Documente Academic

Documente Profesional

Documente Cultură

BF2000 A R2

Încărcat de

a100acomDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BF2000 A R2

Încărcat de

a100acomDrepturi de autor:

Formate disponibile

Floating ball valve

BF 2000

FLOATING BALL VALVE

PREAMBLE

This technical document contains proprietary information belonging to SRi and cannot be copied, reproduced,

divulged, transfered or edited in any form whatever, including electronically or in any format for transmission or

public diffusion without the prior written agreement of SRi.

This document is for information only regarding the actual technical evolution of the product and as such it is

subject to change without prior notice. It cannot be considered as contractual or binding. SRi declines all

responsibility or obligation for errors or oversights which may appear in this document.

Case history :

Date

Document

Number of revision

15/10/00

DTB2000A

1-Floating ball valve.

Technical Documentation - English -Version 1

SRi is

PARIS

41-43 Rue des Chantiers 78000 Versailles - FRANCE

Tel 33 (0) 139 502 920

Fax 33 (0) 139 027 191

E-mail : sales-paris@sri.fr

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 2 of 28

FLOATING BALL VALVE

SUMMARY

PREAMBLE................................................................................................................................................................ 2

DESIGN BF 2000 ........................................................................................................................................................ 4

TECHNICAL CHARACTERISTICS ....................................................................................................................... 4

CAST OR STAMPED CONSTRUCTION ............................................................................................................... 4

DIMENSIONAL RANGE .......................................................................................................................................... 5

FULL BORE ............................................................................................................................................................... 5

REDUCED BORE ........................................................................................................................................................ 5

EQUIPMENT .............................................................................................................................................................. 5

OPEN/CLOSE LOCKING DEVICE: ............................................................................................................................... 5

STEM EXTENSIONS: .................................................................................................................................................. 5

GEARBOXES ............................................................................................................................................................. 5

LIMIT SWITCHES ....................................................................................................................................................... 5

ACTUATION .............................................................................................................................................................. 5

FIRE SAFE.................................................................................................................................................................. 5

MATERIALS .............................................................................................................................................................. 6

TOP WORKS ............................................................................................................................................................ 18

PRESSURE TEMPERATURE RATING ............................................................................................................. 19

TORQUES AND OPERATING............................................................................................................................... 21

OPENING TORQUE: ................................................................................................................................................. 21

MAXIMUM ALLOWABLE STEM TORQUE.................................................................................................................. 22

HYDRAULIC CHARACTERISTICS..................................................................................................................... 23

FLOW COFFICIENT CV........................................................................................................................................ 24

FULL BORE VALVES ............................................................................................................................................... 24

REDUCED BORE VALVES ........................................................................................................................................ 25

ACCESSORIES......................................................................................................................................................... 26

INSULATING EXTENSION......................................................................................................................................... 26

LOCKING DEVICES ................................................................................................................................................. 27

BF 2000 PRODUCTS................................................................................................................................................ 28

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 3 of 28

FLOATING BALL VALVE

DESIGN BF 2000

SRi Taking advantage of its experience in high and

very high pressure technology, SRI offers a complete

range of floating ball valves.

A modern approach to dimensioning and to concept

reliability in conjunction with proven technical

solutions assure :

- Complete conformity

with norms, codes and

specifications

- Quality in

conformance with the

criteria of ISO 9001.

BF 2000 valves are

made to withstand the

full differential pressure of each pressure class in every

Nominal Diameter.

TECHNICAL CHARACTERISTICS

Split body in two blocks bolted together. Double body

static sealing, primary joint in elastomer or polymer

and a secondary firesafe gasket. Bolts threaded blind

holes with anti-corrosion protection.

Solid stainless steel ball.

Anti-blowout stem profiled to minimize stresses (no

grooves or threads)

Dynanic Stem Sealing with standard body housing

available in 3 versions :

1-fixed composition with O-ring and fire safe

graphite gasket

2-adjustable arrangement with graphite gaskets

only

3-adjustable arrangement with PTFE gaskets

for use in very corrosive applications

Polymer seats assure the sealing and the bracing in the

block position using a controlled pre-charge..

ISO interface for simple and rapid connections of

gearboxes and other automatic controls.

Positive antistatic device through physical contact

between the different parts.

Strict conformity to the Pressure/Temperature

relations per ISO PN for each pressure class, within the

capacity limits of the composants. This requirement

is superior to that imposed by BS 5351 Norm.

CAST OR STAMPED CONSTRUCTION

The basic model is made from cast parts (carbon or

stainless steel) for the body and forged metal for the

other parts.

Alternatively the pressure containing parts are made

from stamped roughs up to ND 2 inch and in forged

roughs for larger sizes especially for noble alloys

(Duplex Steel, Inconel, etc.).

In both cases all the elements are completely

interchangeable between all versions.

AUTOMATIC LIMITATION OF

OVERPRESSURE IN THE BODY CAVITY

Seat conception and placement in the line sealing mechanism

Seat volum

reduced

Conical rear face for

self-positionning

Relief seat

grooves

All sealing arrangements are independent

of the stem to facilitate maintenance and

adjustment.

Solid seat

preloaded

Fire safe lip

assure automatic decompression in the body cavity with the

upstream connector. This pressure equalization is effective

at a very low level (lowest to 5 bars) necessary to equilibrate

the pre-loading of the seats.

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 4 of 28

FLOATING BALL VALVE

TORQUE AND OPERATING

EQUIPMENT

Particular attention is paid to reliability and consistence

in operating by optimizing the dimensions of the

composants and the friction between surfaces.

Lever :

Solid stainless steel for all sizes.

Open/Close Locking device:

DIMENSIONAL RANGE

Readily available for lever or gearbox operators.

Full bore

PN/DIN

16 25

10

40

"

"

1"

1"

1"

2"

2"

3"

4"

6"

Gearboxes

Connected by a vented spacer per ISO 5211. Possible

combinations are given in the table below :

20

10

PN / DIN

16 25 40

2" x 1"

3"x 2"

4"x 3"

6"x 4"

8"x 6"

Lever

Levier

PN / DIN

16 25 40

Lever

10

Lever

ISO PN

50 100

Note : ISO PN 20-50-100 related of classes 150-300-600

respectively.

Note : ISO PN 20-50-100 related of classes 150-300-600

respectively.

PRINCIPAL APPLICATIONS FOR

STANDARD COMPOSITIONS

The following is non-exhaustive and only gives typical

repartition by domain.

INDICATIVE DOMAIN OF USE

CODE

20

Lever

ISO PN

50 100

ND

bore

"

"

1"

1"

1"

2"

2"

3"

4"

6"

Lever

Reduced bore

ND

Extends maneuvering axis for heat insulating, standard

lengths available in 100 and 150 mm.

Special lengths available upon request.

Lever

ND

ISO PN

20

50 100

Stem Extensions:

GAS & OIL

CHEMICAL

CORROSIVE

GENERAL

USES

CS

SS 1

SS 2

DUPLEX

Technical Documentation - FLOATING BALL VALVE Rev : 2

Limit switches

Readily connected on manual or gearbox operated

valves.

Actuation

Pneumatics, hydraulics, electrics , "dead men system ",

etc

FIRE SAFE

The full range of SRi floating ball valves is fire tested

and approved to BS 6755 Part 2.

Page 5 of 28

FLOATING BALL VALVE

MATERIALS

"Bicone" system SS2

Graphit system

CS-SS1-DUPLEX

O RING SYSTEM

CS-SS1-DUPLEX

Materials indicated represent the standard manufactured compositions.

Other metals can be used. Consult your sales person.

Rep

1

2

4

5

6

8

10

11

17

21

22

25

26

32

38A-B

69

80

141

142-143

Part name

BODY

FLANGE

BALL

SEAT

STEM + Anti-static

PACKING GLAND

STUD

NUT

PACKING GLAND BEARING

FIRE-SAFE STEM GASKET

FIRE-SAFE BODY GASKET

STOP SCREW

STOP PLATE

FLANGE SEAL

STEM SEAL

TRUST BEARING STEM

PACKING GLAND WASHER

SEAL STEM SUPPORT

CHEVRON RING

CS

A216WCB(1)

A216WCB(1)

A182F316

PTFE (3)

A182F316

A182F316

A193 B7

A194 2H

PTFE

GRAPHIT

GRAPHIT

AISI 316

AISI 316L

FKM (4)

FKM (4)

PTFE+304

A182F316

A182F316

NA

STANDARD MATERIAL

SS 1

SS 2

A351CF8M(2)

A351CF8M(2)

A351CF8M(2)

A351CF8M(2)

A182F316

A182F316

PTFE (3)

PTFE (3)

A182F316

A182F316

A182F316

A182F316

A193 B8M

A193 B8M

A194 Gr 8

A194 Gr 8

PTFE

PTFE

GRAPHIT

NA

GRAPHIT

GRAPHIT

AISI 316

AISI 316

AISI 316L

AISI 316L

PTFE+304

PTFE+304

FKM (4)

NA

PTFE+304

PTFE+304

A182F316

A182F316

A182F316

NA

NA

PTFE

DUPLEX

A182F51

A182F51

A182F51

PTFE (3)

A182F51

A182F316

A193 B8M

A194 Gr 8

PTFE

GRAPHIT

GRAPHIT

AISI 316

AISI 316L

FKM (4)

FKM (4)

PTFE+304

A182F316

A182F316

NA

Notes : 1- Possible manufacture in A350 LF2 Stamped for ND <= 2"

2- Possible manufacture in A182F316 Stamped for ND<=2"

3- PTFE +25% glass filler & PTFE +15% graphite in ISO PN 100 (600 lbs) only

Other quality (Devlon V, Peek, etc.) upon request

4-FKM=Fluoroelastomer

Various elastomers are available depending on service conditions.

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 6 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

CLASS

ISO PN 10-16-25-40

Materials

Materials

Group 1-1 (Bar)

Group 2-3 (Bar)

10 16 25 40 10 16 25 40

10 16 25 40 8 13 21 33

16 25 40 60 12 20 31 49

11 18 28 44 9 15 23 36

5.6 5.6 5.6 5.6 5.6 5.6 5.6 5.6

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

FULL BORE

ND

DIMENSIONS

B

PN16 PN25

95

95

105

105

115

115

140

140

150

150

165

165

(1 )

(mm)

E

Inches

mm

mm

PN10

PN40

"

15

12.5

95

95

130 43.5

"

20

17

105

105

150 43.5

1"

25

24

115

115

160

53

1"

32

30

140

140

180 60.5

1"

40

37

150

150

200 60.5

2"

50

49

165

165

230

72

Notes : Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

(1) NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Weight

K

49

66

73

68

68

72

106

106

128.5

136

136

160

150

150

200

200

200

330

Kg

2.5

3.2

4.6

6.9

7.7

11.6

Page 7 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

CLASS

ISO PN 10-16

Materials

Group 1-1 (Bar)

10

16

10

16

16

25

11

18

5.6

5.6

Materials

Group 2-3 (Bar)

10

16

8

13

12

20

9

15

5.6

5.6

FULL BORE

ND

DIMENSIONS

(1 )

C

E

K

B

Inches

mm

mm

PN10

PN16

2"

65

64

185

185

290

90.5

82

3"

80

75

200

200

310

90.5

82

4"

100

100

220

220

350

118.5

100

6"

150

150

285

285

480

166

150

Notes : Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Weight

(mm)

F

178.5

178.5

221

274

L

330

330

450

500

Kg

16.5

21.6

39

83

Page 8 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

CLASS

ISO PN 25-40

Materials

Group 1-1 (Bar)

25

40

25

40

40

60

28

44

5.6

5.6

Materials

Group 2-3 (Bar)

25

40

21

33

31

49

23

36

5.6

5.6

FULL BORE

ND

DIMENSIONS

A

B

PN40

185

200

235

300

(1 )

Weight

(mm)

K

Inches

mm

mm PN25

2"

65

64

185

290 104.5 115

207

450

3"

80

75

200

310 104.5 115

207

450

4"

100

100

235

350

136

130

244

500

Not applicable

6"

150

150

300

480

185

180

Notes : Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Kg

17.6

32.5

61.6

96

Page 9 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

CLASS ISO PN 20

ANSI 150 lbs

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

Materials

Group 1-1

Bar

Psi

20

285

30

425

22

300

5.6

80

Materials

Group 2-3

Bars

Psi

16

230

24

345

18

360

5.6

80

FULL BORE

A

ND

Inches

"

"

1"

1"

2"

3"

4"

6"

Notes :

mm

15

20

25

40

Norm 1

DIMENSIONS

(1 )

C

B

E

K

F

108

89

43.5

44

106

117.3

99

43.5

49

106

127

108

53

53

128.5

165.1

127

60.5

68

136

177.8

152

72

72

160

50

49

203

152

72

72

160

203.2

190

90.5

82

178.5

80

75

241

190

90.5

82

178.5

228.6

229

118.5

100

221

100

100

305

229

118.5

100

221

2

150

150

393.7

279

166

150

274

Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

12.5

17

24

37

B16-10

B16-10

B16-10

B16-10

B16-10

BS2080

B16-10

BS2080

B16-10

BS2080

B16-10

Weight

(mm)

L

150

150

200

200

330

330

330

330

450

450

500

Kg

2.3

2.9

4.2

7

10.5

11.2

18

19.1

32.5

34

80

End to end ANSIB16-10 or BS 2080 Table 1 Raised face

Long pattern

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 10 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

CLASS ISO PN 50

ANSI 300 lbs

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

Materials

Group 1-1

Bar

Psi

51

740

78

1100

57

800

5.6

80

Materials

Group 2-3

Bars

Psi

41

600

63

900

46

660

5.6

80

FULL BORE

ND

Inches

"

"

1"

1"

2"

3"

4"

6"

Notes :

DIMENSIONS

(1 )

(mm)

A

mm

C

B

E

K

F

L

15

12.5

139.7

95

43.5

49

106

150

20

17

152.4

117

43.5

66

106

150

25

24

165.1

124

53

73

128.5

200

40

37

190.5

156

60.5

68

136

200

50

49

215.9

165

72

72

160

330

80

75

282.5

210

104.5

115

207

450

100 100

304.8

254

136

130

244

500

150 150

403.4

318

185

180

Not applicable

Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Weight

Kg

3.2

4.3

5.8

9.8

11.2

30.7

58.7

128

Page 11 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

CLASS ISO PN 100

ANSI 600 lbs

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

Materials

Group 1-1

Bar

Psi

102

1480

154

2175

113

1600

5.6

80

Materials

Group 2-3

Bars

Psi

82.5

1200

125

1780

92

1310

5.6

80

FULL BORE

ND

Inches

"

"

1"

1"

2"

Notes :

DIMENSIONS

(1 )

(mm)

mm mm

C

B

E

K

F

L

15

12.5

165.1

95

43.5

66

106

150

20

17

190.5

117

43.5

66

106

150

25

24

215.9

124

53

73

128.5

200

40

37

241.3

156

66.5

90

155

330

50

49

292.1

165

88.5

105

191

450

Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Weight

Kg

3.1

4.5

6.6

14

25

Page 12 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

CLASS

ISO PN 10-16

Materials

Group 1-1 (Bar)

PN 10

PN 16

10

16

16

25

11

18

5.6

5.6

Materials

Group 2-3 (Bar)

PN 10

PN 16

8

13

12

20

9

15

5.6

5.6

REDUCED BORE

Weight

ND

A0

DIMENSIONS

(1 )

(mm)

C

E

K

B

Inches

mm

mm

mm PN10

PN16

2"x 1" 50x40

49

37

165

165

230

60.5

72

3"x 2"

80x50

75

49

200

200

310

72

90

4"x 3"

100x80

100

75

220

220

350

90.5

100

6"x 4" 150x100 150

100

285

285

480

118.5 135

8"x 6" 200x150 200

150

340

340

600

166

170

Allowance on A : 0/+0.3

Notes :

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

F

136

160

178.5

221

274

L

200

330

330

450

500

Kg

11.4

20.2

26

48.5

98 3

Weight is valid for PN10 and PN16

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 13 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

Materials

Group 1-1 (Bar)

PN 25

PN 40

25

40

40

60

28

44

5.6

5.6

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

CLASS

ISO PN 25-40

Materials

Group 2-3 (Bar)

PN 25

PN 40

21

33

31

49

23

36

5.6

5.6

REDUCED BORE

ND

DIMENSIONS

A0

B

PN25

PN40

165

165

200

200

235

235

300

300

360

375

(1 )

Inches

mm

mm

mm

2" x 1"

50x40

49

37

230 60.5

3"x 2"

80x50

75

49

310

72

4"x 3"

100x80

100

75

350 104.5

6"x 4"

150x100

150

100

480

136

8"x 6"

200x150

200

150

600

185

Notes : Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

(mm)

Weight

72

90

130

165

210

136

160

207

244

200

330

450

500

Not applicable

Kg

11.4

20.2

36

73

1214 1285

Weight ISO PN 25

Weight ISO PN 40

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 14 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

Materials

Group 1-1

Bar

Psi

20

285

30

425

22

300

5.6

80

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

CLASS ISO PN 20

ANSI 150 lbs

Materials

Group 2-3

Bars

Psi

16

230

24

345

18

360

5.6

80

REDUCED BORE

ND

Inches

mm

2" x 1" 50x40

3" x 2"

80x50

4"x 3"

100x80

6"x 4" 150x100

8"x 6"

200x150

Weight

Form

A0

LP

mm

49

75

100

150

mm

37

49

75

100

C

177.8

203.2

228.6

393.7

B

152

190

229

279

E

60.5

72

90.5

118.5

K

72

90

100

135

F

136

160

178.5

221

L

200

330

330

450

Kg

9.2

17.2

25

48

LP

200

150

457.2

343

166

170

274

500

96.2

DIMENSIONS

(1 )

(mm)

Notes : Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

LP = Long pattern

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 15 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

Materials

Group 1-1

Bar

Psi

51

740

78

1100

57

800

5.6

80

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

CLASS ISO PN 50

ANSI 300 lbs

Materials

Group 2-3

Bars

Psi

41

600

63

900

46

660

5.6

80

REDUCED BORE

ND

Form

A0

DIMENSIONS

Inches

mm

mm

mm

C

B

E

2" x 1"

50x40

49

37

215.9

165

60.5

3" x 2"

80x50

75

49

282.4

210

72

4"x 3"

100x80

100

75

304.8

254

104.5

6"x 4"

150x100

150

100

403.4

318

136

8"x 6"

200x150

LP

200

150

501.6

381

185

Notes : Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

LP = Long pattern

Technical Documentation - FLOATING BALL VALVE Rev : 2

(1 )

Weight

(mm)

K

72

90

130

165

210

F

136

160

207

244

L

200

330

450

500

NA

Kg

12

23

42.5

81

143.5

Page 16 of 28

FLOATING BALL VALVE

DIMENSIONS AND

WEIGHT

Materials

Group 1-1

Bar

Psi

102

1480

154

2175

113

1600

5.6

80

WORKING AND TEST PRESSURE

MAXIMUM WORKING PRESSURE

BODY TEST PRESSURE

HIGH PRESSURE SEAT TEST

AIR SEAT TEST PRESSURE

CLASS ISO PN 100

ANSI 600 lbs

Materials

Group 2-3

Bars

Psi

82.5

1200

125

1780

92

1310

5.6

80

REDUCED BORE

ND

A0

DIMENSIONS

(1 )

Inches

mm

mm

mm

C

B

E

K

2"x1"

50x40

49

37

292.1

165

66.5

105

3" x 2"

80x50

75

49

355.6

210

88.5

130

Notes : Allowance on A : 0/+0.3

All weight are related on cast valves only. Lever not included.

1-NFE 29305 Serie 1

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Weight

(mm)

F

155

191

L

330

450

Kg

16

33

Page 17 of 28

FLOATING BALL VALVE

TOP WORKS

ISO 5211 standard

Warning !

Connecting devices for actuators should not

exert any axial or radial loads on the valve

stem

NA= Not applicable

ND Inches

Full

Reduced

"

NA

"

NA

1"

NA

1"

NA

1"

2"x 1"

2"

3"x 2"

2"

NA

3"

4"x 3"

4"

6"x 4"

6"

8"x 6"

Classes

150

300

600

150

300

600

150

300

600

150

300

600

150

300

600

150

300

150

300

150

300

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN10-16

PN25-40

PN10-16

PN25-40

PN10-16

PN25-40

Type

ISO

Dimensions (mm)

G

H

J

F03

14.5

10

4.5

25

11

F03

14.5

10

4.5

25

F04

19

12

30

F04

19

12

F04

19

12

F05

26

F05

F10

F05

F10

F05

F10

F10

F12

F12

F16

M6

36

M4

11

M6

36

M4

11

14

M6

42

M5

30

11

14

M6

42

M5

30

11

14

M6

42

M5

19

35

16

19

M6

50

M6

12

26

19

35

16

19

M6

50

M6

12

42.5

26

42.5

26

42.5

42.5

55

55

70

29

19

29

19

29

29

39

39

50

13.5

7

13.5

7

13.5

13.5

16

16

20

70

35

70

35

70

70

85

85

130

22

16

22

16

22

22

32

32

44

29

19

29

19

29

29

39

39

54

4

4

4

4

4

4

4

4

4

M10

M6

M10

M6

M10

M10

M12

M12

M20

102

50

102

50

102

102

125

125

165

M8

M6

M8

M6

M8

M8

M10

M10

M10

12

12

12

12

12

12

15

15

15

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 18 of 28

FLOATING BALL VALVE

PRESSURE TEMPERATURE RATING

Seats materials :

A= PTFE+25% Fiber Glass filled

B= PTFE+15% Carbon / Graphite filled

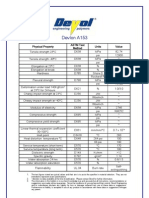

C= DEVLON V API DEVOL ENGINEERING

D= PEEK

Full

"

"

1"

ND

Reduced

NA

NA

NA

1"

NA

1"

2"x 1"

2"

3"x 2"

2"

NA

3"

4"x 3"

4"

6"x 4"

6"

8"x 6"

Pressure Classes

150

300

600

150

300

600

150

300

600

NA

150

300

600

150

300

600

NA

150

300

150

300

150

300

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN100

PN10-16

PN25-40

PN10-16

PN25-40

PN10-16

PN25-40

PN10-16

PN25-40

Seats

B-C-D

NA

NA

NA

NA

NA

Note : NA= Not applicable

The heat resistance of the seat and gastkets is for information only since they vary according to chemical

compatibility. Consult sales or technical services for questions regarding selection of these materials.

Pressure/temperature limits for standard classes are based on values expressed in ANSI B16-34 Group

Materials 1-16. For other materials, maximum allowable working pressure at higher temperatures must be

recalculated.

Materials : Group 1-1 : Carbon Steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steel s(18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 19 of 28

FLOATING BALL VALVE

ANSI B16-34 -

SEATS

Polymers quality

PTFE+25% glass filled

PTFE+15% Graphite

PEEK

DEVLON V API

Temperatures C

Min

Max

-200

200

-200

200

-65

250

-100

160

DEVOL ENGINEERING

BS 5351

Pressures temperature

rating for Group material 1-1

All materials Pressure > to

Table 3 "Minimum Pressure /

Temperature Seat rating for Ball

valves"

API 6D Pipeline Valves (ND >= 2")

Valves having non metallic seals shall conform to the ratings of sections

2.2a and 2.2b for the temperature range -20F + 100F (-29C +

38C).

Maximum service temperature must take into account the temperature/pressure ratio of the seat polymer and

the temperature limit of the gasket elastomer.

Pressures in MPa (Standard Class)

15

DEVLON V API

PEEK

10

PTFE+GRAPHIT

600 lbs

400 lbs

300 lbs

PTFE+25%Glass

150 lbs

38

93

149

204

260

316

Temperature (C)

Materials : Group 1-1 : Carbon steels (C,C-Si,C-Mn-Si,C-Mn,Si,V)

Group 2-3 : Austenitic steels (18Cr-8Ni,16Cr-12Ni-2Mo)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 20 of 28

FLOATING BALL VALVE

TORQUES AND OPERATING

Opening Torque:

Opening torque in the following table are indicated for full differential pressure and for soft seats PTFE +

25% glass filled, PTFE + graphite.

For PEEK seats, multiply the values by 1.3

To size an actuator , please add a 50% safety factor at the requested torque for the maximum service

differential pressure.

1000

6" 300

4" 300

6" 150

2" 1/2

3" 300

2" 600

100

4" 150

Torquues Nm

1" 1/2 600

2" 150/300

2" 1/2

3" 150

1" 1/2 150/300

1" 1/4 150/300

1" 150/600

10

1/2"&3/4" 150/600

1

0

0,5

1,5

2,5

3,5

4,5

5,5

6,5

7,5

8,5

9,5 10

Differential pressure MPa

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 21 of 28

FLOATING BALL VALVE

Maximum allowable Stem Torque

The following table indicates the maximum admissible torque before reaching the conventional yield strength

limit of the material at the most critical point of stem.

This value should never be surpassed in any case since excess force can lead to irreversible damage to the

stem and other moving parts.

Caution must be used when connecting hydraulic, pneumatic, or electric operators to insure that the maximum

force or pressure of the operator does not generate an excessive torque on the stem.

Shear torque values in Nm

Stem dimensions on page 18

Stem

ND (bore) & Class

Stem materials Torque

ISO dimensions

ISO PN20

ISO PN50 ISO PN100

316

410

F51

17-4PH

N

(PN 10-16)

(PN 25-40)

(PN 100)

G

Sy=207 Sy=500 Sy=450 Sy=724

H

12

9

28

67

60

154

" "

F03

15

12

52

126

113

182

1" - 1" - 1"

1"

F04

20

16

144

347

312

798

2"- 2" - 3"

2"

1"

F05

30

22

416

1004

904

2310

4"

2" 3"

2"

F10

40

32

1149

2774

2497

6381

6"

4"

F12

54

44

2470

5966

5369

8639

6"

F16

ISO PN 20 50 -100 related to 150 300 - 600 class respectively.

Notes :

Sy =Min yield strength (determining by the 0.2% offset) in MPa

H =Outside stem diameter in mm

G =On flat stem dimension in mm

Codification materials UNS (Unified Numbering System)

316 : UNS S31600

410: UNS S41000

F51 : UNS S31803 (Ferritic Austenitic)

17-4PH :UNS S17400 Quenched and tempered H1150

Technical Documentation - FLOATING BALL VALVE Rev : 2

Page 22 of 28

FLOATING BALL VALVE

HYDRAULIC CHARACTERISTICS

SRi can recommend the size of valve to be installed or evaluate pressure loss caused by a given valve upon

receipt of the service conditions.

Flow coefficient calculations are taken from the following references :

-NF EN 60534-2-2 June 1993 C 46-504

-NF E 29 312 December 1984

LIQUID

Cv = Flow coefficient

q = Volumic flow (m3/h)

W = Mass flow (ton / h) at flowing

temperature

P = Pressure drop (bar)

Gf = Liquid density related to water

(1 15,6C)

Volum flow

Cv = 116

. q

Mass flow

Cv =

Gf

P

116

. W

G f P

GAS

Q = Volumic flow (Nm3/h)

W = Mass flow (ton/h)

G = Gas density at 15,6C and 1013 mbar

related air (= 1)

Gf = Gas density at flowing temperature

condition and 1013 mbar related 'air

(=1) = G

288.75

T

Volumic flow

Cv =

Q

GT

P ( P1 + P2 )

295

Mass flow

Cv =

Cv = Flow coefficient

P = Pressure drop (bar)

T = Absolute temperature of gas (K)

P1

=Upstream pressure (bar abs.)

P2

=Downstream pressure (bar abs.)

47.2 W

P ( P1 + P2 ) G f

STEAM

Cv

W

P

Tsh

P1

P2

=

=

=

=

Flow coefficient

Mass flow (ton/h)

Pressure drop (bar)

SuperHeated temperature related to

saturated temperature (C)

= Upstream pressure (bar abs.)

= Downstream pressure (bar abs.)

Technical Documentation - FLOATING BALL VALVE Rev : 2

Mass flow Saturated steam

Cv =

72.4 W

P ( P1 + P2 )

Mass flow SuperHeated steam

Cv =

72.4 (1 + 0.00126 Tsh ) W

P ( P1 + P2 )

Page 23 of 28

FLOATING BALL VALVE

FLOW COFFICIENT CV

Flow coefficients Cv and Kv :

Cv = Water flow in US Gallons (3,78 liters) by minute for 1 psi constant pressure drop.

Kv = Water flow in m3 by hour for 1 bar constant pressure drop.

Kv =

Cv

and Cv = 1.16 Kv

1.16

Full Bore Valves

Indicated flow coefficients are identical in both flow directions

ND

Pressure Class

Inches mm

150

300

600

PN10 PN16 PN25 PN40

"

15

25

22

20

22

22

22

22

"

20

51

45

40

45

45

45

45

1"

25

116

102

89

103

103

103

103

NA

1"

32

170

170

170

170

1" "

40

301

280

249

273

273

273

273

2"

50

585

531

456

514

514

514

514

NA

2"

65

893

893

893

893

3"

80

1585 1344

1198

1283

1283

1283

1283

4"

100 2917 2526

2122

2357

2357

2357

2357

6" LP

150 6230 6154

5229

5642

5642

5642

5642

Note :

Classes 150-300-600 related to class ISOPN 20-50-100 respectively.

Documentation technique Rev :2-FLOATING BALL VALVE

Page 24 of 28

FLOATING BALL VALVE

Reduced bore Valves

1

2

IMPORTANT :

Due to the asymetry of a reduced passage valve, the flow coefficient varies according to the flow direction

FLOW direction 1

ND

Pressure Class

Inches

mm

150

300

600

PN10 PN16 PN25 PN40

2"x1"

50 x 40

108

116

102

101

101

106

106

3"x 2"

80 x 50

157

172

315

148

148

166

166

4"x 3"

100 x 80

446

481

746

761

6"x 4" LP

150 x 100

1011

955

1097

1159

NA

8"x 6" SP

200 x 150

NA

2175

NA

2175

8"x 6" LP

200 x150

2663

2679

2851

2907

NA= Not applicable

Classes 150-300-600 related to class ISOPN 20-50-100 respectively.

FLOW direction 2

ND

Pressure Class

600

PN10 PN16

98

101

101

240

148

148

722

702

NA

NA

2486

Inches

mm

150

300

PN25 PN40

2"x 1"

50 x 40

108

110

102

102

3"x 2"

80 x 50

157

158

150

150

4"x 3"

100 x 80

446

454

599

6"x 4" LP

150 x 100

703

955

967

8"x 6" SP

200 x 150

NA

2180

2180

8"x 6" LP

200 x150

2532 2247

2230

NA= Not applicable

Classes 150-300-600 related to class ISOPN 20-50-100 respectively.

Documentation technique Rev :2-FLOATING BALL VALVE

Page 25 of 28

FLOATING BALL VALVE

ACCESSORIES

Insulating Extension

Rep

150

148

149

37

Part name

UPPER SEAL

STEM

EXTENSION

BOLTING

MATERIALS

Carbon steel

Stainless steel

Nitrile (NBR)

Nitrile (NBR)

A182F316 or UNS17400

A182F316 or UNS17400

A216WCB -A350GrLF2

A351CF8M -A182F316

A193 B8- A4/70

A193 B8- A4/70

Length Hc

ND (bore) & Class

ISO

(mm)

ISO PN20

ISO PN50 ISO PN100

N

(PN 10-16)

(PN 25-40)

(PN 100)

Hc

100

" "

F03

100

1" - 1" - 1"

1"

F04

100

2"- 2" - 3"

2"

1"

F05

100

4"

2" 3"

2"

F10

100

6"

4"

F12

120

6"

F16

Class 150-300-600 related to class ISOPN 20-50-100 respectively.

Documentation technique Rev :2-FLOATING BALL VALVE

Page 26 of 28

FLOATING BALL VALVE

Locking Devices

The locking device has been designed to lock open or closed without any further change in the valve.

Once the locking device is installed it cannot be removed.

All parts of the locking device are in stainless steel 316.

Locking stem

Locking Key

Open or Close

The locking device is available for five ISO sizes.

The maximum pin sizes for padlocks (not supplied) are indicated in the following table

Padlock

pin

ND (bore) & Classes

ISO

diameter

N

ISO PN20

ISO PN50 ISO PN100

(PN 10-16)

(PN 25-40)

(PN 100)

mm

4

" "

F03

4

1" - 1" - 1"

1"

F04

6

2"- 2" - 3"

2"

1"

F05

6

4"

2" 3"

2"

F10

6

6"

4"

F12

Classes 150-300-600 related to class ISOPN 20-50-100 respectively.

Documentation technique Rev :2-FLOATING BALL VALVE

Page 27 of 28

FLOATING BALL VALVE

BF 2000 PRODUCTS

Metal /Metal Floating Ball Valves

Size range " to 6" full and reduced bore, ISO PN 20-50-100 PN 10-16-25-40.

Seats and ball with tungsten carbide coating.

Manual and motorized operations.

Low Temperature and Cryogenic Floating Ball Valves

Size range " to 6" full and reduced bore, ISO PN 20-50-100 PN 10-16-25-40.

Standard cryogenic extension designed for fluids down to 196C.

Manual and motorized operations.

High Temperature Floating Ball Valves

Size range " to 6" full and reduced bore, ISO PN 20-50-100 PN 10-16-25-40.

Designed for fluid up to 450C.

Metal/metal seated and expanded graphit" seals

Top stem temperature stabilized at 150C max

Manual and motorized operations.

Multi-way floating ball valves ( 3 ways "L" type") .

Size range " to 6" full and reduced bore, ISO PN 20-50-100 PN 10-16-25-40.

Soft Seats or metal seats with Tungsten carbide coating.

2 seats ball valves , non transflow .

Manual and motorized operations.

SUD ROBINETTERIE industrie

Post Box 316

13309 MARSEILLE CEDEX 14 FRANCE

Tel 33 (0) 495 055 050

Fax 33 (0) 495 055 070

Email : sales@sri.fr

Internet : http://www.sri.fr

Documentation technique Rev :2-FLOATING BALL VALVE

Page 28 of 28

S-ar putea să vă placă și

- TMBVDocument16 paginiTMBVbmanojkumar16Încă nu există evaluări

- Sure Seal LBF Lined Butterfly ValveDocument8 paginiSure Seal LBF Lined Butterfly ValvebbmokshÎncă nu există evaluări

- Neojv 0040 enDocument0 paginiNeojv 0040 enLuis GuevaraÎncă nu există evaluări

- Crane Katalog-RS AngDocument29 paginiCrane Katalog-RS AngNNÎncă nu există evaluări

- DBBV-Double Block and BleedDocument16 paginiDBBV-Double Block and BleedUncircleDecoderÎncă nu există evaluări

- Crane - Series.rs Center LineDocument23 paginiCrane - Series.rs Center LinenedwestÎncă nu există evaluări

- SBF LongdDocument10 paginiSBF LongdcatalineulaÎncă nu există evaluări

- KLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Document36 paginiKLINGER Ballostar KHA 3 Pieces Ball Valve DN 10 - 150: Edition 2011Andy LuthorÎncă nu există evaluări

- SWI Products MetalDocument21 paginiSWI Products MetalPrasanth PrasadÎncă nu există evaluări

- D 500203 X 012Document20 paginiD 500203 X 012Aarthi PadmanabhanÎncă nu există evaluări

- Alco Hi Tek Mono FlangeDocument7 paginiAlco Hi Tek Mono FlangelimresÎncă nu există evaluări

- Butterfly Valve ConcentricDocument6 paginiButterfly Valve ConcentricpramodtryÎncă nu există evaluări

- Catalogue Armacon-Valve 20190522Document26 paginiCatalogue Armacon-Valve 20190522Scipp ZengÎncă nu există evaluări

- Bursting Discs Breather Valves Signalling UnitsDocument16 paginiBursting Discs Breather Valves Signalling Unitssmab2162094Încă nu există evaluări

- Ball Valve CatalogDocument16 paginiBall Valve CatalogRamaswamy Neelakantan NÎncă nu există evaluări

- IOM Ball Valve Top EntryDocument8 paginiIOM Ball Valve Top Entrytoader56Încă nu există evaluări

- Phoenix 350 Ec14-Os and Ec15-OsDocument8 paginiPhoenix 350 Ec14-Os and Ec15-Oskeyur1109Încă nu există evaluări

- Flow Divertor Ball Valve DN20 - DN32 - DN50: DescriptionDocument3 paginiFlow Divertor Ball Valve DN20 - DN32 - DN50: Description윤병택Încă nu există evaluări

- Birkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Document52 paginiBirkett Safety Relief Valves: Simply Photocopy and Fax To Us For More Information On..Mark RomeroÎncă nu există evaluări

- L&T Pipeline Ball ValvesDocument24 paginiL&T Pipeline Ball Valvesjamil vora100% (1)

- D 101363 X 012Document20 paginiD 101363 X 012AmiroucheBenlakehalÎncă nu există evaluări

- Kent IntrolDocument15 paginiKent IntrolVladimir VuletinÎncă nu există evaluări

- Safety Relief ValvesDocument52 paginiSafety Relief ValvesHamza NoumanÎncă nu există evaluări

- Double Eccentric Butterfly Valves R1Document20 paginiDouble Eccentric Butterfly Valves R1Sandi AslanÎncă nu există evaluări

- GF System Specification PVC-U BS InchDocument14 paginiGF System Specification PVC-U BS InchDale CokleyÎncă nu există evaluări

- FisherDocument20 paginiFishermanmohansingh1999Încă nu există evaluări

- Velan Ball Valve 1 PDFDocument9 paginiVelan Ball Valve 1 PDFMilena Lemus FonsecaÎncă nu există evaluări

- Model"Dc": Dual Chamber Orifice FittingDocument13 paginiModel"Dc": Dual Chamber Orifice FittingFrankÎncă nu există evaluări

- Des Cote Actuated Globe ValvesDocument4 paginiDes Cote Actuated Globe ValvesOrueta ClaudioÎncă nu există evaluări

- Flowcon ABM InstructionDocument4 paginiFlowcon ABM InstructionJeff Anderson CollinsÎncă nu există evaluări

- Sapag JHP Valves Jun04 enDocument18 paginiSapag JHP Valves Jun04 enanwar01Încă nu există evaluări

- Valve0114 PDFDocument14 paginiValve0114 PDFbinhjukiÎncă nu există evaluări

- Valvulas KiezelMannDocument0 paginiValvulas KiezelMannManuel SaavedraÎncă nu există evaluări

- Floating and Trunnion Ball Valves PDFDocument15 paginiFloating and Trunnion Ball Valves PDFAlienshowÎncă nu există evaluări

- HKSF-W100 E (1) AumaDocument9 paginiHKSF-W100 E (1) AumaccdumitraÎncă nu există evaluări

- Mark One XDocument4 paginiMark One XTiu TonÎncă nu există evaluări

- CO2 AnsulDocument17 paginiCO2 AnsulJorge RVÎncă nu există evaluări

- LCM ValvesDocument40 paginiLCM ValvesAlexa Harper100% (1)

- FM-200 Alpha Series SystemsDocument6 paginiFM-200 Alpha Series SystemsGurusumiÎncă nu există evaluări

- Fisher V260 Ball Valve CatalogueDocument8 paginiFisher V260 Ball Valve CatalogueAbd Elrahman HamdyÎncă nu există evaluări

- Riser Module 747m VictaulicDocument2 paginiRiser Module 747m Victaulicrvalentino2012Încă nu există evaluări

- VNotchDocument3 paginiVNotchThiruThirunavukkarasuÎncă nu există evaluări

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 paginiFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraÎncă nu există evaluări

- Deu BlinDocument58 paginiDeu Blinraghunath.psÎncă nu există evaluări

- TB01 - Bleed HoleDocument2 paginiTB01 - Bleed HoleHieu NguyenÎncă nu există evaluări

- Butterfly Valve-Concentric DesignDocument6 paginiButterfly Valve-Concentric Designbharadwaj037Încă nu există evaluări

- 201501F2 03 s3.2 Mechanical EquipmentsDocument24 pagini201501F2 03 s3.2 Mechanical EquipmentsNguyễn ChâuÎncă nu există evaluări

- LT Pipeline Ball ValvesDocument19 paginiLT Pipeline Ball ValvessiswoutÎncă nu există evaluări

- PCC Technova: Series "CPL" Cylindrical ValvesDocument5 paginiPCC Technova: Series "CPL" Cylindrical ValvesAnju VijayanÎncă nu există evaluări

- Floating Ball ValvesDocument16 paginiFloating Ball ValvesGovundan Guru0% (1)

- 8 Bomba Tornillo Alliweiler AebDocument14 pagini8 Bomba Tornillo Alliweiler AebHugo Miño Carrasco100% (1)

- Product Overview: Valves Actuators Automation TechnologyDocument36 paginiProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaÎncă nu există evaluări

- Aturia Process Api610 092012low1Document4 paginiAturia Process Api610 092012low1Goce VasilevskiÎncă nu există evaluări

- API 6A ValveDocument12 paginiAPI 6A Valveedo_tapia_ur100% (1)

- Apollo ValvesDocument44 paginiApollo ValvesDevdatt WaghuleÎncă nu există evaluări

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- COG 070508 StocklistDocument164 paginiCOG 070508 Stocklista100acomÎncă nu există evaluări

- OmniFlex MaterialsDocument4 paginiOmniFlex Materialsa100acomÎncă nu există evaluări

- Comparison ChartDocument1 paginăComparison Charta100acomÎncă nu există evaluări

- Meldin 7000 PDFDocument10 paginiMeldin 7000 PDFa100acomÎncă nu există evaluări

- Zetpol 4320Document1 paginăZetpol 4320a100acomÎncă nu există evaluări

- Dichtomatik Handbook PDFDocument225 paginiDichtomatik Handbook PDFErick LedezmaÎncă nu există evaluări

- KalrezDocument8 paginiKalreza100acomÎncă nu există evaluări

- Meldin 7000Document10 paginiMeldin 7000a100acomÎncă nu există evaluări

- Energy BrochuraDocument6 paginiEnergy Brochuraa100acomÎncă nu există evaluări

- CelazoleDocument1 paginăCelazolea100acomÎncă nu există evaluări

- Devlon A153Document1 paginăDevlon A153a100acomÎncă nu există evaluări

- COG Broschuere Industrie ENGDocument28 paginiCOG Broschuere Industrie ENGa100acomÎncă nu există evaluări

- Temperatur Best and Igh EdDocument1 paginăTemperatur Best and Igh Eda100acomÎncă nu există evaluări

- Enflow Floating BallvalvesDocument8 paginiEnflow Floating Ballvalvesa100acomÎncă nu există evaluări

- Two-Piece Mounted Trunnion Ball ValveDocument3 paginiTwo-Piece Mounted Trunnion Ball Valvea100acomÎncă nu există evaluări

- GT S 8000 BrochureDocument8 paginiGT S 8000 Brochurea100acomÎncă nu există evaluări

- Materials List: Bronze Ball Valve Two-Piece, Full-Port 600 Psig Wog / 150 Psig SWP Threaded EndsDocument1 paginăMaterials List: Bronze Ball Valve Two-Piece, Full-Port 600 Psig Wog / 150 Psig SWP Threaded Endsa100acomÎncă nu există evaluări

- Nitro Nic 50 BookDocument18 paginiNitro Nic 50 Booka100acomÎncă nu există evaluări

- Friction and Wear of Ptfe Comp at Cry TempDocument10 paginiFriction and Wear of Ptfe Comp at Cry Tempa100acomÎncă nu există evaluări

- Zeus Catalog 11Document76 paginiZeus Catalog 11a100acomÎncă nu există evaluări

- Thermoplastic Seals & Components For The Oil & Gas IndustryDocument20 paginiThermoplastic Seals & Components For The Oil & Gas Industrya100acom100% (1)

- PEEK PropertiesDocument56 paginiPEEK Propertiesa100acom50% (2)

- Green Tyre TechnologyDocument4 paginiGreen Tyre TechnologyAnuj SharmaÎncă nu există evaluări

- Taifun GT User GuideDocument5 paginiTaifun GT User GuidecarloslarumbeÎncă nu există evaluări

- Me Con Compressed Air SystemsDocument8 paginiMe Con Compressed Air SystemsesvwestÎncă nu există evaluări

- Ped Med HandbookDocument27 paginiPed Med HandbookSoad Shedeed0% (1)

- 2.1 Article On Reasonable Compensation Job Aid 4-15-2015Document3 pagini2.1 Article On Reasonable Compensation Job Aid 4-15-2015Michael GregoryÎncă nu există evaluări

- Flex Comp Gas Cryo Catalog 2013 ADocument40 paginiFlex Comp Gas Cryo Catalog 2013 ABenh ThanKinhÎncă nu există evaluări

- TQM - Juran ContributionDocument19 paginiTQM - Juran ContributionDr.K.Baranidharan100% (2)

- Food Safety and StandardsDocument8 paginiFood Safety and StandardsArifSheriffÎncă nu există evaluări

- Tween 80 CoADocument1 paginăTween 80 CoATấn Huy HồÎncă nu există evaluări

- Top 50 World Pharma 2001Document11 paginiTop 50 World Pharma 2001Juraj KubáňÎncă nu există evaluări

- Diodat PDFDocument4 paginiDiodat PDFFatmir KelmendiÎncă nu există evaluări

- Woman Magazine Who Was Changing Jobs To Be The Editor Of: Family Circle AdweekDocument11 paginiWoman Magazine Who Was Changing Jobs To Be The Editor Of: Family Circle AdweekManish RanaÎncă nu există evaluări

- WabimalunoxowevefoDocument3 paginiWabimalunoxowevefoChitmin KhantÎncă nu există evaluări

- Ems Accounting Term 2Document39 paginiEms Accounting Term 2Paballo KoopediÎncă nu există evaluări

- Teit Cbgs Dmbi Lab Manual FH 2015Document60 paginiTeit Cbgs Dmbi Lab Manual FH 2015Soumya PandeyÎncă nu există evaluări

- System Error Codes (0-499)Document33 paginiSystem Error Codes (0-499)enayuÎncă nu există evaluări

- Cost Estimate, RevisedDocument6 paginiCost Estimate, RevisedUdit AmatÎncă nu există evaluări

- Vishnu Institute of Technology: V2V CommunicationsDocument22 paginiVishnu Institute of Technology: V2V CommunicationsBhanu PrakashÎncă nu există evaluări

- BF2207 Exercise 6 - Dorchester LimitedDocument2 paginiBF2207 Exercise 6 - Dorchester LimitedEvelyn TeoÎncă nu există evaluări

- Bp344 RampDocument29 paginiBp344 RampmaeÎncă nu există evaluări

- Node MCU CarDocument4 paginiNode MCU CarYusuf MuhthiarsaÎncă nu există evaluări

- 24th SFCON Parallel Sessions Schedule (For Souvenir Program)Document1 pagină24th SFCON Parallel Sessions Schedule (For Souvenir Program)genesistorres286Încă nu există evaluări

- Best of SEO#1 SEO Training & Content Marketing Course 2022Document2 paginiBest of SEO#1 SEO Training & Content Marketing Course 2022Oscar MascarenoÎncă nu există evaluări

- EECI-Modules-2010Document1 paginăEECI-Modules-2010maialenzitaÎncă nu există evaluări

- VLLAR2019Document81 paginiVLLAR2019Christian MallorcaÎncă nu există evaluări

- Slid e 4-1Document67 paginiSlid e 4-1Rashe FasiÎncă nu există evaluări

- Sarcosine MsdsDocument41 paginiSarcosine MsdsAnonymous ZVvGjtUGÎncă nu există evaluări

- Simple Usecases of PI B2B - SFTP and PGPDocument35 paginiSimple Usecases of PI B2B - SFTP and PGPPiedone640% (1)

- Minimalist CV ResumeDocument1 paginăMinimalist CV ResumeSijith MathewÎncă nu există evaluări

- EC1002 Commentary 2022Document32 paginiEC1002 Commentary 2022Xxx V1TaLÎncă nu există evaluări