Documente Academic

Documente Profesional

Documente Cultură

Notch Strengthening Omega Research Inc

Încărcat de

detriwiatnoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Notch Strengthening Omega Research Inc

Încărcat de

detriwiatnoDrepturi de autor:

Formate disponibile

9/10/2015

OmegaResearchInc.|NOTCHEDTENSILESTRENGTH

Help

Login

SiteNews

Home|AboutUs|Services|Publications|Links|ContactUs|Accreditation|Q&AForums

PrintThisDocument

Occasionally, we are asked the question,".... My notched tensile samples appear to be over 350,000 psi, I

thoughttheywererequiredtobe260,000280,000psi?...."

This is called notch strengthening and is a normal phenomenon with hydrogen embrittlement

samples

Notch strengthening falls in the field of Fracture Mechanics, and can be present in any ductile metal. When

yourhydrogenembrittlementsamplesaremanufacturedtheyarefirstblankedout,andthenheattreatedto

therequired260,000280,000psitensilestrengthrange.Thisistherequiredtensilestrengthforthebase

steelalloy,e.g.AISI4340.Aheattreattensilestrengthtestisthenperformedonthesesmooth,unnotched

samples to verify the proper heat treat. Then the samples are finish machined and ground, with notch

placementthelastmanufacturingoperationtooccur.Duringthefinaltestingandcertificationofthesamples,

now with a notch present, a final notched tensile strength test is performed. (In the field of mechanical

metallurgy,alwaysrememberthedifferencebetweenatensileload,inpoundsandtensilestrength/stressin

poundspersquareinchorpsi)

Donotconfusetheresultsoftheheattreattensilestrengthtestwiththe notch tensile strength tests. The

heat treat tensile strength test establishes proper heat treat The notched tensile strength test simply

providesthenotchedtensilestrengthnecessaryforthetestlaboratoriestoevaluateyourplatedtestsamples.

Eventhoughthecrosssectionalareaatthebaseofthenotchislessthanthecrosssectionalareaofasmooth

sample, an increase in the tensile strength/stress happens due to this phenomenon called notch

strengthening. For our 4340 low alloy steel, an increase in the tensile strength/stress approaching 50% is

possible.Thisphenomenonisnotpresent in brittle materials, but only in materials exhibiting ductility. Even

highheattreat4340lowalloysteelat260,000280,000psitensilestrengthwillexhibitupwardsof1014%

ductility.

The rest of this Technical Commentary is reprinted portions of section 7.5 of "Deformation and Fracture

MechanicsofEngineeringMaterials",byRichardW.Hertzberg,JohnWiley&Sons,NewYork1976whichgoes

intomoredetailconcerningthisphenomenoncallednotchstrengthening.

7.5NOTCHSTRENGTHENING

Whenanappreciableamountofplasticdeformationispossible,aninterestingturnofeventsmayoccurwith

regard to the fracture behavior of notched components. We saw in Chapter One that plastic constraint is

developedintheneckedregionofatensilebarasaresultofatriaxialstressstatetheunneckedregionsofthe

sampleexperiencealowertruestressthantheneckedsectionand,therefore,restrictthelateralcontractionof

thematerialintheneck.Similarstressconditionsexistinthevicinityofanotchinaroundbar.Whenthenet

section stress reaches the yield strength level, the material in the reduced section attempts to stretch

plastically in the direction parallel to the loading axis. Since conservation of volume is central to the plastic

http://www.omegaresearchinc.com/Publications/getpub.cfm?pub_id=18

1/3

9/10/2015

OmegaResearchInc.|NOTCHEDTENSILESTRENGTH

deformation process, the notch root material seeks to contract also, but is constrained by the bulk of the

sample still experiencing an elastic stress. The development of tensile stresses in the other two principal

directionstheconstrainingstressesmakesitnecessarytoraisetheaxialstresstoinitiateplasticdeformation.

Thedeeperthenotch,thegreateristheplasticconstraintandthehighertheaxialstressmustbetodeform

the sample. Consequently, the yield strength of a notched sample may be greater than the yield strength

foundinasmoothbartensiletest.ThedatashowninTable7.2demonstratethe"notchstrengthening"effect

in1018steelbars,notchedtoreducethecrosssectionalareabyupto70%.

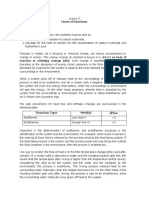

TABLE7.2NotchStrengtheningin1018Steel

ReductionofArea

inNotchSample

yieldstrength,

notchedbar

smoothbar

1.00

20

1.22

30

1.36

40

1.45

50

1.64

60

1.85

70

2.00

Inthiscasenotethatthenetsectionstresswillincreasewithnotchdepthasaresultoftheincreasedplastic

constraint. In this manner, you may prove to yourself that materials with limited deformation capacity will

notchweaken,andhighlyductilematerialswillnotchstrengthen.

Two factors need to be emphasized when discussing the observed notch strengthening effect. First, even

thoughthenotchedcomponentmayhaveahighernetsectionstress,itrequiresalowerloadforfracturethan

does the smooth sample when based on the gross crosssectional area. I trust that this should temper the

enthusiasmofanyoverzealousstudentwhomightotherwiseraceabout,hacksawinhand,withtheintentof

"notchstrengthening"allthebridgesintown.Second,thereisalimittotheamountofnotchstrengthening

thatamaterialmayexhibit.Fromtheoryofplasticityconsiderations,itisshownthatthenetsectionstressina

deformablematerialmaybeelevatedto2~to3timesthesmoothbaryieldstrengthvalue.

Copyright20022008,OmegaResearchInc.AllRightsReserved

Text,Content,ConceptsandInformationProtectedundertheCopyrightLawsoftheUnitedStates.

ThisinformationMAYNOTBEreproducedinwholeorinpart,storedinaretrievalsystem,photocopied,recordedortransmittedin

anyformormeanselectronic,mechanical,photographicorotherwise.ThisCopyrightedmaterialisintendedsolelyfortheclientsof

OmegaResearchInc.andundernoconditionsmaytheText,Content,Conceptand/orInformationshownbeusedforfinancialgain,

profit,businessorprofessionalenhancementbyanyindividualparty.

NOTE:

Thereaderiscautionedthatthesubjectnatureofmetalfinishingandhydrogenembrittlementistechnicaland

complex.Somesimplificationofmetallurgicalconceptsmaybepresentedinorderforaneasierunderstandingof

thesubjectmatterfortheintendedreader.

Theinformationcontainedinthiswebsiteshouldbeconsideredgeneralinformationonthesubjectsofmetal

finishing,hydrogenembrittlementandassociatedproblems,astheyexistinthemetallurgicalsciencestoday.

Somecontractor,agencyorspecificationrequirementsmaydifferorvaryfromtheparametersdiscussedwithin.If

http://www.omegaresearchinc.com/Publications/getpub.cfm?pub_id=18

2/3

9/10/2015

OmegaResearchInc.|NOTCHEDTENSILESTRENGTH

areasofconflictarise,alwaysfollowtheguidelinessetforthbyyourcontractingagency,customeror

specification.Thereaderissolelyresponsiblefordeterminingtheusefulnessoftheinformationpresented,asit

pertainstothereadersspecificproductorapplication.

OmegaResearchInc.assumesnoliabilityeitherexplicitorimpliedastothesuitability,accuracy,orapplicability

thereof.Anyreaderchoosingtoutilizetheinformationfromthiswebsitedoessobytheirowndiscretionand

accord,andassuchwithoutrecourseagainstOmegaResearchInc.

Copyright |PleaseReadOurDisclaimer |Help|

20012015OmegaResearchInc.AllRightsReserved

http://www.omegaresearchinc.com/Publications/getpub.cfm?pub_id=18

3/3

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- 3D FEM of Welding Process Using Element Birth & Element Movement TechniquesDocument7 pagini3D FEM of Welding Process Using Element Birth & Element Movement TechniquesDebabrata PodderÎncă nu există evaluări

- Refrigeration and AirconditioningDocument107 paginiRefrigeration and Airconditioningadrian paul relayosaÎncă nu există evaluări

- Piping and Instrument Diagram SymbolsDocument15 paginiPiping and Instrument Diagram Symbolsaviz gumayaÎncă nu există evaluări

- Hydro Metallurgy of Complex Sulfide Ores by P. Dharma RaoDocument172 paginiHydro Metallurgy of Complex Sulfide Ores by P. Dharma RaoFerudun Akyol100% (1)

- Moonsighting For Shawwal 1434Document3 paginiMoonsighting For Shawwal 1434detriwiatnoÎncă nu există evaluări

- Iron Ore Pelletizing Iron Ore Pelletizing: IndustryDocument1 paginăIron Ore Pelletizing Iron Ore Pelletizing: IndustrydetriwiatnoÎncă nu există evaluări

- Iwatani Welding Seminar - FormDocument5 paginiIwatani Welding Seminar - FormdetriwiatnoÎncă nu există evaluări

- Bulletin Jun Jul13Document7 paginiBulletin Jun Jul13detriwiatnoÎncă nu există evaluări

- Surat Izin SeminarDocument6 paginiSurat Izin SeminardetriwiatnoÎncă nu există evaluări

- Corel - Test Page #1Document1 paginăCorel - Test Page #1detriwiatnoÎncă nu există evaluări

- Aisi 4340 Alloy Steel (Uns g43400)Document3 paginiAisi 4340 Alloy Steel (Uns g43400)detriwiatnoÎncă nu există evaluări

- Bhs. Inggris 1995Document1 paginăBhs. Inggris 1995detriwiatnoÎncă nu există evaluări

- Module 1.6 Settling and SedimentationDocument37 paginiModule 1.6 Settling and SedimentationLong EÎncă nu există evaluări

- DownloadLecture 10 - Entropy, Clausius InequalityDocument4 paginiDownloadLecture 10 - Entropy, Clausius Inequalityeuglena6Încă nu există evaluări

- Answer Before P612 LT1Document5 paginiAnswer Before P612 LT1ina17_eaglerÎncă nu există evaluări

- 5.3 Dynamic Earth Pressure Methods: Mononobe-Okabe MethodDocument2 pagini5.3 Dynamic Earth Pressure Methods: Mononobe-Okabe MethodJesús Rodríguez RodríguezÎncă nu există evaluări

- Internal Erosion Due To Water Flow Through Earth Dams and Earth StructuresDocument25 paginiInternal Erosion Due To Water Flow Through Earth Dams and Earth StructuresFioz AriyandiÎncă nu există evaluări

- Che1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 AcpDocument2 paginiChe1005 - Momentum-Transfer - Eth - 1.1 - 47 - Che1005 - 55 Acpblub blueÎncă nu există evaluări

- CHEM12 - C1803 - SRVS (Correct)Document2 paginiCHEM12 - C1803 - SRVS (Correct)xr aimÎncă nu există evaluări

- Lift Load Distribution and Structural Load DistributionDocument3 paginiLift Load Distribution and Structural Load DistributionPrajeesh RajÎncă nu există evaluări

- Two-Stage Compression Centrifugal Chiller: Model RTGC SeriesDocument6 paginiTwo-Stage Compression Centrifugal Chiller: Model RTGC SeriesOM Eksperlik HizmetleriÎncă nu există evaluări

- UNIT4-MEC236-Bending Stresses in BeamsDocument18 paginiUNIT4-MEC236-Bending Stresses in Beamsintustan leeÎncă nu există evaluări

- Conduits ASSIGNMENTDocument12 paginiConduits ASSIGNMENTishaq kazeemÎncă nu există evaluări

- MENGR Module 4Document10 paginiMENGR Module 4Once TWICEÎncă nu există evaluări

- Pumps - Dairy Processing HandbookDocument6 paginiPumps - Dairy Processing HandbookMeera NairÎncă nu există evaluări

- 64bestPaper1Uniaxial True Stress-Strain After NeckingDocument12 pagini64bestPaper1Uniaxial True Stress-Strain After NeckingBrian ForsmanÎncă nu există evaluări

- UTC UTI Report 003Document243 paginiUTC UTI Report 003sbaia amineÎncă nu există evaluări

- Building Name: Office Building / Structure: RC Construction / Building Scale: Multiple StoreyDocument4 paginiBuilding Name: Office Building / Structure: RC Construction / Building Scale: Multiple StoreyFaquruddin AliÎncă nu există evaluări

- Virtual Lecture - 3-Tutorials-ThermodynamicsDocument20 paginiVirtual Lecture - 3-Tutorials-ThermodynamicsRukmani DeviÎncă nu există evaluări

- Strain Gage Hole Drilling MethodDocument1 paginăStrain Gage Hole Drilling MethodMarcoshhÎncă nu există evaluări

- geodESIGN ZID SPRIJIN PDFDocument24 paginigeodESIGN ZID SPRIJIN PDFDamian Florin DanielÎncă nu există evaluări

- Mass, Momentum and Energy EquationsDocument25 paginiMass, Momentum and Energy Equationslassi19a100% (1)

- Wind Load Predicting How Could CFD Replaced-SusilaDocument15 paginiWind Load Predicting How Could CFD Replaced-SusilaiGedeASÎncă nu există evaluări

- eArt-Calculating Overpressure From BLEVE ExplosionsDocument6 paginieArt-Calculating Overpressure From BLEVE ExplosionsJurizal Julian LuthanÎncă nu există evaluări

- Hognestad-A Study of Combined Bending and Axial Load in Reinforced Concrete MembersDocument134 paginiHognestad-A Study of Combined Bending and Axial Load in Reinforced Concrete MembersJhonatan Sedano50% (2)

- ThermalDocument3 paginiThermalDora AyeÎncă nu există evaluări

- Broquet Gamme IndustrieDocument8 paginiBroquet Gamme IndustrieJavierÎncă nu există evaluări

- Aerodynamic Evaluation On Formula SAE VehiclesDocument9 paginiAerodynamic Evaluation On Formula SAE Vehiclesmikael bezerra cotias dos santosÎncă nu există evaluări

- Activity 5 Heats of Reactions AnswerDocument6 paginiActivity 5 Heats of Reactions AnswerJohn Wilkins ToraynoÎncă nu există evaluări