Documente Academic

Documente Profesional

Documente Cultură

Blast Resistant: Doors & Frames

Încărcat de

Amjad Pervaz0 evaluări0% au considerat acest document util (0 voturi)

39 vizualizări1 paginăDS_Blast_Flyer

Titlu original

DS Blast Flyer

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDS_Blast_Flyer

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

39 vizualizări1 paginăBlast Resistant: Doors & Frames

Încărcat de

Amjad PervazDS_Blast_Flyer

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

Blast Resistant

Doors & Frames

BULLET & BLAST RESISTANT PRODUCTS

and frame products have been

analyzed and/or tested by

independent laboratories. The

door units are labeled and

certified by Deansteel.

Testing Agencies

Architectural Testing Inc.

Baker Engineering and

Risk Consultants Inc.

Texas Tech University

Wind Engineering Labs

Fire Protection

Many of Deansteel's Blast

Resistant Door and Frame

assemblies can be certified under

Underwriters Laboratories 10B

and 10C Positive Pressure Fire

tests.

Options

Door designs with optional full

or half-glass or 10"x10" visions

are available in most of our

DSLB rating levels. depending

on the projected blast

conditions. Please inquire for

1958-2008

www.deansteel.com

nationally recognized engineering laboratory to

meet the blast conditions for which they are

certified. Most of the analyses are validated by

actual shock tube or static pressure testing, and

are either used to extend the physical sizes of

door/frame assemblies or to extend the peak

blast pressure and/or impulse that the designs

will resist.

Deansteel offers the Architectural and

Engineering communities a wide range of blast

resistant products to withstand a variety of

projected blast conditions and installations.

Our door assembly model designations for a

"standard" 3'-0"X7'-0" door are:

DSLB-1The lowest peak blast loads

up to 2 psi for all blast load durations.

DSLB-2Low pressure blast events

from 2 psi and very long duration

loads, up to 4 psi with a blast load

duration of 35 milliseconds or less.

DSLB-3Medium pressure blast events

from 4 and very long duration loads, up

to 10 psi with a blast load duration of

10 milliseconds or less.

DSLB-4Moderate pressure blast events

from 9 psi and very long duration

loads, up to 15 psi with a blast load

duration of 10 milliseconds or less.

DSLB-5High pressure blast events

from 15 psi and very long duration

loads, up to 35 psi with a blast load

duration of 10 milliseconds or less.

Note: Blast parameter limits (pressure

and duration) for each model are lower

for larger doors sizes.

Deansteel blast resistant door and frame

assemblies are certified to provide a minimum of

a Category II response per the ASTM F 2247-03

characterized by limited permanent deformation

to the door/frame assembly, but the door unit

remains operational.

Door assemblies are available in standard or

custom sizes and are furnished as complete

assemblies with all required hardware. Vision

lites (fixed glass openings) are optionally

available depending on the projected blast

level. A permanent label is affixed to the

assembly certifying the blast resistance rating

of the unit.

Many of our blast resistant door designs can be

certified as UL Fire Doors with 20 minutes to

3 hour ratings. We can also offer ballistic

resistance ratings on most of our blast resistant

doors to meet the various ballistic resistance

levels as specified in UL 752, NIJ 0108.1,

ASTM F 1233 or MIL-SAMIT specifications.

Deansteel also offers custom engineered

solutions for most blast resistance applications.

For example, we have manufactured custom

door assemblies that were designed to

withstand special blast events. One assembly

was manufactured to withstand a peak pressure

of 50 psi with a blast wave duration of 30

milliseconds. Contact our Sales Department if

you have special blast resistance requirements.

BLAST RESISTANT DOOR UNITS

Standard units up to 35 psi with

custom units for higher pressures

American Made ~ American Owned ~ Buy American

111 Merchant Street San Antonio, Texas 78204 Telephone: 1-800-825-8271 Fax: 210-226-0913

S-ar putea să vă placă și

- Open Inviting and Safe - Designing Secure Buildings PDFDocument4 paginiOpen Inviting and Safe - Designing Secure Buildings PDFArighna MitraÎncă nu există evaluări

- Blast Door - Frame SpecificationsDocument4 paginiBlast Door - Frame SpecificationsMujjo SahbÎncă nu există evaluări

- Blast Door Frame AssemblyDocument11 paginiBlast Door Frame AssemblyAnonymous CsDebViÎncă nu există evaluări

- DB 200 SLDocument2 paginiDB 200 SLkanchanabalajiÎncă nu există evaluări

- Division 7 Thermal and Moisture ProtectionDocument17 paginiDivision 7 Thermal and Moisture ProtectionSajjadAhmadÎncă nu există evaluări

- Panel Door SpecsDocument7 paginiPanel Door Specssajid hussainÎncă nu există evaluări

- Application & Technical Manual 10 Penetration SealsDocument62 paginiApplication & Technical Manual 10 Penetration SealskenwongwmÎncă nu există evaluări

- Sapa Building System Protection and Security Solutions - ENDocument15 paginiSapa Building System Protection and Security Solutions - ENSapa Building SystemÎncă nu există evaluări

- Ficha Tecnica - Microseal - DSDocument2 paginiFicha Tecnica - Microseal - DSedocducÎncă nu există evaluări

- SECTION 08 14 00 Interior Wood DoorsDocument8 paginiSECTION 08 14 00 Interior Wood DoorsAlronavee MambajeÎncă nu există evaluări

- Lorient BrochureDocument28 paginiLorient BrochureJerry Lee LiongsonÎncă nu există evaluări

- Ansi-Bhma 156.15-2021 HHDocument1 paginăAnsi-Bhma 156.15-2021 HHRey Eduard Q. UmelÎncă nu există evaluări

- Fire-Rated Glazing ProductsDocument3 paginiFire-Rated Glazing ProductsKristoffer Jose AlcantaraÎncă nu există evaluări

- Blast 20 Resistant 20 AIA20 Course 20 ExcerptDocument12 paginiBlast 20 Resistant 20 AIA20 Course 20 Excerpthendri sukrisnoÎncă nu există evaluări

- BRDFDocument4 paginiBRDFKamil ÇiftçiÎncă nu există evaluări

- SDI - 118 - Standard Steel Doors and FramesDocument9 paginiSDI - 118 - Standard Steel Doors and FramesPangit BertÎncă nu există evaluări

- Boral DstudDocument28 paginiBoral DstudlaurenjiaÎncă nu există evaluări

- Specification GPX Curtain Wall Framing Part 1 General: Section 08 8810: Fire Rated Glass & FramingDocument6 paginiSpecification GPX Curtain Wall Framing Part 1 General: Section 08 8810: Fire Rated Glass & Framingmaris_sasecÎncă nu există evaluări

- Build TechDocument4 paginiBuild Techahmad nadzriÎncă nu există evaluări

- Windows: DoorsDocument8 paginiWindows: Doorsansal mtechÎncă nu există evaluări

- Wood DoorsDocument8 paginiWood DoorsJad Antonios JelwanÎncă nu există evaluări

- Idm June 2013 g21Document62 paginiIdm June 2013 g21Marco FoglieriÎncă nu există evaluări

- Fire Door CatalogDocument29 paginiFire Door CatalogcharibackupÎncă nu există evaluări

- Aerospace Airframe Engine GBDocument16 paginiAerospace Airframe Engine GBEhab GhandourÎncă nu există evaluări

- Za Citat DicotechDocument8 paginiZa Citat DicotechEnes S. SejranicÎncă nu există evaluări

- Cofrete Polyester PLADocument88 paginiCofrete Polyester PLATalos Sorin100% (1)

- Concrete & CKD Shelters PDFDocument4 paginiConcrete & CKD Shelters PDFReno SaibihÎncă nu există evaluări

- KNAUF Plasterboard Installation Guide - April 2013Document52 paginiKNAUF Plasterboard Installation Guide - April 2013amazonfedÎncă nu există evaluări

- QTs EcoSeriesDocument22 paginiQTs EcoSeriesasrihamidÎncă nu există evaluări

- BWF Guide To Weather Performance Testing v1 July 2017Document8 paginiBWF Guide To Weather Performance Testing v1 July 2017duraisingh.me6602Încă nu există evaluări

- Sluice Gates - Slide Gates - PenstocksDocument28 paginiSluice Gates - Slide Gates - Penstocksnazar750100% (2)

- Arch Window Selection GuideDocument4 paginiArch Window Selection GuideuddinnadeemÎncă nu există evaluări

- Fire-Rated Glass Document38Document5 paginiFire-Rated Glass Document38jefftemple0% (1)

- A156.4 - 2008 Door Control-Closers Hardware HighlightsDocument1 paginăA156.4 - 2008 Door Control-Closers Hardware HighlightsteramodÎncă nu există evaluări

- System 9000 Resilient Blanket Insulation Spec SheetDocument4 paginiSystem 9000 Resilient Blanket Insulation Spec SheetSethuraman Saravanakumar100% (1)

- TKO BrochureDocument8 paginiTKO BrochureModern Group, ltdÎncă nu există evaluări

- Wintech Engineering Limited - Brochure 2014Document12 paginiWintech Engineering Limited - Brochure 2014WintechEngineeringÎncă nu există evaluări

- ANSI-BHMA 156.17 HH 2019 RevisedDocument1 paginăANSI-BHMA 156.17 HH 2019 RevisedRey Eduard Q. UmelÎncă nu există evaluări

- Bundle Division 8Document21 paginiBundle Division 8sahilÎncă nu există evaluări

- Bursting Discs Breather Valves Signalling UnitsDocument16 paginiBursting Discs Breather Valves Signalling Unitssmab2162094Încă nu există evaluări

- Ansi-Bhma 156.2 HH 2019Document1 paginăAnsi-Bhma 156.2 HH 2019Rey Eduard Q. Umel0% (1)

- Roll Up SerrandaDocument9 paginiRoll Up SerrandasizwehÎncă nu există evaluări

- 09250.517.gypsum DrywallDocument7 pagini09250.517.gypsum DrywallNguyen BachÎncă nu există evaluări

- SECTION 08 14 00 Interior Wood DoorsDocument11 paginiSECTION 08 14 00 Interior Wood DoorsJuanPaoloYbañezÎncă nu există evaluări

- Wiurila Marine DoorsDocument10 paginiWiurila Marine DoorsleroniusÎncă nu există evaluări

- Fire Doors CatalogueDocument30 paginiFire Doors CatalogueMahipal Singh Rao100% (2)

- ANSI/BHMA A156.8-2015: American National Standard For Door Controls - Overhead Stops & HoldersDocument1 paginăANSI/BHMA A156.8-2015: American National Standard For Door Controls - Overhead Stops & HoldersJoseph Allan TolentinoÎncă nu există evaluări

- Precast Façade WallDocument19 paginiPrecast Façade WallNikhil ThakurÎncă nu există evaluări

- FireRatedWallsDES PDFDocument24 paginiFireRatedWallsDES PDFwhwy99Încă nu există evaluări

- UPVC Window - UPVC Window Manufacturer, Supplier, Trading Company, Dehradun, IndiaDocument2 paginiUPVC Window - UPVC Window Manufacturer, Supplier, Trading Company, Dehradun, IndiaDillibabu RamanujamÎncă nu există evaluări

- Specifiers Guide To Steel ProtectionDocument6 paginiSpecifiers Guide To Steel ProtectionKumararaja KonikkiÎncă nu există evaluări

- Knauf Installation Guide 2012 WEBDocument52 paginiKnauf Installation Guide 2012 WEBamazonfedÎncă nu există evaluări

- Durabuilt Door Catalog 2014Document164 paginiDurabuilt Door Catalog 2014Shiva Kumar Shunmugam100% (1)

- FEMA PR-RA5 Protecting Windows and Openings in BuildingsDocument9 paginiFEMA PR-RA5 Protecting Windows and Openings in BuildingsScribdemdÎncă nu există evaluări

- Windows Specification SheetDocument10 paginiWindows Specification Sheetpraveen0907Încă nu există evaluări

- Certificate 062 99Document6 paginiCertificate 062 99ferdinandbataraÎncă nu există evaluări

- Blast Mitigation TechniquesDocument21 paginiBlast Mitigation TechniquesMohamed ElfawalÎncă nu există evaluări

- Special-Lite FRP Flush Door Testing Summary BrochureDocument4 paginiSpecial-Lite FRP Flush Door Testing Summary BrochureSpecial-Lite DoorsÎncă nu există evaluări

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- Your Home Inspected: An Addendum for Residential Home Inspection ReportsDe la EverandYour Home Inspected: An Addendum for Residential Home Inspection ReportsÎncă nu există evaluări

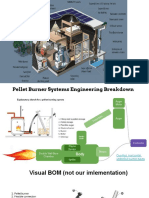

- Pellet BurnerDocument11 paginiPellet BurnerAmjad PervazÎncă nu există evaluări

- Pelltech Model PV 50Document2 paginiPelltech Model PV 50Amjad PervazÎncă nu există evaluări

- ZK Cold Press QuotationDocument2 paginiZK Cold Press QuotationAmjad PervazÎncă nu există evaluări

- Analysis of The Cutting Parameters in Uence During Machining Aluminium Alloy A2024-T351 With Uncoated Carbide InsertsDocument10 paginiAnalysis of The Cutting Parameters in Uence During Machining Aluminium Alloy A2024-T351 With Uncoated Carbide InsertsAmjad PervazÎncă nu există evaluări

- Automatic Edge Banding Machine For ABS PVC by Tiffany Price 9,230.00 USDDocument2 paginiAutomatic Edge Banding Machine For ABS PVC by Tiffany Price 9,230.00 USDAmjad PervazÎncă nu există evaluări

- Wood Pellets BurnerDocument16 paginiWood Pellets BurnerAmjad PervazÎncă nu există evaluări

- Biomass Pellet-Fired BoilersDocument17 paginiBiomass Pellet-Fired BoilersAmjad PervazÎncă nu există evaluări

- Schneeberger Linear Bearing BMB45Document4 paginiSchneeberger Linear Bearing BMB45Amjad PervazÎncă nu există evaluări

- Fazail M Eid+FitrDocument8 paginiFazail M Eid+FitrAmjad PervazÎncă nu există evaluări

- Single Room CO-Hut PlanDocument1 paginăSingle Room CO-Hut PlanAmjad PervazÎncă nu există evaluări

- Yadon-Powered by SchulerDocument1 paginăYadon-Powered by SchulerAmjad PervazÎncă nu există evaluări

- XL200 Technical Reference Installation GuideDocument150 paginiXL200 Technical Reference Installation GuideAmjad PervazÎncă nu există evaluări

- Millat Equipment Limited: Request For QuotationDocument1 paginăMillat Equipment Limited: Request For QuotationAmjad PervazÎncă nu există evaluări

- Mazznine ModelDocument1 paginăMazznine ModelAmjad PervazÎncă nu există evaluări

- Buckwheat: Cover Crop Fact Sheet Series Fact Sheet 3Document2 paginiBuckwheat: Cover Crop Fact Sheet Series Fact Sheet 3stevicablÎncă nu există evaluări

- Special Steel Sheet: Cat - No.B1E-005-04Document16 paginiSpecial Steel Sheet: Cat - No.B1E-005-04Arnaldo Macchi MillanÎncă nu există evaluări

- HSS Stamping Design ManualDocument67 paginiHSS Stamping Design ManualjschuryÎncă nu există evaluări

- Burmuda Triangle MysteryDocument4 paginiBurmuda Triangle MysteryAmjad PervazÎncă nu există evaluări

- Shipping Container Weldable Twist Locks Drawing CHWTLDocument1 paginăShipping Container Weldable Twist Locks Drawing CHWTLAmjad PervazÎncă nu există evaluări

- Stevil Corporation: Steel Structure PEB, PFB and LGSFH From A 2 ZDocument2 paginiStevil Corporation: Steel Structure PEB, PFB and LGSFH From A 2 ZAmjad PervazÎncă nu există evaluări

- Abid FilterDocument3 paginiAbid FilterAmjad PervazÎncă nu există evaluări

- Breakfast Recipes PDFDocument61 paginiBreakfast Recipes PDFmutton moonswamiÎncă nu există evaluări

- Islamicus No.4,2010 PDFDocument229 paginiIslamicus No.4,2010 PDFRifqiSyuja'HilmanAsyaÎncă nu există evaluări

- EFT For Back PainDocument310 paginiEFT For Back Paindanaxor100% (16)

- Anwar Masood - Deewaar E GiryaDocument72 paginiAnwar Masood - Deewaar E GiryaAmjad PervazÎncă nu există evaluări

- Tools For PFBDocument28 paginiTools For PFBAmjad PervazÎncă nu există evaluări

- Steel Wall PanelDocument4 paginiSteel Wall PanelAmjad PervazÎncă nu există evaluări

- Engine Block CastingDocument34 paginiEngine Block CastingAmjad Pervaz100% (1)

- LGSF Container Front WallDocument1 paginăLGSF Container Front WallAmjad PervazÎncă nu există evaluări

- Java Complete Collection FrameworkDocument28 paginiJava Complete Collection FrameworkkhushivanshÎncă nu există evaluări

- Lesson 1: Composition: Parts of An EggDocument22 paginiLesson 1: Composition: Parts of An Eggjohn michael pagalaÎncă nu există evaluări

- Seizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Document14 paginiSeizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Sulaman AbdelaÎncă nu există evaluări

- Reflection On The PoorDocument5 paginiReflection On The Poorapi-347831792Încă nu există evaluări

- Algorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzDocument6 paginiAlgorithms For Automatic Modulation Recognition of Communication Signals-Asoke K, Nandi, E.E AzzouzGONGÎncă nu există evaluări

- MDI - Good Fellas - ScriptDocument20 paginiMDI - Good Fellas - ScriptRahulSamaddarÎncă nu există evaluări

- Omnitron CatalogDocument180 paginiOmnitron Catalogjamal AlawsuÎncă nu există evaluări

- Gastroesophagea L of Reflux Disease (GERD)Document34 paginiGastroesophagea L of Reflux Disease (GERD)Alyda Choirunnissa SudiratnaÎncă nu există evaluări

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDocument18 paginiGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDÎncă nu există evaluări

- Psychoanalytic Theory byDocument43 paginiPsychoanalytic Theory byjoy millano100% (1)

- Neet Question Paper 2019 Code r3Document27 paginiNeet Question Paper 2019 Code r3Deev SoniÎncă nu există evaluări

- Sheltered 2 Item Recycle ListDocument5 paginiSheltered 2 Item Recycle ListRachel GÎncă nu există evaluări

- Resistance & Resistivity: Question Paper 1Document15 paginiResistance & Resistivity: Question Paper 1leon19730% (1)

- Reflection in Sexually Transmitted DiseaseDocument1 paginăReflection in Sexually Transmitted Diseasewenna janeÎncă nu există evaluări

- Taoist Master Zhang 张天师Document9 paginiTaoist Master Zhang 张天师QiLeGeGe 麒樂格格100% (2)

- 4B - Urp - Shavya's FarmDocument22 pagini4B - Urp - Shavya's FarmSnehansh KishoreÎncă nu există evaluări

- Stucor Qp-Ec8095Document16 paginiStucor Qp-Ec8095JohnsondassÎncă nu există evaluări

- Literature Review of Service Quality in RestaurantsDocument7 paginiLiterature Review of Service Quality in RestaurantsuifjzvrifÎncă nu există evaluări

- L5V 00004Document2 paginiL5V 00004Jhon LinkÎncă nu există evaluări

- Accounting Students' Perceptions On Employment OpportunitiesDocument7 paginiAccounting Students' Perceptions On Employment OpportunitiesAquila Kate ReyesÎncă nu există evaluări

- Bioinformatics Computing II: MotivationDocument7 paginiBioinformatics Computing II: MotivationTasmia SaleemÎncă nu există evaluări

- 32 Hyderabad HITEC City BisleriDocument23 pagini32 Hyderabad HITEC City BisleriSridhar ViswanathanÎncă nu există evaluări

- Bench-Scale Decomposition of Aluminum Chloride Hexahydrate To Produce Poly (Aluminum Chloride)Document5 paginiBench-Scale Decomposition of Aluminum Chloride Hexahydrate To Produce Poly (Aluminum Chloride)varadjoshi41Încă nu există evaluări

- Guided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaDocument9 paginiGuided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaAlexander DeckerÎncă nu există evaluări

- Jpedal ManualDocument20 paginiJpedal ManualDamián DávilaÎncă nu există evaluări

- Rights of Parents in IslamDocument11 paginiRights of Parents in Islamstoneage989100% (2)

- 2023 Teacher Email ListDocument5 pagini2023 Teacher Email ListmunazamfbsÎncă nu există evaluări

- Table of Specification 1st QDocument5 paginiTable of Specification 1st QVIRGILIO JR FABIÎncă nu există evaluări

- Persuasive Speech 2016 - Whole Person ParadigmDocument4 paginiPersuasive Speech 2016 - Whole Person Paradigmapi-311375616Încă nu există evaluări

- Nutrition 2022 PIRDocument22 paginiNutrition 2022 PIRAlmira LacasaÎncă nu există evaluări