Documente Academic

Documente Profesional

Documente Cultură

Oil Rig Components List

Încărcat de

samirgoranDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Oil Rig Components List

Încărcat de

samirgoranDrepturi de autor:

Formate disponibile

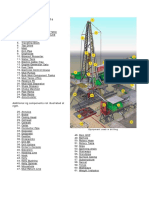

List of components of oil drilling rigs:

From Wikipedia, the free encyclopedia

This article lists the main components of a petroleum onshore drilling rig.

Offshore drilling rigs have similar elements, but are configured with a number of different drilling

systems to suit drilling in the marine environment.

The equipment associated with a rig is to some extent dependent on the type of rig but typically

includes at least some of the items listed below.

1. Mud tank

2. Shale shakers

3. Suction line (mud pump)

4. Mud pump

5. Motor or power source

6. Vibrating hose

7. Draw-works

8. Standpipe

9. Kelly hose

10. Goose-neck

11. Traveling block

12. Drill line

13. Crown block

14. Derrick

15. Racking Board (Sometimes referred to as the Monkey Board

16. Stand (of drill pipe)

17. Setback (floor)

18. Swivel (On newer rigs this may be replaced by a top drive)

19. Kelly drive

20. Rotary table

21. Drill floor

22. Bell nipple

23. Blowout preventer (BOP) Annular type

24. Blowout preventer (BOP) Pipe ram & blind ram

25. Drill string

26. Drill bit

27. Casing head or Wellhead

28. Flow line

Explanation

Bell nipple (#22) is a section of large diameter pipe fitted to the top of the blowout

preventers that the flow line attaches to via a side outlet, to allow the drilling mud to flow back to

the mud tanks.

Blowout preventers (BOPs) (#23 and #24) are devices installed at the wellhead to prevent fluids

and gases from unintentionally escaping from the wellbore. #23 is the annular(often referred to

as Hydril named after a manufacturer), and #24 is the pipe rams and blind rams.

Casing head (#27) is a large metal flange welded or screwed onto the top of the conductor

pipe (also known as drive-pipe) or the casing and is used to bolt the surface equipment such as

the blowout preventers (for well drilling) or the Christmas tree (oil well) (for well production).

Centrifuge (not pictured) is an industrial version of the device that separates fine silt and sand

from the drilling fluid. It is typically mounted on top or just off of the mud tanks.

Crown block (#13) is the stationary end of the block and tackle.

Degasser (not pictured) is a device that separates air and/or gas from the drilling fluid. It is

typically mounted on top of the mud tanks.

Derrick (#14) is the support structure for the equipment used to lower and raise the drill

string into and out of the wellbore. This consists of the sub-structure (structure below the drill

floor level) and the mast.

Desander / desilter (not pictured) contains a set of hydrocyclones that separate sand and silt

from the drilling fluid. Typically mounted on top of the mud tanks.

Draw-works (#7) is the mechanical section that contains the spool, whose main function is to

reel in/out the drill line to raise/lower the traveling block.

Drill bit (#26) is a device attached to the end of the drill string that breaks apart the rock being

drilled. It contains jets through which the drilling fluid exits.

Drill floor (#21) is the area on the rig where the tools are located to make the connections of the

drill pipe, bottom hole assembly, tools and bit. It is considered the main area where work is

performed.

Drill line (#12) is thick, stranded metal cable threaded through the two blocks (traveling and

crown) to raise and lower the drill string.

Drill pipe (#16) is a joint of hollow tubing used to connect the surface equipment to the bottom

hole assembly (BHA) and acts as a conduit for the drilling fluid. In the diagram, these

are stands of drill pipe which are 2 or 3 joints of drill pipe connected and stood in the derrick

vertically, usually to save time while tripping pipe.

Drill string (#25) is an assembled collection of drill pipe, heavy weight drill pipe, drill collars and

any of a whole assortment of tools, connected and run into the wellbore to facilitate the drilling of

a well. The collection is referred to singularly as the drill string.

Elevators (not pictured) are hinged devices that is used to latch to the drill pipe or casing to

facilitate the lowering or lifting (of pipe or casing) into or out of the wellbore.

Flow line (#28) is large diameter pipe that is attached to the bell nipple and extends to the shale

shakers to facilitate the flow of drilling fluid back to the mud tanks.

Goose-neck (#10) is a thick metal elbow connected to the swivel and standpipe that supports

the weight of and provides a downward angle for the kelly hose to hang from.

Kelly drive (#19) is a square, hexagonal or octagonal shaped tubing that is inserted through and

is an integral part of the rotary table that moves freely vertically while the rotary table turns it.

Kelly hose (#9) is a flexible, high pressure hose that connects the standpipe to the kelly (or more

specifically to the gooseneck on the swivel above the kelly) and allows free vertical movement of

the kelly, while facilitating the flow of the drilling fluid through the system and down the drill

string.

Racking board (#15) is the catwalk along the side of the derrick (usually about 35 or 40 feet

above the "floor"). The monkey board is where the derrick man works while "tripping" pipe.

Mud motor (not pictured) is a hydraulically powered device positioned just above the drill

bit used to spin the bit independently from the rest of the drill string.

Mud pump (#4) is a reciprocal type of pump used to circulate drilling fluid through the system.

Mud tank (#1) is often called mud pits and stores drilling fluid until it is required down the

wellbore.

Setback (#17) is a part of the drill floor (#21) where the stands of drill pipe are stood upright. It is

typically made of a metal frame structure with large wooden beams situated within it. The wood

helps to protect the end of the drill pipe.

Rotary table (#20) rotates, along with its constituent parts, the kelly and kelly bushing, the drill

string and the attached tools and bit.

Shale shaker (#2) separates drill cuttings from the drilling fluid before it is pumped back down

the wellbore.

Stand (#16) is a section of 2 or 3 joints of drill pipe connected and stood upright in the derrick.

When they are pulled out of the hole, instead of laying down each joint of drill pipe, 2 or 3 joints

are left connected and stood in the derrick to save time.

Standpipe (#8) is a thick metal tubing, situated vertically along the derrick, that facilitates the

flow of drilling fluid and has attached to it and supports one end of the kelly hose.

Suction line (#3) is an intake line for the mud pump to draw drilling fluid from the mud tanks.

Swivel (#18) is the top end of the kelly that allows the rotation of the drill string without twisting

the block.

Traveling block (#11) is the moving end of the block and tackle. Together, they give a significant

mechanical advantage for lifting.

Vibrating hose (#6) is a flexible, high pressure hose (similar to the kelly hose) that connects the

mud pump to the stand pipe. It is called the vibrating hose because it tends to vibrate and shake

(sometimes violently) due to its close proximity to the mud pumps.

S-ar putea să vă placă și

- Rig Components PDFDocument19 paginiRig Components PDFBalant AxÎncă nu există evaluări

- Introduction To Oil RigsDocument25 paginiIntroduction To Oil RigsballasreedharÎncă nu există evaluări

- List of Components of Oil Drilling RigsDocument4 paginiList of Components of Oil Drilling RigsIjlal AhmadÎncă nu există evaluări

- Daily Tool Pusher ChecklistDocument2 paginiDaily Tool Pusher ChecklistKaleem UllahÎncă nu există evaluări

- Units of Competence: Assistant Driller Level - 7Document17 paginiUnits of Competence: Assistant Driller Level - 7Ben BieberÎncă nu există evaluări

- Drilling TerminologyDocument75 paginiDrilling TerminologyAshish Kumar JhaÎncă nu există evaluări

- Formulas and Calculations for Drilling OperationsDe la EverandFormulas and Calculations for Drilling OperationsÎncă nu există evaluări

- Arabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill PipeDocument4 paginiArabian Drilling Company Rig Specific Procedure AD - 32 Pick Up Drill Pipehosam aliÎncă nu există evaluări

- Drillpipe and Bottom Hole Assembly StandardsDocument2 paginiDrillpipe and Bottom Hole Assembly StandardsSasan Abbasi100% (1)

- Attachment B1 Rig Move Plan ChecklistDocument4 paginiAttachment B1 Rig Move Plan ChecklistJennifer WangÎncă nu există evaluări

- Rig Pre-Commencement Inspection Guide ChecklistDocument115 paginiRig Pre-Commencement Inspection Guide Checklisthosam ali100% (1)

- Rig Move Plan TO ABHD 155 AD-68Document20 paginiRig Move Plan TO ABHD 155 AD-68yousef nÎncă nu există evaluări

- Draw WorksDocument3 paginiDraw WorksUsman AhmedÎncă nu există evaluări

- Idc 37 Rig Move PlanDocument15 paginiIdc 37 Rig Move PlanKarim Lehtihet100% (1)

- 14a - Joe Hurt-John Auth Rig Pass PresentationDocument36 pagini14a - Joe Hurt-John Auth Rig Pass PresentationEduardo Guajardo100% (1)

- Responsibilities of Rig Superintendent StudyDocument7 paginiResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavÎncă nu există evaluări

- Attachment D Pre Rig Move ChecklistDocument2 paginiAttachment D Pre Rig Move ChecklistJennifer WangÎncă nu există evaluări

- Rig component definitions guide under 40 charactersDocument70 paginiRig component definitions guide under 40 charactersHarpreetk87Încă nu există evaluări

- Mast and Dwks Lowering ChecklistDocument5 paginiMast and Dwks Lowering Checklistjinyuan74Încă nu există evaluări

- Rig Components: We LL Drilling Eng Dana MohammadDocument129 paginiRig Components: We LL Drilling Eng Dana Mohammaddana mohammedÎncă nu există evaluări

- Rig Personnel Job DescriptionsDocument6 paginiRig Personnel Job DescriptionsKachur Aleksey100% (1)

- Drawworks and Rig Sizing PDFDocument8 paginiDrawworks and Rig Sizing PDFAmine Mimo100% (1)

- 10 Work On Mud PumpsDocument5 pagini10 Work On Mud PumpsdraghiceanuÎncă nu există evaluări

- 37 Drill Stem Tools 1 PDFDocument2 pagini37 Drill Stem Tools 1 PDFRizwan FaridÎncă nu există evaluări

- Rig Inspection Check ListDocument4 paginiRig Inspection Check ListEd Calhe100% (1)

- Rig Inspection Workshop: Land Rigs, Platform Rigs and Jack-Up RigsDocument2 paginiRig Inspection Workshop: Land Rigs, Platform Rigs and Jack-Up Rigsjohangomezruiz100% (1)

- Rig Handling and Installation Procedure DALIADocument269 paginiRig Handling and Installation Procedure DALIACarlos Gloogh100% (1)

- Safety Lines 75Document7 paginiSafety Lines 75Ben FriskneyÎncă nu există evaluări

- FLOORMAN Sign-Off WorkbookDocument16 paginiFLOORMAN Sign-Off WorkbookBen BieberÎncă nu există evaluări

- Koomey Accumulator Bottle Isolation DOP-PR-R76-080Document5 paginiKoomey Accumulator Bottle Isolation DOP-PR-R76-080cmrig74Încă nu există evaluări

- RP 3.0A For Structures, Drawworks and Rig CarrierDocument25 paginiRP 3.0A For Structures, Drawworks and Rig CarrierDarshan MakwanaÎncă nu există evaluări

- Well Engineering Level 1Document4 paginiWell Engineering Level 1SHOBHIT KUMARÎncă nu există evaluări

- Rig Move Operational Process Flowchart New A4Document1 paginăRig Move Operational Process Flowchart New A4aymenmoatazÎncă nu există evaluări

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersDe la EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersÎncă nu există evaluări

- Rig Components & Equipment ReviewDocument19 paginiRig Components & Equipment Reviewking ghÎncă nu există evaluări

- Lower the Mast SOPDocument2 paginiLower the Mast SOPakv9005Încă nu există evaluări

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Document40 paginiDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUÎncă nu există evaluări

- Table of Contents Iadc Safety Meeting TopicsDocument4 paginiTable of Contents Iadc Safety Meeting TopicsfarisÎncă nu există evaluări

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDocument6 paginiArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusÎncă nu există evaluări

- Cyber BaseDocument39 paginiCyber BaseayhamÎncă nu există evaluări

- BOP Nipple Down 17-May-2010Document1 paginăBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- Drilling Safety Induction Rev 1Document108 paginiDrilling Safety Induction Rev 1Sinan Halboob75% (4)

- Rig Up and Rig Down Potential HazardDocument3 paginiRig Up and Rig Down Potential HazardRizwanButtÎncă nu există evaluări

- Floorman-Tasks & ProjDocument9 paginiFloorman-Tasks & ProjAmeerÎncă nu există evaluări

- Top Drive Systems Dropped Objects Prevention White PaperDocument4 paginiTop Drive Systems Dropped Objects Prevention White PaperneusadÎncă nu există evaluări

- 024 - Competence Requirements For Drilling and Well Service PersonnelDocument16 pagini024 - Competence Requirements For Drilling and Well Service PersonnelmashanghÎncă nu există evaluări

- ERP Travelling Block - Hook BlockDocument9 paginiERP Travelling Block - Hook BlocknobodymagdesignÎncă nu există evaluări

- Rig Component PDFDocument23 paginiRig Component PDFjim carry93% (30)

- EPHH-GPC-Final Report-Nationa Rig & Stack equip-V2-SignedDocument65 paginiEPHH-GPC-Final Report-Nationa Rig & Stack equip-V2-SignedAmir100% (1)

- Technical and Economic Evaluation of Compact Drill Rigs for Deep Geothermal WellsDocument82 paginiTechnical and Economic Evaluation of Compact Drill Rigs for Deep Geothermal WellsKolawole Adisa100% (2)

- Specialized Tools CatalogDocument60 paginiSpecialized Tools CatalogGiorgiana Rosu100% (1)

- RIG EQUIPMENTDocument2 paginiRIG EQUIPMENTRoger AddyÎncă nu există evaluări

- Drilling Supervisor: Passbooks Study GuideDe la EverandDrilling Supervisor: Passbooks Study GuideÎncă nu există evaluări

- List of Components of Oil Drilling RigsDocument5 paginiList of Components of Oil Drilling RigsAlzaki AbdullahÎncă nu există evaluări

- Oil Rig ComponentsDocument3 paginiOil Rig ComponentsIrfan ShaikÎncă nu există evaluări

- Lists Ofdrilling EquipmentsDocument9 paginiLists Ofdrilling EquipmentsNicat NezirovÎncă nu există evaluări

- Bomba Lodo MotorDocument3 paginiBomba Lodo MotorRubén López LemaÎncă nu există evaluări

- Everything You Need to Know About Oil Drilling RigsDocument21 paginiEverything You Need to Know About Oil Drilling RigsOmosigho Osaro100% (1)

- List of Components of Oil Drilling RigsDocument3 paginiList of Components of Oil Drilling RigsExpertise MlcsÎncă nu există evaluări

- Oil Rig Components ListDocument9 paginiOil Rig Components ListsamirgoranÎncă nu există evaluări

- Rumus NgeborDocument5 paginiRumus NgeborafrianÎncă nu există evaluări

- Hydrochloric Acid HandbookDocument51 paginiHydrochloric Acid HandbookCarlos DiazÎncă nu există evaluări

- Casing Drilling TechnologyDocument19 paginiCasing Drilling Technologysamirgoran50% (2)

- Metric SystemDocument66 paginiMetric SystemZoebairÎncă nu există evaluări

- Oil Rig Components ListDocument9 paginiOil Rig Components ListsamirgoranÎncă nu există evaluări

- Metric SystemDocument66 paginiMetric SystemZoebairÎncă nu există evaluări

- Casing Design Hand Calculation Design ExampleDocument34 paginiCasing Design Hand Calculation Design Examplenmtweety88100% (5)

- HSE UK - Driving at Work - Managing Work Related Road Safety BookletDocument24 paginiHSE UK - Driving at Work - Managing Work Related Road Safety BookletramasamigscÎncă nu există evaluări

- Ju Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperDocument11 paginiJu Complete Face Recovery GAN Unsupervised Joint Face Rotation and De-Occlusion WACV 2022 PaperBiponjot KaurÎncă nu există evaluări

- Eritrea and Ethiopia Beyond The Impasse PDFDocument12 paginiEritrea and Ethiopia Beyond The Impasse PDFThe Ethiopian AffairÎncă nu există evaluări

- NAC Case Study AnalysisDocument25 paginiNAC Case Study AnalysisSushma chhetriÎncă nu există evaluări

- Globalisation - Theories of Digital CommunicationDocument12 paginiGlobalisation - Theories of Digital CommunicationDiya Patel-10SÎncă nu există evaluări

- I. ICT (Information & Communication Technology: LESSON 1: Introduction To ICTDocument2 paginiI. ICT (Information & Communication Technology: LESSON 1: Introduction To ICTEissa May VillanuevaÎncă nu există evaluări

- Diagnostic Information For Database Replay IssuesDocument10 paginiDiagnostic Information For Database Replay IssuesjjuniorlopesÎncă nu există evaluări

- Milwaukee 4203 838a PB CatalogaciónDocument2 paginiMilwaukee 4203 838a PB CatalogaciónJuan carlosÎncă nu există evaluări

- ABS Rules for Steel Vessels Under 90mDocument91 paginiABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianÎncă nu există evaluări

- Discursive Closure and Discursive Openings in SustainabilityDocument10 paginiDiscursive Closure and Discursive Openings in SustainabilityRenn MÎncă nu există evaluări

- Make a Battery Level Indicator using LM339 ICDocument13 paginiMake a Battery Level Indicator using LM339 ICnelson100% (1)

- Inflatable Packers enDocument51 paginiInflatable Packers enDavid LuhetoÎncă nu există evaluări

- 28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017Document26 pagini28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017ekangÎncă nu există evaluări

- Conplast SP430 0407Document4 paginiConplast SP430 0407Harz IndÎncă nu există evaluări

- Academy Broadcasting Services Managerial MapDocument1 paginăAcademy Broadcasting Services Managerial MapAnthony WinklesonÎncă nu există evaluări

- Weibull Statistic and Growth Analysis in Failure PredictionsDocument9 paginiWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaÎncă nu există evaluări

- Craft's Folder StructureDocument2 paginiCraft's Folder StructureWowÎncă nu există evaluări

- Organisation Study Report On Star PVC PipesDocument16 paginiOrganisation Study Report On Star PVC PipesViswa Keerthi100% (1)

- Rebranding Brief TemplateDocument8 paginiRebranding Brief TemplateRushiraj Patel100% (1)

- Chapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationDocument16 paginiChapter 6: Structured Query Language (SQL) : Customer Custid Custname OccupationSarmila MahendranÎncă nu există evaluări

- PNB - Recruitment For The Post of Chief Security OfficerDocument3 paginiPNB - Recruitment For The Post of Chief Security OfficerCareerNotifications.comÎncă nu există evaluări

- Self-Assessment On Accountability: I. QuestionsDocument2 paginiSelf-Assessment On Accountability: I. QuestionsAjit Kumar SahuÎncă nu există evaluări

- 50TS Operators Manual 1551000 Rev CDocument184 pagini50TS Operators Manual 1551000 Rev CraymondÎncă nu există evaluări

- Leases 2Document3 paginiLeases 2John Patrick Lazaro Andres100% (1)

- Battery Impedance Test Equipment: Biddle Bite 2PDocument4 paginiBattery Impedance Test Equipment: Biddle Bite 2PJorge PinzonÎncă nu există evaluări

- Supplier Quality Requirement Form (SSQRF) : Inspection NotificationDocument1 paginăSupplier Quality Requirement Form (SSQRF) : Inspection Notificationsonnu151Încă nu există evaluări

- (SIRI Assessor Training) AM Guide Book - v2Document19 pagini(SIRI Assessor Training) AM Guide Book - v2hadeelÎncă nu există evaluări

- QSK45 60 oil change intervalDocument35 paginiQSK45 60 oil change intervalHingga Setiawan Bin SuhadiÎncă nu există evaluări

- EU Letter To Liz Truss 2016Document2 paginiEU Letter To Liz Truss 2016MadeleineÎncă nu există evaluări

- 7458-PM Putting The Pieces TogetherDocument11 pagini7458-PM Putting The Pieces Togethermello06Încă nu există evaluări

- Distribution of Laptop (Ha-Meem Textiles Zone)Document3 paginiDistribution of Laptop (Ha-Meem Textiles Zone)Begum Nazmun Nahar Juthi MozumderÎncă nu există evaluări