand padding and backfilling as per Section 2.5.7.5

11. Prepare detailed report as per Section 2.5.7.7

2.5.8.2 Plidco Split + Sleeve

These can be used for temporary and permanent repairs. The seal welded Plidco Split

+ Sleeve is considered as permanent repair solution.

Page 23 of 76

GU-379 Pipeline Emergency Repair Manual

Note: It is preferable only to use this system as a temporary repair method because of the high cost. It

is recommended not to weld the clamp to the pipeline and to replace it as soon as practicable

with a permanent repair such as sectional replacement of the defective section.

The size of the sleeve to be used shall be selected based on the diameter of the line

pipe and the length of the defect. The length shall be such that the sleeve extends a

minimum of 0.1m beyond the defect. Adjacent sleeves shall not be placed closer than

one-half pipe diameter from each other. Over sleeves can be used to cover defects in

area`s adjacent to or between the sleeves. These shall be welded to the original sleeve

using qualified welding procedures. The minimum required wall thickness and steel

grade of the sleeve shall be based on the wall thickness and design factor applied to

the pipeline. The sleeve thickness shall be adequately increased to compensate for the

groove of the backing strips or seams of the pipeline. The length of sleeve shall not be

less than 0.1m. Reference shall be made to Appendix-2 for details.

Applications:

1. Standard Plidco split + sleeves are available for a working pressure up to 1000

psig (~ 69 barg).

2. Available in API pipe sizes from 1.5 to 48

3. Higher working pressure or longer length sleeves can be made to order

4. The sleeve shall not be used to couple pipes without sufficient end restraint

because it does not provide any longitudinal restraint in an unwelded condition.

5. Standard body materials are A 106 seamless pipe, A 216 WCC cast steel, A 516 or

equivalent. Other materials are available on request.

6. The seal can tolerate only minor surface irregularities up to +1/32

7. The seals and girder rings on the sleeve can be damaged by careless handling with

lifting devices such as chains, cables or lift truck forks which can result in the

seals being dislocated from the groove.

8. The sleeves can be field tested up to 1.5 times the design working pressure.

9. The sleeve should be stored in a dry environment to prevent the unpainted

surfaces from rusting. Storage temperatures should not exceed 120 deg.F (49 deg

C). They shall be covered with dark polyethylene to protect the material from

direct sunlight. Improperly stored units can cause the seal material to become

brittle and cracked and thus lose the sealing properties.

Procedure for installation on live line: For temporary repair:

1.

2.

3.

4.

5.

Verify the pipeline as per Section 2.5.3

Ensure all safety precautions as per Section 5.0

Clean the defect area as per Section 2.5.7.1

Install Plidco Split + Sleeve as per manufacturers procedure

Prepare detailed report as per Section 2.5.7.7

For permanent repair continue as follows:

6. Verify and confirm the suitability of the pipeline for welding as per Section

2.5.7.2

Page 24 of 76

GU-379 Pipeline Emergency Repair Manual

7. Seal weld the ends, sides and bottom of nuts as per Section 2.5.7.3

8. Inspect the weld as per Section 2.5.7.3.

9. Recoat/paint the system as per Section 2.5.7.4

10. Sand padding and backfilling as per Section 2.5.7.5

11. Prepare detailed report as per Section 2.5.7.7

2.5.8.3 Spool Piece with Plidco Weld + End couplings

The installation of a spool piece using Plidco Weld + End couplings requires

shutdown and depressurisation of the pipeline. The thickness and material grade of

the spool piece shall be the same as that of the line pipe and shall be determined using

the equations and safety factors as given in SP-1211. The material shall conform to

API 5L specification. Welding in cases of unequal wall thicknesses shall be done as

per ASME B 31.4 or 31.8 as appropriate. Reference shall be made to Appendix 5 for

details.

Plidco weld+end couplings cannot sustain external forces such as temperature

expansion and contraction, ground movement etc.

Application: 1. This method of repair requires shutdown and depressurisation of the pipeline to

remove the defective section with complete draining and isolation of the product

from the affected area.

2. It is a time consuming permanent process as compared to other methods of repair

as it requires dismantling and replacement of the affected piece of the line pipe.

3. Temporary repair for a period of not more than 6 months can be achieved by

clamping and tightening the thrust screws without welding the coupling.

4. Permanent repair is achieved by welding the coupling to the line pipe. This may

require additional time because liquid flow through the pipeline will have to be recommenced and safe conditions reached to permit welding. Welding on a line

under no-flow or intermittent flow conditions shall not be attempted unless it can

be positively established that no explosive or flammable mixture will develop

during the welding operation.

5. Where significant longitudinal loads are present and it is not feasible to weld the

coupling, additional rows of clamping screws can be provided or the Pildco clamp

+ Ring may be used.

6. Standard sizes are available from 1.5 to 48

7. Standard materials are A-106, A-105, A-285, A-516.

8. Couplings are suitable for anchored pipeline joints only.

9. The model of the coupling must be selected to the same pressure/ temperature

rating as the line pipe.

10. Couplings are suitable for the minimum pipe wall thicknesses as specified in

Table 2. Pipelines with wall thicknesses less than those specified in the table will

not withstand the force of the clamp screws and hence this application will be

unsuitable. As a solution, Plidco Clamp + Ring should be considered.

11. The use of these coupling on elbows and bends is limited due to the possibility of

pullouts caused by external and internal forces.

12. For badly misaligned or out of round pipe, it is helpful to grind a pilot bevel with

a generous taper on the pipe. This should eliminate the risk of damage to the seals

Page 25 of 76

GU-379 Pipeline Emergency Repair Manual

while installing the coupling over the end of the pipe. Refer to Appendix 5 for

details.

Nominal pipe size (inch)

4

6

8

10

12

14

16 & larger

Min. wall thickness ( mm)

6.0

7.1

8.2

9.3

10.4

11.1

12.7

Table 2: Minimum pipe wall thicknesses for Plidco Weld + End couplings

Procedure for installation: For temporary repair:

1. Shutdown the pipeline system

2. Ensure all safety precautions are in place as per Section 5.0

3. Depressurise the complete pipeline system to atmospheric pressure by opening the

necessary drain/vent valves as per Section 2.5.7.6

4. Ensure that the isolated section has been adequately drained and is free from any

trapped fluid as per Section 2.5.7.6

5. If required, isolate the defective section as per Section 2.5.7.6

6. Select the spool piece of wall thickness and grade as specified above.

7. Hydro-test the spool piece separately as per SP-1211

8. Clean the defect area as per Section 2.5.7.1

9. Cold cut the defective portion of the pipeline as per general guidelines given in

PR-1146

10. Install Plidco Weld + End coupling as per manufacturers recommendation

11. Slide the spool piece in the coupling and tighten the screws

12. Prepare detailed report as per Section 2.5.7.7

For permanent repair, continue as follows:

13. Re-commission the system, verify and confirm the suitability of the pipeline for

welding as per Section 2.5.7.2

14. Seal weld the coupling as per Section 2.5.7.3

15. Inspect the weld as per Section 2.5.7.3

16. Recoat/paint the system as per Section 2.5.7.4

17. Sand padding and backfilling as per Section 2.5.7.5

18. Prepare detailed report as per Section 2.5.7.7

Note : Pildco Weld + End couplings only takes into account the forces on a joint due to the internal

pressure and does not consider additional external forces like thermal expansion and contraction,

underwater currents, ground movement or combination thereof. If any of these additional forces

are expected to occur, it is recommended that either the coupling be welded or use of Plidco

Clamp + Ring along with Plidco Weld + End is recommended

Page 26 of 76

GU-379 Pipeline Emergency Repair Manual

2.5.8.4 Plidco Flange + Repair-Ring

These are useful for stopping leaks through the gaskets of the flanges. Plidco Flange +

Repair Rings are installed by placing the two halves around the flange and using studs

and nuts to draw them together. Bolt leakage is stopped by injecting a recommended

sealant with a pressure gun. Reference shall be made to Appendix-6 for details.

Application/Limitations: 1.

2.

3.

4.

5.

6.

Can be used to stop the leakage through the gasket portion of the flanges only.

Available for standard flange sizes to 12 150 lb to 600 lb

Sealant injection required to stop leakage through the bolts.

Pressure gun required to inject sealant

Cannot be used to couple the flanges and provides no longitudinal restraint.

It is only a temporary method of repair.

Procedure: 1.

2.

3.

4.

5.

6.

7.

8.

9.

2.5.8.5

Verify the pipeline as per Section 2.5.3

Ensure all safety precautions are in place as per Section 5.0

Clean the defect area of the leaking flange as per Section 2.5.7.1

Install Plidco Flange + Repair Ring as per manufacturers procedure

Seal the bolts using sealant and pressure gun as per manufacturers procedure

Inspect the system visually

Recoat/repaint the area as per Section 2.5.7.4

Place sand padding and backfill as per Section 2.5.7.5

Prepare detailed report as per Section 2.5.7.7

Plidco Flange-Repair + Split-Sleeve

The Plidco Flange Repair +Split Sleeve fully encapsulates the mated flanges and seals

to the pipe beyond the weld of the flanges. They are useful for stopping leaks through

any portion of the flanges. Reference shall be made to Appendix 7 for details.

Limitations: 1. It is a temporary method of repair.

2. High cost.

Procedure: 1.

2.

3.

4.

5.

6.

7.

8.

Verify the pipeline as per Section 2.5.3

Ensure all safety precautions are in place as per Section 5.0

Clean the defect area of the leaking flange as per Section 2.5.7.1

Install Plidco Flange Repair + Split Sleeve as per manufacturers procedure

Inspect the system visually

Recoat/repaint the area as per Section 2.5.7.4

Place sand padding and backfill as per Section 2.5.7.5

Prepare detailed report as per Section 2.5.7.7

Page 27 of 76

GU-379 Pipeline Emergency Repair Manual

2.5.8.6 Hot Tapping

This method is used to rectify a defect in a pipeline in service. A hot tap fitting is

installed around the defective segment and the defective segment is removed in the

same way as removing a segment from the pipe wall for branch connections using the

hot tap method. It can also be used for installing a temporary bypass to the main line

to carry out a sectional replacement.

All requirements as specified in DEP 31.38.60.10 shall apply whilst carrying out the

hot tapping.

2.5.8.7 Sectional Replacement (without couplings)

Sectional replacement is a permanent method of repair. However, this requires

depressurisation of the pipeline and shutdown of the system. The replacement pipe

section shall have strength of at least that of the pipeline and shall meet the

requirements of API 5L . The section shall be designed as per SP-1211 with same

factor of safety as used for the original pipeline and shall be hydro tested as per SP1211 and DEP 31.40.40.38-PDO prior to installation. The length of the replacement

section shall not be less than half the diameter of the pipeline or 300mm, whichever is

greater. No section shall be installed closer than 150mm to an existing weld.

Application: 1.

This method is a time consuming process of repair due to requiring

shutdown and de-commissioning of the pipeline.

2.

The properties of the original pipeline need to be known to determine the

properties of the replacement pipe material to be used.

3.

The method requires end preparation of the existing pipeline for

welding. The length of the pipe to be cut out shall be such that in addition to

replacing the defective section, the wall thickness where the pipe is to be joined is

suitable for end preparation and welding.

Procedure: 1. Shutdown the pipeline system and transfer the product at the block valve or end

stations

2. Ensure all safety precautions are in place as per Section 5.0

3. Isolate and de-commission the section to be replaced to make the section free

from hydrocarbons as per Section 2.5.7.6

4. Select a spool piece of the required wall thickness and grade as specified above.

5. Hydro-test the spool piece separately as per SP-1211.

6. Clean the defect area as per Section 2.5.7.1

7. Cold cut the defective section to be replaced.

8. Clean the cut ends of the pipeline to be welded and prepare/bevel the ends

9. Weld the replacement section with the existing pipeline as per SP-1177

10. Inspect the weld as per SP-1177

11. Recoat/repaint the system as per Section 2.5.7.4

12. Place sand padding and backfill as per SP-1208

13. Re-commission the pipeline as per requirements of SP-1211, verify and confirm if

de-rating of the pipeline is required.

Page 28 of 76

GU-379 Pipeline Emergency Repair Manual

14. Prepare detailed report as per Section 2.5.7.7

2.5.9

Minimum recommended tools and equipment

The repair crews shall be equipped with all suitable equipment as required for the

specific type / manufacture of the pipeline being repaired and shall carry an adequate

range of fully compatible spare pipe and fittings.

In addition the following tools and consumables shall be carried:

1.

2.

3.

4.

5.

6.

7.

Temperature and relative humidity measuring equipments

Measuring tape, sliding gauge, pipe marker (pen)

Bevelling Machine

Winches

Grinders

Solvent cleaner, cleaning rags

PPE (gloves, eye protection, dust mask)

Any additional tools/ equipment required shall be advised by the engineer-in-charge.

2.6

Composite Repair: An Alternative Repair Method

Composite repair method is an upcoming technology for repair of corrosion and

through wall defects in a pipeline. The composite material considered within the

document, are those with glass (GRP) or carbon (CFRP) reinforcement in a polyester,

vinyl ester or epoxy matrix. These repairs can be used as an alternative to the use of

Mechanical Clamp or Plidco Split Sleeve for a leaking defect (through wall defects),

if designed, qualified and applied in accordance with the ASME code Non Metallic

Composite Repair Systems for Pipelines and Pipe work: High Risk Applications

with in the limits of the qualification. The ASME article is currently in review.

The ASME draft requires a repair lifetime to be specified, which can range from less

than 2 years up to anticipated service life of the system. The composite repair shall be

designed in such a manner that it takes into account the future growth of the defect for

the remaining design life of the pipeline.

A major advantage of the method is the relative ease of application, using simple hand

tools without any welding. The composite repair is most suitable where clamp/sleeves

cannot be installed due to geometric constraint e.g. bends, reducers, T-pieces etc. For

straight pipe sections this method can be used, in case suitable clamp/ sleeves are not

available at the time of leak.

For each repair situation a risk assessment shall be carried out. The risk assessment

shall include consideration of the hazards associated with the system service, the

availability of the personnel with the necessary skills, the ease with which it is

practicable to execute surface preparation operations, the availability of design data.

Leak before break, inspectability, and performance under upset and major incident

situations including fire, explosion, collision and environmental loading.

Page 29 of 76

GU-379 Pipeline Emergency Repair Manual

Manufacturer of composite repair material should provide full installation instructions

including surface preparation, grit blasting, installer qualifications, laminate lay up

etc.

Repair shall be carried out in accordance with the manufacturers procedures and by

manufacturer approved and trained personnel.

The key point that must be considered in design and application of bonded repair is

that the combination of pipe material/ surface preparation technique/ composite is the

basic design unit. Data derived using one set of material cannot be used to assist in

the design of another even if it is only one of the components comprising the

arrangement that has changed.

The limitations of this method are that it needs a dry and mechanically clean surface

for achieving a durable bonded connection between pipe and laminate. To achieve the

required dry surface, it is necessary to plug the leak on-line or depressurize the line.

The second important aspect of repair is surface preparation. Surface preparation

activity involves removal of loose debris and corrosion products followed by

mechanical abrasion. Normally, quality of surface preparation should be in

conformity with SA 2 . For surface preparation using grit-blasting technique on live

lines, all necessary safety precautions should be followed as per PDO procedures.

2.7

Level II Emergency Defects- Injurious non leaking defects

These defects are as described in section 2.2. They have a nominal impact on the

productivity of the pipeline due to the requirement for pressure reduction. Reference

is made to SP-1235 for possible repair options and methods for level-II emergency

defects.

2.8

Repair organisation

The repair organisation and contingency plans for PDO pipelines are given in the

Emergency Response Document, Part-III in the following volumes:Volume-3, Production Operations, PR-1066

- Clause 2.3.9 Oil Pipeline Failure

- Clause 2.3.10 Gas Pipeline Failure

Volume-4, Main Oil Line PR-1067

Volume-5, Terminal & Tank Farm Operations, PR-1068

Volume-14, Government Gas System Pipeline & Terminals, PR-1246

Volume-15, South Oman Gas Line PR-1275

Page 30 of 76

GU-379 Pipeline Emergency Repair Manual

3.0 Emergency Repairs for Glass Reinforced Plastic (GRP)

Pipelines

3.1

General

GRP pipelines for PDO have been constructed after satisfactory and rigorous

qualification tests have been carried out on the GRP systems. Further quality checks

are made by carrying out visual inspection and pressure testing prior to

commissioning of the system. Most of the GRP pipelines are of buried type.

GRP pipeline systems can suffer operational defects, which may be catastrophic in

nature. This manual identifies the possible catastrophic defects, categorised as

emergency defects, and specifies the appropriate repair methods.

3.2

Scope

This part of the document defines the emergency defects and the repair respective

requirements for GRP pipelines. The emergency repairs for other non-metallic

pipelines including HDPE systems are excluded from the scope.

ISO 14692 (part 1 to 4) and DEP 31.40.10.19, GRP Pipelines and Piping Systems

(Amendments/Supplements to ISO 14692) form the basis for this document.

The defects considered are those that could be encountered during the operation of the

GRP pipelines. Defects detected during the manufacturing, installation, testing and

commissioning stages are excluded from this manual.

3.3

Causes of defects in an operating GRP pipeline system

The occurrence of defects in an operating GRP pipeline system can normally be

attributed to either one or a combination of the following.

3.4

Third party interference (the most common reason)

Excessive operational loads/upset conditions (refer Section 3.4 below)

Defects due to over pressurisation

The over pressurisation of a GRP pipeline system due to failure of the over pressure

protection systems or excessive surge beyond design limits normally leads to weepage

or rupture of the pipeline. If any such situation occurs, it is advised to replace the

complete line or else fitness for purpose evaluation shall be carried out as per

manufacturers recommendation.

3.5

Defect categorisation

The defect categorisation of GRP Class-I pipelines is similar to that of CS pipelines

specified in Section 2 of this document, with the exception that weeping defects are

included in Level-1 emergency defects.

Page 31 of 76

GU-379 Pipeline Emergency Repair Manual

Weeping defects : - This is the most common type of Level-I defect in a GRP pipeline

system. It mainly constitutes seepage, sweating or penetration of the liquid through

the wall of the pipeline. In weeping there is no apparent visual indication of a defect

in the GRP material and mainly occurs due to disturbance in the fibre matrix. It is

difficult to identify the minor weeping defects in buried GRP pipelines (Minor

weeping can only be identified during hydrotesting).

3.6

Repair of Level-I Emergency Defects

The leak detection, defect assessment methods and major activities following