Documente Academic

Documente Profesional

Documente Cultură

RMA-223 User Guide

Încărcat de

marc_2ice@yahoo.comTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RMA-223 User Guide

Încărcat de

marc_2ice@yahoo.comDrepturi de autor:

Formate disponibile

500 Main Street, Suite 18

PO Box 989

Deep River, CT 06417 USA

RMA-223, Rosin Mildly Active Solder Paste

Toll Free: 800.435.0317

Phone: 860.526.8300

Fax: 860.526.8243

www.amtechsolder.com

Product Data Sheet

Product Highlights

n ROL0 flux classification

n Exceptional print definition

n Excellent wetting on most board finishes

n Low voiding

n Long stencil life

n Wide process window

n REACH compliant

n Compatible with enclosed print heads

n Print & dispense grade solder paste available

Available Alloys

Alloy

63Sn/37Pb

62Sn/36Pb/2Ag

62.8Sn/36.8Pb/0.4Ag

60Sn/40Pb

43Sn/43Pb/14Bi

42Sn/58Bi

10Sn/88Pb/2Ag

Temp C

Temp F

183 361

179 354

179-183 354-361

183-191 361-376

144-163 291-325

138 280

268-290 514-554

Packaging

500 gram jars

700 gram cartridges

35 or 100 gram syringes

ProFlow cassettes

Test Results

Test J-STD-004 or

Test Requirement

other requirements (as stated)

Copper Mirror

IPC-TM-650: 2.3.32

Corrosion

IPC-TM-650: 2.6.15

Quantitative Halides

IPC-TM-650: 2.3.28.1

Electrochemical Migration

IPC-TM-650: 2.6.14.1

IPC-TM-650: 2.6.3.7

Surface Insulation Resistance 85 oC,

85% RH @ 168 Hours

Tack Value

IPC-TM-650: 2.4.44

o

Viscosity - Malcom @ 10 RPM/25 C

IPC-TM-650: 2.4.34.4

(x103mPa/s)- Sn63/Pb37 T3/T4

Visual

IPC-TM-650: 3.4.2.5

Conflict Minerals Compliance

Electronic Industry Citizenship Coalition (EICC)

REACH Compliance

Articles 33 and 67 of Regulation

(EC) No 1907/2006

Result

L: No breakthrough

L: No Corrosion

L: <0.5%

L: <1 decade drop

(No-cleaned)

L: 100 M (No Clean)

48g

Print: 200-275

Dispensing: 110-150

Clear and free

from precipitation

Compliant

Contains no substance

>0.1% w/w that is listed

as a SVHC or restricted

for use in solder materials

RMA-223, Rosin Mildly Active Solder Paste

Printer Operation

The following are general guidelines for stencil printer

optimization with RMA-223. Some adjustments may be

necessary based on your process requirements.

Print Speed: 25-100 mm/sec

Squeegee Pressure: 70-250g/cm of blade

Under Stencil Wipe: Once every 10-25 prints,

or as necessary

Stencil Life

> 8 hours @ 30-45% RH and 20-25 oC

~ 4 hours @ 45-75% RH and 20-25 oC

Cleaning

RMA-223 is a Rosin Mildly Active solder paste that can

be left on the board for many SMT assemblies. For

applications requiring cleaning, RMA-223 can be cleaned

using commercially available flux residue removers such

as Kyzen Aquanox A4241, A4520, A4625 and A4625B

(Batch Cleaners). Kyzen brand cleaners are available

from Amtech.

Amtech Low Oxide Powder Distribution

Micron Size

45-75

25-45

20-38

15-25

5-15

2-11

Type

Type-2

Type-3

Type-4

Type-5

Type-6

Type-7

Pitch Requirements

24 mil and above

16-24 mil

12-16 mil

8-12 mil

5-8 mil

< 5 mil

Note: Type-6 and Type-7 may not be available in certain alloys.

Other powder distributions are available on request.

Storage

Solder paste should be stored between 3-8 oC

(37-46 oF) to obtain the maximum refrigerated shelf life

of six months. Unopened solder paste stored at room

temperature, 25 oC (77 oF) will have a one month shelf

life. Syringes and cartridges should be stored vertically

in the refrigerator with the dispensing tip down. Allow

4-8 hours for solder paste to reach an operating

temperature of 20-25 oC (68-77 oF). Keep the solder

paste container sealed while warming the solder paste

to operating temperature.

NEVER FREEZE SOLDER PASTE.

Recommended Profile

This profile is designed to serve

as a starting point for process

optimization using RMA-223. To

achieve better results with voiding

or to reduce tombstoning, consider

using a longer soaking zone,

(140-180 oC) for 60-90 seconds,

with a rapid pre-heat stage.

If there is evidence of solder

de-wetting, consider lowering the

peak reflow temperature, or reduce

the time above liquidus to <60

seconds.

AMTECH Part Numbers

RMA-223 63Sn/37Pb, Type 3, 500 gram jar: Part Number: 15480

RMA-223 63Sn/37Pb, Type 4, 500 gram jar: Part Number: 15510

RMA-223 63Sn/37Pb, Type 3, 700 gram cartridge: Part Number: 15490

RMA-223 63Sn/37Pb, Type 4, 700 gram cartridge: Part Number: 15511

RMA-223 63Sn/37Pb, Type 3, 35 gram syringe: Part Number: 15430

Other alloy and packaging combinations available upon request.

Revised 2/3/2014

S-ar putea să vă placă și

- NC-559-ASM Rev 0510Document2 paginiNC-559-ASM Rev 0510electrosysro8560Încă nu există evaluări

- Amtech - RMA-223 Rev 0510Document2 paginiAmtech - RMA-223 Rev 0510Mohammed AbbariÎncă nu există evaluări

- Soldering electronic circuits: Beginner's guideDe la EverandSoldering electronic circuits: Beginner's guideEvaluare: 4.5 din 5 stele4.5/5 (9)

- Rma 223Document2 paginiRma 223Sergio ChicÎncă nu există evaluări

- Solder Paste SC 170: Physical PropertiesDocument2 paginiSolder Paste SC 170: Physical PropertiesluismcmcÎncă nu există evaluări

- MS 01 91Document6 paginiMS 01 91RritalLÎncă nu există evaluări

- Full CatalogDocument26 paginiFull Catalogbiowan250901Încă nu există evaluări

- Gasket Catalog SEPCODocument12 paginiGasket Catalog SEPCOJaime Lozano GonzálezÎncă nu există evaluări

- Amtech: LF-4300 Lead-Free Water Washable No-Clean Solder PasteDocument2 paginiAmtech: LF-4300 Lead-Free Water Washable No-Clean Solder PastebehzadÎncă nu există evaluări

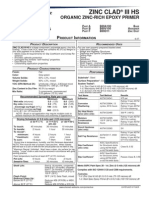

- Zinc Clad IIIDocument4 paginiZinc Clad IIIScott Van PeltÎncă nu există evaluări

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 paginiNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinÎncă nu există evaluări

- Om 340Document3 paginiOm 340RÎncă nu există evaluări

- Alpha Om-338 Teknisk DatabladDocument3 paginiAlpha Om-338 Teknisk Databladnormans00Încă nu există evaluări

- Coal Tar PDFDocument4 paginiCoal Tar PDFMohammadreza AsheghÎncă nu există evaluări

- Acrolon 218 HSDocument4 paginiAcrolon 218 HSAndres MoralesÎncă nu există evaluări

- Solder Paste SC Blf03: Lead-FreeDocument2 paginiSolder Paste SC Blf03: Lead-FreeluismcmcÎncă nu există evaluări

- Duraplate Uhs EnglishDocument4 paginiDuraplate Uhs EnglishLuis JaraÎncă nu există evaluări

- Winterizing Section CC Marine Catalogue Pages 1119 To 1138Document20 paginiWinterizing Section CC Marine Catalogue Pages 1119 To 1138GregGGHÎncă nu există evaluări

- Solder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PasteDocument4 paginiSolder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PastebehzadÎncă nu există evaluări

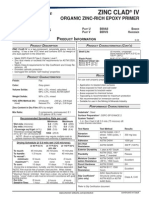

- Zinc Clad IVDocument4 paginiZinc Clad IVvitrolaÎncă nu există evaluări

- Oilfield Hoses Fittings AccembliesDocument29 paginiOilfield Hoses Fittings Accembliesthapa786mÎncă nu există evaluări

- Material Data Sheet NC 259 Sn100c Solder Paste Rev 1Document3 paginiMaterial Data Sheet NC 259 Sn100c Solder Paste Rev 1vkmsÎncă nu există evaluări

- Oli Energol GR-XPDocument2 paginiOli Energol GR-XPakun leptopÎncă nu există evaluări

- 7001 - E-Notes On Injection MouldingDocument8 pagini7001 - E-Notes On Injection MouldingStåle EliassenÎncă nu există evaluări

- R276 Global (03oct07)Document2 paginiR276 Global (03oct07)Dave GershawÎncă nu există evaluări

- Qa Lab Inventory 2Document19 paginiQa Lab Inventory 2John P. BandoquilloÎncă nu există evaluări

- Pigging Valves PDFDocument8 paginiPigging Valves PDFmarkobilo100% (1)

- Carboguard 890 PDSDocument2 paginiCarboguard 890 PDSLinnie McleodÎncă nu există evaluări

- 7) PPG Amercoat 385 - Pds - AiDocument4 pagini7) PPG Amercoat 385 - Pds - AididbeauÎncă nu există evaluări

- Dura-Plate UHS Epoxy - JSP PDFDocument4 paginiDura-Plate UHS Epoxy - JSP PDFNageswara Rao BavisettyÎncă nu există evaluări

- Corning Glass CatalogDocument76 paginiCorning Glass CataloggersonÎncă nu există evaluări

- Spatter Guard Resistant Tubing Without A Jacket!Document2 paginiSpatter Guard Resistant Tubing Without A Jacket!Emma MartinÎncă nu există evaluări

- Amercoat 370Document3 paginiAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Rexam Closures Beverage BrochureDocument2 paginiRexam Closures Beverage BrochurederdorÎncă nu există evaluări

- K267 - PDS - en - GBDocument2 paginiK267 - PDS - en - GBJennifer BradleyÎncă nu există evaluări

- Carbozinc 11 PDS-MarineDocument2 paginiCarbozinc 11 PDS-MarineJulie WillisÎncă nu există evaluări

- UOP77Document8 paginiUOP77arnautdusan100% (1)

- Kester NP545 Solder Paste Lead Free en 20oct21 TBDocument5 paginiKester NP545 Solder Paste Lead Free en 20oct21 TBthang.tranÎncă nu există evaluări

- Carbomastic 15 PDS 2013Document2 paginiCarbomastic 15 PDS 20134508366279Încă nu există evaluări

- Dip Viscosity Cups, Zahn Type: Assembly & Operating InstructionsDocument2 paginiDip Viscosity Cups, Zahn Type: Assembly & Operating InstructionsSayed WaqasÎncă nu există evaluări

- Castseal Tech DatasheetDocument1 paginăCastseal Tech DatasheetChandra SekarÎncă nu există evaluări

- TEADIT CamprofileDocument4 paginiTEADIT CamprofileMichael SandersÎncă nu există evaluări

- Roberts Oxygen Welding Industrial Catalog 2011Document104 paginiRoberts Oxygen Welding Industrial Catalog 2011sanjibkrjanaÎncă nu există evaluări

- Aht Fold Eiscreme en WebDocument10 paginiAht Fold Eiscreme en WebRadu VladÎncă nu există evaluări

- Mecanic AsDocument6 paginiMecanic AsAnderson SantosÎncă nu există evaluări

- Glass Ware BrochureDocument40 paginiGlass Ware BrochureckkimbleÎncă nu există evaluări

- Compression PackingsDocument28 paginiCompression PackingsRupanathan RagupathiÎncă nu există evaluări

- 0400GF Amerlock 400 GF PDSMay 08Document2 pagini0400GF Amerlock 400 GF PDSMay 08amadan64Încă nu există evaluări

- Solder Paste LiteratureDocument1 paginăSolder Paste LiteraturescmeswarÎncă nu există evaluări

- K C Mouldings CatalogueDocument90 paginiK C Mouldings CatalogueTomas Cruz0% (1)

- Carboguard 891: Selection & Specification DataDocument4 paginiCarboguard 891: Selection & Specification DataPrakashÎncă nu există evaluări

- KCC DATASHEET Galvany Shopprimer IZ182 (J) (IMO) (Two-Component) EngDocument3 paginiKCC DATASHEET Galvany Shopprimer IZ182 (J) (IMO) (Two-Component) EngIsabelo AbaoÎncă nu există evaluări

- Res Q SteelDocument4 paginiRes Q SteelTrịnh Minh KhoaÎncă nu există evaluări

- OVN 04 Digital ViscometerDocument5 paginiOVN 04 Digital Viscometersatya_chagantiÎncă nu există evaluări

- Cold Mounting EnglishpdfDocument6 paginiCold Mounting EnglishpdfJorge BonillaÎncă nu există evaluări

- Carboguard 89dfsfs0 PDSDocument2 paginiCarboguard 89dfsfs0 PDSMayur PatelÎncă nu există evaluări

- Carbo Guard 893 SGDocument2 paginiCarbo Guard 893 SGsuzilamatsallehÎncă nu există evaluări

- Regulation 48Document116 paginiRegulation 48marc_2ice@yahoo.comÎncă nu există evaluări

- Iec 60810 - SauDocument36 paginiIec 60810 - Saumarc_2ice@yahoo.comÎncă nu există evaluări

- H11F3MDocument11 paginiH11F3Mmarc_2ice@yahoo.comÎncă nu există evaluări

- Samsung Bn44 00214aDocument2 paginiSamsung Bn44 00214aMarco Dei Bi Aiv0% (2)

- Engineering Statistics HandbookDocument2.333 paginiEngineering Statistics Handbookngpham100% (2)

- Weibull Analysis Using R, in A NutshellDocument7 paginiWeibull Analysis Using R, in A Nutshellmarc_2ice@yahoo.comÎncă nu există evaluări

- Fitting Distributions With RDocument24 paginiFitting Distributions With RJazmín GarcíaÎncă nu există evaluări

- Lq800 TFT SMDocument34 paginiLq800 TFT SMmarc_2ice@yahoo.comÎncă nu există evaluări

- Perfect PastaDocument3 paginiPerfect Pastamarc_2ice@yahoo.comÎncă nu există evaluări

- Fitting Distributions With RDocument24 paginiFitting Distributions With RJazmín GarcíaÎncă nu există evaluări

- Scheme HP Compaq Cq61 Quanta Op8Document40 paginiScheme HP Compaq Cq61 Quanta Op8Alija SirotanovićÎncă nu există evaluări

- Intro To PneumaticsDocument30 paginiIntro To PneumaticskabirbÎncă nu există evaluări

- Indesit Wt100csiDocument48 paginiIndesit Wt100csimarc_2ice@yahoo.comÎncă nu există evaluări

- A Novel and Cleaner Technological Process of Extracting L-Glutamic Acid From PDFDocument8 paginiA Novel and Cleaner Technological Process of Extracting L-Glutamic Acid From PDFGooi Ming YanÎncă nu există evaluări

- EWC 333 Introduction To Wastewater EngineeringDocument24 paginiEWC 333 Introduction To Wastewater EngineeringAzgar AliÎncă nu există evaluări

- 03Document1 pagină03Popoaia MarianÎncă nu există evaluări

- Optimization Studies in Sulfuric Acid Production: 1. AbstractDocument6 paginiOptimization Studies in Sulfuric Acid Production: 1. Abstractdiegotorete1994Încă nu există evaluări

- Kitchen Improvised, Complete (Blasting Caps, 2, Same As BeforeDocument79 paginiKitchen Improvised, Complete (Blasting Caps, 2, Same As BeforeAsad Imran90% (10)

- Platinum Alloys For Shape Memory ApplicationsDocument15 paginiPlatinum Alloys For Shape Memory ApplicationsKursalÎncă nu există evaluări

- Valence Bond Theory Sm21Document7 paginiValence Bond Theory Sm21But Nobody CameÎncă nu există evaluări

- Physical and Chemical Change Virtual Lab ST Lesson Santellano Victoria ADocument3 paginiPhysical and Chemical Change Virtual Lab ST Lesson Santellano Victoria Aapi-255434272Încă nu există evaluări

- Astm 4590Document3 paginiAstm 4590Gyna SH67% (3)

- A Gas Plant 1Document2 paginiA Gas Plant 1eng20072007Încă nu există evaluări

- CLS Aipmt 19 20 XII Che Study Package 6 Level 2 Chapter 15Document14 paginiCLS Aipmt 19 20 XII Che Study Package 6 Level 2 Chapter 15Himanshu ChhikaraÎncă nu există evaluări

- Noble GasesDocument3 paginiNoble GasessadasdÎncă nu există evaluări

- IncinerationDocument30 paginiIncinerationOMSAIRAMAÎncă nu există evaluări

- Unit Test-1 - Chemical Basis of LifeDocument9 paginiUnit Test-1 - Chemical Basis of LifeMighty Warrior GSRÎncă nu există evaluări

- A286 (Ficha Tecnica)Document3 paginiA286 (Ficha Tecnica)Alex Zambrana RodríguezÎncă nu există evaluări

- Super Coolant AF-NAC - 50522Document6 paginiSuper Coolant AF-NAC - 50522Noviandra Sallasa0% (1)

- Chemical Technology Self Study Topic: Polyvinyl Chloride (PVC)Document11 paginiChemical Technology Self Study Topic: Polyvinyl Chloride (PVC)Paridhi GargÎncă nu există evaluări

- Topic 4.1 E.SDocument2 paginiTopic 4.1 E.SPrecious GalanÎncă nu există evaluări

- BIODEDocument17 paginiBIODEBayikati PavaniÎncă nu există evaluări

- 100 Passage Based Chemistry Questions SolutionsDocument17 pagini100 Passage Based Chemistry Questions SolutionsChemistry courseÎncă nu există evaluări

- Chemistry Practical Basics, Calibration, Titration and StanderdisationDocument22 paginiChemistry Practical Basics, Calibration, Titration and StanderdisationPritam SarkarÎncă nu există evaluări

- Anodised AluminumDocument12 paginiAnodised AluminumDEVIKA PHULEÎncă nu există evaluări

- 2.2 Boilers - Revised (Table Format)Document11 pagini2.2 Boilers - Revised (Table Format)Gajanan JagtapÎncă nu există evaluări

- Chlor Alkali BrochureDocument4 paginiChlor Alkali BrochureMojtabaÎncă nu există evaluări

- Experiment-2 ChemistryDocument2 paginiExperiment-2 Chemistryanshsoni1101Încă nu există evaluări

- TN 25Document8 paginiTN 25paulo_linanÎncă nu există evaluări

- Banyur16: Exxonmobil Refining and Supply CompanyDocument4 paginiBanyur16: Exxonmobil Refining and Supply CompanyrudiandriesÎncă nu există evaluări

- Project Report On Latex Based Rubber Adhesives With Process and FormulaeDocument6 paginiProject Report On Latex Based Rubber Adhesives With Process and FormulaeEIRI Board of Consultants and PublishersÎncă nu există evaluări

- 13.periodic Table and Periodicity ExerciseDocument23 pagini13.periodic Table and Periodicity Exerciseabdimoh7522Încă nu există evaluări

- Ullmann's Enc. of Industrial ChemistryDocument72 paginiUllmann's Enc. of Industrial ChemistrySlim Toumi50% (2)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDe la EverandArizona, Utah & New Mexico: A Guide to the State & National ParksEvaluare: 4 din 5 stele4/5 (1)

- The Bahamas a Taste of the Islands ExcerptDe la EverandThe Bahamas a Taste of the Islands ExcerptEvaluare: 4 din 5 stele4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoDe la EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoEvaluare: 5 din 5 stele5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptDe la EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptEvaluare: 5 din 5 stele5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensDe la EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensÎncă nu există evaluări

- New York & New Jersey: A Guide to the State & National ParksDe la EverandNew York & New Jersey: A Guide to the State & National ParksÎncă nu există evaluări