Documente Academic

Documente Profesional

Documente Cultură

Passivation of Welded AISI 316L Stainless Steel

Încărcat de

Karna2504Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Passivation of Welded AISI 316L Stainless Steel

Încărcat de

Karna2504Drepturi de autor:

Formate disponibile

RMZ Materials and Geoenvironment, Vol. 55, No. 4, pp.

408419, 2008

408

Passivation of welded AISI 316L stainless steel

Pasivacija varjenega nerjavnega jekla AISI 316L

Mirko Goji1, Draen Marijan2, Marijan Tudja2, Stjepan Kouh1

1

University of Zagreb, Faculty of Metallurgy, Aleja narodnih heroja 3, 44103 Sisak, Croatia;

E-mail: kozuh@simet.hr; gojic@simet.hr

2

PLIVA Croatia, Ltd, Quality, Prilaz baruna Filipovia 25, 10000 Zagreb, Croatia;

E-mail: drazen.marijan@pliva.hr

Received: September 15, 2008

Accepted: November 17, 2008

Abstract: The paper deals with the results of passivation of welded AISI 316L austenitic stainless steel. The effectiveness of passivation in a volume fraction

6.0 % HNO3 solution containing the mass fraction of CuSO45H2O 2.0 %

was tested by potentiodynamic polarization. Polarization was carried out in

demineralized water before passivation and after it. At 80 C demineralized

water induced pitting corrosion and passivation was undertaken to protect

the steel surface. As a result of passivation the pitting potential decreased.

The satisfactory protective properties of the passive film on steel surface

were found to agree with the high value of the pitting potential. After passivation, the presence of white dotty agglomerations of copper atoms was

observed on the surface in the proximity of the melted zone.

Povzetek: lanek obravnava rezultate pasivacije varjenega nerjavnega jekla

AISI 313L. Uinek pasivacije v volumenski 6-odstotni raztopini HNO3,

ki vsebuje e masni dele 2 % CuSO45H2O smo preizkuali s potenciodinamino polarizacijo. Polarizacija je potekala v deminerilizirani vodi

pred polarizacijo in po njej. Pri 80 C deminerilizirana voda povzroi tokasto korozijo, pasivacija pa zagotavlja zaito povrine jekla. Posledica

pasivacije je zmanjanje potenciala za tokasto korozijo. Zadostna zaita

pasivacijskega filma plasti na povrini jekla je v skladu z velikim potencialom za tokasto korozijo. Po pasivaciji pa je znailna prisotnost tokastih

aglomeratov bakrovih atomov v okolici vara.

Key words: stainless steel, passivation, pitting corrosion, morphology

Kljune besede: nerjavno jeklo, pasivacija, tokasta korozija, morfologija

Original scientific paper

Passivition of welded AISI 316L stainless steel

Introduction

Austenitic stainless steels find important

and manifold applications as construction

materials in chemical and petrochemical

industries, in oil and gas exploitation, shipbuilding, food and drug processing, and

in water purification and distribution systems. Their chief characteristics are good

resistance to corrosion and elevated temperatures, good cryogenic strength, and

low magnetic permeability[1,2]. The AISI

304 and 316 austenitic stainless steels,

with their low-carbon 304L and 316L

grades, account for the largest fraction of

the worlds stainless steel production and

exploitation. Welding of stainless steels

causes formation of a very heterogeneous

melted zone because of impurities segregated at delta ferrite/austenite interphases

and because of possible presence of secondary precipitates (carbides, chi and sigma

phases, etc.)[2].

Numerous investigations have shown the

impairment of the corrosive and mechanical properties of the melted zone to be due

in the first place to the dominant attack of

corrosion at segregation sites, in dendrite

nuclei, at the austenite/delta ferrite interphases, and at the interphases of the secondary precipitates present in the zone[3,4].

In certain environments and conditions,

although belonging to a group of corrosion-resistant materials, austenitic stainless

steels are prone to damage by corrosion,

i.e. pitting corrosion.

Among various metals that are used to

protect the surface of the water purification and distribution systems stainless steels

come first. In real-life operating conditions

RMZ-M&G 2008, 55

409

corrosion causes dissolution of the surface

layers of the construction material, enhances roughness and porosity of the surface,

and accounts for uneven distribution of

the alloying elements. To diminish those

effects the passivation process must be

carried out efficiently and on time[5]. In this

work emphasis was placed on investigating

the effectiveness of surface passivation of

a welded joint (base metal, heat-affected

zone, melted zone) because of its specific

composition and microstructure.

Experimental

Investigation of corrosion behaviour was

performed on a weld joint from AISI 316L

austenitic stainless steel which formed

part of a water purification and distribution system. The chemical composition of

the steel is given in Table 1. The choice

of measuring equipment, electrochemical

reactor, and auxilliary and reference electrodes, and the preparation of the working

electrode were made in conformity with

ASTM standards[6,7]. The equipment for

electrochemical measurements consisted

of an EG&G PAR 273 A potentiostat/galvanostat, a Cole-Parmer 12700-55 thermostat, and an EG&G Corrosion Cell System, Model K47 electrochemical reactor.

A standard three-electrode corrosion cell

was used. A disc-shaped working electrode

(A = 1 cm2) was prepared from the AISI

316L weld joint. Welding was performed

under a protective argon flow. The weld

included the melted zone, the heat-affected

zone, and the painted fraction of the base

metal. An Ag/AgCl electrode served as the

410

reference electrode, and the counter electrode was a roller-shaped graphite electrode. Anodic potentiodynamic polarization

curves were recorded in conformity with

ASTM standards.

Goji, M., Marijan, D., Tudja, M., Kouh, S.

Results and discussion

Electrochemical measurements combined

with surface analysis facilitated assessment of the surface condition of the AISI

316L steel weld. With the two methods the

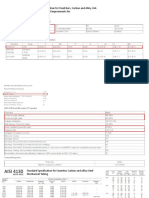

Table 1. Chemical composition of AISI 316L modifications produced by chemical clesteel in mass fractions, w/%

aning and passivation could be followed

Tabela 1. Kemina sestava jekla AISI 316L v simultaneously. In this way it was possible

masnih deleih, w/%

to establish a link between the corrosion

parameters (Rp, ECORR, jCORR, and Ep) and

C

Si Mn

P

S

Cr

Ni Mo

the morphological features of the surface.

0.023 0.35 0.71 0.033 0.007 17.49 11.27 2.09

Electrochemical measurements were carried out in a real medium (demineralized water, 80 C) and the passivating in volume

fraction 6.0 % HNO3 solution containing

the mass fraction of CuSO45H2O 2.0%.

In addition to electrochemical measurements, a comparative examination of the

surface of welded and non-welded AISI

316L steel samples was performed with a

Jeol JSM-5800 scanning electron microscope and an Oxford ISIS-302 chemical

analyser. The welded sample was examined without prior mechanical treatment,

whereas the non-welded one was polished

with a 1000 grit abrasive paper in Al2O3

(0.5 m) solution. The non-welded surface

was machined to conform to ASTM criteria, to facilitate detection of defects due

to passivation, and to make electrochemical measurements easier to conduct. For

chemical cleaning the mass fraction 2 %

of citric acid solution with 5 % the mass

fraction of ammonia (1800 s, 80 C) was

used. Passivation was carried out at 60

C in the volume fraction 6.0 % of HNO3

solution containing the mass fraction of

CuSO45H2O 2 % for 3400 s.

Electrochemical measurements

Before testing the capability for passivation of the 6.0 % HNO3 solution containing

the mass fraction of CuSO45H2O 2 % with

the help of a potentiodynamic polarization

curve we first investigated how demineralized water (real medium), at 80 C, affected the surface stability of the AISI 316L

steel weld (Figure 1). We then determined

the corrosive properties of the steel in demineralized water after passivation (Figure

2) and in the passivation solution (Figure

3). The general and pitting corrosion parameters as read from the potentiodynamic

polarization curves are listed in Table 2. In

practice, to be considered corrosion-resistant, steel is expected to have achieved the

corrosion potential (ECORR) before use. Defects on the steel surface due to long-term

use will initiate porosity and roughness. A

rough and porous structure will facilitate

oxidation and dissolution of the surface

layers, in other words it will become more

susceptible to pitting corrosion. The instability of the steel surface will produce as a

result a lower pitting potential (Ep). By undertaking a timely protective treatment i.e.

RMZ-M&G 2008, 55

Passivition of welded AISI 316L stainless steel

411

Figure 1. Anodic potentiodynamic polarization curve for AISI 316L steel weld in demineralized water before passivation, at the potential

scan rate of 5 mV s1

Slika 1. Krivulja anodne potenciometrine polarizacije zvara jekla AISI 316L v deminerilizirani vodi pred pasivacijo pri hitrosti menjave

potenciala 5 mV s1

Figure 2. Anodic potentiodynamic polarization curve for AISI 316L steel weld in demineralized water after passivation, at the potential

scan rate of 5 mV s1

Slika 2. Krivulja anodne potenciometrine

polarizacije zvara jekla AISI 316L v deminerilizirani vodi po pasivaciji pri hitrosti menjave

potenciala 5 mV s1

passivation, the Ep potential will be shifted

towards more positive values.

The values of general corrosion parameters measured in demineralized water demonstrated that general corrosion did not

cause any major damage to the surface

of the AISI 316L steel weld. The general

corrosion rate of 4.530 103 mm a1 was

taken to represent the average rate of deterioration of the weld surface. As well

as from the rate, general corrosion could

be assessed from the mass loss occurring

over the period of steel exposure to demineralized water. Equivalent to the general

corrosion rate of 4.530 103 mm a1 was

a mass loss of 0.036 g dm2 a1. It is well

established that a medium having a general

corrosion rate exceeding 0.127 mm a1, or

a mass loss in excess of 10.087 g dm2 a1,

is not considered appropriate for use[8] he

low values of general corrosion parameters

were proof that general corrosion was not

the reason why the surface of the welded

AISI 316L steel needed to be passivated

(Table 2). The chief reason for passivation

was the onset of pitting corrosion. The pitting potential (Ep) at the steel surface was

0.228 V (Figure 1, Table 2). From Figure 1

it is evident that the Ep value was too low

and the Ep ECORR difference too small for

the weld surface to resist pitting corrosion.

The susceptibility to pitting corrosion of

AISI 316L steel was the main reason why

it was necessary to protect the steel surface

by passivation.

The passivation effectiveness of the volume fraction 6.0 % HNO3 solution containing the mass fraction of CuSO45H2O

2.0 % was evaluated using the parameters

from the potentiodynamic polarization curve recorded in demineralized water after

passivation (Figure 2, Table 2). The values of general corrosion parameters after

passivation indicated that the corrosion

RMZ-M&G 2008, 55

412

Goji, M., Marijan, D., Tudja, M., Kouh, S.

Figure 3. Anodic potentiodynamic polarization

curve for AISI 316L steel weld in passivation

solution, at the potential scan rate of 5 mV s1

Slika 3. Krivulja anodne potenciometrine polarizacije zvara jekla AISI 316L v raztopini za pasivacijo pri hitrosti menjave potenciala 5 mV s1

rate decreased (from 4.530 103 mm a1

to 1.204 103 mm a1), i.e. that general

corrosion resistance increased. The pitting

potential at the passivated surface was higher (1.098 V) than the one at the nonpassivated surface (0.228 V). A rise in the Ep

value led to a higher Ep ECORR value (from

0.287 V to 1.063 V). The Ep and Ep ECORR

values indicated that the chosen passivation treatment provided effective protection

against pitting corrosion to the AISI 316L

steel surface exposed to demineralized water. However, unless the steel surface was

thoroughly rinsed with demineralized water

there was a risk of galvanic corrosion[9]. Galvanic corrosion occurs when two dissimilar

metals, immersed in a corrosive medium,

come in direct contact and form a galvanic

couple. The greater the difference between

standard electrode potentials (E0) of individual metals in the couple the more pronounced galvanic corrosion. After passivation, the residual copper atoms (E0 = 0.337

V) absorbed on the steel surface may have

formed microcouples with the steel constituents, iron (E0 = 0.037 V), nickel (E0 =

0.250 V), and chromium (E0 = 0.744 V),

and thus may have induced galvanic corrosion. To prevent this from hapenning it was

essential that the steel surface be thoroughly

rinsed after passivation.

Taking the volume fraction 6.0 %

HNO3 solution with the mass fraction of

CuSO45H2O 2.0 % to be an efficacious

protective agent against pitting corrosion, it was important to determine general

and pitting corrosion parameters for the

situation where the steel was exposed solely to the passivation solution. Analysis

Table 2. General and pitting corrosion parameters of AISI 316L steel weld in demineralized

water before and after passivation, and in passivation solution

Tabela 2. Parametri splone in tokaste korozije zvara jekla AISI 316L v deminerilizirani vodi

pred pasivacijo in po njej ter v raztopini za pasivacijo

Solution

Rp/

k

ba/

dek-1/V

bc/

dek-1/V

ECORR/

V

jCORR/

(A cm2)

vCORR/

mm a-1

Ep/

V

Demineralized water

0.251

0.312

0.152

-0.059

0.430

4.530 103

0.228

Demineralized water

after passivation

0.406

0.354

0.153

0.035

0.148

1.204 103

1.098

Passivation solution

0.010

0.387

0.296

0.643

4.74

0.049

0.900

RMZ-M&G 2008, 55

Passivition of welded AISI 316L stainless steel

413

Figure 4. SEM micrograph of the initial surface of AISI 316L steel base metal (a)

and weld joint (b)

Slika 4. Mikrografiji zaetne povrine jekla AISI 316L (osnovni material) (a) in

zvarnega spoja (b)

Figure 5. SEM micrograph of the surface of

AISI 316L steel after polishing

Slika 5. Mikrografija polirane povrine jekla

AISI 316L; SEM

of the results obtained from the potentiodynamic polarization curve recorded in the

passivation solution demonstrated that the

passivation solution was more aggressive

RMZ-M&G 2008, 55

than demineralized water (Figure 3, Table

2). The aggressiveness of the passivation

solution was as expected because, were it

not so, the protection against pitting corrosion provided by the solution would not

have been effective. However, the adverse

effect of the passivation solution was still

not strong enough to cause the steel surface

to dissolve, i.e. to induce general corrosion

(Table 2). A general corrosion rate of over

0.127 mm a1 was considered to be hazardous to the steel surface[10]. The pitting potential value (0.900 V) was taken to prove that

the passivation medium was well chosen.

Of the methods used for protecting the steel

surface none has proved capable of completely stopping the process of corrosion. By

efficient and timely protection of the steel

surface only the rate of corrosion can be diminished. It is therefore essential to repeat

the protective passivation treatment after a

certain period. How often passivation needs

repeating will depend on a number of fac-

414

Goji, M., Marijan, D., Tudja, M., Kouh, S.

Figure 6. SEM micrograph of the surface of AISI 316L steel base metal (a) and

weld joint (b) after passivation

Slika 6. Mikrografija pasiviranih povrin jekla AISI 316L (osnovni material) (a)

in zvarnega spoja (b); SEM

tors: operating conditions of the water purification and distribution system, type and

frequency of welding, temperatures of the

media present in the system, temperature

stresses during exploitation, oxygen content in the system, reduced oxygen values,

etc[11]. Assessment of the steel surface condition will therefore require not only laboratory studies but also real-life investigations

in water distribution systems[12].

Surface analysis

Analysis of surface morphology of the AISI

316L base metal and weld joint was carried

out before and after polishing, and also after passivation (Figures 46). Initially, the

base metal surface showed the presence of

grooves as well as of impurities, cracks, and

dimples (Figure 4a). In the weld two zones

could be distinguished: the melted zone and

the zone adjacent to the melted zone (Figure

4b). The melted zone morphology was characterized by an even and compact struc-

ture (Figure 4b, right). The adjacent zone,

contrariwise, exhibited cracks and grain

boundaries (Figure 4b, left). Despite morphological differences, a quantitative linear

analysis demonstrated equal proportions of

individual elements in the two zones (Figure 7). Chemical cleaning helped reduce the

cracks width and achieve a more uniform

structure of the welded surface.

The polished surface of AISI 316L steel

was characterized by a smooth and uniform structure (Figure 5). After polishing

there were no signs of cracks or impurities

on the steel surface. The passivated surface of the base metal exhibited an irregular

distribution of indentations (with a maximum diameter of up to 5m) (Figure 6a).

Quantitative linear analysis showed the

chemical composition of the steel surface

inside and outside indentations (dimples)

to be identical (Figure 8). The appearance

of dimples was the result of dissolution of

unstable surface sulphur in the acidic meRMZ-M&G 2008, 55

Passivition of welded AISI 316L stainless steel

415

Figure 7. Quantitative linear analysis of the initial surface of AISI 316L steel weld

joint

Slika 7. Kvantitativna kemina rtna analiza na zaetni povrini zvara jekla AISI

316L; EDXS

dium, i.e. in the passivation medium.

The passivation process is known to reduce

not only localized sulphur concentration in

AISI 316L steel but also its total concentration thus increasing steel resistance to

pitting corrosion[10]. Increase in the pitting

resistance of the weld following passivation

was established by analysis of the parameters obtained by potentiodynamic measurements (Table 2). The passivated surface

in the close proximity of the melted zone

exhibited white dotty agglomerations and

slightly less pronounced grain boundaries in comparison with the nonpassivated

RMZ-M&G 2008, 55

surface. The structure was granular, with

grains having a smooth surface. Surface

analysis showed the granular agglomerations to consist of copper atoms (Figure 9).

Quantitative linear analysis of the steel surface following passivation failed to show a

major difference in the content of individual

elements between the melted zone and the

adjacent zone (Figure 10). It may therefore

be concluded that the passivation medium

attacked the steel weld surface in a uniform manner. As a result of passivation all

steel constituents formed oxides without

prior dissolution. On the other hand, had

416

Goji, M., Marijan, D., Tudja, M., Kouh, S.

Figure 8. Quantitative linear analysis of the passivated surface of AISI 316L steel

base metal

Slika 8. Kvantitativna kemina rtna analiza pasivirane povrine jekla AISI 316L

(osnovni material); EDXS

Figure 9. Quantitative linear analysis of small agglomerations on the surface of

AISI 316L steel weld joint

Slika 9. Kvantitativna kemina rtna analiza drobnih aglomeratov na povrini

zvara jekla AISI 316L; EDXS

RMZ-M&G 2008, 55

Passivition of welded AISI 316L stainless steel

417

Figure 10. Quantitative linear analysis of the passivated surface of AISI 316L

steel weld joint

Slika 10. Kvantitativna kemina rtna analiza pasivirane povrine zvara jekla

AISI 316L; EDXS

dissolution taken place before oxidation

of surface atoms, quantitative analysis would have shown an uneven distribution of

the alloying elements. The uniform surface

composition of the steel weld, by warranting invariable ratios of chromium and iron

mass fractions, proved to be a measure of

effectiveness of passivation treatment[13,14].

Roughness measurements (Ra) are often

used for testing the efficacity of passivation media. The postpassivation roughness

values were 1.6 m for the melted zone,

0.37 m for the painted zone, and 0.25 m

for the base metal. The painted area of the

passivated surface adjacent to the melted

RMZ-M&G 2008, 55

zone exhibited a highest level of roughness, being the site of highest exposure

to the negative effect of heat input during

welding. By failing to enhance surface

roughness, passivation helped prevent a

possible drop in surface stability of AISI

316L steel.

Conclusions

From the results of potentiodynamic measurements and surface analysis of the AISI

316L steel weld exposed to demineralized

water it may be concluded that:

418

Goji, M., Marijan, D., Tudja, M., Kouh, S.

General corrosion did not cause a major References

damage to the steel surface.

At 80 C demineralized water caused da- [1] Lula, R. A. (1986): Stainless Steel,

American Society for Metals,

mage to the steel surface inducing pitting

Metals Park, Ohio.

corrosion so that passivation treatment

[2]

in the volume fraction 6.0 % HNO3 so- Kouh S., Goji M. (2006):

Zavarivanje.; Vol. 49, No. 5, pp.

lution containing the mass fraction of

177185.

CuSO45H2O 2.0 % was undertaken.

[3]

M

udali

U. K., Dayal R. K. (2000):

After passivation the general corrosion

3

Materials Science and Technology.;

rate diminished (from 4.530 10 mm

Vol. 16, No. 4, pp. 392398.

a1 to 1.204 103 mm a1), and general

[4]

evikov J., Tuleja S., Kocich J.

corrosion resistance increased.

(1996): Corrosion Resistance of

The pitting potential at the passivated

Stainless Steel Welds, Proc. of the

steel surface (1.098 V) was more positiInt. Welding Conference Welding

ve than the one at the nonpassivated surScience&Technology. Faculty of

face (0.228 V). A rise in the pitting poMetallurgy Technical University

tential was accompanied by increase in

of Koice, Koice, pp. 279282.

Ep ECORR value (from 0.287 V to 1.063

[5]

EHEDG

Update (2007): Trends in

V) indicating that the chosen passivation

Food Science Technology. Vol 18,

treatment provided efficacious protectiNo. 1, pp. s112s115.

on against pitting corrosion.

The passivation solution was more ag- [6] G 5-94 (1997):, Standard Reference Test

Method for Making Potentiostatic

gressive than demineralized water. The

and Potentiodynamic Anodic

noted aggressivity was insufficient to caPolarization Measurements, 1997

use dissolution of the steel surface.

Annual Book of ASTM Standards,

After passivation the steel surface needed

ASTM, Easton, pp. 55.

to be thoroughly rinsed with demineralized water to prevent adsorption of copper [7] G 1-90 (1997): Standard Practise

for Preparing, Cleaning and

atoms on the welded surface and possible

Evaluating

Corrosion

Test

occurrence of galvanic corrosion.

Specimens, 1997 Annual Book of

After passivation the surface adjacent to

ASTM Standards, ASTM, Easton,

the melted zone exhibited white dotty

pp. str. 15.

agglomerations. Analysis showed the

agglomerations to consist of copper [8] Fontana M. G. (1986): Corrosion

Engineering, Mc Grow-Hill,

atoms.

Singapur, pp. 172.

The painted portion of the passivated

surface adjacent to the melting zone [9] Kirby G. N. (1980): Selecting

Materials for Process Equipment,

was characterized by the highest level

Mc Grow-Hill, New York 1980,

of roughness, being the site of the most

pp. 180.

pronounced negative effect of heat input

during welding.

RMZ-M&G 2008, 55

Passivition of welded AISI 316L stainless steel

419

Coleman D. C., Evans R. W. (1990):

Pharm. Engineering. Vol. 10, pp.

43.

[11]

Uhlig H. H., Revie R. W. (1985):

Corrosion and Corrosion Control,

J. Wiley & Sons., New York, pp.

278.

[12]

G 4694 (1997): Standard Guide for

Examination and Evaluation of

Pitting Corrosion, 1997 Annual

Book of ASTM Standards, ASTM,

Easton, pp. 169.

[13]

Grant A., Henon B. K., Mansfeld F.

(1997): Pharm. Engineering. Vol.

1, pp. 46.

[14]

Grant A., Henon B. K., Mansfeld F.

(1997): Pharm. Engineering. Vol.

2, pp. 94.

[10]

RMZ-M&G 2008, 55

S-ar putea să vă placă și

- Inox Tester User Manual EP04Document36 paginiInox Tester User Manual EP04Ramon PachecoÎncă nu există evaluări

- How To Carry Out Tack WeldingDocument2 paginiHow To Carry Out Tack WeldingwentropremÎncă nu există evaluări

- Guidelines for Specification, Welding and Inspection of Stainless Alloy PipingDocument19 paginiGuidelines for Specification, Welding and Inspection of Stainless Alloy Pipingafr5364Încă nu există evaluări

- M2010051in-Mcb - Rolling Suggestions PDFDocument42 paginiM2010051in-Mcb - Rolling Suggestions PDFthaivinhtuyÎncă nu există evaluări

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 paginiWFP 2-01 ASME B31 Piping Welding Procedureleodavid87Încă nu există evaluări

- Nav22 - Welding/Weld Repair Audit ChecklistDocument23 paginiNav22 - Welding/Weld Repair Audit ChecklistdurraaiÎncă nu există evaluări

- Ductile Iron Data For Design EngineersDocument3 paginiDuctile Iron Data For Design EngineersSourav HaitÎncă nu există evaluări

- 2017 07 03 Sanitaryware CPR GuidanceDocument49 pagini2017 07 03 Sanitaryware CPR Guidancere gardeniaÎncă nu există evaluări

- Paint For SteelDocument11 paginiPaint For SteelSaud PathiranaÎncă nu există evaluări

- Impact AR500 PlateDocument2 paginiImpact AR500 PlateMario Diez100% (1)

- How To Perform Tack Welding SuccessfullyDocument2 paginiHow To Perform Tack Welding SuccessfullyLucaRoldoÎncă nu există evaluări

- Handbook MetrodeDocument371 paginiHandbook Metrodejf2587Încă nu există evaluări

- ISO 8501-Pictorial Clasiification Standard For Surface CleanlinessDocument29 paginiISO 8501-Pictorial Clasiification Standard For Surface CleanlinessabhibmaneÎncă nu există evaluări

- Feroxyl and Copper Sulfate TestingDocument23 paginiFeroxyl and Copper Sulfate TestingPrashant RaneÎncă nu există evaluări

- Standard Specification For Hot Dip GalvanizingDocument4 paginiStandard Specification For Hot Dip GalvanizingNuzul Furqony100% (1)

- FactoryDocument72 paginiFactorywhitebrosÎncă nu există evaluări

- Summary of Changes - ASME 2015Document17 paginiSummary of Changes - ASME 2015mbc_enggÎncă nu există evaluări

- Ferroxyl Test For Iron ContaminationDocument9 paginiFerroxyl Test For Iron ContaminationteokalÎncă nu există evaluări

- DNV Os C401Document44 paginiDNV Os C401Paul Tese AhireÎncă nu există evaluări

- FPC AsfDocument24 paginiFPC AsfSherif YehiaÎncă nu există evaluări

- AISI 4130: Standard Specification For Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForDocument3 paginiAISI 4130: Standard Specification For Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements ForAndy SaputroÎncă nu există evaluări

- Implications of NORSOK M-650 Standard in The OffshoreDocument15 paginiImplications of NORSOK M-650 Standard in The OffshoreBehroozÎncă nu există evaluări

- Welding Inspector: Weld Repairs Section 16Document20 paginiWelding Inspector: Weld Repairs Section 16manojballaÎncă nu există evaluări

- Material Traceability ProcedureDocument12 paginiMaterial Traceability Procedureqamar qateebÎncă nu există evaluări

- Introduction To Welding - MetallurgyDocument15 paginiIntroduction To Welding - Metallurgyramkishore_87100% (1)

- Mc1091 Recrushed SlagDocument4 paginiMc1091 Recrushed Slagtoxicity23Încă nu există evaluări

- Design File - Tack and Temporary WeldsDocument5 paginiDesign File - Tack and Temporary WeldsLora BoydÎncă nu există evaluări

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 paginiA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingÎncă nu există evaluări

- PDF Iso 3834 Checklist 1 CompressDocument12 paginiPDF Iso 3834 Checklist 1 CompressViệt VũÎncă nu există evaluări

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 paginiRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriÎncă nu există evaluări

- Preparation and Control of WeldingDocument3 paginiPreparation and Control of Weldingbalakumar rajaramÎncă nu există evaluări

- LT7 Tractor Operator Manual IM279Document88 paginiLT7 Tractor Operator Manual IM279Waldo AtÎncă nu există evaluări

- The Role of Niobium in Austenitic and Duplex Stainless SteelsDocument25 paginiThe Role of Niobium in Austenitic and Duplex Stainless SteelsZoe SideriÎncă nu există evaluări

- Iso 3834-2Document16 paginiIso 3834-2NONNE NaineÎncă nu există evaluări

- GMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)Document3 paginiGMAW (Solid Wire) vs. FCAW (Flux-Cored Wire)momoitachiÎncă nu există evaluări

- Dimensional Inspection Report PDFDocument1 paginăDimensional Inspection Report PDFThe Welding Inspections CommunityÎncă nu există evaluări

- 12 Storage of Parent MaterialsDocument3 pagini12 Storage of Parent MaterialselmiraÎncă nu există evaluări

- Manufacturer of Stainless Steel Kitchen EquipmentDocument3 paginiManufacturer of Stainless Steel Kitchen EquipmentMUTQAN STEELÎncă nu există evaluări

- Welding Specification for Austenitic, Duplex and Superduplex PipeworkDocument45 paginiWelding Specification for Austenitic, Duplex and Superduplex Pipeworkmurugesan0% (1)

- Pressure Vessel Dimension InspectionDocument2 paginiPressure Vessel Dimension InspectionNorman MoralesÎncă nu există evaluări

- Visual Inspection of Steel Pipes PlatesDocument72 paginiVisual Inspection of Steel Pipes PlatesLiam Choon SengÎncă nu există evaluări

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 paginiThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungÎncă nu există evaluări

- ADOR Booklet F Web FDocument132 paginiADOR Booklet F Web FbadesharamkÎncă nu există evaluări

- (Signed) Quality Manual Revision K 7th EditionDocument32 pagini(Signed) Quality Manual Revision K 7th EditionCricri Cri100% (1)

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelDocument16 paginiGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanÎncă nu există evaluări

- Improving Quality of Welding with ISO 3834Document53 paginiImproving Quality of Welding with ISO 3834AlienshowÎncă nu există evaluări

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 paginiSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzÎncă nu există evaluări

- Mandatory Procedure ISO9001, APIQ1, APIQ2Document1 paginăMandatory Procedure ISO9001, APIQ1, APIQ2KiagusÎncă nu există evaluări

- Poster Welding P VoxXa PDFDocument1 paginăPoster Welding P VoxXa PDFAd Man GeTigÎncă nu există evaluări

- BS 1724 (Bronze Welding by Gas)Document24 paginiBS 1724 (Bronze Welding by Gas)nandi_scrÎncă nu există evaluări

- Auditing Oof Welding Under ASME Section IXDocument21 paginiAuditing Oof Welding Under ASME Section IXsabahiraqÎncă nu există evaluări

- Deviation List & FormDocument2 paginiDeviation List & FormRohit AttriÎncă nu există evaluări

- I Object: Repair Procedure For Tank BottomDocument6 paginiI Object: Repair Procedure For Tank BottomZouhair BenmabroukÎncă nu există evaluări

- Iso 3834 1 2021Document10 paginiIso 3834 1 2021sosheyanÎncă nu există evaluări

- Work Instructions - Gas CuttingDocument2 paginiWork Instructions - Gas Cuttingvivek sureshÎncă nu există evaluări

- BS en Iso 9606-4 - 1999Document26 paginiBS en Iso 9606-4 - 1999jesoneliteÎncă nu există evaluări

- Welding Procedure Specification Review and Approval ProcessDocument4 paginiWelding Procedure Specification Review and Approval ProcessfallalovaldesÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- Corrosion of Aged and Annealed 18 Ni 250 Grade Maraging Steel in Phosphoric Acid MediumDocument16 paginiCorrosion of Aged and Annealed 18 Ni 250 Grade Maraging Steel in Phosphoric Acid MediumSharat ChandraÎncă nu există evaluări

- Deaerator CorrosionDocument7 paginiDeaerator Corrosionanindya1986Încă nu există evaluări

- Lesson 19 - API-510 - New2Document56 paginiLesson 19 - API-510 - New2Fahim MarwatÎncă nu există evaluări

- Tank DesignDocument89 paginiTank DesignDietrich von BismarckÎncă nu există evaluări

- Part+IIIA1 2++How+RBI+&+AIM+Become+corrosivity+of+crude++UnreliableDocument26 paginiPart+IIIA1 2++How+RBI+&+AIM+Become+corrosivity+of+crude++UnreliableKarna2504Încă nu există evaluări

- Lesson 19 - API-510 - New2Document56 paginiLesson 19 - API-510 - New2Fahim MarwatÎncă nu există evaluări

- 04 - Ammended Chapter 5 - InspectionDocument119 pagini04 - Ammended Chapter 5 - InspectionKarna2504Încă nu există evaluări

- Lesson 19 - API-510 - New2Document56 paginiLesson 19 - API-510 - New2Fahim MarwatÎncă nu există evaluări

- Environmental Stress Cracking of Heat Exchanger in High Temperature Boiler Feed WaterDocument44 paginiEnvironmental Stress Cracking of Heat Exchanger in High Temperature Boiler Feed WaterKarna2504Încă nu există evaluări

- Corrosion Analysis of Stainless Steel: Seifedine KadryDocument9 paginiCorrosion Analysis of Stainless Steel: Seifedine KadryMarcos GonzalezÎncă nu există evaluări

- TOFD CV PDFDocument19 paginiTOFD CV PDFKarna2504Încă nu există evaluări

- Nikon D5200 ManualDocument100 paginiNikon D5200 Manualdyc123100% (1)

- Corrosion Inhibition of Mild Steel in HydrochloricDocument6 paginiCorrosion Inhibition of Mild Steel in HydrochloricKarna2504Încă nu există evaluări

- Simulation Heat Transfer Convection Fired HeatersDocument8 paginiSimulation Heat Transfer Convection Fired HeatersPedro DiazÎncă nu există evaluări

- Tank DesignDocument89 paginiTank DesignDietrich von BismarckÎncă nu există evaluări

- Weldolet Inspection at Higher TemperaturesDocument7 paginiWeldolet Inspection at Higher TemperaturesKarna2504Încă nu există evaluări

- JoiningDocument52 paginiJoiningJade Al BoodoosinghÎncă nu există evaluări

- BORSIG Process Heat Exchanger - Transfer Line ExchangersDocument28 paginiBORSIG Process Heat Exchanger - Transfer Line ExchangersKarna2504100% (1)

- 6502-Methods For Predicting Maximum HardnessDocument8 pagini6502-Methods For Predicting Maximum Hardnessaw_engineerÎncă nu există evaluări

- 13% CR Sensitivity To Hydrogen Crack and Its ProtectionDocument9 pagini13% CR Sensitivity To Hydrogen Crack and Its ProtectionKarna2504Încă nu există evaluări

- Glass Lined BrochureDocument8 paginiGlass Lined BrochureKarna2504Încă nu există evaluări

- Repair of HP Mod AlloyDocument8 paginiRepair of HP Mod AlloyKarna2504Încă nu există evaluări

- Austenitic Cast Steel Phase Changes7C3carbides into M23C6 carbides in 0.4C-55Ni-25Cr cast steelDocument6 paginiAustenitic Cast Steel Phase Changes7C3carbides into M23C6 carbides in 0.4C-55Ni-25Cr cast steelKarna2504Încă nu există evaluări

- CleaningandDescalingStainlessSteel 9001Document38 paginiCleaningandDescalingStainlessSteel 9001Kiran DuggarajuÎncă nu există evaluări

- 5) Oil Chalk Test PDFDocument2 pagini5) Oil Chalk Test PDFkyeong cheol lee75% (16)

- SCC of Ss in NAOHDocument9 paginiSCC of Ss in NAOHKarna2504Încă nu există evaluări

- Calculations Help Determine Carbon Steel Piping in Cold Temperature Relief ServiceDocument5 paginiCalculations Help Determine Carbon Steel Piping in Cold Temperature Relief ServiceSuchart TarasapÎncă nu există evaluări

- Storage & Handling Welding ConsumablesDocument1 paginăStorage & Handling Welding ConsumablesKarna2504Încă nu există evaluări

- Failure Analysis of Hot Corrosion of Weldments in Ethylene Cracking TubesDocument12 paginiFailure Analysis of Hot Corrosion of Weldments in Ethylene Cracking TubesKarna2504Încă nu există evaluări

- Paper 3 Acid Dew Point Corrosion in HRSGsDocument83 paginiPaper 3 Acid Dew Point Corrosion in HRSGsKarna2504100% (1)

- Thesis Paper On Lean ManufacteringDocument70 paginiThesis Paper On Lean Manufacteringisabelgonreyes100% (1)

- Super T StandardsDocument16 paginiSuper T Standardschithirai10Încă nu există evaluări

- CJN BS 8558 2011PresentationFeb13 PDFDocument57 paginiCJN BS 8558 2011PresentationFeb13 PDFMaram Al-Masri100% (1)

- AP Human Geography Chapter 11 Key Issue 4Document1 paginăAP Human Geography Chapter 11 Key Issue 4a0lost0angel0% (1)

- Clean Sweep: Floor Cleaning Robot Idea for Automated CleaningDocument16 paginiClean Sweep: Floor Cleaning Robot Idea for Automated CleaningSaurabh RautÎncă nu există evaluări

- Section 12 - Welding Consumables - Stainless Steel266 - 27357Document106 paginiSection 12 - Welding Consumables - Stainless Steel266 - 27357getgateclose100% (1)

- Oil Refinery ProcessDocument13 paginiOil Refinery Processmch4561696% (26)

- Application Bulletin - Paints and CoatingsDocument2 paginiApplication Bulletin - Paints and CoatingsjoseÎncă nu există evaluări

- Kurva S (Kelompok 1) FixDocument2 paginiKurva S (Kelompok 1) FixGurusuÎncă nu există evaluări

- AFV Modeller 97 2017-11-12 - SuperunitedkingdomDocument67 paginiAFV Modeller 97 2017-11-12 - Superunitedkingdomjoausmaximus100% (5)

- Honey Well Thermostat ManualDocument12 paginiHoney Well Thermostat ManualGARTH64100% (1)

- ASTM F 1718 - 99Document7 paginiASTM F 1718 - 99Oh No PotatoÎncă nu există evaluări

- HA-YS310 Basic Seminar PL ENG 170126 (MHa) PDFDocument36 paginiHA-YS310 Basic Seminar PL ENG 170126 (MHa) PDFEduardo Expósito EspinosaÎncă nu există evaluări

- PNOZ X2 8P enDocument9 paginiPNOZ X2 8P enHamed MokhtariÎncă nu există evaluări

- Car Park Jet FanDocument14 paginiCar Park Jet FanYan Aung100% (1)

- Structural Steel ErectionDocument7 paginiStructural Steel Erectionzaki fadlÎncă nu există evaluări

- Is 694Document30 paginiIs 694nm_rangaÎncă nu există evaluări

- Recent Innovations in Concrete and Foundations Lead to More Sustainable GrowthDocument49 paginiRecent Innovations in Concrete and Foundations Lead to More Sustainable Growthprakash.sharmaÎncă nu există evaluări

- JORC DrainsDocument36 paginiJORC DrainsMod KaewdaengÎncă nu există evaluări

- Bending - Wikipedia, The Free EncyclopediaDocument12 paginiBending - Wikipedia, The Free EncyclopediajazzclubÎncă nu există evaluări

- Cement Practice QuestionsDocument2 paginiCement Practice QuestionsSureshKonamÎncă nu există evaluări

- MBSA1523 Managerial Economics Group 4 Presentation 1 ReportDocument12 paginiMBSA1523 Managerial Economics Group 4 Presentation 1 ReportPIONG MENG ZIAN MBS211233Încă nu există evaluări

- VW Touareg MaintenanceDocument102 paginiVW Touareg MaintenanceNick PÎncă nu există evaluări

- SRA166 210 01A BrochureDocument2 paginiSRA166 210 01A BrochureXanti Zabala Da RosaÎncă nu există evaluări

- Shell Morlina s2 B 320Document4 paginiShell Morlina s2 B 320Aep HidayatÎncă nu există evaluări

- Breast Cancer Risk in Relation To Occupations With Exposure To Carcinogens and Endocrine Disruptors: A Canadian Case - Control StudyDocument17 paginiBreast Cancer Risk in Relation To Occupations With Exposure To Carcinogens and Endocrine Disruptors: A Canadian Case - Control StudyJerika Marie ArceoÎncă nu există evaluări

- Traditional Machining Processes Research AdvancesDocument242 paginiTraditional Machining Processes Research AdvancesGema Rodriguez DelgadoÎncă nu există evaluări

- Session 11Document21 paginiSession 11Kais Garchi CasalÎncă nu există evaluări

- Choosing The Inductor For A Buck ConverterDocument8 paginiChoosing The Inductor For A Buck ConverterjboronatsÎncă nu există evaluări

- Electrobombas Verticales Sumergibles Lowara Serie SVIDocument52 paginiElectrobombas Verticales Sumergibles Lowara Serie SVIscoutper100% (1)