Documente Academic

Documente Profesional

Documente Cultură

Productivity

Încărcat de

GS Shawon0 evaluări0% au considerat acest document util (0 voturi)

90 vizualizări2 paginifull describtion

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentfull describtion

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

90 vizualizări2 paginiProductivity

Încărcat de

GS Shawonfull describtion

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

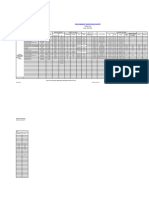

Problem of productivity

1. An IPS manufacturing company changes production system from present

system to new system. With present system, the company uses 25 workers,

who can produce on an average 30 and 25 IPS per day of type-1 and type-2

respectively, but on an average 20% manufactured IPS are rejected. Each

worker receives Tk.5000 per month and tools and equipment cost (i.e.,

machine cost for the first system) was Tk.6000 per day. With the new system

the company can produce 50 and 30 IPS per day of type-1 and type-2

respectively. The machine of the new system costs 60 million taka and the

operation life of the machine is 10 years. Five operators are required to

operate the new machine. Wage of each of the operator is Tk.15000 per

month. Price of the type-1 and type-2 IPS is Tk.18000 and Tk.25000 per unit

respectively. Part/material cost is 50% and 60% of the price of type-1 and

type-2 respectively. Consider 25 working days in a month.

a. Compute labor and machine productivity under each system.

b. Compute the overall productivity under each system.

c. Explain what the main factor of this productivity is.

2. BRB cables manufacturing company produces two types of cables from same

raw materials; wire and plastic resins. To produce one meter first type cable

200 gm resin and 0.5 kg wire are required. Whereas, 250 gm resin and 0.8 kg

wire are required to produce one meter of the second type cable. Cost of

resin and wire is Tk.60/Kg and Tk.100/Kg respectively. The company can

produce 75000 meter first type and 50000 meter second type cable per

month by using 200 labors. Each labor receives Tk.400 per day, and

overhead cost is 2 million taka per month. To set up the machine

Tk.60000000 is invested on it. Life of the machine is 10 years. Price of the

first and second type cable is Tk.200/meter and Tk.250/meter respectively.

Consider 25 working days make a month.

a) Compute labor, material, machine, overhead and multi factor

productivity.

b) If production time for every meter of second type cable is double to

that of first type cable then compute overall productivity of 1 st and

2nd type of the cables.

3. A company produces two types of measuring devices. Price of per unit of

the 1st and 2nd type of the device is $10 and & $12 respectively. Material

cost to produce the devices is 40% of their prices. The company used ten

workers, who can produce an average of 30 and 50 devices of 1 st and 2nd

types per day. Workers receive $10 per day and machine and overhead

cost is $120 and $100 per day respectively.

a. Compute labor, material, machine and overhead productivity.

b. Compute the overall productivity.

c. If production time of each 2nd type device is 25% more than that of 1st

type then compute overall productivity of 1 st and 2nd types of the

product.

S-ar putea să vă placă și

- Problem of ProductivityDocument1 paginăProblem of ProductivityFaysal Ahmed0% (1)

- Or PracticeProblems 2015Document24 paginiOr PracticeProblems 2015Hi HuÎncă nu există evaluări

- OR Question BankDocument29 paginiOR Question BankSuhas Mv50% (4)

- 2014 Bep Analysis ExercisesDocument5 pagini2014 Bep Analysis ExercisesaimeeÎncă nu există evaluări

- Group 7 Homework Chap1 Introduction of POMDocument6 paginiGroup 7 Homework Chap1 Introduction of POMLâm NguyễnÎncă nu există evaluări

- Solving Linear ProblemasDocument27 paginiSolving Linear ProblemasLinita MariaÎncă nu există evaluări

- Solution 77Document10 paginiSolution 77karthu48100% (1)

- LP Formulation ExercisesDocument10 paginiLP Formulation ExercisesLakshay NagpalÎncă nu există evaluări

- Quiz II SCM AnsDocument3 paginiQuiz II SCM AnsCostina Luc0% (1)

- Assignment 2Document3 paginiAssignment 2Sodhani AnkurÎncă nu există evaluări

- Chapter 3 Resource PlanningDocument70 paginiChapter 3 Resource PlanningHieu TruongÎncă nu există evaluări

- Homework/Assignment: Full Name of Submitter: Vo Thi Thien My Student ID: IEIEIU18057Document7 paginiHomework/Assignment: Full Name of Submitter: Vo Thi Thien My Student ID: IEIEIU18057Trân LêÎncă nu există evaluări

- 68957Document9 pagini68957Mehar WaliaÎncă nu există evaluări

- Online Mid-Term POM May-Aug 2020 G-6Document5 paginiOnline Mid-Term POM May-Aug 2020 G-6Hossain TanjilaÎncă nu există evaluări

- (Quantitative Analysis) Linear ProgrammingDocument2 pagini(Quantitative Analysis) Linear ProgrammingKiran BasuÎncă nu există evaluări

- Case Study 5Document5 paginiCase Study 5Mary Apple D. Cirpo100% (1)

- Midterm Exam 522Document5 paginiMidterm Exam 522Ghulam AliÎncă nu există evaluări

- Management Accounting Practice QuestionsDocument6 paginiManagement Accounting Practice QuestionsSayantan NandyÎncă nu există evaluări

- Practice Problems Set 4 InstructionsDocument2 paginiPractice Problems Set 4 InstructionsJoli SmithÎncă nu există evaluări

- Quiz 2Document6 paginiQuiz 2Mukund AgarwalÎncă nu există evaluări

- ADM3346 Assignment 2 Fall 2019 Revised With Typos CorrectdDocument3 paginiADM3346 Assignment 2 Fall 2019 Revised With Typos CorrectdSam FishÎncă nu există evaluări

- Pom Review QaDocument38 paginiPom Review QaShijaAbihudKabola100% (1)

- Assignment 2Document4 paginiAssignment 2Noor KhanÎncă nu există evaluări

- Comm 225: Pom, Winter 2012 - Review Questions,: Topic: Statistical Process ControlDocument4 paginiComm 225: Pom, Winter 2012 - Review Questions,: Topic: Statistical Process ControlWayli90Încă nu există evaluări

- Managerial Accounting - Ch.1Document2 paginiManagerial Accounting - Ch.1Ammar HussainÎncă nu există evaluări

- Taguchi'S Quality Loss FunctionDocument17 paginiTaguchi'S Quality Loss FunctionAvi Barua100% (1)

- CVP Question 6Document1 paginăCVP Question 6Humphrey OsaigbeÎncă nu există evaluări

- Chapter 3 - Linear Programming: Computer Solution and Sensitivity AnalysisDocument9 paginiChapter 3 - Linear Programming: Computer Solution and Sensitivity AnalysisRel XandrrÎncă nu există evaluări

- DM Mid TermDocument102 paginiDM Mid TermSourya MitraÎncă nu există evaluări

- PDF QT Practice SetDocument13 paginiPDF QT Practice Setpankaj5470100% (1)

- Inoper2 q2Document9 paginiInoper2 q2api-353305207100% (1)

- Forecast HW QsDocument3 paginiForecast HW QsSamuelPark0% (2)

- MA Tutorial 2Document6 paginiMA Tutorial 2Jia WenÎncă nu există evaluări

- Homework 2Document3 paginiHomework 2Tú QuyênÎncă nu există evaluări

- ManAcc Quiz 2Document13 paginiManAcc Quiz 2Deepannita ChakrabortyÎncă nu există evaluări

- Operation Research HWDocument5 paginiOperation Research HWMuhammad Raditya RahagiÎncă nu există evaluări

- Mms AssignDocument3 paginiMms AssigndarekarroshanÎncă nu există evaluări

- New Microsoft Office Word DocumentDocument5 paginiNew Microsoft Office Word DocumentTariq RahimÎncă nu există evaluări

- A Capacity Planning Assignment 2016 Bassam Senior Modified SolutionDocument10 paginiA Capacity Planning Assignment 2016 Bassam Senior Modified SolutionAhmad Ayman FaroukÎncă nu există evaluări

- CH - 12 LPPDocument4 paginiCH - 12 LPPAyush Prashar100% (1)

- 10 Case StudiesDocument5 pagini10 Case Studieschacha_420Încă nu există evaluări

- Solution Problem 1 Problems Handouts MicroDocument25 paginiSolution Problem 1 Problems Handouts MicrokokokoÎncă nu există evaluări

- Capacity Planning ProblemsDocument6 paginiCapacity Planning Problemsvita sarasi100% (1)

- BudgetsDocument4 paginiBudgetsRohit BiyalaÎncă nu există evaluări

- Mba PracticalsDocument7 paginiMba PracticalsRohit SinghÎncă nu există evaluări

- HW2 2015Document1 paginăHW2 2015Prashanth BhaskaranÎncă nu există evaluări

- Costing Prob FinalsDocument52 paginiCosting Prob FinalsSiddhesh Khade100% (1)

- Cost Accounting AssignmentDocument3 paginiCost Accounting AssignmentMkaeDizonÎncă nu există evaluări

- Logistics - Section - 02 - Locating - Facility - Soan - Nhi Anh - Sao ChépDocument53 paginiLogistics - Section - 02 - Locating - Facility - Soan - Nhi Anh - Sao ChépLan PhanÎncă nu există evaluări

- Marginal Costing Numericals PDFDocument7 paginiMarginal Costing Numericals PDFSubham PalÎncă nu există evaluări

- Cost II AssignmentDocument4 paginiCost II AssignmentmeazadgafuÎncă nu există evaluări

- FALL2019 ECON2113 HomeworkDocument9 paginiFALL2019 ECON2113 HomeworkNamanÎncă nu există evaluări

- Budget Test - 5Document3 paginiBudget Test - 5Winidzai NyamukuseÎncă nu există evaluări

- Test 1 PDFDocument7 paginiTest 1 PDFMallory Ennis0% (1)

- Worksheet 2 - CapacityDocument2 paginiWorksheet 2 - Capacitylaxmi joshiÎncă nu există evaluări

- Quantitative Analysis of Flexible Manufacturing SystemDocument9 paginiQuantitative Analysis of Flexible Manufacturing SystemJaydeep PatelÎncă nu există evaluări

- Short Term Decision Making 2Document8 paginiShort Term Decision Making 2Pui YanÎncă nu există evaluări

- Home Assignment - RevisedDocument4 paginiHome Assignment - RevisedLê Quỳnh Anh100% (1)

- Problem of Productivity - UpdatedDocument2 paginiProblem of Productivity - UpdatedMoumita AhmedÎncă nu există evaluări

- Lab ManualDocument51 paginiLab ManualGS ShawonÎncă nu există evaluări

- MLG 4Document20 paginiMLG 4GS ShawonÎncă nu există evaluări

- Wireless Broadband Services:: Emerging Technology Solutions and Business ModelsDocument16 paginiWireless Broadband Services:: Emerging Technology Solutions and Business ModelsGS ShawonÎncă nu există evaluări

- A Project On Solar Home System: Submitted By: Md. Masudur RahmanDocument13 paginiA Project On Solar Home System: Submitted By: Md. Masudur RahmanGS ShawonÎncă nu există evaluări

- Group Members: 1.golam Sharwoar Shawon 2.shamim Hasan Niloy 3.mahadi Hasan Taheri 4.Md. Kamrul Islam 5.Md. Sohel RanaDocument24 paginiGroup Members: 1.golam Sharwoar Shawon 2.shamim Hasan Niloy 3.mahadi Hasan Taheri 4.Md. Kamrul Islam 5.Md. Sohel RanaGS ShawonÎncă nu există evaluări

- Golam Mostafa 70, North Senteral Road, Dhanmondi, Dhaka Mobil Number: 01551817277 (Fax)Document2 paginiGolam Mostafa 70, North Senteral Road, Dhanmondi, Dhaka Mobil Number: 01551817277 (Fax)GS ShawonÎncă nu există evaluări

- Welcome To My PresentationDocument22 paginiWelcome To My PresentationGS ShawonÎncă nu există evaluări

- CaseDocument2 paginiCaseGS ShawonÎncă nu există evaluări

- Cisco B200M4 - Compatability MatrixDocument73 paginiCisco B200M4 - Compatability MatrixmmihmÎncă nu există evaluări

- A Line Follower Robot-ICCAE 2010Document6 paginiA Line Follower Robot-ICCAE 2010Ioan DorofteiÎncă nu există evaluări

- WS500 Getting Started PDFDocument23 paginiWS500 Getting Started PDFkhalid100% (1)

- A 5 CM Diameter Sphere Solidifies in 1050 S. Calcu...Document3 paginiA 5 CM Diameter Sphere Solidifies in 1050 S. Calcu...huzaifa mustafaÎncă nu există evaluări

- Xtrapower Nigeria Inverter and Battery 2021 U.S.E. Price - Feb-1Document3 paginiXtrapower Nigeria Inverter and Battery 2021 U.S.E. Price - Feb-1Iyaka JamesÎncă nu există evaluări

- Valuation: Philippine Residential Broadband MarketDocument5 paginiValuation: Philippine Residential Broadband MarketNico Angeles MenesesÎncă nu există evaluări

- Icjecapu 09Document7 paginiIcjecapu 09meghanamavuru30Încă nu există evaluări

- 45CMV Series Manual en v1.1Document77 pagini45CMV Series Manual en v1.1Kamran CarayevÎncă nu există evaluări

- Advanced Database Management System Course Code: 3340701Document5 paginiAdvanced Database Management System Course Code: 3340701Madhav KotechaÎncă nu există evaluări

- 1990 Volvo 740 Wiring DiagramsDocument14 pagini1990 Volvo 740 Wiring DiagramsDavid Cooley67% (3)

- 441 1105 1 PBDocument6 pagini441 1105 1 PBblackraidenÎncă nu există evaluări

- MAcro ResumeDocument5 paginiMAcro ResumehumayunÎncă nu există evaluări

- PCP - VersionDocument33 paginiPCP - VersionKiran JoshiÎncă nu există evaluări

- Flyback Using Microcontroller AN2122 MicrochipDocument70 paginiFlyback Using Microcontroller AN2122 MicrochipCarlos Zevallos100% (1)

- En Rhel Deploy Oracle Rac Database 12c Rhel 7Document50 paginiEn Rhel Deploy Oracle Rac Database 12c Rhel 7Alessandro SilveiraÎncă nu există evaluări

- Agnes CVDocument3 paginiAgnes CVMaziwa ProÎncă nu există evaluări

- Network Lab MCQDocument7 paginiNetwork Lab MCQ5006 AbineshÎncă nu există evaluări

- Manual Hand Drill: Mini - Project - CADDocument34 paginiManual Hand Drill: Mini - Project - CADKengsuen KhooÎncă nu există evaluări

- 7 Reasons Why Tesla Has Succeeded Where Others Have FailedDocument3 pagini7 Reasons Why Tesla Has Succeeded Where Others Have FailedPuri PuspitaÎncă nu există evaluări

- Denon Home Theater Sys 5 1 Avr x500Document2 paginiDenon Home Theater Sys 5 1 Avr x500D_D_76Încă nu există evaluări

- Computer Integrated ManufacturingDocument51 paginiComputer Integrated Manufacturingkasateesh67% (3)

- Get Current Location Address For Android App - Stack Overflow PDFDocument5 paginiGet Current Location Address For Android App - Stack Overflow PDFShoaib QuraishiÎncă nu există evaluări

- Value Engineering - Prof. Emad ShublaqDocument52 paginiValue Engineering - Prof. Emad Shublaqmalikasal100% (1)

- Utilization of Aerial Drone Technology in LogisticsDocument12 paginiUtilization of Aerial Drone Technology in LogisticsaxyyÎncă nu există evaluări

- Home Automation Using Android And: Raspberry Pi (Literature Review)Document11 paginiHome Automation Using Android And: Raspberry Pi (Literature Review)Shubham TogargeÎncă nu există evaluări

- Procurement Monitoring Report JuneDocument2 paginiProcurement Monitoring Report JuneKaJong JaclaÎncă nu există evaluări

- Design For Test by Alfred L CrouchDocument117 paginiDesign For Test by Alfred L CrouchEdwin Singh100% (1)

- PAM-1, PAM-2, and PAM-4: Multi-Voltage Relay ModulesDocument2 paginiPAM-1, PAM-2, and PAM-4: Multi-Voltage Relay Modulestrinadh pillaÎncă nu există evaluări

- JETPRO DM-wind (English Small)Document2 paginiJETPRO DM-wind (English Small)Royal Kasepuhan IndonesiaÎncă nu există evaluări

- Zepto Product Teardown - Likhita ParasuDocument6 paginiZepto Product Teardown - Likhita ParasuVikas DeshmaneÎncă nu există evaluări