Documente Academic

Documente Profesional

Documente Cultură

Separator (1) Sizing Spread Sheets

Încărcat de

Steve WanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Separator (1) Sizing Spread Sheets

Încărcat de

Steve WanDrepturi de autor:

Formate disponibile

SEPARATOR SIZING SPREADSHEET

MAIN MENU

INSTRUCTIONS

HORIZONTAL SEPARATOR

( 3 PHASE WITH BOOT)

HORIZONTAL SEPARATOR

( 3 PHASE, NO BOOT,

DRAW OFF PIPE FOR CONDENSATE )

VERTICAL SEPARATOR ( 2 PHASE )

SPREADSHE

HORIZONT

( 3 PHAS

WEIRPLAT

HORIZONTAL SE

SEPARATOR SIZING SPREADSHEET

MAIN MENU

REV:

DATE:

A

FEBRUARY 1999

SPREADSHEET INFORMATION

HORIZONTAL SEPARATOR

( 3 PHASE, NO BOOT,

WEIRPLATE PARTITION )

HORIZONTAL SEPARATOR ( 2 PHASE )

FILE SEPARP1.XLS

SEPARATOR SIZING SPREADSHEET

INSTRUCTION NOTES

REV:

DATE:

A

February 1999

I.PURPOSE

The aim of the separator sizing spreadsheet is to assist

the designer in saving valuable time resources by providing a

user-friendly spreadsheet in Excel to calculate sizing

parameters for both horizontal and vertical separators.

II.DESIGN BASES

A. Gas residence times are calculated using the normal liquid level

as the basis. In the case of the horizontal separator

with weirplate partition, the basis used is the height of

the weir for the gas volume. Dished end volumes have

been neglected for the gas residence time calculations.

B. K-values to be used as input data for the spreadsheets

are found in the GPSA Handbook(10thedition), figure 7.9 on page 7-7.

The K factors must be converted to m/s to be placed into

the spreadsheet. The purpose of the K-factor is for

designs which include woven wire demisters. Demisters

(mist extractors) can significantly reduce the required

diameter of vertical separators.

C. Dished-end volume calculations have been included for

both vertical and horizontal separators. For the

vertical separator, an option is provided for choosing

between semi-ellipsoidal and semi-hemispherical ends,

however, for all horizontal separators, the ends have

been assumed to be semi-ellipsoidal.

(Reference: GPSA Handbook section 6 Fig 6.21-6.22)

D. Other standards used in calculations include

API RP 521 Section 5.4.2 and calculations for the

standpipe were from EXXON Criteria in Design Practice 5B

(September 1978).

III.METHOD

The following procedure is a step-by step outline for the

designer.

A. Step One: Choose the type of separator required.

The separators available in this spreadsheet include:

-Horizontal, 3 Phase, with boot

-Horizontal, 3 Phase, no boot, weirplate

partition.

-Horizontal, 3 Phase, no boot, standpipe

for condensate.

-Horizontal, 2 Phase

-Vertical, 2 Phase

Page 1 of 3

SEPARATOR SIZING SPREADSHEET - INSTRUCTION NOTES

Vertical separators are usually selected when the gasliquid ratio is high or total gas volumes are low.

Horizontal separators are most efficient where large

volumes of total fluids and large amounts of dissolved

gas are present with the liquid. For more information on

separators please refer to GPSA Handbook, Section 7.

B. Step Two: After the separator type is chosen, begin

inputting data into the cells of the spreadsheet which

have blue italicised text. Do not write in cells which

contain red or black text! Input data is summarised in

the top left hand side of the spreadsheet. Feed

flowrates, properties and nozzle velocity specifications

are entered in this section. Data on vessel

length, diameter and liquid levels are entered on the

vessel sketch. Unknown values need to be assumed,

otherwise errors will occur in the results.

C. Step Three: When all blue cells are filled - including the

dimensions on the sketch, the spreadsheet will calculate

all relevant values. The intermediate calculations can

be found below the sketch. Final output results are

listed on the sketch and in the top section of the

spreadsheet. All formulae are in red text.

D. Step Four: Before final outputs can be used, warnings

must be considered. Warnings appear in bold green text,

and will appear as "OK" when there is no warning present.

If a warning does exist, try to change the relevant

parameters to remove or reduce the warnings. These

generally relate to liquid levels in the separator and gas

residence times.

E. Step Five: Check your units!!! The units defined on the

spreadsheets can be found in the nomenclature section.

The notes section may also assist with understanding

which units to use. You can change the values in the

blue cells as many times as you like.

F. Step Six: When you have your final output, SAVE your

file by choosing the "SAVE AS" option under the "FILE"

menu in Excel . Make sure that you use a different file

name to the original master copy. (this will safeguard

against deletion of the master copy)

G. Step Seven: Your work is now ready to PRINT. You may

find that Excel does not have enough memory to display

the spreadsheet fully. The print range has been setup for

A4 landscape paper and will print only the first 2-3 pages of

the spreadsheet (the rest of the spreadsheet consists of

intermediate calculations). If you find that the spreadsheet

will not fit on the paper, choose "PAGE SETUP" from the

"FILE" menu in Excel and reduce the size of the sheet.

Page 2 of 3

SEPARATOR SIZING SPREADSHEET - INSTRUCTION NOTES

Another option available is to choose A3 sized paper

(page setup menu) to print out your spreadsheet. It is

not recommended that the print area be altered as this

has been preset. However, if the print area needs to be

altered, please use the following procedure.

"TOOLS"

"OPTIONS"

"GENERAL"

"MICROSOFT EXCEL 4 MENUS"

"OK"

(HIGHLIGHT THE AREA THAT YOU WISH TO PRINT)

"OPTIONS"

"SET PRINT AREA"

IV. ADDITIONAL NOTES

A.

THE CALCULATION TITLE BLOCK

There is a title block at the bottom of each page

of the spreadsheet.

Spaces have been

provided for entering the calculation title, project

number and calculation number. These spaces are accessed

by moving the mouse pointer into the particular box and

clicking once with the left hand mouse button. At this

point, an object box will appear. Simply click inside

the box once using the left hand mouse button and enter

the data in the normal way. When you have finished

typing the information, move the mouse pointer to another

part of the spreadsheet and click once with the left hand

mouse button.

NOTE: While space has been provided on the title block

for entering the originators and checkers initials and

relevant dates, these spaces cannot be accessed by the

user. This is because signatures are required to be

hand written by the originator and checker.

B. MAIN MENU

The main menu on the separator sizing spreadsheet

allows the user to access any of the sheets in the

workbook through the use of a macro button. Once the

designer is in a particular worksheet, they can return to

the menu by clicking the "MENU" macro button in

the individual worksheet.

Page 3 of 3

SEPARATOR SIZING SPREADSHEET

SEPARATORS

HORIZONTAL SEPARATOR (3 phase with boot)

HORIZONTAL SEPARATOR (3 phase, no boot, weirplate partition)

HORIZONTAL SEPARATOR (3 phase, no boot, standpipe for condensate.)

HORIZONTAL SEPARATOR (2 phase)

VERTICAL SEPARATOR (2 phase)

SPREADSHEET APPLICATION

Sizing of oil/gas/water separators for the hydrocarbon production industry.

BASIS

GPSA Handbook, Volume 1, Section 7. And also Section 6 Fig 6-21,6-22

API RP 521, Section 5.4.2 - Sizing a Knockout Drum

REVISION HISTORY

Revision P1 issued in February 1996 - file SEPARP1.XLS

With help from Don Borchert, Rod Harper, Nerrida Scott and Mark Sloma

INSTRUCTIONS FOR USE

Spreadsheet Conventions & Format

Input

Data to be entered by the user is shown on the screen in blue italicised type.

When printed the input appears in italics only.

Input data is summarised at the top left hand side of the spreadsheet. Feed

flowrates, properties and nozzle velocity specifications are entered in this section.

Information on vessel length, diameter and liquid levels is entered on the vessel sketch

described below.

Output

Cells containing formulae are shown in red text.

Cells containing formulae have been protected.

Final output data refers specifically to gas, oil and water residence times and oil and water

droplet settling times. This data is summarised at the top centre of the spreadsheet.

Data on calculated nozzle sizes and other vessel specific dimensions are shown on the

vessel sketch.

Warnings

Warning messages will appear to the right of the output data summary to indicate when

results fall outside the design criteria described in the KRJB procedure. Where results

satisfy the design requirements the message 'OK' will appear in the WARNINGS section.

Warning messages may also appear on the vessel sketch, however in this case there

will be no message if the input/output data meets the design requirements.

Messages are shown on the screen in bold green type. When printed, the messages

appear in bold type and will be enclosed in double asterisks.

Date and time printed:

30-Sep-15

1:06 PM

Kvaerner RJ Brown Pte Ltd

Page 1 of 2

SEPARATOR SIZING SPREADSHEET - INFORMATION

Sketch

The vessel sketch appears immediately below the input section. Some input and final

output data is shown on this sketch as noted above. Intermediate calculation results

such as volumes and flowrates are also shown on the sketch.

Calculations

This section follows the sketch and includes all the equations and intermediate

calculations of the spreadsheet.

Defaults

These include specified residence and settling times.

Defaults are the minimum design requirements that are required for comparison

against calculations.

Other recommended values for variables or constants such as K, droplet size, V2 ,

maximum nozzle velocities and liquid levels may be found in the KRJB procedure.

Notes

This section includes some important equations and general assumptions used in the

spreadsheet.

Nomenclature

Nomenclature used in the spreadsheets including units used, is detailed below

the notes section.

Calculation Title Block

There is a title block at the bottom of each page of the spreadsheet.

Spaces are provided for entering the calculation title, project

number and calculation number. These spaces are accessed by moving the mouse pointer into the

particular box and clicking once with the left hand mouse button. At this point an object box will

appear. Simply click inside the box once using the left hand mouse button and enter the data in the

normal manner. When you have finished typing the information, move the mouse pointer to another part

of the spreadsheet and click once with the left hand mouse button.

Note: While space has been provided on the title block for entering the originators and checkers

initials and relevant dates, these spaces cannot be accessed by the user. This is because

signatures are required to be hand written by the originator and checker.

Printing

The print range is pre-set and covers all of the sections described above. Printing is carried out

by selecting the 'Print' command from the normal EXCEL pull down menu and selecting 'OK'.

Date and time printed:

30-Sep-15

1:06 PM

Kvaerner RJ Brown Pte Ltd

Page 2 of 2

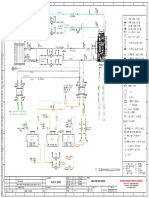

HORIZONTAL SEPARATOR (3 phase with boot)

INPUT

OUTPUT

Feed

Flow (t/d)

Density (kg/m3)

Viscosity (cP)

Droplet Size ()

Droplet Size ()

Droplet Size ()

GAS

OIL

WATER

2950.0

500.0

50.0

11.1

829.2

972.0

0.02

7.00

0.49

Oil in Gas

RESIDENCE TIMES

Shell

3.0

3.0

NLL-LLL

LLL-LLSD

LLSD to Outlet

1000

500

.v2 max for inlet nozzle (kg/m.s2)

.v2 max for gas outlet nozzle (kg/m.s2)

(mins)

Gas residence time (seconds)

HLL-HLSD

NLL-HLL

100

Oil in Water

Water in Oil

Specified

3.0

3.0

3.0

Oil Residence Time at NLL

1500

Actual

(mins)

17.7

5.6

5.0

4.4

5.4

3.0

** WARNINGS **

OK

OK

OK

OK

** Warning ! Residence time insufficient **

12.8

3750

Max vel. in Oil out nozzle (m/s)

1.0

Max vel. in water out nozzle (m/s)

K Value (m/sec)

Mixture density (kg/m3)

1.0

0.06

13.1

RESIDENCE TIMES

Specified

Actual

Boot

HIL-HILSD

NIL-HIL

NIL-LIL

LIL-LILSD

LILSD to bottom

Water residence time at NIL

(mins)

(mins)

5.5

3.3

3.3

3.3

4.8

11.4

3.0

3.0

3.0

3.0

3.0

** WARNINGS **

OK

OK

OK

OK

OK

SETTLING VELOCITY CRITERION

Maximum allowable Gas Velocity (m/s)

Gas Velocity (m/s) - calculated

Oil Droplet Velocity (m/s) - Gravity Settling Method

Oil from Gas

Water from Oil

Oil from Water

Droplet fall time (Oil in gas)

NOTE:

0.52 m/s

0.51 m/s OK

Water velocity in Boot

0.00 m/sec

0.145 m/s

0.003 m/s

0.038 m/s OK

16.5 secs OK

Gas Velocity Criteria are based on HLSD

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE AND TIME PRINTED:

DATE

CHECKED

30-Sep-15

1:06 PM

DATE

SK.CALC.NO

PAGE 1 OF 3

HORIZONTAL SEPARATOR (3 phase with boot)

SKETCH

Min. Gas Out. nozzle ID

462 mm

Length T/T=

Inlet

Gas =

2950.00 t/d

11073.57 Am3/h

9000 mm

GAS

Minimum Inlet nozzle ID

606 mm

I. D. =

3000 mm

HLSD

HLL

NLL

LLL

LLSD

Height

Vol. (m3)

600 mm

54.56

500 mm

400 mm

2.34

2.08

300 mm

150 mm

OIL

Interface

Height

(Gas)

(HLL-HLSD)

(NLL-HLL)

1.86 (NLL-LLL)

2.27 (LLL-LLSD)

1.24 (LLSD-Boot)

Min Oil Outlet nozz ID: 94 mm

Vol.(m3)

1000 ID

Boot Height (mm)

1000 mm

HILSD

HIL

NIL

LIL

LILSD

750 mm

0.196

500 mm

0.118

350 mm

0.118

200 mm

0.118

100 mm

0.170

(HIL-HILSD)

(NIL-HIL)

(NIL-LIL)

(LIL-LILSD)

(LILSD-Btm)

Oil =

500.00 t/d

25.12 m3/h

WATER

Min. Water out nozzle ID: 50 mm

50.00 t/d

2.14 m3/h

Water =

NOMENCLATURE

LLL

LIL

LLSD

LILSD

NLL

NIL

HLL

Low Liquid Level

Low Interface Level

Low Level Shut Down

Low Interface Level Shut Down

Normal Liquid Level

Normal Interface Level

High Liquid Level

HIL

HLSD

HILSD

Btm

X-Area

l

v

High Interface Level

High Level Shut Down

High Interface Level Shut Down

Bottom

Cross sectional area

Liquid density kg/m3

Vapour density kg/m3

Dp

Droplet (particle diameter)

Vt

Gas viscosity Cp

VMAX

Maximum vapour velocity m/s

K

KCR

Design vapour velocity factor m/s

Settling Velocity m/s

Proportionality constant, dimensionless.

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE

DATE AND TIME PRINTED:

CHECKED

30-Sep-15

1:06 PM

DATE

SK.CALC.NO

PAGE 2 OF 3

HORIZONTAL SEPARATOR (3 phase with boot)

CALCULATIONS

SETTLING VELOCITIES

Oil From Gas ("K" Value method)

K Value (m/s)

*Max Allowable Velocity,Vmax

Gas Horiz. Velocity

Dmax is the upper particle size limit for each of the laws.

Kcr is the critical constant for maximum particle size (from GPSA Handbook). Vt is the

settling velocity in m/s.

see note 1

0.06

0.52 m/s

0.51 m/s

*note 2

Actual Gas Velocity OK

Oil in Gas (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

Settling Velocity

Settling Law Used

0.15

m/s

Intermediate Law

Law Used:

Kcr

Stoke's Law

Intermediate Law

Newton's Law

Oil in Water (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

Settling Velocity

Settling Law Used

Law Used:

Stoke's Law

Intermediate Law

Newton's Law

Dp max

()

47

621

33733

Water in Oil (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

0.038

m/s

Intermediate Law

Vt

Dp max

()

(m/s)

0.03

0.158

194

0.33

0.038

2588

18.13

0.072

140464

Kcr

0.03

0.33

18.13

Vt

(m/s)

0.28

0.15

0.47

Settling Velocity

Settling Law Used

Law Used:

Kcr

Stoke's Law

Intermediate Law

Newton's Law

Stoke's Law (Kcr = 0.025)

Intermediate Law (Kcr = 0.334)

Newton's Law (Kcr = 18.13)

Vt = 1488 g Dp2 (l - v)

Vt = 3.54*g0.71 Dp1.14 (l - v)0.71

Vt = 1.74 * SQRT(g Dp (l-v) / v )

0.03

0.33

18.13

0.003

m/s

Stoke's Law

Vt

Dp max

()

(m/s)

0.003

1134

0.006

15153

0.051

822517

v0.29 * 0.43

18

NOTES

1.

Equations for Stokes Law, Intermediate Law and Newtons Law are taken from GPSA Handbook, Volume 1, Section 7.

Figure 7.4

2.

Maximum allowable vapour velocity is calculated from the equation in GPSA Handbook, Volume 1, Section 7:

VMAX

3.

K [ (l - v) / v ] 0.5

LLSD height calculation is based on the distance between the bottom of the cylinder and the low level shut down for the oil.

LILSD height calculation is based on the distance from the base of the boot dished end to the low interface level shut down for the water.

4.

Information for partial volumes and dished ends was from GPSA handbook (10th edition) Section 6, and in particular, fig.6-21.6-22.

Calculations for gas residence time and area/volume calculations use the normal liquid level, NLL as the height basis. End volumes is ignored for gas volume calculations.

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE AND TIME PRINTED:

DATE

CHECKED

30-Sep-15

1:06 PM

DATE

SK.CALC.NO

PAGE 3 OF 3

HORIZONTAL SEPARATOR (3 phase with weir, no boot)

INPUT

OUTPUT

Feed

Flow (t/d)

Density (kg/m3)

Viscosity (cP)

Droplet Size ()

Droplet Size ()

Oil in Gas

Oil in Water

Droplet Size ()

Water in Oil

GAS

OIL

RICH MEG

0.014

72.5

2451.0

3.57

646.3

1049.0

0.01

0.27

1.79

RESIDENCE TIMES

Gas

Right Side of Weir

HLL-HLSD

150

** WARNINGS **

60.0

91691

seconds

1.0

9.52

OK

1.5

1.5

18.25

13.34

OK

OK

1500

LLL-LLSD

1.0

4.01

OK

3750

LLSD to Outlet

1.0

4.00

OK

Oil Residence Time at NLL

0.50

21.35

OK

Actual

(mins)

** WARNINGS **

150

Max vel. in Oil out nozzle (m/s)

Max vel. in water out nozzle (m/s)

K Value (m/s) per GPSA fig 7.9

Actual

(mins)

NLL-HLL

NLL-LLL

150

.v2 max for inlet nozzle (kg/m.s2)

.v2 max for gas outlet nozzle (kg/m.s 2)

(mins)

Specified

1.0

1.0

0.12

Mixture density (kg/m3)

1028.9

RESIDENCE TIMES

Specified

(mins)

SETTLING VELOCITY CRITERION

Maximum Allowable Gas Velocity (m/s)

1.64 m/s

Gas Velocity (m/s) - calculated

0.00006 m/s

OK

Oil Droplet Velocity (m/s) - Gravity Settling Method

Oil from Gas

Water from Oil

Oil from Water

0.33 m/s

0.013 m/s

0.003 m/s

DROPLET FALL TIMES (Left Side of Weir)

Oil in Gas

(Top-Liquid)

1.7 secs

MEG in Oil

(NIL to Weir)

.8 min

Oil in MEG

(Btm-NIL)

6.51 min

NOTE:

Left Side of Weir

HIL-Weir

1.0

1.3

OK

NIL-HIL

1.5

3.39

OK

NIL-LIL

3.0

3.23

OK

LIL-LILSD

1.5

1.69

OK

1.63

97.13

6.54

OK

mins

mins

LILSD to Outlet

1.5

Oil Residence Time (NIL to Weir)

Rich MEG Residence Time (Btm to NIL)

OK

OK

OK

Gas Velocity Criteria are based on weir height, Hw.

TITLE

LIQUID SEPARATOR

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE

CHECKED

DATE

CALC.NO

2001 - KGD6 - D1 - PF - B - PRR - 402

SV

DATE AND TIME PRINTED:

RELIANCE'S KGD6 FIELD DEVELOPMENT

30-Sep-15

1:06 PM

PAGE 2 OF 4

HORIZONTAL SEPARATOR (3 phase with weir, no boot)

SKETCH

Gas Outlet

nozzle ID

50 mm

Length T/T =

Gas =

0.01 t/d

0.16 Am3/h

6600 mm

Inlet Nozzle ID

173 mm

Vol. (m3)

4.16

2.07

5.50

5.24

2.73

2.64

Ht.(mm)

(Gas)

(HIL-Weir)

(NIL-HIL)

(NIL-LIL)

(LIL-LILSD)

(LILSD-Out)

GAS

Interface

HIL

NIL

LIL

LILSD

1500

1075

650

400

Weir Height,Hw = 1650 mm

I. D. =

OIL

2200 mm

RICH MEG

Ht(mm)

HLSD

HLL

NLL

LLL

LLSD

Vol. (m3)

1550

1400

925

450

300

0.74

1.42

1.04

0.31

0.31

(HLL-HLSD)

(NLL-HLL)

(NLL-LLL)

(LLL-LLSD)

(LLSD-Out)

OIL

T/W =

Oil Outlet nozzle ID

50 mm

5600 mm

(If 2 phase set Hw=0, t/w=t/t)

Rich MEG outlet

Nozzle ID

186 mm

Oil =

72.47

4.67

t/d

m3/h

Rich MEG =

2451.00

97.35

t/d

m3/h

TITLE

SEPARATOR SIZING SPREADSHEET

LIQUID SEPARATOR

PROJ.

RELIANCE'S KGD6 FIELD DEVELOPMENT

CALCULATION SHEET

BY

DATE

CHECKED

SV

DATE AND TIME PRINTED:

DATE

CALC.NO

2001 - KGD6 - D1 - PF - B - PRR - 402

30-Sep-15

1:06 PM

PAGE 3 OF 4

HORIZONTAL SEPARATOR (3 phase with weir, no boot)

CALCULATIONS

Dmax is the upper particle size limit for each of the laws.

Kcr is the critical constant for maximum particle size (from GPSA

Handbook). Vt is the settling velocity in m/s.

SETTLING VELOCITIES

Oil From Gas ("K" Value method)

K Value, m/s

Max allowable velocity,Vmax

Gas Horiz. Velocity

Oil in Gas (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

0.12

1.64 m/s

0.00006 m/s

0.33

m/s

Intermediate Law

Settling Velocity

Settling Law Used

Law Used:

Kcr

Vt

Dp max

0.03

(m/s)

0.79

()

54

0.33

18.13

0.33

0.90

716

38843

Actual Gas Velocity OK

Stoke's Law

Intermediate Law

Newton's Law

Oil in Water (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

Water in Oil (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

0.003

Settling Velocity

Settling Law Used

Law Used:

Kcr

Stoke's Law

Intermediate Law

Newton's Law

0.03

0.33

18.13

Stoke's Law (Kcr = 0.025)

Vt = 1488 g Dp2 (l - v)

m/s

Stoke's Law

Vt

(m/s)

0.003

0.006

0.05

Settling Velocity

Settling Law Used

Law Used:

Dp max

()

352

4702

255242

Kcr

Stoke's Law

Intermediate Law

Newton's Law

Intermediate Law (Kcr = 0.334)

Vt = 3.54*g0.71 Dp1.14 (l - v)0.71

Newton's Law (Kcr = 18.13)

Vt = 1.74 * SQRT(g Dp (l-v) / v )

0.013

m/s

Intermediate Law

Vt

Dp max

()

(m/s)

0.03

0.018

100

0.33

0.013

1330

18.13

0.053

72218

NOTE:

Equations for Stokes Law, Intermediate Law and Newtons Law are

taken from GPSA Handbook, Volume 1, Section 7, Figure 7.4

v0.29 * 0.43

18

NOMENCLATURE

LLL

LIL

LLSD

LILSD

NLL

NIL

HLL

HIL

HLSD

HILSD

Btm

Low Liquid Level

Low Interface Level

Low Level Shut Down

Low Interface Level Shut Down

Normal Liquid Level

Normal Interface Level

High Liquid Level

High Interface Level

High Level Shut Down

High Interface Level Shut Down

Bottom

X-Area

l

v

Dp

Vt

VMAX

K

KCR

Hw

Cross sectional area

Liquid density kg/m3

Vapour density kg/m3

Droplet diameter

Gas viscosity Cp

Settling Velocity m/s

Maximum vapour velocity m/s

Design vapour velocity factor m/s

Proportionality constant, dimensionless.

Height of Weir, mm

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE

CHECKED

DATE

RELIANCE'S KGD6 FIELD DEVELOPMENT

CALC.NO

2001 - KGD6 - D1 - PF - B - PRR - 402

SV

DATE AND TIME PRINTED:

LIQUID SEPARATOR

30-Sep-15

1:06 PM

PAGE 4 OF 4

HORIZONTAL SEPARATOR (3 phase, no boot, draw off pipe for condensate)

INPUT

OUTPUT

Feed

Flow (t/d)

Density (kg/m3)

Viscosity (cP)

Droplet Size ()

Droplet Size ()

Droplet Size ()

GAS

OIL

WATER

250.0

11.1

1116.2

829.2

1000.0

972.0

0.02

5.00

0.40

Oil in Gas

Oil in Water

Water in Oil

RESIDENCE TIMES

(mins)

150

1000

500

.v2 max for inlet nozzle (kg/m.s2)

.v2 max for gas outlet nozzle (kg/m.s2)

Max vel. in Oil out nozzle (m/s)

Max vel. in water out nozzle (m/s)

K Value (m/s)

Mixture density (kg/m3)

Specified

Gas

HLL-HLSD

NLL-HLL

NLL-LLL

LLL-LLSD

LLSD to Withdrawl pipe height

HIL-HILSD

NIL-HIL

NIL-LIL

LIL-LILSD

LILSD to Outlet

1500

3750

1.0

1.0

0.06

1.0

1.5

1.0

0.5

1.0

1.0

2.0

1.0

1.0

** WARNINGS **

seconds

** Warning ! Residence time insufficient **

** Warning ! Residence time insufficient **

** Warning ! Residence time insufficient **

** Warning ! Residence time insufficient **

OK

OK

OK

** Warning ! Residence time insufficient **

OK

OK

95.0

NIL-Standpipe

Oil residence time (NLL - NIL)

Water residence time (NIL-Bottom)

SETTLING VELOCITY CRITERION

4.1

4.34

4.2

mins

mins

mins

3.0

2.4

0.2

seconds

mins

mins

DROPLET FALL TIMES

K Factor Gas Velocity (m/s)

Gas Velocity (m/s) - calculated

Oil Droplet Velocity (m/s) - Gravity Settling Method

Oil from Gas

Water from Oil

Oil from Water

NOTE:

1.0

Actual

(mins)

10.44

0.95

0.97

1.02

0.86

0.68

1.3

1.24

1.68

1.42

1.09

0.52 m/s

0.46 m/s

Oil in Gas Top-Liquid

Water from Oil NLL-NIL

Oil from Water Btm-NIL

OK

OK

OK

OK

0.23 m/s

0.004 m/s

0.042 m/s

Gas Velocity Criteria are based on HLSD Height.

STANDPIPE CALCULATIONS - FROM VESSEL BASE

INTERMEDIATE CALCULATIONS

WATER INTERFACE HILSD

700.00

DIST. BETWEEN WATER HILSD AND OIL OUTLET NOZZLE

OIL OUTLET NOZZLE (STANDPIPE) ELEVATION, (Hs)

DIST. BETWEEN OIL OUTLET NOZZLE AND OIL LLSD

OIL LEVEL LLSD

117

817

50.0

867

mm

mm

mm

mm

116.89

1.00

47.11

1.00

40.88

0.6

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE and TIME PRINTED:

DATE

CHECKED

30-Sep-15

1:06 PM

DATE

SK.CALC.NO

PAGE 1 OF 3

HORIZONTAL SEPARATOR (3 phase, no boot, draw off pipe for condensate)

SKETCH

Gas =

Inlet

Length T/T= 4800 mm

Minimum Inlet nozzle ID 304 mm

Ht. (mm)

oil HLSD

oil HLL

oil NLL

oil LLL

oil LLSD

Minimum Gas Out Nozzle ID = 134 mm

Incremental

Vol. (m3)

1250 mm

2.72

1150 mm

1050 mm

0.89

950 mm

0.95

867 mm

0.80

0.91

0.48

250.00 t/d

938.44 Am3/h

GAS

(Gas)

(HLL-HLSD)

(NLL-HLL)

(NLL-LLL)

(LLL-LLSD)

(LLSD-HILSD)

I. D. =

1750 mm

Height of draw off pipe, Hs =

817 mm

Interface

water HILSD

water HIL

water NIL

water LIL

water LILSD

OIL

700 mm

600 mm

0.93

500 mm

0.89

350 mm

1.20

200 mm

1.01

0.78

(HIL-HILSD)

(NIL-HIL)

(NIL-LIL)

(LIL-LILSD)

(LILSD-Outlet)

WATER

HEIGHT WARNINGS

Minimum Water out nozzle ID = 123 mm

OK

OK

Minimum Oil Outlet nozzle ID =

Water =

1000.00 t/d

42.87 m3/h

Oil =

1116.20 t/d

56.09 m3/h

141 mm

OK

OK

OK

OK

NOMENCLATURE

LLL

LIL

LLSD

LILSD

NLL

NIL

HLL

Low Liquid Level

Low Interface Level

Low Level Shut Down

Low Interface Level Shut Down

Normal Liquid Level

Normal Interface Level

High Liquid Level

HIL

HLSD

HILSD

KCR

Hs

l

v

High Interface Level

High Level Shut Down

High Interface Level Shut Down

Proportionality constant, dimensionless.

Height of Standpipe, mm

Liquid density kg/m3

Vapour density kg/m3

Dp

Vt

VMAX

K

Droplet diameter

Gas viscosity Cp

Settling Velocity m/s

Maximum vapour velocity m/s

Design vapour velocity factor m/s

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE and TIME PRINTED:

DATE

CHECKED

30-Sep-15

1:06 PM

DATE

SK.CALC.NO

PAGE 2 OF 3

HORIZONTAL SEPARATOR (3 phase, no boot, draw off pipe for condensate)

CALCULATIONS

Cont'd)

SETTLING VELOCITIES

Oil From Gas ("K" Value method)

Oil in Gas (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

K Value, m/s

Max allowable velocity,Vmax

Gas Horiz. Velocity

0.06

0.52

0.46

m/s

m/s

Dmax is the upper particle size limit for each of the laws.

Kcr is the critical constant for maximum particle size (from GPSA

Handbook). Vt is the settling velocity in m/s.

see note 1

Settling Velocity

Settling Law Used

Law Used:

Kcr

Actual Gas Velocity OK

Stoke's Law

Intermediate Law

Newton's Law

0.23

m/s

Intermediate Law

Vt

(m/s)

0.03

0.62

0.33

0.23

18.13

0.57

Dp max

()

47

621

33733

Oil in Water (Gravity Settling Laws method)

Water in Oil (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

Particle size calc for determination of appropriate law

0.042

Settling Velocity

Settling Law Used

Law Used:

Kcr

Stoke's Law

Intermediate Law

Newton's Law

Intermediate Law

Vt

(m/s)

0.03

0.195

0.33

0.042

18.13

0.07

m/s

Settling Velocity

Settling Law Used

Law Used:

Kcr

Dp max

()

168

2248

122026

Stoke's Law

Intermediate Law

Newton's Law

0.004

Stoke's Law

Vt

(m/s)

0.03

0.004

0.33

0.006

18.13

0.051

m/s

Dp max

()

906

12108

657243

NOTES

1.

Stoke's Law (Kcr = 0.025)

Intermediate Law (Kcr = 0.334)

Vt = 1488 g Dp (l - v)

Vt = 3.54*g

0.71

Dp

18

0.29

1.14

(l - v)

Newton's Law (Kcr = 18.13)

Vt = 1.74 * SQRT(g Dp (l-v) / v )

0.71

0.43

Equations for Stokes Law, Intermediate Law and Newtons Law are taken from GPSA Handbook, Volume 1, Section 7.

Figure 7.4

2.

Maximum allowable vapour velocity is calculated from the equation in GPSA Handbook, Volume 1, Section 7:

VMAX

K [ (l - l) / l ] 0.5

3.

Settling times for water and oil are based on the normal interface level (NIL).

4.

Information for partial volumes and dished ends was from GPSA handbook Section 6, and in particular, fig. 6-21,6-22.

5.

Calculations for gas residence time and area/volume calculations use the NLL height as the height basis. End volumes ignored for gas volume calculations.

TITLE

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE and TIME PRINTED:

DATE

CHECKED

30-Sep-15

1:06 PM

DATE

SK.CALC.NO

PAGE 3 OF 3

CALCULATION FOR SUMP TANK T-2Y40

INPUT

OUTPUT

Feed

Flow (t/d)

Density (kg/m3)

Viscosity (cP)

Droplet Size ()

Oil in Gas

.v2 max for inlet nozzle (kg/m.s2)

.v2 max for gas outlet nozzle (kg/m.s2)

GAS

Mixed Liquid

42.6

0.1

853

Gas (seconds)

0.01

2.39

HLL-HLSD

NLL-HLL

1.0

NLL-LLL

LLL-LLSD

LLSD to bottom

1.0

300

6000

3750

1.00

K Value (m/s)

Mixture density (kg/m3)

0.08

Actual

(mins)

** WARNINGS **

3

Specified

(mins)

1.10

Max vel. in Oil out nozzle (m/s)

NOTE:

RESIDENCE TIMES

Gas velocity critera all based on HLSD

1.0

1.0

0.5

2380.3

2464.2

OK

5978.0

3446.1

10914.7

OK

OK

OK

OK

SETTLING VELOCITY CRITERION

(m/s)

Maximum allowable Gas Velocity (m/s)

Gas Horiz. Velocity (m/s) - calculated

Oil Droplet Velocity (m/s)

2.27

1E+00

1.16

OK

0.5

OK

(Gravity Settling Method)

Droplet fall time (seconds)

CALCULATIONS

SETTLING VELOCITIES

Oil From Gas ("K" Value method)

K Value

Max Allowable Velocity,Vmax

Gas Horiz. Velocity

Minimum Vessel Diameter

0.08

2.27

1.10

501

m/s

m/s

m/s

mm

Oil from Gas (Gravity Settling Laws method)

Particle size calc for determination of appropriate law

Dmax is the upper particle size limit for each of the laws.

Kcr is the critical constant for maximum particle size (from GPSA Handbook).

Vt is the settling velocity in m/s.

Settling Velocity

Settling Law Used

Law Used:

Stoke's Law (Kcr = 0.025)

Intermediate Law (Kcr = 0.334)

Newton's Law (Kcr = 18.13)

Vt = 1488 g Dp2 (l - v)

Vt = 3.54*g0.71 Dp1.14 (l - v)0.71

Vt = 1.74 * SQRT(g Dp (l-v) / v )

Stoke's Law

Kcr

Vt

(m/s)

Dp max

()

0.03

3.48

82

0.33

18.13

1.16

2.63

1089

59113

v0.29 * 0.43

18

NOTE:

Intermediate Law

Newton's Law

1.16

m/s

Intermediate Law

Equations for Stoke's Law, Intermediate Law and Newton's Law are taken from GPSA Handbook, Volume 1, Section 7,

Figure 7.4. Results of these calculations will not be used for Sump Tank Sizing.

13

27.11.07

APPROVED FOR DESIGN

12

16.03.07

APPROVED FOR DESIGN

AUT

SKP

TITLE

11

29.09.06

APPROVED FOR DESIGN

SUP

PJ

10

23.08.06

ISSUED FOR COMMENTS

SUP

PJ

CALCULATION FOR SUMP TANK (T-2Y40)

PROJ.

BONGKOT 3F

Rev.

DATE

DATE AND TIME PRINTED:

DESCRIPTION

30-Sep-15

1:06 PM

BY

CHECK

APPR.

THAI NIPPON STEEL

ENGINEERING & CONSTUCTION CO., LTD

DOCUMENT NUMBER

THAI-3F-GEN-11-07-0002

PAGE 1 OF 2

CALCULATION FOR SUMP TANK T-2Y40

SKETCH

Inlet

Minimum Inlet nozzle ID

88 mm

Minimum

Gas Outlet

Nozzle ID =

Length T/T= 3050 mm

GAS

Gas =

99 mm

Vol. (m3)

1.24

0.19

0.20

0.5

0.28

0.89

Height

HLSD

HLL

NLL

LLL

LLSD

I. D. =

1130 mm

42.6 t/d

1612.73 Am3/h

650 mm

600 mm

550 mm

425 mm

350 mm

(Gas)

(HLL-HLSD)

(NLL-HLL)

(NLL-LLL)

(LLL-LLSD)

(LLSD-Btm)

LIQUID

Note : Working Condition Volume (LAL-LAH) = 3.8 m3

Minimum

Mixed Liquid Outlet

50 mm

Nozzle ID =

Mixed Liquid =

0.1

0.00

t/d

m3/h

NOMENCLATURE

LLL

LLSD

NLL

HLL

HLSD

Btm

l

v

Dp

Vt

VMAX

Low Liquid Level

Low Level Shut Down

Normal Liquid Level

High Liquid Level

High Level Shut Down

Bottom

Liquid density kg/m3

Vapour density kg/m3

K

KCR

g

Dmax

Droplet diameter

Gas viscosity Cp

Settling Velocity m/s

Maximum vapour velocity m/s

Design vapour velocity factor m/s

Proportionality constant, dimensionless.

Gas constant

Upper Particle Size Limit

TITLE

13

27.11.07

APPROVED FOR DESIGN

12

16.03.07

APPROVED FOR DESIGN

AUT

SKP

11

29.09.06

APPROVED FOR DESIGN

SUP

PJ

ISSUED FOR COMMENTS

SUP

PJ

CALCULATION FOR SUMP TANK (T-2Y40)

PROJ.

BONGKOT 3F

10

Rev.

23.08.06

DATE

DATE AND TIME PRINTED:

DESCRIPTION

30-Sep-15

1:06 PM

BY

CHECK

APPR.

THAI NIPPON STEEL

ENGINEERING & CONSTUCTION CO., LTD

DOCUMENT NUMBER

THAI-3F-GEN-11-07-0002

AGE 2 OF 2

VERTICAL SEPARATOR (2 phase)

INPUT

PRODUCTION SEPARATOR

OUTPUT

Feed

Flow (t/d)

Density (kg/m3)

Viscosity (cP)

Droplet Size, () Oil in Gas

K Value (m/s) from mist extractor data GPSA fig.7.9

.v2 max for inlet nozzle (kg/m.s2)

.v2 max for gas outlet nozzle (kg/m.s2)

GAS

LIQUID

11401

17.6

57.02

1051.0

0.01

1.796

RESIDENCE TIMES

Actual

(mins)

56.8

56.8

56.8

56.8

113.5

Specified

(mins)

HLL-HLSD

NLL-HLL

NLL-LLL

LLL-LLSD

LLSD to bottom

300

0.10

5000

1.0

1.5

1.5

1.0

1.0

** WARNINGS **

OK

OK

OK

OK

OK

3750

Max vel. in Oil outlet nozzle (m/s)

Mixture density (kg/m3)

SETTLING VELOCITY CRITERION

K Factor Gas Velocity (m/s)

Gas Velocity (m/s) - calculated

Oil Droplet Velocity (m/s)

Gravity Settling Method

1.00

57.10

Choose Dished end shape by clicking on arrow.

See note 6

semi-ellipsoidal

0.42

0.35

0.39

OK

OK

CALCULATIONS

LIQUID / VAPOUR SEPARATION

K Value Method

(Note 2)

K Value

Max allow. Velocity (Vmax)

Gas Velocity

Minimum Vessel Diameter

0.10

0.42

0.35

2656

m/s

m/s

m/s

mm

Dmax is the upper particle size limit for each of the

laws.

Kcr is the critical constant for maximum particle size

(from GPSA Handbook).

Vt is the settling velocity in m/s.

Oil from Gas (Gravity Settling Laws method)

Particle / droplet size calc for determination of appropriate law

Settling Velocity

Settling Law Used

Law Used:

0.39

m/s

Newton's Law

Kcr

Actual Gas Velocity OK

Stoke's Law

Intermediate Law

Newton's Law

Stoke's Law (Kcr = 0.025)

Intermediate Law (Kcr = 0.334)

Newton's Law (Kcr = 18.13)

Vt = 1488 g Dp2 (l - v)

Vt = 3.54*g0.71 Dp1.14 (l - v)0.71

Vt = 1.74 * SQRT(g Dp (l-v) / v )

0.03

0.33

18.13

Vt

(m/s)

3.69

0.40

0.39

Dp max

()

22

296

16049

v0.29 * 0.43

18

TITLE

PRODUCTION SEPARATOR

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE

CHECKED

DATE

CALC.NO

2001 - KGD6 - D1 - PF - B - PRR - 402

SV

DATE AND TIME PRINTED:

RELIANCE'S KGD6 FIELD DEVELOPMENT

30-Sep-15

1:06 PM

PAGE 2 OF 4

VERTICAL SEPARATOR (2 phase)

SKETCH

Min Gas Outlet

Nozz. Size =

Calculated Total

T/T Height:

4012 mm

consider

4000 mm

Gas =

11400.84

8331.02

603 mm

t/d

Am3/h

300 mm

with L/D of approx

1.4

Wire Mesh Demister

100 mm

ID=2900mm

1740 mm

(Note 4)

1122 mm

(Note 5)

150 mm

(Note 2)

GAS

Inlet

Min Inlet Nozzle Size =

561 mm

NOMENCLATURE

LLSD

LLL

NLL

HLL

HLSD

g

Dmax

L

V

Dp

Low Level Shut Down

Low Liquid Level

Normal Liquid Level

High Liquid Level

High Level Shut Down

Gas constant

Upper Particle Size Limit

Liquid density (kg/m3)

Vapour density (kg/m3)

Droplet diameter (

Vt

VMAX

Gas viscosity Cp

Settling Velocity (m/s)

Maximum vapour velocity (m/s)

Design vapour velocity factor (m/s)

Proportionality constant, dimensionless.

K

KCR

HLSD

HLL

600 mm

NLL

400 mm

Volume increment

0.66 m3

500 mm

0.66 m3

OIL

LLL

LLSD

0.66 m3

300 mm

(Note 3)

200 mm

Volume to LLSD including dished end =

Min Liquid Outlet

Nozz. Size =

0.66 m3

4.51 m3

Oil =

50 mm

17.61

0.70

t/d

m3/h

TITLE

PRODUCTION SEPARATOR

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE

CHECKED

SV

DATE AND TIME PRINTED:

RELIANCE'S KGD6 FIELD DEVELOPMENT

DATE

CALC.NO

2001 - KGD6 - D1 - PF - B - PRR - 402

30-Sep-15

1:06 PM

PAGE 3 OF 4

VERTICAL SEPARATOR (2 phase)

CALCULATIONS Cont'd

AREA & VOLUME INFORMATION

Area

Cylinder

Volume

Volume +

Dished

Volume

Increment

(m2)

(m3)

end (m3)

(m3)

3.963

3.303

2.642

1.982

1.321

7.156

6.495

5.835

5.174

4.514

0.661

0.661

0.661

0.661

1.321

GAS Cross Sectional Area

6.605

STORAGE (Volume from Bottom)

Oil HLSD

Oil HLL

Oil NLL

Oil LLL

Oil LLSD

6.605

6.605

6.605

6.605

6.605

Dished End Type

Dished End

Volume

(m^3)

3.193

6.385

semi-ellipsoidal

hemispherical

3.193

NOTES

1. Maximum allowable vapour velocity is calculated from the equation:

VMAX

K [ (L - V) / V ] 0.5

2. 150 mm minimum.

3. Space for instrument nozzles and/or emergency liquid capacity - minimum 150 mm.

4. 60% of vessel diameter or 750mm whichever is greater.

5. twice inlet nozzle diameter.

6 . Semi-ellipsoidal end-volume is calculated using the formula V = (x (ID)3 )/24 which applies to one end only of the separator (ie. the bottom).

Hemispherical end-volume for one dished end is calculated using the formula: V = (P x (ID) 3 )/12

Information taken from GPSA handbook Sections SI - 6, and in particular, figs. 6.21&6.22

TITLE

PRODUCTION SEPARATOR

SEPARATOR SIZING SPREADSHEET

PROJ.

CALCULATION SHEET

BY

DATE

CHECKED

SV

DATE AND TIME PRINTED:

RELIANCE'S KGD6 FIELD DEVELOPMENT

DATE

CALC.NO

2001 - KGD6 - D1 - PF - B - PRR - 402

30-Sep-15

1:06 PM

PAGE 4 OF 4

S-ar putea să vă placă și

- All Sep CalcDocument22 paginiAll Sep Calcbharathscds100% (3)

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design Separatorsgrabetty100% (3)

- Separator All Oil and Gas SpreadsheetDocument22 paginiSeparator All Oil and Gas SpreadsheetSatria 'igin' Girindra Nugraha100% (1)

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 paginiNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnÎncă nu există evaluări

- Three Phase Separator Sizing - Overflow WeirDocument2 paginiThree Phase Separator Sizing - Overflow WeirSaeid Rahimi MofradÎncă nu există evaluări

- Vertical Separator SizingDocument4 paginiVertical Separator SizingnemprrÎncă nu există evaluări

- Three Phase Separator Sizing - Submerged WierDocument2 paginiThree Phase Separator Sizing - Submerged WierSaeid Rahimi MofradÎncă nu există evaluări

- Master - Three Phase Horizontal Separator Rev 0Document6 paginiMaster - Three Phase Horizontal Separator Rev 0Naeem HussainÎncă nu există evaluări

- Line Sizing - 2PHASEDocument11 paginiLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Knockout DrumDocument9 paginiKnockout Drumgautam_96948069Încă nu există evaluări

- Guide For Vessel Sizing PDFDocument24 paginiGuide For Vessel Sizing PDFManish542Încă nu există evaluări

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 paginiMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqÎncă nu există evaluări

- Separator Sizing and DesignDocument44 paginiSeparator Sizing and DesignKay EenÎncă nu există evaluări

- Maz - Design - Separator Capacity EvaluationDocument5 paginiMaz - Design - Separator Capacity EvaluationNaeem HussainÎncă nu există evaluări

- Horizontal 3 Phase Separator With Boot SizingDocument16 paginiHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- Three Phase Separator Sizing - Bucket & PipeDocument2 paginiThree Phase Separator Sizing - Bucket & PipeSaeid Rahimi MofradÎncă nu există evaluări

- CPF-010 Process Line Sizing Attachment - 0Document38 paginiCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- Pump (English) TemplateDocument1 paginăPump (English) TemplateMichael HaiseÎncă nu există evaluări

- Vertical Knock Out Drum With Wire Mesh For NDocument1 paginăVertical Knock Out Drum With Wire Mesh For Nteegala_1950% (2)

- Vessel Sizing SpreadsheetDocument28 paginiVessel Sizing SpreadsheetEmamokeÎncă nu există evaluări

- PSV 0764 CD Vent KO Drum Liquid Pump - L03Document3 paginiPSV 0764 CD Vent KO Drum Liquid Pump - L03Ebby OnyekweÎncă nu există evaluări

- Three Phase Separator Sizing (Double Weir 2)Document3 paginiThree Phase Separator Sizing (Double Weir 2)12377466790% (2)

- Condensate Line SizingDocument2 paginiCondensate Line SizingAnonymous oVRvsdWzfBÎncă nu există evaluări

- Boiling Up Rate For Batch DistillationDocument4 paginiBoiling Up Rate For Batch DistillationKanhaiyalal PatilÎncă nu există evaluări

- Vessel - Vertical Sizing - IPunitsDocument25 paginiVessel - Vertical Sizing - IPunitsAnders FTÎncă nu există evaluări

- Three Phase Separator Sizing (Double Weir 1)Document3 paginiThree Phase Separator Sizing (Double Weir 1)Saeid Rahimi MofradÎncă nu există evaluări

- Separator SizingDocument9 paginiSeparator SizingTolstoy LeoÎncă nu există evaluări

- Horizontal Three Phase Separator vap-IPDocument5 paginiHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- 3Ph Vert Sep 2010 Weir VerA FPS PDFDocument5 pagini3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderÎncă nu există evaluări

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 paginiPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoÎncă nu există evaluări

- TEMA Sheet Heat Exchanger Specification SheetDocument3 paginiTEMA Sheet Heat Exchanger Specification SheetSonNguyenÎncă nu există evaluări

- CPF-010 Utility Line Sizing Attachment - 0Document31 paginiCPF-010 Utility Line Sizing Attachment - 0goodspeed_phÎncă nu există evaluări

- Line Sizing For Liquid, (DO IT OWN)Document11 paginiLine Sizing For Liquid, (DO IT OWN)sumitÎncă nu există evaluări

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterDocument3 paginiDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaÎncă nu există evaluări

- Instrument Process Datasheet (IPDS)Document3 paginiInstrument Process Datasheet (IPDS)Vraja KisoriÎncă nu există evaluări

- Vertical 2 Phase Separator SizingDocument5 paginiVertical 2 Phase Separator SizingJermaine Heath100% (1)

- Three Phase Horizontal SeparatorDocument6 paginiThree Phase Horizontal SeparatorHani KirmaniÎncă nu există evaluări

- Calculation Sheet For Centrifugal Pumps: Excel Program File: Pumpmast - Xls Version: 1.02 / RehDocument9 paginiCalculation Sheet For Centrifugal Pumps: Excel Program File: Pumpmast - Xls Version: 1.02 / RehCast Ed IvÎncă nu există evaluări

- Petronas Design Manual: Column SizingDocument10 paginiPetronas Design Manual: Column SizingHazizi AkmarÎncă nu există evaluări

- Separator SizingDocument3 paginiSeparator SizingMaryJane Ayisha Sado-ObahÎncă nu există evaluări

- PSV Sizing For Two Phase FlowDocument28 paginiPSV Sizing For Two Phase FlowSyed Haideri100% (1)

- FGCP Line Sizing CalculationsDocument86 paginiFGCP Line Sizing CalculationsToyinÎncă nu există evaluări

- Validation Report On The 2-Phase Line SizingDocument18 paginiValidation Report On The 2-Phase Line SizingEbby Onyekwe100% (1)

- Flare SystemDocument60 paginiFlare Systemmmairaja100% (1)

- Three Phase Separator Sizing - No InternalDocument2 paginiThree Phase Separator Sizing - No InternalSaeid Rahimi MofradÎncă nu există evaluări

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Document3 paginiLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieÎncă nu există evaluări

- Vertical Separator SizingDocument4 paginiVertical Separator SizingSyed Waqas HaiderÎncă nu există evaluări

- Steam Pressure DropDocument8 paginiSteam Pressure DropDavid Muñoz CastroÎncă nu există evaluări

- Draining Time (Gravity Flow)Document2 paginiDraining Time (Gravity Flow)Saeid Rahimi MofradÎncă nu există evaluări

- PSV Sizing (Liquid)Document2 paginiPSV Sizing (Liquid)Saeid Rahimi Mofrad50% (2)

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 paginăTube Rupture (Two Phase-Omega Method) PDFAmin RoisÎncă nu există evaluări

- Specification Sheet For Separator: Operating Conditions SketchDocument12 paginiSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- SeparatorDocument23 paginiSeparatorLeonardo Ramirez GuzmanÎncă nu există evaluări

- Separator Sizing Spreadsheet Main Menu: File Separp1Document23 paginiSeparator Sizing Spreadsheet Main Menu: File Separp1Amiruddin Kubik100% (1)

- Separator 1 Sizing Spread SheetsDocument21 paginiSeparator 1 Sizing Spread SheetsYustianÎncă nu există evaluări

- Separator 1 Sizing Spread Sheets PDF FreeDocument21 paginiSeparator 1 Sizing Spread Sheets PDF FreeHenry WicaksanaÎncă nu există evaluări

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design SeparatorsreninbabaskiÎncă nu există evaluări

- Separator Calculation For MedcoDocument25 paginiSeparator Calculation For MedcoTifano Khristiyanto100% (1)

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design Separatorssemarasik_651536604Încă nu există evaluări

- Spreadsheet To Design SeparatorsDocument21 paginiSpreadsheet To Design Separatorssemarasik_651536604Încă nu există evaluări

- F 12102 Rules of CalculationDocument9 paginiF 12102 Rules of CalculationSteve WanÎncă nu există evaluări

- Pump Sizing Calculation SheetDocument10 paginiPump Sizing Calculation SheetSteve WanÎncă nu există evaluări

- Selection PresentationDocument15 paginiSelection PresentationSteve WanÎncă nu există evaluări

- Esp 100 TPD Precicon 3 Drawing PDFDocument1 paginăEsp 100 TPD Precicon 3 Drawing PDFSteve WanÎncă nu există evaluări

- Air Damper Control System671 PDFDocument1 paginăAir Damper Control System671 PDFSteve WanÎncă nu există evaluări

- Plano Rizzi Sopladores B 6102 FCCDocument2 paginiPlano Rizzi Sopladores B 6102 FCCSteve WanÎncă nu există evaluări

- Combustion CalculationDocument2 paginiCombustion CalculationSteve WanÎncă nu există evaluări

- Line List Ammonia Urea P1 RevisiDocument17 paginiLine List Ammonia Urea P1 RevisiSteve WanÎncă nu există evaluări

- Steam Boilers VeloaDocument96 paginiSteam Boilers VeloaSteve WanÎncă nu există evaluări

- Auxiliary BoilerDocument102 paginiAuxiliary BoilerSteve WanÎncă nu există evaluări

- Boiler Safety Checklist &Document185 paginiBoiler Safety Checklist &Steve WanÎncă nu există evaluări

- Process Control BoilerDocument70 paginiProcess Control BoilerSteve WanÎncă nu există evaluări

- Part 8 Exhaust FanDocument7 paginiPart 8 Exhaust FanSteve WanÎncă nu există evaluări

- Chimney CalculationsDocument3 paginiChimney CalculationsSteve WanÎncă nu există evaluări

- Furnace Typical Draft ProfileDocument1 paginăFurnace Typical Draft ProfileSteve WanÎncă nu există evaluări

- Heat Recovery P Id Raymond RV 06Document1 paginăHeat Recovery P Id Raymond RV 06Steve WanÎncă nu există evaluări

- Compensation (Gas) eDocument1 paginăCompensation (Gas) eSteve WanÎncă nu există evaluări

- Tank SizeDocument7 paginiTank SizeSteve WanÎncă nu există evaluări

- Hall Yarborough Z 1Document1 paginăHall Yarborough Z 1Steve WanÎncă nu există evaluări

- Heat Loss Analysis 03Document3 paginiHeat Loss Analysis 03Steve WanÎncă nu există evaluări

- Lab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Document4 paginiLab 9: Standard Plate Count: How Do We Know How Many Bacteria Are in A Liquid?Penelope MeloÎncă nu există evaluări

- Mechanical Damage and Fatigue Assessment of Dented Pipelines Using FeaDocument10 paginiMechanical Damage and Fatigue Assessment of Dented Pipelines Using FeaVitor lopesÎncă nu există evaluări

- 3.032 Problem Set 2 Solutions: Due: Start of Lecture, 09.21.07Document16 pagini3.032 Problem Set 2 Solutions: Due: Start of Lecture, 09.21.07Pkay TandohÎncă nu există evaluări

- Astm C97/C97M-09Document3 paginiAstm C97/C97M-09Azuriak150% (2)

- Decompiled With CFR ControllerDocument3 paginiDecompiled With CFR ControllerJon EricÎncă nu există evaluări

- Direct Analysis MethodDocument31 paginiDirect Analysis MethodgayalamÎncă nu există evaluări

- List of IEC StandardsDocument12 paginiList of IEC Standardsaravindeee08100% (1)

- Reversible and Irreversible ChangesDocument10 paginiReversible and Irreversible ChangesXerish DewanÎncă nu există evaluări

- CA Abb V-ContactDocument92 paginiCA Abb V-ContactWiliam CopacatiÎncă nu există evaluări

- Mozart Symphony 6 TimpaniDocument2 paginiMozart Symphony 6 Timpaniגיל עברוןÎncă nu există evaluări

- Humiseal 1C49Lv Silicone Conformal Coating Technical Data SheetDocument2 paginiHumiseal 1C49Lv Silicone Conformal Coating Technical Data Sheetmario230991Încă nu există evaluări

- G3600 A4 Brochures PDFDocument4 paginiG3600 A4 Brochures PDFVictor NunezÎncă nu există evaluări

- Maintenance Component Main Function Level Activity Frequency Line DepartmentDocument7 paginiMaintenance Component Main Function Level Activity Frequency Line DepartmentBarathÎncă nu există evaluări

- Camber For Construction StageDocument18 paginiCamber For Construction StageOanh PhanÎncă nu există evaluări

- Tesp12205pi R1Document36 paginiTesp12205pi R1arabsniperÎncă nu există evaluări

- 2017 Alcon Catalogue NewDocument131 pagini2017 Alcon Catalogue NewJai BhandariÎncă nu există evaluări

- ASM Lab Record BookDocument36 paginiASM Lab Record BookNandan HegdeÎncă nu există evaluări

- SAE-J1850 Communication Protocol Conformity Transmission Controller For Automotive LANDocument59 paginiSAE-J1850 Communication Protocol Conformity Transmission Controller For Automotive LANMa Ngoc TrungÎncă nu există evaluări

- Sample Questions Paper 2 - TNQT Digital-4July19Document6 paginiSample Questions Paper 2 - TNQT Digital-4July19Gudimetla KowshikÎncă nu există evaluări

- Atomic Structure ActivityDocument4 paginiAtomic Structure ActivityClarisse BonaobraÎncă nu există evaluări

- 10 - Chapter 4 PDFDocument143 pagini10 - Chapter 4 PDFKalyan ChakravarthyÎncă nu există evaluări

- Programming in C - CPU Scheduling - Round RobinDocument3 paginiProgramming in C - CPU Scheduling - Round RobinGenus SumÎncă nu există evaluări

- FAR21x7 28x7 Operator's Manual P 4-8-11Document312 paginiFAR21x7 28x7 Operator's Manual P 4-8-11Miguel PerezÎncă nu există evaluări

- Change ManDocument17 paginiChange Mansrikanth9gannuÎncă nu există evaluări

- CAD-based Design of Three Phase Transformer and CoDocument13 paginiCAD-based Design of Three Phase Transformer and CoM4gne7icÎncă nu există evaluări

- Market Manipulation Rules and IPO Underpricing: Huu - Duong@monash - EduDocument54 paginiMarket Manipulation Rules and IPO Underpricing: Huu - Duong@monash - EduTI Logic ?? sobayedÎncă nu există evaluări

- UK Assemblies PDFDocument284 paginiUK Assemblies PDFFernando Borges ChachaÎncă nu există evaluări

- Punching Shear PDFDocument13 paginiPunching Shear PDFmohamedadel100Încă nu există evaluări

- Recent Developments On The Interpretation of Dissolved Gas Analysis in TransformersDocument33 paginiRecent Developments On The Interpretation of Dissolved Gas Analysis in TransformersputrasejahtraÎncă nu există evaluări

- 2210 w18 Ms 12Document12 pagini2210 w18 Ms 12Fiyazul HaqueÎncă nu există evaluări