Documente Academic

Documente Profesional

Documente Cultură

GC9520

Încărcat de

Aleksander AlexanderDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GC9520

Încărcat de

Aleksander AlexanderDrepturi de autor:

Formate disponibile

Steam Generator

GC9520

Philips Consumer Lifestyle

Service Manual

PRODUCT INFORMATION

Fast & powerful crease removal

- Soleplate: SteamGlide

- OptimalTemp

- Continiuous steam output: 120 g/min

- Steam boost: 270 g/min

- Vertical steam

- Steam pressure: Up to 6.0 bar

- Steam tip

- Power: 2400 W

Easy to use

- Water tank capacity: 1500 ml

- Filling and emptying water: Detachable water tank

Extra large opening door

- Refill any time

- Heat-up time: 2 min

- Auto Off

- Hose storage: Hose storage compartment

- Cord storage: Cord storage compartment

- Power cord lenght: 1.8 m

- Cord freedom (swivel): 180 degree cord freedom

- Hose length: 1.7 m

- Safe for all fabrics: Even for delicates like silks

- Carry Lock

Sustainability

- ECO setting: 20% energy reduction

12/01

TECHNICAL INFORMATION

Voltage

: 220 - 240 V

Frequency

: 50 - 60 Hz

Power - Iron

: 800 W at 230 V

- Boiler

: 1370 W at 230 V

Product Dimensions : 28.3 x 26.3 x 42.4 cm

Weight

: Weight of iron: 1.2 kg

Weight of iron + base: 5.4 kg

Optimal Temp technology

- Delivers always perfect combination of steam and

temperature

- 100% easy to use, no adjustment required

- 100% safe on all ironable garments

- 100% effective on all fabrics, no other iron is faster

- Tested and approved by independent textile experts

1

Always the perfect setting thanks to:

1 - Cylonic ste am chamber

2 - Advanced Smart control processor

Easy De-calc

Easy De-calc cap allows hassle free & effective scale removal

to extend the life of the steam generator.

Calc management

- Suitable for tap water

- Calc clean solution: Easy De-calc

Published by Philips Consumer Lifestyle

EMF & Service Information

- This product meets the requirements regarding interference

suppression on radio & TV.

- After the product has been repaired, it should function

properly & has to meet the safety requirements as officially

laid down at this moment.

Carry Lock

Lock your iron securely & carry your appliance easy.

Printed in the Netherlands

Copyright reserved

Subject to modification

DISASSEMBLY ADVICE - IRON

GC9520

BACKPLATE ASSY 16

SOS KNOB 13

INLAY MOLDED 17

MICRO-SWITCH ASSY 12

HOSE CORD MOUNTED

ASSY SOS 15

HOUSING & LENS

ASSY PRINTED 9

LIGHT GUIDE ASSY 10

COVER MOLDED SOS 8

DEVIATOR ASSY 3

SOLEPLATE MOUNTED

ASSY 1

Remove

Disassemble

Remove

Disassemble

Remove

Remove

Disassemble

Screw A

BACKPLATE SCREW PLATE 21

Screws B1, B2

BACKPLATE ASSY 16

Screws C1, C2

Cord clamp

SOS KNOB COVER 18

Tip for disassembling SOS KNOB COVER 18:

Carefully insert a sharp object into the gap at the side & slowly

lift up the part

Disassemble

Remove

Disassemble

Remove

Disassemble

Remove

Disassemble

Remove

Disassemble

Remove

Disassemble

Remove

Disassemble

SOS KNOB 13

Screw D

INLAY MOLDED 17

Screw E

MICRO-SWITCH ASSY 12

Screw F

HOUSING & LENS ASSY PRINTED 9

Screws G1, G2

LIGHT GUIDE ASSY 10

Screws H1 - H3

COVER MOLDED SOS 8

Screws J1 - J6

DEVIATOR ASSY 3

2-12

PARTS LIST - IRON

GC9520

Pos

Service code

Description

1

2

3

4

5

4239 021 66252

4239 021 61471

4239 021 61523

4239 015 59151

4239 010 11991

Soleplate mounted assy 230 V / 800 W

Thermistor assy Iron

Deviator assy

Braided rubber hose iron

Hose clip (ID=8.7)

6

7

8

9

10

4239 010 10281

4239 015 70153

4239 021 67662

4239 021 68303

4239 021 61772

Hose clip-Braided rubber hose

Ryton ring

Cover SOS spray painted

Housing & Lens assy printed

Light Guide assy

11

12

13

14

15

4239 021 67692

4239 021 61561

4239 021 67711

4239 026 42481

4239 021 67721

Deco_Plate & Top Cover assy Printed

Micro-switch assy

SOS knob sprayed painted

SOS lever molded

Hose cord mounted assy SOS

16

17

18

19

20

4239 021 67741

4239 021 67752

4239 026 42521

4239 026 47861

4239 014 54961

Backplate assy

Inlay spray painted

SOS knob cover

Trigger molded

Trigger spring

21

4239 026 42551

Backplate screw cap

3-12

EXPLODED VIEW - IRON

GC9520

18

13

D

E

Micro Switch holder

17

12

A1

11

20

21

B2

14

B1

19

C2

F

16

C1

Cord clamp

9

10

G1

H2

G2

H1

H3

15

8

J2

J1

J3

5

J4

3

J6

J5

4

6

Rubber gasket

2

7

4-12

DISASSEMBLY ADVICE - STAND

GC9520

WATER TANK PRINTED

ASSY 58

TRAY MOLDED 53

DISPLAY COVER PRINTED

ASSY 50

STAND TOP MOLDED 45

POWER CORD STORAGE

MOLDED 42

HOSE CORD STORAGE

COMPARTMENT ASSY 43

RINSE CAP ASSY 56

RINSE HOUSING

PRINTED 39

BOILER ASSY 36

BUTTON PANEL ASSY 51

POWER BOARD PCB

ASSY 60

FLOATING PLATFORM

ASSY 61

Remove

Remove

Remove

Disassemble

Remove

Remove

Remove

Disassemble

Remove

Disassemble

Remove

Disassemble

Disassemble

Remove

Remove

Disassemble

Remove

Disassemble

Disassemble

Remove

Disassemble

Remove

Disassemble

Remove

Disassemble

Disassemble

WATER TANK PRINTED ASSY 58

TRAY RUBBER CAP 54

Screws K1, K2

TRAY MOLDED 53

Screws L1 - L4

Screw M

Screws N1 - N4

DISPLAY COVER PRINTED ASSY 50

Screws P1 P3

STAND TOP MOLDED 45

Screws Q1, Q2

POWER CORD STORAGE MOLDED 42

HOSE CORD STORAGE COMPARTMENT

ASSY 43

RINSE CAP ASSY 56

Screws R1, R2

RINSE HOUSING PRINTED 39

Screws S1, S2, S3

BOILER SUPPORT BRACKET MOLDED 41

BOILER ASSY 36

Screws T1, T2

BUTTON PANEL ASSY 51

Screw U

POWER BOARD PCB ASSY 60

Screws X1 - X4

PLASTIC CAP MOLDED 62

FLOATING PLATFORM ASSY 61

5-12

PARTS LIST - STAND

GC9520

Pos

Service code

Description

30

31

32

33

34

4239 021 68322

4239 021 68311

4239 026 42081

4239 015 59201

4239 010 10261

Stand bottom assy

Pump assy

De-air valve

Braided rubber hose boiler

Inox clamp

35

36

37

38

39

4239 026 32181

4239 021 68331

4239 017 12802

4239 021 61812

4239 021 68341

Spacer Bottom molded

Boiler assy

Electrovalve

Thermistor assy Boiler

Rinse Housing Printed

40

41

42

43

44

4239 026 31641

4239 026 42581

4239 026 47671

4239 021 67521

2422 070 98357

Spacer top molded

Boiler support bracket molded

Power cord storage molded

Hose cord storage compartment assy

Cord set EU

45

46

47

48

49

4239 021 67771

4239 026 44771

4239 014 54982

4239 021 63562

4239 026 44801

Stand top printed

Tank Catch molded

Tank Catch Spring

Inlet coupling plate welded

De-air coupling molded

50

51

52

53

54

4239 021 67543

4239 021 69521

4239 021 67831

4239 021 68442

4239 015 59221

Display cover printed assy

Button panel assy

Front lock assy

Tray assy

Tray rubber cap

55

56

57

58

59

4239 015 59531

4239 021 67851

4239 015 58201

4239 021 67872

4239 021 61723

Rinse Rubber Bush

Rinse cap assy

O-ring

Water tank printed assy

Hall sensor PCBA assy

60

61

62

4239 021 68572

4239 021 68812

4239 026 47651

Power Board PCB assy

Floating platform assy

Plastic cap molded

6-12

EXPLODED VIEW - STAND

GC9520

L2

L1

52

K1

K2

47

54

58

53

46

49

L3

L4

50

M

48

P2

P1

45

P3

43

42

Q2

37

Q1

S1

T2

S2

T1

40

36

32

51

33

U

34

31

60

62

35

X4

X3

X1

X2

S3

41

59

38

Cord

clamp

55

R1

R2

56

61

39

57

30

N4

N3

N2

N1

44

7-12

ELECTRICAL BLOCK DIAGRAM

GC9520

Thermistor

Stand Electronics

L

N

E

UI Board

Trigger

Switch

N

E

Power Board

Iron

LED

Hall Sensor

Board

Steam

E-valve

STAND

Boiler Heating

Element

Thermal

Fuse

Iron

Heating

Element

Thermal

Fuse

Pump

Thermistor

IRON

8-12

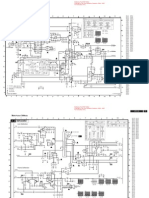

WIRING DIAGRAM

GC9520

#1

THERMAL

FUSE (L)

PUMP

sF

sF

#2

#1

WA19 : HE-Fuse (L)

M #1

sF

#2 M

#2

THERM-BOILER

sF

#1

THERMAL

FUSE (N)

WA20 : HE-Fuse (N)

WA3 : EARTH WIRE_BOILER

WA6 : PCB-Fuse (N)

WA5 : PCB-Fuse (L)

WA4 : PCB-EV (L)

WA7 : PCB-EV (ctrl)

WA2 : PCB-Pump (ctrl)

WA1 : PCB-Pump (L)

#2

UI

BOARD

#1

#2

EVALVE-EARTH

sF

9003 (Boiler-L)

9009 (Boiler-N)

9006 (To UI)

9014 (Live)

9007

2x

2

1

3

9012

HALL

SENSOR

BOARD

3x

2

1

3

sPB

sF

9004 (Iron Live)

NEUTRAL

9018 (Iron LED)

sM

TRIGGER

sF

THERMISTOR

9002 (Neutral)

sF

(3.96 mm)

9017

mF

9001 (Live)

POWER BOARD

sF

9015 (Evalve-Control)

9016 (Pump-Control)

9013 (Live)

7x

HOSCORD

IRON

FLEX ASSY

Sleeve - Fiber Glass

Female Push-on 5.2 x 0.8 mm L-shape Connector

Insulated Tab - Silicon Rubber

sM

Male Tab Terminal 4.8 x 0.8 mm

Ring Terminal M4.3

Female Push-on L-shape Connector 6.35 x 0.8 mm

Splice 6.0 mm

mF

Female Push-on 4.8 x 0.8 mm L-shape Connector

sF

LEGEND:

Female Push-on Connector 6.35 x 0.8 mm

Male Tab Terminal 6.35 x 0.8 mm

7-pin Board-in Connector 2 mm (horizontal)

Piggy Back Push-on Connector 4.8 x 0.8 mm

7-pin Connector 2 mm (vertical)

sPB

Directly soldered on PCB

9-12

GC9520

REPAIR INSTRUCTIONS

- Due to the high wattage of the iron, only the specified cord set must be used.

- Should damage be observed on the HOSE CORD MOUNTED ASSY 15 or CORD SET 44, they must be replaced.

Continued usage is not allowed.

- When replacing the MICROSWITCH ASSY 12, please dress the 2 attached wires such that they are free of tension. Pulling

force on the wires may affect the steam triggering.

- To avoid damage to the sealing & components of the BOILER ASSY 36, NEVER clean the boiler assy with vinegar, descaling

agent or other corrosive chemicals.

- When replacing ELECTROVALVE 37 or PUMP ASSY 31, please be reminded to apply loctite at the joints for good sealing.

- After the product has been repaired, it should function properly and has to meet the safety requirements & legal regulations as

laid down & officially established at this moment.

- The following tests are common checks that are conducted on a repaired product before it is returned to the consumer.

1. Soleplate temperature

Check that soleplate temperature is within below requirement.

Measure the temperature of the soleplate after the iron has reached steady state i.e connected to the mains for at least 15 minutes.

The table below shows the temperature requirement.

Soleplate temperature (Deg C)

Materials, for example

Maximum

120

143

Testpoint

=

Minimum

All fabric types

2. Leakage current

Check that leakage current is within IEC requirement.

Measure leakage current between LIVE/NEUTRAL & EARTH.

IEC requirement is that at 230 V supply, the EARTH leakage current must be less than 0.75 mA.

3. Water leakage / Functionality

Check that there is no water leakage from any part of the product during operation.

Check that the functionality of the product (product dependent) eg. steaming, variable steam, SOS, ASO etc is working properly.

4. Loose part

Check that there are no loose parts eg. extra screw in the product that can cause short-circuit or product malfunction.

10-12

GC9520

REPAIR INSTRUCTIONS

5. Crimping INOX CLAMP 34

When exchanging BOILER ASSY 36 or DE-AIR VALVE 32 or BRAIDED RUBBER HOSE BOILER 33, it is necessary to

replace the INOX CLAMP 34. Below instructions ensure that the inox clamp is crimped correctly.

Inox clamp

Crimping tool

Knipex Crimping tool

2.7 mm

(max)

Direct crimp form

3.5 mm

(max)

Fold in crimp

1 - 2 mm

Distance from edge of

crimp to rubber hose

CAUTION: When crimping on plastic part like DE-AIR VALVE, avoid over crimping which may lead to plastic part crack.

11-12

GC9520

REPAIR INSTRUCTIONS

6. Replacing ELECTROVALVE 37

To prevent damage to the electrovalve during service activity, please observe below precautions during disassembly & reassembly.

Tools required: Torque wrench (set to 6kgf)

CAUTION #1: The torque wrench engagement is allowed ONLY at the yellow box locations in below picture.

Contact area for torque

wrench to screw/unscrew

the electrovalve.

CAUTION #2: Ensure torque wrench jaw does not contact the solenoid body.

Torque wrench

Maintain gap between

the torque wrench and

the solenoid body

Electro-valve

solenoid body

12-12

S-ar putea să vă placă și

- Service Manual: Steam Generator GC9245Document12 paginiService Manual: Steam Generator GC9245Aleksander AlexanderÎncă nu există evaluări

- Service Manual: Provapor Inox New Profi HI 922Document6 paginiService Manual: Provapor Inox New Profi HI 922pukymottoÎncă nu există evaluări

- Service Manual: Provapor Vario New Profi HI 924Document6 paginiService Manual: Provapor Vario New Profi HI 924pukymottoÎncă nu există evaluări

- Service Manual: Boiler Steam Iron Provapor GC 6022Document6 paginiService Manual: Boiler Steam Iron Provapor GC 6022pukymottoÎncă nu există evaluări

- Boiler Steam Iron ©Document6 paginiBoiler Steam Iron ©pukymottoÎncă nu există evaluări

- Philips Steam Iron Elixir GC4020Document5 paginiPhilips Steam Iron Elixir GC4020eyoakeÎncă nu există evaluări

- Iron Provapor ®Document6 paginiIron Provapor ®pukymottoÎncă nu există evaluări

- Service Manual: Ironing Board HL 5420Document3 paginiService Manual: Ironing Board HL 5420pukymottoÎncă nu există evaluări

- Philips GC9540 Service ManualDocument12 paginiPhilips GC9540 Service Manualpwnuk wnukÎncă nu există evaluări

- MaterialDocument83 paginiMaterialAbhijeet DesaiÎncă nu există evaluări

- Hydraulic Inhalt GBDocument36 paginiHydraulic Inhalt GBvirendra0504Încă nu există evaluări

- fc8716 142Document6 paginifc8716 142Роман ПрокопчукÎncă nu există evaluări

- Aisladores para 24-72kVDocument8 paginiAisladores para 24-72kVMiguel GalarzaÎncă nu există evaluări

- Lock CatalogDocument38 paginiLock CatalogEngineering Group ContractorsÎncă nu există evaluări

- B&J USA Cam Switches PDFDocument95 paginiB&J USA Cam Switches PDFHeri SetyantoÎncă nu există evaluări

- Valve and Actuator CatalogueDocument60 paginiValve and Actuator Catalogueashfaq-matte-79930% (1)

- Schneider 3-Way ValvesDocument5 paginiSchneider 3-Way Valvesdarby1028Încă nu există evaluări

- Valves ActuatorsCAT0408Document60 paginiValves ActuatorsCAT0408Rami ReddyÎncă nu există evaluări

- Process Study SheetDocument14 paginiProcess Study SheetBalachandar SathananthanÎncă nu există evaluări

- Licon Heat - Catalog 2009Document68 paginiLicon Heat - Catalog 2009Iosif BabiasÎncă nu există evaluări

- Pull Wire and Trip Switch PDFDocument76 paginiPull Wire and Trip Switch PDF450gasgas100% (1)

- Koro - Espresso - Instant - 220v 50-60hz May 2011Document48 paginiKoro - Espresso - Instant - 220v 50-60hz May 2011Leah LopezÎncă nu există evaluări

- Colibri LX PartsDocument36 paginiColibri LX PartsNestor PasseriniÎncă nu există evaluări

- TV Repair 625 ®Document7 paginiTV Repair 625 ®Enrik VillaÎncă nu există evaluări

- Ghidini p87 88 Navod ND enDocument31 paginiGhidini p87 88 Navod ND enjunkyjunk7116Încă nu există evaluări

- 30HXC CNDocument12 pagini30HXC CNtechnokakiÎncă nu există evaluări

- Service Manual: Vacuum Cleaner FC8620Document6 paginiService Manual: Vacuum Cleaner FC8620milojko256Încă nu există evaluări

- Electrical & Electronic ItemsDocument6 paginiElectrical & Electronic ItemsVipinVijayÎncă nu există evaluări

- Calydra-Comfort Spare PartsDocument16 paginiCalydra-Comfort Spare PartsnitescucipÎncă nu există evaluări

- Whirlpool ManualDocument14 paginiWhirlpool ManualRene Antonio Delgado SobalvarroÎncă nu există evaluări

- Korinto - Espresso - Instant - 220 Volt - 50 HZ: Spare Parts Catalogue Updating: January 2006Document26 paginiKorinto - Espresso - Instant - 220 Volt - 50 HZ: Spare Parts Catalogue Updating: January 2006nubercard6111Încă nu există evaluări

- Philips Fc8402 City-Line BarcelonaDocument5 paginiPhilips Fc8402 City-Line BarcelonamihaimiitÎncă nu există evaluări

- York Cat LC 2012 enDocument148 paginiYork Cat LC 2012 enMary Andrews100% (1)

- Spare Parts Catalogue Catalogue de Pièces de Rechange: 471 1544-67 Doc. No. EDITION 46.2000Document89 paginiSpare Parts Catalogue Catalogue de Pièces de Rechange: 471 1544-67 Doc. No. EDITION 46.2000carlos lopesÎncă nu există evaluări

- Catalog Piese Brio250Document39 paginiCatalog Piese Brio250Sutu Cristi DanielÎncă nu există evaluări

- Palazzoli Disconnect SwitchDocument8 paginiPalazzoli Disconnect Switchshar2atÎncă nu există evaluări

- Trouble Free Series "V" Bottom Dump Control ValvesDocument2 paginiTrouble Free Series "V" Bottom Dump Control ValvesLuis Eduardo Albarracin RugelesÎncă nu există evaluări

- Plexo IP 55 Weatherproof Wiring Devices GuideDocument20 paginiPlexo IP 55 Weatherproof Wiring Devices GuideMeylia RodiawatiÎncă nu există evaluări

- Legrand Plexo Catalogue 02Document20 paginiLegrand Plexo Catalogue 02antonpgmÎncă nu există evaluări

- Cassette Air Conditioner Installation and Operation ManualDocument8 paginiCassette Air Conditioner Installation and Operation ManualjesÎncă nu există evaluări

- Venta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)Document5 paginiVenta: Two-Way Plug Valve, Pressure Balanced PN 25 (362 Psi)isombardÎncă nu există evaluări

- Spare Part List for PC1055Document2 paginiSpare Part List for PC1055Oliveira eletricidadeÎncă nu există evaluări

- Whirlpool Awm 6121Document18 paginiWhirlpool Awm 6121Ненад Митровић100% (1)

- Whirlpool Awod 41135Document20 paginiWhirlpool Awod 41135smara_1009Încă nu există evaluări

- Venta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)Document5 paginiVenta: Two-Way Pressure Balanced Valve PN 16 (232 Psi)DedeKurniawanÎncă nu există evaluări

- Alternators AAG PDFDocument4 paginiAlternators AAG PDFZoran TrajkovicÎncă nu există evaluări

- Ceiling Concealed Chilled Water Fan Coil UnitDocument14 paginiCeiling Concealed Chilled Water Fan Coil UnitRodrigo Neira De FinoÎncă nu există evaluări

- AWM8143Document22 paginiAWM8143pinticaniulian9042100% (1)

- Despiece Necta Snakky Max en - WatermarkDocument22 paginiDespiece Necta Snakky Max en - WatermarkMarco IdoneÎncă nu există evaluări

- Brio 250 Fresh-Brew: Spare Parts Catalogue Updating: November 2002Document25 paginiBrio 250 Fresh-Brew: Spare Parts Catalogue Updating: November 2002Homeopatica Capullo Macro PlazaÎncă nu există evaluări

- Venezia Es Schemat Złożeniowy 10-2004ENDocument33 paginiVenezia Es Schemat Złożeniowy 10-2004ENSalon ParkieciarniaÎncă nu există evaluări

- Steam SterilizationDocument27 paginiSteam SterilizationJm Larrea CasanovaÎncă nu există evaluări

- Awe 6516Document20 paginiAwe 6516m_tOmÎncă nu există evaluări

- Epoxy Resin BushingDocument12 paginiEpoxy Resin BushingSURJIT SINGHÎncă nu există evaluări

- Whirlpool Awod 41125 (ET)Document20 paginiWhirlpool Awod 41125 (ET)Florin GainaÎncă nu există evaluări

- Beginning Digital Electronics through ProjectsDe la EverandBeginning Digital Electronics through ProjectsEvaluare: 5 din 5 stele5/5 (1)

- Soldering electronic circuits: Beginner's guideDe la EverandSoldering electronic circuits: Beginner's guideEvaluare: 4.5 din 5 stele4.5/5 (9)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- SMD CatalogDocument80 paginiSMD CatalogMarudhasalamMarudhaÎncă nu există evaluări

- Equivalencia de Transistor BipolarDocument35 paginiEquivalencia de Transistor Bipolarsonhador4583% (18)

- Replacing AT90S8515 by ATmega8515Document10 paginiReplacing AT90S8515 by ATmega8515Aleksander AlexanderÎncă nu există evaluări

- Service Manual: Essence Foodprocessor HR7764Document7 paginiService Manual: Essence Foodprocessor HR7764Aleksander AlexanderÎncă nu există evaluări

- Service Manual: CoolskinDocument2 paginiService Manual: CoolskinAleksander AlexanderÎncă nu există evaluări

- Data Pin FlybackDocument35 paginiData Pin FlybackAleksander AlexanderÎncă nu există evaluări

- Service Manual: CoolskinDocument2 paginiService Manual: CoolskinAleksander AlexanderÎncă nu există evaluări

- Service Manual: Juicer HR1858/55Document5 paginiService Manual: Juicer HR1858/55Aleksander AlexanderÎncă nu există evaluări

- Toshiba 32Z13BG (SCH) PDFDocument41 paginiToshiba 32Z13BG (SCH) PDFAleksander AlexanderÎncă nu există evaluări

- Sunon: Specification For ApprovalDocument14 paginiSunon: Specification For ApprovalAleksander AlexanderÎncă nu există evaluări

- Service Manual: Cucina Blender HR 1739 /CBDocument4 paginiService Manual: Cucina Blender HR 1739 /CBAleksander AlexanderÎncă nu există evaluări

- Philips Chasis L03Document9 paginiPhilips Chasis L03Aleksander AlexanderÎncă nu există evaluări

- 20LL27 19y600 7560 PDFDocument26 pagini20LL27 19y600 7560 PDFAleksander AlexanderÎncă nu există evaluări

- Admiral TG 2100 ST ChasisPTSM02Document1 paginăAdmiral TG 2100 ST ChasisPTSM02sonivitelÎncă nu există evaluări

- LS17HAH - LS19HAH Schematic - Diagram (740B Plus 940B Plus)Document4 paginiLS17HAH - LS19HAH Schematic - Diagram (740B Plus 940B Plus)Aleksander AlexanderÎncă nu există evaluări

- TS2750J - Similar A Chasis PX20084-2CDocument34 paginiTS2750J - Similar A Chasis PX20084-2CAleksander AlexanderÎncă nu există evaluări

- LCD Monitor Technical TrainingDocument28 paginiLCD Monitor Technical TrainingAleksander AlexanderÎncă nu există evaluări

- Samsung An17hs, An17is, An19ms, An19is, An19mtDocument8 paginiSamsung An17hs, An17is, An19ms, An19is, An19mtAleksander AlexanderÎncă nu există evaluări

- Samsung 797DF, 997DF Chassis LE17IS, LE19IS, LE19IT - Schematic DiagramDocument8 paginiSamsung 797DF, 997DF Chassis LE17IS, LE19IS, LE19IT - Schematic DiagramAleksander AlexanderÎncă nu există evaluări

- KS17CN 794MBplus 796MBplus 798MB - Schematic DiagramDocument4 paginiKS17CN 794MBplus 796MBplus 798MB - Schematic DiagramAleksander AlexanderÎncă nu există evaluări

- Fashion Styling & Image CreationDocument7 paginiFashion Styling & Image CreationTanya choudharyÎncă nu există evaluări

- Type 25T Pilot Operated Temperature Regulator-Installation Maintenance ManualDocument8 paginiType 25T Pilot Operated Temperature Regulator-Installation Maintenance ManualNz CaÎncă nu există evaluări

- After The Red Rain (Preview)Document45 paginiAfter The Red Rain (Preview)Little, Brown Books for Young ReadersÎncă nu există evaluări

- Understanding The Global Apparel Manufacturing ProcessDocument18 paginiUnderstanding The Global Apparel Manufacturing Processyasin husen100% (1)

- Movers - Revision Test 2 (M2)Document12 paginiMovers - Revision Test 2 (M2)Vân PhạmÎncă nu există evaluări

- Noah's Ark HandbookDocument24 paginiNoah's Ark HandbooktolterÎncă nu există evaluări

- Ho-Shang-Kung's Commentary On Lao-Tse Part 2Document25 paginiHo-Shang-Kung's Commentary On Lao-Tse Part 2Shao LeeÎncă nu există evaluări

- DH 1128Document10 paginiDH 1128The Delphos HeraldÎncă nu există evaluări

- Fuss Free Baby Cardigan v1.2 PDFDocument3 paginiFuss Free Baby Cardigan v1.2 PDFMarina RotaruÎncă nu există evaluări

- Sucker Rod Pump Assembly and Maintenance InstructionsDocument31 paginiSucker Rod Pump Assembly and Maintenance Instructionsibraokasha100% (3)

- De 2Document2 paginiDe 2Nguyễn Huỳnh Toàn ThắngÎncă nu există evaluări

- An Account of Timbuctoo and Housa Territories in The Interior of Africa by Shabeeny, Abd SalamDocument240 paginiAn Account of Timbuctoo and Housa Territories in The Interior of Africa by Shabeeny, Abd SalamGutenberg.org100% (1)

- Sweet BoundlessDocument29 paginiSweet BoundlessBethany House PublishersÎncă nu există evaluări

- Argus Classified 050215Document4 paginiArgus Classified 050215Digital MediaÎncă nu există evaluări

- The Science of Welding PowerPointDocument27 paginiThe Science of Welding PowerPointPubudu KudahettiÎncă nu există evaluări

- The BFGDocument16 paginiThe BFGgbalrajÎncă nu există evaluări

- Unit 1: A Visit From A Pen Pal (TC) I. LISTEN: Listen To The CD (Text Books) and Decide Whether The Statements Are True or False. (1.0 PT) ADocument39 paginiUnit 1: A Visit From A Pen Pal (TC) I. LISTEN: Listen To The CD (Text Books) and Decide Whether The Statements Are True or False. (1.0 PT) AChris LêÎncă nu există evaluări

- 60 Grotowski Farewell Speech To The PupilsDocument13 pagini60 Grotowski Farewell Speech To The PupilsMirta Suquet100% (1)

- Procedure Mesure D'epaisseurDocument15 paginiProcedure Mesure D'epaisseurYoucef ChorfaÎncă nu există evaluări

- Hello, welcome to our store. How can I help you today?Customer: Hi, I'm looking for some new shirts and pants. Do you have any casual clothes in stockDocument8 paginiHello, welcome to our store. How can I help you today?Customer: Hi, I'm looking for some new shirts and pants. Do you have any casual clothes in stockflor trinidadÎncă nu există evaluări

- St. Anthony's Laundry Business PlanDocument49 paginiSt. Anthony's Laundry Business PlanJosiah Andrei Villodres CastilloÎncă nu există evaluări

- OK! Magazine - August 1, 2016 AU PDFDocument84 paginiOK! Magazine - August 1, 2016 AU PDFSabina FloreaÎncă nu există evaluări

- 08-18-11 - Moneysaver - Lewis-Clark EditionDocument20 pagini08-18-11 - Moneysaver - Lewis-Clark EditionDavid ArndtÎncă nu există evaluări

- The Necklace by Guy de MaupassantDocument3 paginiThe Necklace by Guy de MaupassantDibakar BhattacharjeeÎncă nu există evaluări

- Mctage'S Leather Trouser Worm Carp Fly: Foam VersionDocument70 paginiMctage'S Leather Trouser Worm Carp Fly: Foam VersionJoseph Castleberry100% (1)

- ch13 PDFDocument5 paginich13 PDFmalikaleÎncă nu există evaluări

- 1 Bachillerato Extra Grammar Full With ExplanationDocument13 pagini1 Bachillerato Extra Grammar Full With ExplanationAndreaTürmeÎncă nu există evaluări

- JEOPARDY - Level BeginnerDocument53 paginiJEOPARDY - Level BeginnerkarenÎncă nu există evaluări

- Design of Transmission Systems Question BankDocument26 paginiDesign of Transmission Systems Question BankJennifer WilsonÎncă nu există evaluări