Documente Academic

Documente Profesional

Documente Cultură

Metal Tower Spec

Încărcat de

Safi Zabihullah SafiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Metal Tower Spec

Încărcat de

Safi Zabihullah SafiDrepturi de autor:

Formate disponibile

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

08/10

This Product MasterSpec Section is licensed by ARCOM to Metl-Span LLC ("Licensee").

This Product MasterSpec Section modifies the original MasterSpec text.

Revisions made to the original MasterSpec text are made solely by the Licensee and are not endorsed by,

or representative of the opinions of, ARCOM or The American Institute of Architects (AIA). Neither AIA

nor ARCOM are liable in any way for such revisions or for the use of this Product MasterSpec Section by

any end user. A qualified design professional should review and edit the document to suit project

requirements.

For more information, contact Metl-Span LLC, Lewisville, TX 75057; Phone: (972) 221-6656; Fax (972)

436-0648; Website: www.metlspan.com; Email: panel@metlspan.com.

For information about MasterSpec contact ARCOM at (800) 424-5080 or visit www.MasterSpec.com.

SECTION 074113.23 - INSULATED METAL ROOF PANELS

PART 1 - GENERAL

SCHEDULE 0 - SUMMARY

PRODUCT DATA SHEET 0 - Section includes insulated metal roof panels.

SCHEDULE 1 - PREINSTALLATION MEETINGS

PRODUCT DATA SHEET 0 - Preinstallation Conference:

<Insert location>.

Conduct conference at [Project site]

SCHEDULE 2 - ACTION SUBMITTALS

PRODUCT DATA SHEET 0 - Product Data: For each type of product.

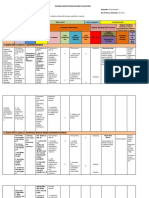

PRODUCT DATA SHEET 1 - LEED Submittals:

1.1

SS - Sustainable Sites:

A.

SS Credit 7.2: Heat Island Effect.

1.

1.2

Solar Reflectance Index (SRI) for low sloped and/or steep roof application any color from Metl-Span standard color chart.

EA - Energy and Atmosphere:

A.

EA Credit 1: Optimize Energy Performance.

INSULATED METAL ROOF PANELS

074113.23 - 1

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

1.

B.

MR Credit 1.1 and 1.2: Building Reuse.

1.

2.

B.

C.

2.

3.

D.

Maintain Existing Walls, Floors & Roof

Maintain Interior Non-Structural Elements.

MR Credit 3: Materials Reuse.

MR Credit 4: Recycled Content.

1.

Percentage weight of post-consumer and pre-consumer recycled content.

Use materials with recycled content.

Recycled content value of product assembly by weight.

Indicate total value (cost) of each product used.

MR Credit 6: Rapidly Renewable Materials.

1.

The foam core in the wall panels contains a component that contributes to

one point for using rapidly renewable buildings materials and products for

2.5 percent of the total value of all building materials and products used in

the project (based on cost).

IEQ - Indoor Environmental Quality:

A.

IEQ Credit 4.1: Low-Emitting Materials - Adhesives and Sealants.

1.

2.

1.5

Insulated metal roof panels will contribute to higher energy efficiency of a

building that must comply with a 10 percent improvement in the

performance compared to benchmark rating based on ASHRAE/IESNA

Standard 90.1-2007 (with errata but without addenda) in EA Prerequisite 2.

MR - Material Resource:

A.

1.4

Demonstrating percentage of performance improvement that meets or

surpasses ASHRAE/IESNA Standard 90.1-2004.

EA Credit 2: Minimum Energy Performance.

1.

1.3

08/10

Product data on adhesives and sealants to comply with standards of South

Coast Air Quality Management District Rule #1168.

Product data for paint and coatings have no VOC's.

WE - Water Efficiency:

A.

WE Credit 1 and 2: Water Efficient Landscaping and Innovative Wastewater

Technology.

1.

2.

Demonstrated reduction in irrigation water by 50 percent from calculated

mid-summer base line case.

Demonstrated reduction in potable used for building sewage conveyance by

50 percent.

INSULATED METAL ROOF PANELS

074113.23 - 2

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

B.

WE Credit 3: Water Use Reduction.

1.

1.6

08/10

The CFR roof panels, integrate into a buildings rainwater harvesting

system, can contribute to points for employing a strategy that in aggregate

uses at least 20 percent less water than the water use baseline calculated for

the building (not including irrigation) after meeting the Energy Policy Act of

1992 fixture performance requirements in WE Credit 3.

ID - Innovation in Design:

A.

ID Credits 1.1 to 1.4.

1.

The CFR roof panel integrated into a building's overall design can contribute

to points if the building's design team applies strategies or measures that

demonstrate performance above the requirements in categories and/or

innovative performance not specifically addressed by LEED in ID Credits

1.1 to 1.4.

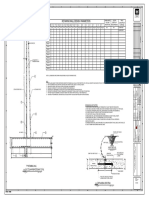

PRODUCT DATA SHEET 2 - Shop Drawings: Include fabrication and installation layouts of metal

panels; details of edge conditions, joints, panel profiles, corners, anchorages, attachment

system, trim, flashings, closures, and accessories; and special details.

PRODUCT DATA SHEET 3 - Samples: For each type of metal panel indicated.

SCHEDULE 3 - INFORMATIONAL SUBMITTALS

PRODUCT DATA SHEET 0 - Product test reports.

PRODUCT DATA SHEET 1 - Warranties: Samples of special warranties.

PRODUCT DATA SHEET 2 - Buy American Confirmation: Submit documentation certifying that

products comply with provisions of the Buy American Act 41 U.S.C 10a-10d.

SCHEDULE 4 - CLOSEOUT SUBMITTALS

PRODUCT DATA SHEET 0 - Maintenance data.

SCHEDULE 5 - QUALITY ASSURANCE

PRODUCT DATA SHEET 0 - Installer Qualifications: Installed by a contractor with a minimum of

five (5) years experience with this type of construction, and documentation indicating

successful completion of contracts for projects of similar size, scope, and materials.

SCHEDULE 6 - DELIVERY, STORAGE, AND HANDLING

INSULATED METAL ROOF PANELS

074113.23 - 3

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

08/10

PRODUCT DATA SHEET 0 - Protect products of metal panel system during shipping, handling, and

storage to prevent staining, denting, deterioration of components, and other damage.

PRODUCT DATA SHEET 1 - Deliver, unload, store, and erect metal panels and accessory items in a

manner to prevent bending, warping, twisting, and surface damage.

PRODUCT DATA SHEET 2 - Store panels in accordance with manufacturer's written instructions.

PRODUCT DATA SHEET 3 - Shield foam-insulated metal wall panels

installation.

from direct sunlight until

PRODUCT DATA SHEET 4 - Store products off the ground, with panels sloped for drainage and

covered to protect factory finishes from damage. Stack bundles no more than two high.

SCHEDULE 7 - WARRANTY

PRODUCT DATA SHEET 0 - Warranty: Manufacturer's written limited warranty providing panels to

be free from defects in materials and workmanship, excluding coil coatings (paint finishes) that

are covered under separate warranty.

0.1

Warranty Period: Two years from date of Substantial Completion.

PRODUCT DATA SHEET 1 - Warranty on Panel Finishes: Manufacturer's standard form in which

manufacturer agrees to repair finish or replace metal panels that show evidence of deterioration

of factory-applied finishes within specified warranty period.

1.1

Finish Warranty Period:

A.

B.

40 year limited warranty on the exterior paint finish for adhesion to the metal

substrate.

30 year limited warranty on the exterior paint finish for chalk and fade.

PART 2 - PRODUCTS

SCHEDULE 0 - PERFORMANCE REQUIREMENTS

PRODUCT DATA SHEET 0 - Recycled Content of Steel Products: Postconsumer recycled content

plus one-half of preconsumer recycled content not less than [25] percent.

PRODUCT DATA SHEET 1 - Solar Reflectance Index: Not less than [78] [29] when calculated

according to ASTM E 1980 based on testing identical products by a qualified testing agency.

PRODUCT DATA SHEET 2 - Energy Performance: Provide roof panels that are listed on the

EPA/DOE's ENERGY STAR "Roof Product List" for [low] -slope roof products.

PRODUCT DATA SHEET 3 - Energy Performance: Provide roof panels with an aged Solar

Reflectance Index of not less than [0.64] when tested according to CRRC-1.

INSULATED METAL ROOF PANELS

074113.23 - 4

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

08/10

PRODUCT DATA SHEET 4 - Structural Performance: Provide metal panel systems capable of

withstanding the effects of the following loads, based on testing according to ASTM E 72:

4.1

4.2

4.3

4.4

Wind Loads: As indicated on Drawings.

Other Design Loads: [As indicated on Drawings] .

Deflection Limits: For wind loads, no greater than [1/180] [1/240] <Insert deflection>

of the span.

<Insert serviceability requirements>.

PRODUCT DATA SHEET 5 - Air Infiltration: Air leakage of not more than 0.06 cfm/sq. ft. (0.3 L/s

per sq. m) when tested according to ASTM E 1680[ or ASTM E 283] at the following testpressure difference:

5.1

Test-Pressure Difference: [1.57 lbf/sq. ft. (75 Pa)] [6.24 lbf/sq. ft. (300 Pa)].

PRODUCT DATA SHEET 6 - Water Penetration under Static Pressure: No water penetration when

tested according to ASTM E 1646[ or ASTM E 331] at the following test-pressure difference:

6.1

Test-Pressure Difference: [2.86 lbf/sq. ft. (137 Pa)] [6.24 lbf/sq. ft. (300 Pa)].

PRODUCT DATA SHEET 7 - Wind-Uplift Resistance: Provide metal roof panel assemblies that

comply with UL 580 for wind-uplift-resistance class indicated.

7.1

Uplift Rating: [UL 30] [UL 60] [UL 90].

PRODUCT DATA SHEET 8 - FM Global Listing: Provide metal roof panels and component

materials that comply with requirements in FM Global 4471 as part of a panel roofing system

and that are listed in FM Global's "Approval Guide" for Class 1 or noncombustible

construction, as applicable. Identify materials with FM Global markings.

8.1

8.2

Fire/Windstorm Classification: Class 1A-[60] [75] [90] [105] [120] <Insert number>.

Hail Resistance: [MH] [SH].

PRODUCT DATA SHEET 9 - Thermal Movements: Allow for thermal movements from ambient and

surface temperature changes by preventing buckling, opening of joints, overstressing of

components, failure of joint sealants, failure of connections, and other detrimental effects. Base

calculations on surface temperatures of materials due to both solar heat gain and nighttime-sky

heat loss.

9.1

Temperature Change (Range): [68 deg C minum]

SCHEDULE 1 - FOAMED-INSULATION-CORE METAL ROOF PANELS

PRODUCT DATA SHEET 0 - General: Provide factory-formed and -assembled metal roof panels

fabricated from two sheets of metal with insulation core foamed in place during fabrication with

joints between panels designed to form weathertight seals. Include accessories required for

weathertight installation.

0.1

Panel Performance:

INSULATED METAL ROOF PANELS

074113.23 - 5

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

A.

B.

C.

D.

E.

F.

G.

0.2

08/10

Flatwise Tensile Strength:

30 psi (200 kPa) when tested according to

ASTM C 297/C 297M.

Humid Aging: Volume increase not greater than 6.0 percent and no delamination

or metal corrosion when tested for seven days at 140 deg F (60 deg C) and 100

percent relative humidity according to ASTM D 2126.

Heat Aging: Volume increase not greater than 2.0 percent and no delamination,

surface blistering, or permanent bowing when tested for seven days at 200 deg F

(93 deg C) according to ASTM D 2126.

Cold Aging: Volume decrease not more than 1.0 percent and no delamination,

surface blistering, or permanent bowing when tested for seven days at minus 20

deg F (29 deg C) according to ASTM D 2126.

Fatigue: No evidence of delamination, core cracking, or permanent bowing when

tested to a 20-lbf/sq. ft. (958-kPa) positive and negative wind load and with

deflection of L/180 for 2 million cycles.

Autoclave: No delamination when exposed to 2-psi (13.8-kPa) pressure at a

temperature of 212 deg F (100 deg C) for 2-1/2 hours.

Fire-Test-Response Characteristics: Class A according to ASTM E 108.

Insulation Core: Polyurethane foam using a non-CFC blowing agent, with maximum

flame-spread and smoke-developed indexes of 25 and 450, respectively.

A.

B.

C.

D.

Closed-Cell Content: 92 percent when tested according to ASTM D 6226.

Density: 2.0 to 2.6 lb/cu. ft. (32 to 42 kg/cu. m) when tested according to

ASTM D 1622.

Compressive Strength: Minimum 20 psi (140 kPa) when tested according to

ASTM D 1621.

Shear Strength: 26 psi (179 kPa) when tested according to ASTM C 273.

PRODUCT DATA SHEET 1 - Standing-Seam-Profile, Foamed-Insulation-Core Metal Roof Panels:

Formed with vertical tongue-and-groove ribs at panel edges and [intermediate stiffening ribs

symmetrically spaced] [a flat pan] between ribs; designed for sequential installation by

interlocking tongue-and-groove panel edges and mechanically attaching panels to supports

using concealed clips located between panels and engaging edges of adjacent panels, and

mechanically seaming panels together.

1.1 Basis-of-Design Product: Subject to compliance with requirements, provide Metl-Span,

LLC; CFR Roof Panels or comparable product by one of the following:

A.

1.2

Metl-Span LLC

Metallic-Coated Steel Sheet: Facings of zinc-coated (galvanized) steel sheet complying

with ASTM A 653/A 653M, G90 (Z275) coating designation, or aluminum-zinc alloycoated steel sheet complying with ASTM A 792/A 792M, Class AZ50 (Class AZM150)

coating designation; structural quality. Prepainted by the coil-coating process to comply

with ASTM A 755/A 755M.

A.

B.

Nominal Thickness: [0.022 inch (0.56 mm)] [0.028 inch (0.71 mm)] [0.034 inch

(0.86 mm)].

Exterior Finish: Base primer (0.2 mil minimum), and a PVF (70% minimum)

fluropolymer finish coat (0.8 mil minimum).

INSULATED METAL ROOF PANELS

074113.23 - 6

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

1.

C.

1.3

1.4

1.5

1.6

08/10

Color: White and it shall be durable in an intense heat/ UV environment (68

deg. C minimum).

Interior Finish: Base primer (0.2 mil minimum), and a PVF (70% minimum)

fluropolymer finish coat (0.8 mil minimum)

1.

Color: White and it shall be durable in an intense heat/ UV environment (68

deg. C minimum).

2.

Joint Type: [As standard with manufacturer].

Panel Coverage: [36 inches (914 mm)] [42 inches (1067 mm)] <Insert dimension>.

Panel Thickness: [4.0 inches (102 mm)]

Coordinate thermal-resistance value in "Thermal-Resistance Value (R-Value)"

Subparagraph below with panel thickness in "Panel Thickness" Subparagraph above.

Thermal-Resistance Value (R-Value): <Insert number> according to ASTM C 1363.

PRODUCT DATA SHEET 2 - Lap-Seam-Profile, Foamed-Insulation-Core Metal Roof Panels:

Formed for lapping side edges of adjacent panels and mechanically attaching to supports using

exposed fasteners in side laps.

2.1

2.2

Manufacturers: Subject to compliance with requirements, [provide products by the

following] [provide products by one of the following] [available manufacturers

offering products that may be incorporated into the Work include, but are not

limited to, the following]:

Basis-of-Design Product: Subject to compliance with requirements, provide [product

indicated on Drawings] <Insert manufacturer's name; product name or

designation> or comparable product by one of the following:

A.

2.3

Metl-Span LLC

Metallic-Coated Steel Sheet: Facings of zinc-coated (galvanized) steel sheet complying

with ASTM A 653/A 653M, G90 coating designation, Prepainted by the coil-coating

process to comply with ASTM A 755/A 755M.

A.

B.

Nominal Thickness: [0.022 inch (0.56 mm)] [0.028 inch (0.71 mm)] [0.034 inch

(0.86 mm)].

Exterior Finish:

[Two-coat fluoropolymer] [Three-coat fluoropolymer]

[Siliconized polyester] <Insert finish>.

1.

C.

Color:

[As indicated by manufacturer's designations] [Match

Architect's samples] [As selected by Architect from manufacturer's full

range] <Insert color>.

Interior Finish: [Siliconized polyester] <Insert finish>.

1.

Color:

[As indicated by manufacturer's designations] [Match

Architect's samples] [As selected by Architect from manufacturer's full

range] <Insert color>.

INSULATED METAL ROOF PANELS

074113.23 - 7

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

2.4

2.5

2.6

2.7

2.8

08/10

Batten: Same material, finish, and color as exterior facings of roof panels.

Panel Coverage: [24 inches (610 mm)] [30 inches (762 mm)] [36 inches (914 mm)]

[39.6 inches (1000 mm)] [40 inches (1016 mm)] [44.5 inches (1130 mm)] <Insert

dimension>.

Panel Thickness: [4.0 inches (102 mm)]

Coordinate thermal-resistance value in "Thermal-Resistance Value (R-Value)"

Subparagraph below with panel thickness in "Panel Thickness" Subparagraph above.

Thermal-Resistance Value (R-Value): <Insert number> according to ASTM C 1363.

SCHEDULE 2 - MISCELLANEOUS MATERIALS

PRODUCT DATA SHEET 0 - Miscellaneous Metal Subframing and Furring: ASTM C 645, coldformed, metallic-coated steel sheet, ASTM A 653/A 653M, G90 (Z275 hot-dip galvanized)

coating designation or ASTM A 792/A 792M, Class AZ50 (Class AZM150) coating designation

unless otherwise indicated. Provide manufacturer's standard sections as required for support

and alignment of metal panel system.

PRODUCT DATA SHEET 1 - Panel Accessories: Provide components required for a complete,

weathertight panel system including trim, copings, fasciae, mullions, sills, corner units, clips,

flashings, sealants, gaskets, fillers, closure strips, and similar items. Match material and finish

of metal panels unless otherwise indicated.

1.1

1.2

1.3

Closures: Provide closures at eaves and ridges, fabricated of same metal as metal panels.

Backing Plates: Provide metal backing plates at panel end splices, fabricated from

material recommended by manufacturer.

Closure Strips: Closed-cell, expanded, cellular, rubber or crosslinked, polyolefin-foam or

closed-cell laminated polyethylene; minimum 1-inch- (25-mm-) thick, flexible closure

strips; cut or premolded to match metal panel profile. Provide closure strips where

indicated or necessary to ensure weathertight construction.

PRODUCT DATA SHEET 2 - Flashing and Trim: Provide flashing and trim formed from same

material as exterior facings of metal panels as required to seal against weather and to provide

finished appearance. Locations include, but are not limited to, eaves, rakes, corners, bases,

framed openings, ridges, fasciae, and fillers. Finish flashing and trim with same finish system

as adjacent metal panels.

PRODUCT DATA SHEET 3 - Gutters and Downspouts: Formed from same material, finish, and color

as exterior facings of panels according to SMACNA's "Architectural Sheet Metal Manual."

Finish to match [metal roof panels] [roof fascia and rake trim].

PRODUCT DATA SHEET 4 - Roof Curbs: Fabricated from same material, finish, and color as

exterior facings of roof panels, [0.048-inch (1.2-mm)] <Insert dimension> nominal thickness;

with bottom of skirt profiled to match roof panel profiles and with welded top box and integral

full-length cricket. Fabricate curb subframing of 0.060-inch- (1.52-mm-) nominal thickness,

angle-, C-, or Z-shaped steel sheet. Fabricate curb and subframing to withstand indicated loads

of size and height indicated. Finish roof curbs to match metal roof panels.

PRODUCT DATA SHEET 5 - Panel Fasteners: Self-tapping screws designed to withstand design

loads. Provide exposed fasteners with heads matching color of metal panels by means of plastic

INSULATED METAL ROOF PANELS

074113.23 - 8

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

08/10

caps or factory-applied coating. Provide EPDM, PVC, or neoprene sealing washers for exposed

fasteners.

PRODUCT DATA SHEET 6 - Panel Sealants: Provide sealant types recommended by manufacturer

that are compatible with panel materials, are nonstaining, and do not damage panel finish.

6.1

6.2

6.3

Sealant Tape: Pressure-sensitive, 100 percent solids, gray polyisobutylene compound

sealant tape with release-paper backing. Provide permanently elastic, nonsag, nontoxic,

nonstaining tape 1/2 inch (13 mm) wide and 1/8 inch (3 mm) thick.

Joint Sealant: ASTM C 920; elastomeric polyurethane or silicone sealant; of type, grade,

class, and use classifications required to seal joints in metal panels and remain

weathertight; and as recommended in writing by metal panel manufacturer.

Butyl-Rubber-Based, Solvent-Release Sealant: ASTM C 1311.

SCHEDULE 3 - FABRICATION

PRODUCT DATA SHEET 0 - General: Fabricate and finish metal panels and accessories at the

factory, by manufacturer's standard procedures and processes, as necessary to fulfill indicated

performance requirements demonstrated by laboratory testing. Comply with indicated profiles

and with dimensional and structural requirements.

PRODUCT DATA SHEET 1 - Provide panel profile, including major ribs and intermediate stiffening

ribs, if any, for full length of panel.

PRODUCT DATA SHEET 2 - Fabricate metal panel joints with factory-installed captive gaskets or

separator strips that provide a weathertight seal and prevent metal-to-metal contact, and that

minimize noise from movements.

PRODUCT DATA SHEET 3 - Sheet Metal Flashing and Trim: Fabricate flashing and trim to comply

with manufacturer's recommendations and recommendations in SMACNA's "Architectural

Sheet Metal Manual" that apply to design, dimensions, metal, and other characteristics of item

indicated.

SCHEDULE 4 - FINISHES

PRODUCT DATA SHEET 0 - Exterior Facings and Accessories:

0.1

0.2

0.3

Two-Coat Fluoropolymer: AAMA 621. Fluoropolymer finish containing not less than

70 percent PVDF resin by weight in color coat. Prepare, pretreat, and apply coating to

exposed metal surfaces to comply with coating and resin manufacturers' written

instructions.

Three-Coat Fluoropolymer: AAMA 621. Fluoropolymer finish containing not less than

70 percent PVDF resin by weight in both color coat and clear topcoat. Prepare, pretreat,

and apply coating to exposed metal surfaces to comply with coating and resin

manufacturers' written instructions.

Siliconized Polyester: Epoxy primer and silicone-modified, polyester-enamel topcoat;

with a dry film thickness of not less than 0.2 mil (0.005 mm) for primer and 0.8 mil (0.02

mm) for topcoat.

INSULATED METAL ROOF PANELS

074113.23 - 9

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

08/10

PRODUCT DATA SHEET 1 - Interior Facings:

1.1

1.2

Siliconized Polyester: Epoxy primer and silicone-modified, polyester-enamel topcoat;

with a dry film thickness of not less than 0.2 mil (0.005 mm) for primer and 0.8 mil (0.02

mm) for topcoat.

Polyester Finish: Manufacturer's standard white or light-colored acrylic or polyester

finish.

PART 3 - EXECUTION

SCHEDULE 0 - EXAMINATION

SCHEDULE 1 - PREPARATION

PRODUCT DATA SHEET 0 - Miscellaneous Supports:

Install subframing, furring, and other

miscellaneous panel support members and anchorages according to ASTM C 754 and metal

panel manufacturer's written recommendations.

SCHEDULE 2 - METAL PANEL INSTALLATION

PRODUCT DATA SHEET 0 - Lap-Seam, Foamed-Insulation-Core Metal Roof Panels:

Fasten

insulated metal roof panels to supports with fasteners at each lapped joint at location and

spacing recommended by manufacturer.

0.1

0.2

0.3

0.4

0.5

0.6

Lap ribbed or fluted sheets one full-rib corrugation. Apply panels and associated items

for neat and weathertight enclosure. Avoid "panel creep" or applications not true to line.

Provide metal-backed washers under heads of exposed fasteners bearing on weather side

of insulated metal roof panels.

Locate and space exposed fasteners in uniform vertical and horizontal alignment. Use

proper tools to obtain controlled uniform compression for positive seal without rupture of

washer.

Provide sealant tape at lapped joints of insulated metal roof panels and between panels

and protruding equipment, vents, and accessories.

Apply a continuous ribbon of sealant tape to panel side laps and elsewhere as needed to

weatherproof panels.

Apply snap-on battens to seams of insulated metal roof panels to conceal fasteners.

PRODUCT DATA SHEET 1 - Standing-Seam, Foamed-Insulation-Core Metal Roof Panels: Fasten

insulated metal roof panels to supports with concealed clips at each standing-seam joint at

location, spacing, and with fasteners recommended in writing by manufacturer.

1.1

1.2

Install clips to supports with self-tapping fasteners.

Seamed Joint: Crimp standing seams with manufacturer-approved, motorized seamer

tool so cleat, insulated metal roof panel, and factory-applied side-lap sealant are

completely engaged.

INSULATED METAL ROOF PANELS

074113.23 - 10

Copyright 2010 AIA

MasterSpec Short Form

PRODUCT MASTERSPEC LICENSED BY ARCOM TO METL-SPAN LLC.

08/10

PRODUCT DATA SHEET 2 - Accessory Installation: Install accessories with positive anchorage to

building and weathertight mounting, and provide for thermal expansion. Coordinate installation

with flashings and other components.

PRODUCT DATA SHEET 3 - Flashing and Trim:

Comply with performance requirements,

manufacturer's written installation instructions, and SMACNA's "Architectural Sheet Metal

Manual." Provide concealed fasteners where possible, and set units true to line and level.

Install work with laps, joints, and seams that are permanently watertight and weather resistant.

SCHEDULE 3 - CLEANING AND PROTECTION

PRODUCT DATA SHEET 0 - Wipe finished surfaces of filings caused by drilling or cutting to prevent

rust staining.

PRODUCT DATA SHEET 1 - Replace damaged panels and other components of work, which cannot

be repaired by finish touch-up or similar minor repair.

PRODUCT DATA SHEET 2 - Protective film no trim should be removed before exposure to sunlight.

END OF SECTION 074113.23

INSULATED METAL ROOF PANELS

074113.23 - 11

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Stone Retaining Wall DesignDocument25 paginiStone Retaining Wall DesignSafi Zabihullah Safi81% (16)

- State-Of-The-Art Report On Fiber Reinforced Concrete ACI 544-2002Document66 paginiState-Of-The-Art Report On Fiber Reinforced Concrete ACI 544-2002Attie761367% (3)

- CA Inter Group 1 Book November 2021Document251 paginiCA Inter Group 1 Book November 2021VISHAL100% (2)

- Design of Stub For Transmission Line TowersDocument26 paginiDesign of Stub For Transmission Line Towersdebjyoti_das_685% (13)

- AED Design Requirements - Geotechnical Investigations - Jan10Document26 paginiAED Design Requirements - Geotechnical Investigations - Jan10rhunter2010Încă nu există evaluări

- 5 Star Hotels in Portugal Leads 1Document9 pagini5 Star Hotels in Portugal Leads 1Zahed IqbalÎncă nu există evaluări

- Deed of Assignment CorporateDocument4 paginiDeed of Assignment CorporateEric JayÎncă nu există evaluări

- Basic Vibration Analysis Training-1Document193 paginiBasic Vibration Analysis Training-1Sanjeevi Kumar SpÎncă nu există evaluări

- Substation LoadingDocument2 paginiSubstation LoadingSafi Zabihullah SafiÎncă nu există evaluări

- 1988 J B Shah Ludirdja Daniel Mobasher 85-m39Document10 pagini1988 J B Shah Ludirdja Daniel Mobasher 85-m39Safi Zabihullah SafiÎncă nu există evaluări

- Preview AC155EDocument34 paginiPreview AC155ESafi Zabihullah SafiÎncă nu există evaluări

- SLAB2Document1 paginăSLAB2Safi Zabihullah SafiÎncă nu există evaluări

- RC Two Way Slab Design ACI318 05 PDFDocument6 paginiRC Two Way Slab Design ACI318 05 PDFSafi Zabihullah SafiÎncă nu există evaluări

- F D V E: Actors That Etermine Ariation IN StimatiesDocument27 paginiF D V E: Actors That Etermine Ariation IN StimatiesSafi Zabihullah SafiÎncă nu există evaluări

- Duran Research and Analysis: Sustainable Development Conference-SDPI December 9-11, 2014 - IslamabadDocument16 paginiDuran Research and Analysis: Sustainable Development Conference-SDPI December 9-11, 2014 - IslamabadSafi Zabihullah SafiÎncă nu există evaluări

- Preview AC155EDocument2 paginiPreview AC155ESafi Zabihullah SafiÎncă nu există evaluări

- Afghanistan's Transboundary Rivers and Regional Security PDFDocument13 paginiAfghanistan's Transboundary Rivers and Regional Security PDFSafi Zabihullah SafiÎncă nu există evaluări

- Chapter5dropsturcutures 161214131147Document64 paginiChapter5dropsturcutures 161214131147Safi Zabihullah SafiÎncă nu există evaluări

- Surface Water ManagementDocument58 paginiSurface Water ManagementSafi Zabihullah SafiÎncă nu există evaluări

- Power Plan: Lighting CalculationDocument3 paginiPower Plan: Lighting CalculationSafi Zabihullah SafiÎncă nu există evaluări

- MGWC gwc1Document2 paginiMGWC gwc1Safi Zabihullah SafiÎncă nu există evaluări

- 01 02 00 00 48 - Part03 - Sept09Document12 pagini01 02 00 00 48 - Part03 - Sept09Safi Zabihullah SafiÎncă nu există evaluări

- Retaining Wall Design Parameters: Unbalance Filling Height (M) Scour Depth If Required (M) Wall Construct Purpose HDocument1 paginăRetaining Wall Design Parameters: Unbalance Filling Height (M) Scour Depth If Required (M) Wall Construct Purpose HSafi Zabihullah SafiÎncă nu există evaluări

- RCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendDocument1 paginăRCC Retaining Wall 150Mm Thick Leveling Coarse Final Grade Line After Backfill Top of Subgrade Line LegendSafi Zabihullah SafiÎncă nu există evaluări

- Retaining Wall Design Parameters: U.S Army Corps of Engineers Middle East DistrictDocument1 paginăRetaining Wall Design Parameters: U.S Army Corps of Engineers Middle East DistrictSafi Zabihullah SafiÎncă nu există evaluări

- Transparency Documentation EN 2019Document23 paginiTransparency Documentation EN 2019shani ChahalÎncă nu există evaluări

- Doas - MotorcycleDocument2 paginiDoas - MotorcycleNaojÎncă nu există evaluări

- Unit 2Document97 paginiUnit 2MOHAN RuttalaÎncă nu există evaluări

- MORIGINADocument7 paginiMORIGINAatishÎncă nu există evaluări

- Privacy: Based On Slides Prepared by Cyndi Chie, Sarah Frye and Sharon Gray. Fifth Edition Updated by Timothy HenryDocument50 paginiPrivacy: Based On Slides Prepared by Cyndi Chie, Sarah Frye and Sharon Gray. Fifth Edition Updated by Timothy HenryAbid KhanÎncă nu există evaluări

- Course Specifications: Fire Investigation and Failure Analysis (E901313)Document2 paginiCourse Specifications: Fire Investigation and Failure Analysis (E901313)danateoÎncă nu există evaluări

- STM - Welding BookDocument5 paginiSTM - Welding BookAlvin MoollenÎncă nu există evaluări

- Amerisolar AS 7M144 HC Module Specification - CompressedDocument2 paginiAmerisolar AS 7M144 HC Module Specification - CompressedMarcus AlbaniÎncă nu există evaluări

- Basic DfwmacDocument6 paginiBasic DfwmacDinesh Kumar PÎncă nu există evaluări

- A. The Machine's Final Recorded Value Was P1,558,000Document7 paginiA. The Machine's Final Recorded Value Was P1,558,000Tawan VihokratanaÎncă nu există evaluări

- MMC Pipe Inspection RobotDocument2 paginiMMC Pipe Inspection RobotSharad Agrawal0% (1)

- 18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFDocument1 pagină18 - PPAG-100-HD-C-001 - s018 (VBA03C013) - 0 PDFSantiago GarciaÎncă nu există evaluări

- BMA Recital Hall Booking FormDocument2 paginiBMA Recital Hall Booking FormPaul Michael BakerÎncă nu există evaluări

- Sky ChemicalsDocument1 paginăSky ChemicalsfishÎncă nu există evaluări

- CoDocument80 paginiCogdayanand4uÎncă nu există evaluări

- Fidp ResearchDocument3 paginiFidp ResearchIn SanityÎncă nu există evaluări

- Forecasting of Nonlinear Time Series Using Artificial Neural NetworkDocument9 paginiForecasting of Nonlinear Time Series Using Artificial Neural NetworkranaÎncă nu există evaluări

- XgxyDocument22 paginiXgxyLïkïth RäjÎncă nu există evaluări

- CIR Vs PAL - ConstructionDocument8 paginiCIR Vs PAL - ConstructionEvan NervezaÎncă nu există evaluări

- SEERS Medical ST3566 ManualDocument24 paginiSEERS Medical ST3566 ManualAlexandra JanicÎncă nu există evaluări

- Schmidt Family Sales Flyer English HighDocument6 paginiSchmidt Family Sales Flyer English HighmdeenkÎncă nu există evaluări

- Republic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1Document4 paginiRepublic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1brendamanganaanÎncă nu există evaluări

- Unit 1Document3 paginiUnit 1beharenbÎncă nu există evaluări

- 5 Deming Principles That Help Healthcare Process ImprovementDocument8 pagini5 Deming Principles That Help Healthcare Process Improvementdewi estariÎncă nu există evaluări

- SND Kod Dt2Document12 paginiSND Kod Dt2arturshenikÎncă nu există evaluări

- Agricultural Economics 1916Document932 paginiAgricultural Economics 1916OceanÎncă nu există evaluări