Documente Academic

Documente Profesional

Documente Cultură

AC To DC Converter For Low Voltage Small Scale Generator

Încărcat de

IOSRjournalTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

AC To DC Converter For Low Voltage Small Scale Generator

Încărcat de

IOSRjournalDrepturi de autor:

Formate disponibile

IOSR Journal of Electronics and Communication Engineering (IOSR-JECE)

e-ISSN: 2278-2834,p- ISSN: 2278-8735.Volume 10, Issue 5, Ver. I (Sep - Oct .2015), PP 125-133

www.iosrjournals.org

AC to DC Converter for Low Voltage Small Scale Generator

Md. Mujibur Rahman1, Moshfiqul kabir chy.1 Abu Riduan Md Foisal1 and

Abdul Gafur1

1

Electronic and Telecommunications Engineering (ETE), Department, International Islamic University

Chittagong ( IIUC), Bangladesh

Abstract : AC-DC single-stage converters are attractive because of their simplicity. The conventional power

electronics converters used for such application have two stages, a diode bridge rectifier at the front end

followed by a dc-dc boost converter. However, the extremely low output voltage of electromagnetic microgenerator does not allow diode bridge rectification. Even if possible, the losses in the front and diode bridge

make the conventional power electronic interfaces quite inefficient. The proposed single stage converter directly

boosts the micro-generator low ac voltage to usable dc voltage level, and hence, achieves higher efficiency. The

main objective of this study is to minimize the cost, output ripple and minimize use of the dc power sources

which makes converter circuit inefficient in the field of various electronic devices.

Keywords - Small scale generator, energy harvesting, AC to DC Converter, boost converter, pulse wide

modulation (PWM), doublers discontinuous conduction mode (DCM).

I.

Introduction

Energy harvesting is the process which captures energy from different sources, like, radio waves,

traffic induced vibration and so on. Small scale generator or Micro generator is one of the most significant

inventions of our rapidly developed electronic system. It has recently attracted various applications such as

wireless sensor nodes (WSN) including remote environmental monitoring, homeland security, automotive

sensors and biomedical implement etc. [1] [2]. There are different types of micro generator or small scale

generator such as piezoelectric, electromagnetic, and electrostatic. The output voltage of micro generator is ac

type, but almost all the electronic loads require DC voltage for further operation. Power processing system is

another important thing, because micro generator produces very low ac voltage but we need DC voltage for

most of the sensor applications. There are different kinds of power processing systems, but all are not efficient

and cost effective.

Now-a-days, all the portable electronic devices use battery as a power source. Energy harvesting can be

an effective alternative [3]. Some of the studies have designed the power processing circuits, but most of them

are not cost effective. They have used different specific components, such as, polarity detector, comparator, PI

controller, flip-flop, low pass filter, and feedback controller etc.. A few studies have discussed the charge pump

circuit for the boost converter [1]-[8].

The proposed converter presents a dual polarity boost converter as an energy harvesting system. In this

study, Section II presents the background of study, Sections III discusses the proposed converter, mathematical

derivation is presented in Section IV and simulation is presented in section V. A new methodology is proposed

for producing duty cycle which completely depends on power processing circuit of the input voltage.

II.

Background

This paper developed a converter of energy harvesting for the small scale generator or micro generator.

A schematic diagram of micro generator is shown in Fig.1. We find out a method of using voltage multiplier for

the low voltage converter. Furthermore the concept is utilized to design a new converter at low cost.

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

125 | Page

AC to DC Converter for Low Voltage Small Scale Generator

Fig 1: Small scale generator [1].

A. Buck-boost converter

The Buck boost converter (Fig.2) can operate in four modes. Modes (1, 2) are operating for positive

half cycle and Modes (3, 4) for negative half cycle of input sinusoidal voltage [5]. The main advantage of the

buck boost converter is that it works in both cycles and reduces the problem of dual polarity boost converter.

MODE 1: When supply voltage is positive, switch S1will be ON and inductor gets energy through

switch S1.

MODE 2: When switch S1 will be OFF and diode D1 will be forward biased, the stored energy of the

inductor will be delivered to the load. After that, inductor current will decrease to zero.

MODE 3: The buck-boost converter operates in negative half cycle, then the switch will be ON and

inductor preserves the current. The capacitor discharges through the load.

MODE 4: In this mode switch S2 is OFF and diode D2 will be forward biased. Inductor current will be

discharged through the load and capacitor will be charged.

Fig. 2: Buck-boost converter [3].

III.

Proposed Converter

A. Proposed Dual Polarity Boost Converter

The proposed converter separately processes the positive and negative half cycles of the generated

voltage. Diode rectification will be replaced by alternate activation of one of two voltage boost circuits. This is a

form of synchronous rectification which avoids a series connection of separate rectifier and voltage converters.

To limit the step-up ratio, the two circuits will provide half of the output voltage each. The target

output voltage is 4.16V. When the generator voltage is positive, upper half of the output voltage is produced.

Similarly, lower half of the output voltage is generated, when the input voltage is negative. In order to prevent

conduction in the negative polarity boost converter when the generator voltage is positive, it is sufficient to hold

off the MOSFET of the negative polarity converter. This gate voltage of the two converters needs to be

synchronized to the generator voltage. Synchronous rectification has been integrated in the boost converter so as

to avoid series connection of separate rectifier and boost stages. The proposed converter operates the boost

converters in discontinuous conduction mode to avoid turn-on power loss in the MOSFET and reverses recovery

effects in the diode. Several other benefits follow from this choice: relatively small passive components can be

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

126 | Page

AC to DC Converter for Low Voltage Small Scale Generator

added to the output side to manage the device parasitic capacitance etc. Schottky diodes have been used in this

simple example, but synchronously switched MOSFETs could be used instead.

Fig 3: Dual polarity boost converter [2].

B. Startup circuit:

A startup circuit provides dc supply to the controller and gate driver circuit. The node voltage Vdc+

and Vdc- are providing positive and negative DC voltage. Batteries E1 and E2 provide the charge for the

capacitor C1 and C2 through the diode D2 and D3 forward bias and reverse bias respectively. Battery E1 is

charging through the DaR1 and E2 is charging through the DaR2 [2].

Fig 4: Start-up Circuit [2].

C. Voltage doubler

Voltage multipliers are AC-to-DC power conversion devices, comprised of diodes and capacitors that

produces a high potential DC voltage from a lower voltage AC source [9]. Multipliers are made up of multiple

stages. Each stage is comprised of one diode and one capacitor. Two staged multiplier is called voltage doubler.

Voltage doubler consists of two diodes and two capacitors as presented in Fig.5.

Fig: 5 Half wave voltage doublers [4].

During the negative half cycle of AC input voltage (Fig. 5) diode D1 is forward biased and diode D2 is

reverse biased. Therefore, C1 will be charged until the voltage across it becomes equal to the peak value of the

source voltage. During the positive half cycle of AC input voltage, D1 is reverse biased and D2 is forward

biased. Hence C1 (charged to Vs) and C2 will be charged with the sum of series peak voltage, i.e. 2Vs. Hence

doubler circuit passes to the duty voltage (Vduty).

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

127 | Page

AC to DC Converter for Low Voltage Small Scale Generator

IV.

Mathematical derivation

When the input peak voltage V p with frequency is f i , the input power of the circuit is as below[1] :

V p2 D 2

Pi

4 fs L

2

2

0

(1)

sin

2

sin 1

V0

VP

(2)

dt

Here, is close to the unity (Vo>>Vp) and L is the inductor and

2 .

t . Output power of the

Ti

circuit depends on its switching loss and component loss.

Poutput Pin Ploss _ c Psw _ M 1,2

The switching loss can be estimated as:

V p2

Psw _ M 1,2

2TS L

is the switching transistor time.

Total component loss can be calculated by following equation

Ploss _ c Ii2( rms ) .Rind I sw2 ( rms ) .Rds on 4V f I diode( avg )

(3)

(4)

(5)

Where,

I i , I sw and I ( diode ) are input current , switching frequency and diode current respectively.

(a)

(b)

Fig:6 (a) Input current and (b) diode current [1].

The peak of the input current can be defined as:

i p Vi DTS / L

(6)

Where

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

128 | Page

AC to DC Converter for Low Voltage Small Scale Generator

Vi Vp (sin 2 .Ts / Ti )

The rise time of input current is

DTs i p L / Vi

(7)

And the fall time of input current is

d f Ts i p L / (V0 Vi )

(8)

Since the input current has a triangular shape Fig. 7(a), its rms value over a switching cycle can be

derived as [1]:

T

I i2 (rms)

1 s 2

1

I i (t ).dt .i p2 ( D d f )

Ts 0

3

(9)

Using above equation (6), (7), (8) and (9), we can write1 D3Ts2Vi 2

1

I (2rms ) .

.

2

3

L

1 Vi / V0

(10)

The total number of switching cycles in a line cycle can be defined as N = Ts / Ti . Since the converter

is being operated for a high step-up ratio ( Vi / V0 1 ), for a large value of N, the summation can be

approximated as integration over the line cycle. Therefore,

D3Ts2Vp2

2

(11)

I sw

( rms )

6 L2

The switch current and the diode currents can be calculated as :

2

I sw

( rms )

D3Ts2Vp2

(12)

6 L2

And

I diode ( avg )

D 2TsVp2

(13)

4 LV0

Hence, the Capacitor current is Equal to the diode current.

I diode( avg ) I c3 I c 4 .

Hence, T

1

,

fi

where, T=input voltage time

Vc 3

1

2C3

T /2

C3

(14)

dt

And similarly,

T

1

I C 4 dt

2C4 T/2

Output Current across the load resistance is,

(15)

VC 4

I0

VC 3 VC 4

2R

V.

(16)

Simulation and Result

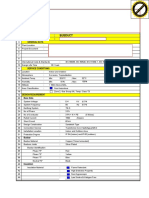

The proposed design is simulated by LTspice software. The converter is shown in Fig. 7. The value of

parameters is given in the table.

The converter operates at a switching frequency of 50 kHz. In practical cases micro generator did not

give the input voltage which is an ideal sinusoid. But here the simulation is done with a pure sinusoidal

waveform [1]. It can be seen that the converter operates in DCM. The input current over a few switching cycles

is along with positive gate signals. The converter operates in DCM to reduce switching losses. It can be seen

that the gate voltage of them-MOSFET (Vgn) is positive when the p-MOSFET gate voltage (Vgp) is negative.

Therefore, both the MOSFET are turned ON at the same instance.

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

129 | Page

AC to DC Converter for Low Voltage Small Scale Generator

Parameter

Value

Switching Frequency

50kHz

Input Voltage

400mV,100Hz

Output Voltage

4.16V

Capacitor(C1 and C2)

1uF

Capacitor(C3 and C4)

4.7uF

Inductor(L)

10uH

Filter capacitor

100uF

Capacitor (C5, C6, C7)

22uF

MOSFET and OPAM

AO6407,AO6408 and LTC6247

Fig 7: Proposed Converter Circuit.

(A)

(B)

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

130 | Page

AC to DC Converter for Low Voltage Small Scale Generator

(C)

Fig 8: (A) Input Voltage (B) Input Current(c). Input Gate Current (Mn) for positive cycle

Fig 9: Sawtooth waveform & Duty cycle.

Fig 10: Doubler circuit output.

Fig 11: PWM waveform for MOSFET.

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

131 | Page

AC to DC Converter for Low Voltage Small Scale Generator

Fig 12: Voltage across capacitor C3 & C4.

Secondary voltages are used for first time triggering gate voltage of the MOSFET. The circuit is

working autonomously. Fig 12 shows the output voltage across the capacitors C3&C4. Each capacitor works as

a charge storage for every half cycle.

Fig 13: Final output voltage

Hence, the output voltage of the converter is 4.16V, duty voltage is 0.613V, steady state time is 150

millisecond, and 70mV is the output voltage ripple.

VI.

Conclusion

In this paper, we have designed a new method for producing duty cycle and minimized the secondary

battery sources for power processing circuit. In most of the previous circuits, duty cycle depends on the battery

of primary stage. But, the proposed circuit removes this disadvantage. The duty cycle of our circuit completely

depends on its input. Another specification of this circuit is that, we can control the duty cycle. For instance, if

we use a silicon diode bridge rectifier then it gives 0.18 duty cycle and Tripler gives 0.9 duty cycle. Our

proposed circuit input power is estimated to be around 30mW. If duty cycle is 0.18 and 0.9 , input power is

estimated 26mW and 65mW respectively. Power consumption of the circuit is 7mW and output power is

23mW.

References

[1]

[2]

[3]

R. Dayal, S. Dwari, and L. Parsa, A New Design for Vibration-Based Electromagnetic Energy Harvesting Systems Using Coil

inductance of Microgenerator, IEEE Trans. Indus. Vol-47,No 2,pp-820-830, March H/Aprile 2011.

A.D.Nath,K.Radhakrishna and Eldhose, Low-Voltage Direct AC-DC Boost

Converter for Micro generator Based Energy

Harvesting, IJAREEIE Vol.2, p.p 2278-8875, March 2013.

V. Vijayan, V.K , A Review of AC-DC Boost Converters for Low Voltage Energy Harvesting, ISSN 2250-2459, ISO 9001:2008

Certified Journal, Volume 4, Issue 6, June 2014.

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

132 | Page

AC to DC Converter for Low Voltage Small Scale Generator

[4]

[5]

[6]

[7]

[8]

[9]

C.L. Yuen, M.H. Lee, W.J. Li, and H.W. Leong. An AA-Sized Vibration-Based Micro generator for Wireless Sensor, Chinese

University of Hong Kong, p.p 1536-1568/07. 2007.

P.D. Mitcheson, T.C. Green and E.M. Yeatman Power Processing Circuits For MEMS Inertial Energy Scavengers, DITP of

MEMS & MOEMS Stresa, Italy, April 2006.

A.D. Joseph, Energy Harvesting Prpject, IEEE Pervasive Computing, Vol.4, pp. 69-71, March-2005.

X. Cao, W.J. Chiang, Y.C. King Electromangnetic Energy Harvesting Circuit With Feedforward and Feedback DC-DC PWM

Boost Converter for Vibration Power Generation System, IEEE Transaction On Power Electronics, Vol. 22, NO.2, March 2007.

K. Madhuri , Dr.A Srujana Low Voltage Energy Harvesting by an Efficient AC-DC Step-Up Converter, IOSR -ISSN: 22781676,p-ISSN: 2320-3331, Volume 7, Issue 3 PP 32-47, (Sep. Oct.)-2013.

M.H.Rashid, power electronics circuit device and application. 3 rd Edition

DOI: 10.9790/2834-1051125133

www.iosrjournals.org

133 | Page

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocument7 paginiA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocument7 paginiSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocument6 paginiThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocument5 paginiAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Document15 paginiA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)Încă nu există evaluări

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocument5 pagini"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocument5 paginiRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocument4 paginiInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Impact of Technologies On Society: A ReviewDocument5 paginiThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocument14 paginiAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocument7 paginiComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocument8 paginiMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Assessment of The Implementation of Federal Character in Nigeria.Document5 paginiAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)Încă nu există evaluări

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocument5 paginiEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocument9 paginiTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocument7 paginiTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocument6 paginiImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocument6 paginiRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocument3 paginiBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Human Rights and Dalits: Different Strands in The DiscourseDocument5 paginiHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Women Empowerment Through Open and Distance Learning in ZimbabweDocument8 paginiWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocument11 paginiSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocument6 paginiAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- The Lute Against Doping in SportDocument5 paginiThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocument9 paginiClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocument6 paginiKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocument5 paginiDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalÎncă nu există evaluări

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocument6 paginiDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocument3 paginiMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocument7 paginiA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)Încă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- 2019 Pahang Physics K2 JawapanDocument10 pagini2019 Pahang Physics K2 JawapanSarveshaah SugumaranÎncă nu există evaluări

- Exercises Chapter29Document8 paginiExercises Chapter29Чего Хочешь?Încă nu există evaluări

- Transient Analysis of AC CircuitsDocument49 paginiTransient Analysis of AC Circuitsasim_ali82Încă nu există evaluări

- Zero Sequence ImpedanceDocument3 paginiZero Sequence Impedanceferdad4realÎncă nu există evaluări

- Cobra Uniden Antenna Amplifiers Microphones CB Uniden Antenna Amplifiers MicrophonesDocument32 paginiCobra Uniden Antenna Amplifiers Microphones CB Uniden Antenna Amplifiers Microphonespetr lowÎncă nu există evaluări

- PPV Technical Sheet Sep18 DmsDocument3 paginiPPV Technical Sheet Sep18 DmsSanimouse MousesaniÎncă nu există evaluări

- Trouble Codes Definition: - Fuel Trim Bank 1Document3 paginiTrouble Codes Definition: - Fuel Trim Bank 1Jessel DongalloÎncă nu există evaluări

- Panasonic Sa Ak230 PDFDocument94 paginiPanasonic Sa Ak230 PDFCOL. CCEEÎncă nu există evaluări

- LIC Unit 3Document14 paginiLIC Unit 3Gaurav SinghÎncă nu există evaluări

- Led TV Led TV: Service Manual Service ManualDocument101 paginiLed TV Led TV: Service Manual Service Manualboroda2410100% (4)

- Wire Length Geometry Velocity FactorDocument5 paginiWire Length Geometry Velocity Factordragon314159Încă nu există evaluări

- Infrared Receiver For Your PCv1Document8 paginiInfrared Receiver For Your PCv1amritpal2489Încă nu există evaluări

- Touch Sensitive AlarmDocument1 paginăTouch Sensitive Alarmchetangs17100% (1)

- Arduino Motor DCDocument3 paginiArduino Motor DCIsnaÎncă nu există evaluări

- Pnoz M1P Eth 773103Document7 paginiPnoz M1P Eth 773103Vlad ConstantinescuÎncă nu există evaluări

- Data Sheet BusductDocument4 paginiData Sheet BusductR Bambang WidiatmokoÎncă nu există evaluări

- TermisthorDocument3 paginiTermisthorHadi Khajouee NejadÎncă nu există evaluări

- Connector Connector: GH Connector GH ConnectorDocument4 paginiConnector Connector: GH Connector GH ConnectorNitin KeshavÎncă nu există evaluări

- Project Report: Fire Alarm: Atharv ShenoyDocument8 paginiProject Report: Fire Alarm: Atharv ShenoyAtharv ShenoyÎncă nu există evaluări

- Application of Australian Standards To HDocument11 paginiApplication of Australian Standards To Hdyıldırım_4Încă nu există evaluări

- Viper50/Sp Viper50A/Asp: Smps Primary I.CDocument23 paginiViper50/Sp Viper50A/Asp: Smps Primary I.Camd reeÎncă nu există evaluări

- 0460 443 301 GB (Caddy TIG 2200i - Manual 2019)Document28 pagini0460 443 301 GB (Caddy TIG 2200i - Manual 2019)maverick kitaroÎncă nu există evaluări

- Remy Hybrid Application Manual Rev 2.0Document28 paginiRemy Hybrid Application Manual Rev 2.0EvTech PhilÎncă nu există evaluări

- Basic 100Document4 paginiBasic 100Hectorl02Încă nu există evaluări

- Worksheet 4 Electric Fields: Electrical Force Between Two Protons Gravitational Force Between Two ProtonsDocument3 paginiWorksheet 4 Electric Fields: Electrical Force Between Two Protons Gravitational Force Between Two ProtonsTinboy100% (1)

- RF FundamentalsDocument53 paginiRF FundamentalsOm PrakashÎncă nu există evaluări

- Power Factor Correction and PWM Controller Combo: Features General DescriptionDocument14 paginiPower Factor Correction and PWM Controller Combo: Features General DescriptionbiggertvÎncă nu există evaluări

- Batteries CellsDocument2 paginiBatteries CellsArun ChakravarthyÎncă nu există evaluări

- Thyristor Controlled Battery Charger / Rectifier Rda/Rdat Series User ManualDocument44 paginiThyristor Controlled Battery Charger / Rectifier Rda/Rdat Series User Manualamhtet67% (3)

- (WWW - Entrance-Exam - Net) - Tata ELXSI Placement Sample Paper 1Document9 pagini(WWW - Entrance-Exam - Net) - Tata ELXSI Placement Sample Paper 1karthikÎncă nu există evaluări