Documente Academic

Documente Profesional

Documente Cultură

CSeal - DBBV Catalogue PDF

Încărcat de

kentchoyDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CSeal - DBBV Catalogue PDF

Încărcat de

kentchoyDrepturi de autor:

Formate disponibile

Netherlands

North

America

Europe

Asia

Africa

South

America

Austrialia

Double Block and

Bleed Dual Expanding

Plug Valve

Norwegian distributor: Haakon Ellingsen AS

renga 8, N-1340 Skui | P.O. Box 184, N-1309 Rud

Phone + 47 67151200 | Fax +47 67151201

post@ellingsen.biz | www.ellingsen.biz

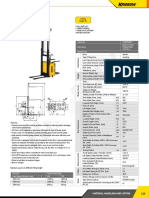

E X E C U T I ONS DB B V

Standard Execution

Part no.

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

20

21

23

30

31

32

33

34

35

36

37

40

41

42

43

44

45

46

47

48

49

56

81

82

83

84

91

93

01

Description

Body

Lower plate

Upper plate

Plug

Slip

Seat seal

Stem

Yoke

Adjusting bushing

Gland

Back seat

Gland flange

Helix trunnion

Helix trunnion fixing plate

Roll pin

Stem pin

Gasket

Packing

Name plate

Body nut

Body / lower plate stud

Body / upper plate stud

Gland stud

Upper plate / yoke stud

Gland nut

Upper plate / yoke nut

Key

Stem nut

Top flange

Handwheel

Bolt

Washer

Nut

Protection pipe

Position indicator

Bearing plate

Bearing

Nut

Drain plug

Lifting lug

Grease nipple

Automatic body bleed

ABB detection ring

Setscrew

F E AT U RE S DB B V

Features Control Seal Double Block and Bleed Valves

Friction Free

An important aspect of a valve is the sealing mechanism. Almost all valves, like standard Ball, Gate and Butterfly

valves have their sealing mechanism based upon shear force, friction and tearing. The Control Seal sealing

mechanism is based upon a radial movement only. The sealing is not liable to shear, friction or tearing. This

means no abrasion on the seal and compared to other type of valves, results into an exceptional long lifetime.

Double Block and Bleed

Control Seal valves have a double block and bleed function up and downstream. Normally this can only be

achieved by using two (2) valves and a spool piece with a drain valve. The use of a Control Seal Double Block

and Bleed Valve will safe cost, space and maintenance for a long period.

In-Line Maintenance and Service

As the Control Seal valve is designed for easy and low cost maintenance Stem packings can be adjusted

while the valve is in service. All valves are executed with a back seat. Bottom and top entry is possible while the

valve is inline. No special tools are required.

Non-Slam

The self-locking operate mechanism on all Control Seal valves, provides that the closing member (plug)

cannot rotate due to line forces. Therefore there is no danger of line slam, shock or injury of personnel.

Fire Safe

The Control Seal valves have been Fire safe tested by independent laboratories and has passed the test to

BS 6755 part 2 and API 6FA succesfully. These tests have been wittnessed by Lloyds on several valves.

Advantages of the Control Seal Design.

Friction free opening and closing, increasing the lifetime of the valve.

Corrosion and wear resistant materials are used on the closure members.

Bottom and top access for inline inspection and maintenance.

Adjustable stem packing while the valve is in service.

All valves are executed with a backseat, which gives the possibility to renew stem packing under pressure.

Non lubricated seal.

Pressure independent sealing.

No coupling cam in the stem construction.

Topworks according to ISO 5210

Optional Valve Executions

Control Seal valves can be supplied in a variety of materials and are also available in accordance with DIN

standards.

Stem extensions and gas column for cryogenic service

Control Seal Double Block and Bleed Valves can be supplied with various types of Viton, which depends

on the medium.

For remote controll electrical, pneumatic and hydraulic actuators can be installed.

Double Block & Bleed Valve Applications

Double Block & Bleed expanding plug Valves are often used in the following applications:

Fiscal metering systems for gas and oil

Ship and truck loading services

Tank storage

Transport pipeline services

Clean hydrocarbon services

Aviation fuel services

MTBE services

02

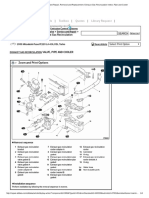

HOW IT WORKS

Opening and Closing Sequence DBBV

1. Open

Valve fully open. Seating slips are protected

from flow path.

4. Double Block and Bleed

Valve seated.

Resilient seals have been compressed.

Resilient seals cannot be damaged by

operator over-torque. Double block and bleed

function can be tested by opening the bleed

valve.

2. Start to close

Plug is rotating. There is no contact between

body and seating slips.

5. Start to Open

Valve starts opening.

Plug moving up, retracting slips from the body

seats. Strong dovetail and stems retract the

slips. Plug is kept centred in body by top and

bottom bushings.

3. Expanding

Plug / slips have rotated 90. Plug starts

expanding

slips.

Slips

only

move

perpendicular to body seats. Plug / slip

assembly is kept centred in body by top and

bottom bushings.

6. Slips retracted

Slips have been retracted prior to rotation.

(Further workings as figure 1 and 2 in reversed

order).

03

B L E E D S Y S T E MS

BLEED SYSTEMS FOR DBBV

Automatic Body Bleed (ABB)

The Control Seal Double Block and Bleed

Valve automatic body bleed is actuated when

the valve is closed. As an option the isolating

valve can be provided with lock open to avoid

any human error.

Caution: When the Double Block and Bleed

Valve comes to its closed position, a cam

opens the Automatic Bleed Valve allowing fluid

to escape. As the valve reaches its fully closed

position, the spurting liquid should cease,

showing positive verification of double seating.

A proper drain system is required as spilled

liquid could be hazardous.

Manual Bleed Valve with Gauge

(MVB-G)

A manual bleed valve connected with gauge

can be provided when emission is undesirable.

The gauge will indicate the cavity pressure and

the seal tightness.

Note: Body pressure

can be increased due to

thermal effects, which

can indicate false

leakage.

Manual Bleed Valve (MBV)

Bleed valve for manual operation. The Control

Seal Double Block and Bleed Valve must

always be bleeded in closed position. The MBV

is the most simple bleed system.

Thermal Relief Upstream with Gauge

(TRU-G)

To avoid body pressure due to thermal

Manual Bleed & Thermal Relief (MBTR)

expansion, a relief valve with gauge can be

provided. This means no emission to the

atmosphere and no sump system is required.

Relief always set on 25 psi.

This principle is the same as that of the TRU,

Thermal Relief Upstream (TRU)

With this system on the Control Seal Double

Block and Bleed Valve, the thermal relief valve

releases the overpressure from the

body cavity which may be caused by thermal

expansion. The system releases from the body

cavity to the upstream side of the valve.

however with the possibility to check the integrity of the Double Block and Bleed Valve

manually.

Note: The relief valve is set to open at 25 psi

on all valves regardless of their working pressure. With the Control Seal Double

Block and Bleed Valve closed, the relief valve

will open at 25 psi above upstream pressure.

This system functions only when the Control

Seal DBBV is closed and the isolation valve is

open.

Caution: All automated Control Seal Double

Block and Bleed Valves require some form of

body pressure relief (TRU / MBTR / ABB /

MBV-G / TRU-G), otherwise the valve may be

difficult to open or may stick in closed position.

04

D I M E N SI ONA L DATA

Dimensional Data - ANSI Class 150 - Reduced Bore - DBBV

Handwheel Operated

Gearbox Operated

Size

B

HO

B

GO

B

AO

Bt

HO

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

216

770

579

370

203

745

557

345

229

813

613

370

266

1110

865

510

920

Bt

GO

Bt

AO

Actuator Operated

Weight

Cv

Value

[kg]

[GPM]

60

234

80

335

Bb

D**

X***

[mm]

[mm]

[mm]

[mm]

412

166

275

255

200

390

175

275

260

230

395

218

375

295

224

86

794

524

590

275

375

394

295

170

1472

292

1042

982

592

652

330

375

470

320

225

2430

10

330

1190

1060

633

981

379

450

532

330

270

2485

12

355

1396

1257

752

806

451

450

645

385

420

4938

14

381

1550

1390

828

880

510

450

730

396

520

6145

16

406

1600

1436

858

906

530

650

780

415

595

6939

18

864

1855

1645

1032

1070

575

650

885

620

1200

10631

20

914

2000

1672

1058

1075

598

850

1050

590

1250

11261

24

914

2293

1912

1172

1195

716

850

1245

710

1980

15163

30

1270*

2900

1895

1704

1960

997

1000

1750

946

4170

26090

36

1981*

4386

4386

2296

2296

2240

1500

2200

1150

4500

51183

Notes:

- Dimensions are reference only. Request certified

drawings when ordered

- HO only up to 6

- Weight = Given weights are valid for Carbon Steel

valves without operating device (bare stem).

05

* Manufacturer standard face to face dimensions

** D = Clearance to remove slips

*** X = Number of tapped holes per flange

D I M E N SI ONA L DATA

Dimensional Data - ANSI Class 300 - Reduced Bore - DBBV

Size

B

HO

B

GO

B

AO

Bt

HO

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

216

770

621

371

283

800

650

376

305

1053

810

492

403

1124

1109

878

515

Bt

GO

Bt

AO

Weight

Cv

Value

[kg]

[GPM]

54

234

88

335

295

177

701

465

340

246

1301

Bb

D**

[mm]

[mm]

[mm]

[mm]

454

167

275

295

200

460

190

375

320

230

580

230

375

390

883

603

275

500

X***

419

1297

1003

605

654

349

500

570

360

319

2430

10

457

1508

1218

755

810

408

650

725

420

529

3271

12

502

1824

1360

852

875

484

850

825

420

680

4938

14

762

1652

1350

1086

784

566

1000

622

440

848

6145

16

838

1910

1600

1304

995

605

1000

665

450

900

6939

18

914

2162

1850

1521

1209

641

1250

706

465

1859

10631

20

991

2338

1990

1662

1314

676

1250

744

620

3695

11261

24

1321

2544

2230

1803

1489

741

1500

815

780

6885

15872

Notes:

- Dimensions are reference only. Request certified

drawings when ordered

- HO only up to 6

* Manufacturer standard face to face dimensions

** D = Clearance to remove slips

*** X = Number of tapped holes per flange

- Weight = Given weights are valid for Carbon Steel

valves without operating device (bare stem).

06

D I M E N SI ONA L DATA

Dimensional Data - ANSI Class 600 - Reduced Bore - DBBV

Size

B

HO

B

GO

B

AO

Bt

HO

Bt

GO

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

292

647

550

333

356

752

652

420

432

1150

865

559

1330

1050

Bt

AO

Weight

Cv

Value

[mm]

[kg]

[GPM]

235

240

125

234

290

255

195

335

500

425

330

238

561

320

1000

545

385

420

1301

Bb

D**

[mm]

[mm]

[mm]

445

214

300

465

232

500

585

608

255

711

732

X***

660

1552

1266

865

849

417

1000

725

455

625

2403

10

787

1975

1510

1025

1017

492

1250

864

520

975

3271

12

838

2049

1750

1225

1350

524

1500

576

445

1225

4938

Notes:

- Dimensions are reference only. Request certified

drawings when ordered

- Weight = Given weights are valid for Carbon Steel

valves without operating device (bare stem).

* Manufacturer standard face to face dimensions

07

** D = Clearance to remove slips

*** X = Number of tapped holes per flange

F E AT U RE S DB B V

DBBV - ANSI Class 900 - DBBV

Double Block & Bleed expanding plug valve 900#

ControlSeal B.V. has recently designed, produced and tested a range of 900# Double Block & Bleed

expanding plug valves. The valves passed testing successfully and were supplied for service in metering

skids.

Dimensions and weights for the new 900# are available upon request.

Please find below a picture of a 3 Full Bore 900# DBBV

08

D I M E N SI ONA L DATA

Dimensional Data - ANSI Class 150 - Full Bore - DBBV

Handwheel Operated

Gearbox Operated

Actuator Operated

Weight

Cv

Value

[mm]

[kg]

[GPM]

407

280

210

2070

470

325

277

4860

500

526

355

330

9000

650

546

365

350

16020

566

850

622

370

400

23400

605

1000

665

440

550

28800

1502

641

1000

706

450

600

39600

1549

2014

676

1250

744

465

1000

52200

1945

1553

2018

741

1250

815

620

1500

67500

3228

2420

2100

2730

828

1500

911

780

2300

100080

3557

2668

2350

3055

907

1500

998

1045

3500

131200

Size

B

HO

B

GO

B

AO

Bt

HO

Bt

GO

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

432

1060

795

489

534

1189

892

559

635

1232

924

10

788

1300

975

12

915

1656

14

864

1900

16

889

18

Bt

AO

Bb

D**

[mm]

[mm]

[mm]

635

370

300

726

428

300

654

850

478

676

878

524

1242

890

1157

1425

1095

1425

2097

2098

1156

1220

2525

1894

20

1220

2594

24

1397

30

1728

X***

Notes:

- Dimensions are reference only. Request certified

drawings when ordered

- Weight = Given weights are valid for Carbon Steel

valves without operating device (bare stem).

* Manufacturer standard face to face dimensions

09

** D = Clearance to remove slips

*** X = Number of tapped holes per flange

D I M E N SI ONA L DATA

Dimensional Data - ANSI Class 300 - Full Bore - DBBV

Weight

Cv

Value

[mm]

[kg]

[GPM]

407

280

277

1980

470

325

365

4860

850

526

355

435

9000

524

850

576

365

640

15390

1448

566

1000

622

370

790

22500

1411

605

1000

665

440

900

27900

1304

1695

641

1250

706

450

955

37800

1872

1521

1977

676

1250

744

465

1950

50400

2703

2027

1662

2160

741

1500

815

620

3850

64800

2931

2198

1803

2344

826

1500

911

780

4400

91800

Size

B

HO

B

GO

B

AO

Bt

HO

Bt

GO

[inch]

[mm]

[mm]

[mm]

[mm]

[mm]

457

1030

772

460

559

1222

916

594

686

1532

1149

10

826

1797

12

965

14

864

16

Bt

AO

Bb

D**

[mm]

[mm]

[mm]

416

370

650

772

428

650

854

1110

478

1348

1073

1395

1880

1410

1114

1991

1494

1086

889

2245

1684

18

1220

2497

20

1220

24

1379

X***

Notes:

- Dimensions are reference only. Request certified

drawings when ordered

** D = Clearance to remove slips

*** X = Number of tapped holes per flange

- Weight = Given weights are valid for Carbon Steel

valves without operating device (bare stem).

* Manufacturer standard face to face dimensions

10

A P P L I CAT I ONS DB B V

Dual Expanding Double Block & Bleed Plug Valves

General Data

Design, Dimensions and Marking According to:

API specification 599

API specification 600

Construction:

3-piece construction, split body, top and bottom entry, trunnion mounted, antistatic design, seating slips

replacable through removable bottom plate,

reduced or full bore.

Characteristics:

Non contact, duel expanding, Double Block & Bleed Plug Valve

Face to Face Dimensions According to:

ANSI B16.10

Manufacturers standard

Flanged Connections According to:

ANSI B16.5 Raised Face smooth finish, stock finish or Ring Type Joint

MSS-SP-44 Raised Face smooth finish, stock finish or Ring Type Joint

Fire Safe Accoring to:

BS 6755 part 2 including AMD 6272 / 6712

API specification 6FA

Marking in Accordance with:

MSS-SP-25

European Directive PED 97/23/EC

API 6D

Optional Marking to client specification

Testing According to:

API 6D

API 598

BS 6755 part 1

Optional client specification

Operating Devices:

Handwheel

Gearbox

Actuator

Bottom Drain Plug:

Standard included

Optional:

ATEX Cat II 2 G/D

Control Seal Double Block & Bleed Valves in line

11

D E L I V ERY P ROGRA MME

Control Seal Delivery Programme

Double Block and Bleed Valves (DBBV)

Size: 1 up to and including 42

Class: 150# up to and including 900#

Rising Stem Ball Valve (RSBV)

Size: 1 up to and including 42

Class: 150# up to and including 4500#

Axial Flow Valve (AFV)

Size: 4 up to and including 48

Class: 150# up to and including 4500#

12

C E RT I FI CATE S

13

C E RT I FI CATE S

14

Control Seal B.V.

Sales, Engineering & Services Office:

Waardsedijk Oost 10-4, 3417XJ Montfoort, the Netherlands

Phone: +31 (0)348 474 315, Fax: +31 (0)348 474 238

Head Office & Manufacturing Facility:

Farmsumerweg 43, P.O. box 330, 9900AH Appingedam, the Netherlands

Phone: +31 (0)596 652 222, Fax : +31 (0)596 629 405

E-mail: sales@controlseal.nl

Website: http://www.controlseal.nl

S-ar putea să vă placă și

- Fog Detector Atex - DATADocument2 paginiFog Detector Atex - DATArocket-vtÎncă nu există evaluări

- Comid - in Situ TestingDocument20 paginiComid - in Situ TestingmunawarÎncă nu există evaluări

- Jolly2 Manual enDocument13 paginiJolly2 Manual enWeiya WeiyaÎncă nu există evaluări

- Cpd200 Genset PG AlsdDocument26 paginiCpd200 Genset PG Alsdoscar72008Încă nu există evaluări

- Model Hsra-2 Hydraulic Actuator TBDocument2 paginiModel Hsra-2 Hydraulic Actuator TBjoÎncă nu există evaluări

- VT GuardDocument2 paginiVT GuardHamed GolzadehÎncă nu există evaluări

- TSI-SC-007 Diagnostics and Logbook Request FormDocument14 paginiTSI-SC-007 Diagnostics and Logbook Request Formg arvÎncă nu există evaluări

- Mokveld Test Unit VTU-1Document1 paginăMokveld Test Unit VTU-1eng_moh04Încă nu există evaluări

- NW User ManualDocument51 paginiNW User Manualscribdhas2006Încă nu există evaluări

- Ervor Air Compressor PDFDocument42 paginiErvor Air Compressor PDFNabila Queen100% (1)

- Fault, Protection and Failure Indications in PSE Soft StarterDocument5 paginiFault, Protection and Failure Indications in PSE Soft StartermichaelÎncă nu există evaluări

- AMETEK, ATC-125B Dry Block Temp Calibrator PDFDocument12 paginiAMETEK, ATC-125B Dry Block Temp Calibrator PDFLulu Sweet ThingÎncă nu există evaluări

- Alphatronic Remote Control SystemDocument29 paginiAlphatronic Remote Control SystemrecutuÎncă nu există evaluări

- Manual Lap Dat VM-25Document60 paginiManual Lap Dat VM-25aladin namlun100% (1)

- Eaton 93e Ups 40kva 60kva Generation 3 ManualDocument120 paginiEaton 93e Ups 40kva 60kva Generation 3 ManualInot KecilÎncă nu există evaluări

- K007 Mk7 Manual Rev4Document91 paginiK007 Mk7 Manual Rev4Anonymous nC9gpUWPÎncă nu există evaluări

- Actuator SchneiderDocument22 paginiActuator SchneiderAbner Ezequias100% (1)

- 1012 1013 PDFDocument120 pagini1012 1013 PDFAndrejs Liepkauls100% (1)

- HCI634H - Winding 311 and 312: Technical Data SheetDocument9 paginiHCI634H - Winding 311 and 312: Technical Data Sheet3efooÎncă nu există evaluări

- Sea Tel Media Xchange Point LMXP Operation ManualDocument24 paginiSea Tel Media Xchange Point LMXP Operation ManualMike Olumide JohnsonÎncă nu există evaluări

- Lenze 8200 Vector-25Document25 paginiLenze 8200 Vector-25poaguiÎncă nu există evaluări

- IQ3 Standard Uhendusskeem 100B0000Document2 paginiIQ3 Standard Uhendusskeem 100B0000hassan hassanÎncă nu există evaluări

- CM442 Manual EngDocument92 paginiCM442 Manual EngBenjamin Moreno SanchezÎncă nu există evaluări

- Delomatic 3 Installation Instructions 4189230125 UkDocument18 paginiDelomatic 3 Installation Instructions 4189230125 UkAris MoutskasÎncă nu există evaluări

- Logica Bernini BM8Document11 paginiLogica Bernini BM8Jorge AgÎncă nu există evaluări

- Sentryum AC UPS Riello UPS User Manual Helios Power Solutions New ZealandDocument44 paginiSentryum AC UPS Riello UPS User Manual Helios Power Solutions New ZealandJose Lopez100% (1)

- ZM9325Installation Manual of Edging MachineDocument11 paginiZM9325Installation Manual of Edging MachineErick HernandezÎncă nu există evaluări

- Manual CIU EnrafDocument4 paginiManual CIU EnrafDiegoJavierJuradoRamirezÎncă nu există evaluări

- Amtech Basler Offers Solution For Replacing ABB1000-15 With DECS200 Digital Excitation SystemDocument4 paginiAmtech Basler Offers Solution For Replacing ABB1000-15 With DECS200 Digital Excitation SystemRamakrishnan AlagarsamyÎncă nu există evaluări

- 234 FNS160 - ContactorDocument13 pagini234 FNS160 - Contactoramin shirkhaniÎncă nu există evaluări

- Manual Motor Siemens 1la8Document174 paginiManual Motor Siemens 1la8Jair ArmandoÎncă nu există evaluări

- Industrial Motors HANNINGDocument28 paginiIndustrial Motors HANNINGBeenish MirzaÎncă nu există evaluări

- Enatel Modular Inverter System V1 - 1Document49 paginiEnatel Modular Inverter System V1 - 1mjmardonesÎncă nu există evaluări

- APC Symmetra PX Operation Manual 208V (10kW - 80kW)Document42 paginiAPC Symmetra PX Operation Manual 208V (10kW - 80kW)Goran JovanovicÎncă nu există evaluări

- Check e Bae PDFDocument28 paginiCheck e Bae PDFjogoram219Încă nu există evaluări

- (5.h.53.a) PROMAG 55S Operation Manual PDFDocument118 pagini(5.h.53.a) PROMAG 55S Operation Manual PDFnovtechÎncă nu există evaluări

- ABB SACE Manual ConnectionsDocument2 paginiABB SACE Manual ConnectionszamoracÎncă nu există evaluări

- W20 SpemosDocument18 paginiW20 Spemosmadou diop100% (1)

- AF-60 Programming (FR)Document71 paginiAF-60 Programming (FR)Zouhair IguerhzifenÎncă nu există evaluări

- MPB Pneumatic Barrel PumpDocument34 paginiMPB Pneumatic Barrel PumpWildan PriatnaÎncă nu există evaluări

- NOVA - BrosuraDocument8 paginiNOVA - BrosuraGhimis Simona BiancaÎncă nu există evaluări

- MES114 Modules: Logic Input / Output ModulesDocument1 paginăMES114 Modules: Logic Input / Output ModulestuanudinÎncă nu există evaluări

- Binder 6Document208 paginiBinder 6Sunil K100% (1)

- Manual Darr en InglesDocument517 paginiManual Darr en Inglespacohert2011Încă nu există evaluări

- P-FRM-K3-001 Identifikasi Bahaya, Pengendalian Dan Penilaian Resiko K3Document17 paginiP-FRM-K3-001 Identifikasi Bahaya, Pengendalian Dan Penilaian Resiko K3Mahdi PiranhaÎncă nu există evaluări

- ZMX Monitor Module For Flame DetectorsDocument2 paginiZMX Monitor Module For Flame DetectorsTalha MairajÎncă nu există evaluări

- Masterys BC: Installation and Operating ManualDocument40 paginiMasterys BC: Installation and Operating Manualzaw zawaungÎncă nu există evaluări

- Masterpact NT: User ManualDocument56 paginiMasterpact NT: User ManualkubikÎncă nu există evaluări

- KewTech KT73 ManualDocument9 paginiKewTech KT73 ManualCluck BerryÎncă nu există evaluări

- Tsurumi LibraryDocument115 paginiTsurumi LibraryManuel Rosas MedinaÎncă nu există evaluări

- Iecex Dek 13.0075Document5 paginiIecex Dek 13.0075Francesco_CÎncă nu există evaluări

- Installation and Maintenance: This Manual Is To Be Given To The End UserDocument12 paginiInstallation and Maintenance: This Manual Is To Be Given To The End UserHoang GiangÎncă nu există evaluări

- Spirax Sarco Sp500Document68 paginiSpirax Sarco Sp500Mário SantosÎncă nu există evaluări

- Preventive Maintenance Kits For ABB Industrial Drives, ACS800Document2 paginiPreventive Maintenance Kits For ABB Industrial Drives, ACS800Jhon RodriguezÎncă nu există evaluări

- Stamford PI734FDocument8 paginiStamford PI734FTaz UddinÎncă nu există evaluări

- lcs+35-DDD-SKF3구리스펌프 레벨센서Document4 paginilcs+35-DDD-SKF3구리스펌프 레벨센서정정호Încă nu există evaluări

- CV Valvulas Twin SealDocument20 paginiCV Valvulas Twin Sealprocesossictec100% (1)

- General Twin Seal 06Document24 paginiGeneral Twin Seal 06Gk GaneshÎncă nu există evaluări

- Iom Gen Truseal 1Document16 paginiIom Gen Truseal 1tsuoscaradrian100% (1)

- AIR JACK - PPTX Group No 17Document21 paginiAIR JACK - PPTX Group No 17B 87 VISHWAKARMA AAKASH ACHCHHELALÎncă nu există evaluări

- YUM2E19: Canada, Europe, OthersDocument49 paginiYUM2E19: Canada, Europe, Othersbarry719Încă nu există evaluări

- NKS, Oa Rhu Ifg S Okys Lopy Okguksa Osq Oghy Fje: HKKJRH EkudDocument13 paginiNKS, Oa Rhu Ifg S Okys Lopy Okguksa Osq Oghy Fje: HKKJRH EkudGaurav SharmaÎncă nu există evaluări

- Operasi Trash RakeDocument5 paginiOperasi Trash RakeKea PratamaÎncă nu există evaluări

- Catalogo Partes de John DeereDocument633 paginiCatalogo Partes de John DeereJonathan ArgotiÎncă nu există evaluări

- Turbocharger Division: Specification: Hs 5800 A1F 91 Ms 156 Serial N°: 527 000Document17 paginiTurbocharger Division: Specification: Hs 5800 A1F 91 Ms 156 Serial N°: 527 000ronny ArdiansyahÎncă nu există evaluări

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument91 paginiIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya AnamÎncă nu există evaluări

- 2hl250-270-290 - SM enDocument109 pagini2hl250-270-290 - SM enНиколай Некрасов100% (9)

- Electric Stacker: Article No. KW0500894 Description Electric Stacker (Triplex Mast) 1.5T x3 M SpecificationDocument1 paginăElectric Stacker: Article No. KW0500894 Description Electric Stacker (Triplex Mast) 1.5T x3 M SpecificationAsty RikyÎncă nu există evaluări

- ZF RL Axle ManualDocument8 paginiZF RL Axle ManualKieran RyanÎncă nu există evaluări

- Detroit Diesel 149 Engine Specs, Bolt Torques and ManualsDocument12 paginiDetroit Diesel 149 Engine Specs, Bolt Torques and ManualsManuel LabradorÎncă nu există evaluări

- MCE416 Moodle 5 Hydraulic MotorDocument20 paginiMCE416 Moodle 5 Hydraulic MotorPaul KonduÎncă nu există evaluări

- 087 Duster HR 15 Product Brochure 8 PagerDocument6 pagini087 Duster HR 15 Product Brochure 8 PagerTop TamilÎncă nu există evaluări

- AnchorsDocument46 paginiAnchorsИнна ВайнинаÎncă nu există evaluări

- The Slavers: Chapter 1: CaptureDocument8 paginiThe Slavers: Chapter 1: CaptureRatcatcher GeneralÎncă nu există evaluări

- ETERNAL A10V Series 52 53Document49 paginiETERNAL A10V Series 52 53Taller PahrÎncă nu există evaluări

- Test SpecificationsDocument2 paginiTest SpecificationsBest Auto Tech100% (1)

- Axera LP - Evo: Training ManualDocument30 paginiAxera LP - Evo: Training ManualCRAC100% (1)

- Ground Handling 90a90b90c90c90ae90 Series King AirDocument3 paginiGround Handling 90a90b90c90c90ae90 Series King AirlocoboeingÎncă nu există evaluări

- Astm 504Document8 paginiAstm 504Marco De SalvoÎncă nu există evaluări

- Eaton Fuller RTLOF 16918B Transmission Parts ManualDocument42 paginiEaton Fuller RTLOF 16918B Transmission Parts ManualPaty CervantesÎncă nu există evaluări

- KoeDocument2 paginiKoelucasohlson99Încă nu există evaluări

- CCEC FR896 N855 DM - 321hp@1500rpmDocument3 paginiCCEC FR896 N855 DM - 321hp@1500rpmnarisÎncă nu există evaluări

- D8T Test Trans Relief ValDocument7 paginiD8T Test Trans Relief ValjaimeÎncă nu există evaluări

- Servo ValveDocument7 paginiServo ValvemecambÎncă nu există evaluări

- Life Saving RulesDocument13 paginiLife Saving RulesNnamdi AmadiÎncă nu există evaluări

- CAT - Contamination Control Tools PDFDocument18 paginiCAT - Contamination Control Tools PDFBeary McBeary100% (1)

- New Vehicle New Tsbs Toolbox Quotes Library Request Vehicle Information CommunityDocument4 paginiNew Vehicle New Tsbs Toolbox Quotes Library Request Vehicle Information CommunityJohn Mark AcederaÎncă nu există evaluări

- Manual Grimme GT300Document10 paginiManual Grimme GT300Fabiano100% (1)

- 4 SPEED FWD (Electronic Control) With LU Con Vert Er: Revision 07/2011Document5 pagini4 SPEED FWD (Electronic Control) With LU Con Vert Er: Revision 07/2011Вадим УрупаÎncă nu există evaluări