Documente Academic

Documente Profesional

Documente Cultură

RCER-2010, Volume II, Form PA-H1 Hazardous Substance Handling & Storage

Încărcat de

WellfroDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RCER-2010, Volume II, Form PA-H1 Hazardous Substance Handling & Storage

Încărcat de

WellfroDrepturi de autor:

Formate disponibile

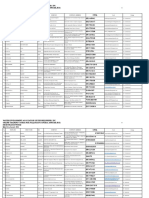

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

PERMIT APPLICATION FOR AUTHORIZATION FOR HANDLING AND

STORAGE OF HAZARDOUS MATERIALS

1. HAZARDOUS MATERIALS HANDLING

Provide the following information on all hazardous substances (raw

materials/feed stocks, products / by products additives, catalysts, fuels,

solvents, lubricants, and any other chemicals or materials) to be used at

the facility and stored in quantities in excess of 50 kg.

Hazardous

Substance/

Major

Hazardous

Constituent

s

Physical

Pro

per

ties

Hazardous

Process/

Maximum

Storage

Quantity

(kg)

Transport/

Storage

Methods*

* Above ground storage tank, underground storage tanks, ISO Container,

cylinder, tote, drum, stockpile or surface impoundment, other

a. Provide Material Safety Data Sheet (MSDS)

substances to be handled

for all hazardous

List the relevant section/ page numbers in the attachment

b. Provide details of any radioactive materials handled by the facility.

2. HAZARDOUS MATERIALS STORAGE MOBILE STORAGE

a. Complete the following table for all hazardous materials stored in above

ground storage tanks

Hazardo

us

Material

Type of

Storage1

No. of

Capacity

(m3)

H1-1

Facility: ______

Initials: ______

Storage

True

( kPa)

Storage

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

1.

2.

3.

ISO container, tote, drum, bags, cylinder, other

Ambient temperature = 40 C

Warehouse, yard or other

b. Provide design details, specifications and drawing for the secondary

containment where the containers for each area where these units are

stored. Details must include

i. Capacity of the area

ii. Construction materials

iii. Impervious liner characteristics

iv. Drainage, if any.

List the relevant section/ page numbers in the attachment

Drawing No. _________________

3. HAZARDOUS MATERIALS STORAGE ABOVE GROUND STORAGE

TANKS

a. Complete the following table for all hazardous materials stored in

above ground storage tanks

Hazardous

Material

Tank

Capacity

(m3)

Shape

Dimensio

Storage

(C)

>>> table continued

True Vapor

Pre

ssur

e at

Stor

age

Tem

p

( kPa)2

Type of Tank3

H1-2

Facility: ______

Initials: ______

Secondary

Conta

inme

nt

Capa

city

(m3)

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

1.

2.

3.

Cylindrical, Horizontal, vertical, rectangular,

if storage is at ambient temperature then provide True Vapor Pressure @

400 C

Fixed roof, Fixed Roof w/Internal Floating Roof, Pressurized Tank,

External Floating Roof

b. Provide the following for each type of storage tank

i. Design details, specifications and materials of construction for

each storage tank

Drawing No.

ii. Overspill and leak detection systems

iii. Secondary containment including construction material and

impervious liner characteristics and drainage, if any.

iv. Inspection criteria including floating roof as well as primary and

secondary seal inspections

List the relevant section/ page numbers in the attachment

c. Provide description of the process that use or generate above

hazardous substances

List the relevant section/ page numbers in the attachment

4. HAZARDOUS MATERIALS STORAGE UNDERGROUND STORAGE

TANKS

a. Complete the following table for all hazardous materials stored in

underground storage tanks

Hazardous

Material

Tank ID

Capacity

(m3)

>>> table continued

H1-3

Facility: ______

Initials: ______

Dimensions (m)

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

Storage

Te

mp

era

tur

e

True Vapor

Pre

ssu

re

at

Sto

rag

e

Te

mp

( kPa)

Secondary

Co

nta

inm

ent

Ca

pac

ity

(m3)

b. Provide the following for each type of underground storage tank

i. Justification for using underground storage

ii. Design details, specifications and materials of construction for

each storage tank

Drawing No.

_________________

iii. Tank corrosion protection and structural integrity

iv. Overspill and leak detection systems

v. Secondary containment including construction material and

impervious liner characteristics and drainage, if any.

vi. Inspection criteria

List the relevant section/ page numbers in the report

c. Provide description of the process that use or generate above

hazardous substances

List the relevant section/ page numbers in the attachment

5. EMISSIONS CONTROL

H1-4

Facility: ______

Initials: ______

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

a. Provide calculations for storage tank emissions using USEPA AP-42

Methods for both static losses and during tank turnovers

List the relevant section/ page numbers in the attachment

b. Are there any emission control devices?

[ ] Yes

[ ] No

If yes, specify type of the control device (add additional rows if necessary)

Source

Control

Device

Control

Unit ID

Pollutant

Pollutant

Inlet

Conc.

(mg/m3)

Pollutant

Inlet

Load

(t/y)

Control

Efficiency

(%)

b. Provide technical information, design details along with vendor

guarantees for each control device

List the relevant section/ page numbers in the attachment

6. AIR POLLUTANTS

Complete the following table for all emission sources. For sources that

are equipped with an emission control device, provide data after the

emission control.

Sourc

e

Uni

t

ID

Polluta

nt

Max

Conc.

(mg/m3

)

Max. Conc.

in Regulated

Unit

Conc.

Unit

H1-5

Facility: ______

Initials: ______

Max.

Emission

Rate

(kg/hr)

Avg.

Emission

Rate

(t/yr)

Emission

Estimation

Technique*

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

* Provide a sample calculation for emission estimation. Emission

estimation must be based on

one of the following

EF: Emission Factors USEPA AP 42

MB: Material Balance

EC: Engineering Calculation

7. DATA FOR USEPA AP-42 EMISSION CALCULATIONS

a.

Fixed Roof Tanks: (insert more columns if necessary)

Fixed Roof Tanks

Tank Identification No.

Total number of identical tanks

Type of tank

Name of material stored in the tank

Tank Diameter (Ft)

Color of the

a) Roof

b) Shell

Tank Capacity (gallons)

Total throughput per year (gallons)

Number of turnover per year

Height of tank

Average vapor space height (ft)

Avg. temperature of storage liquid , Ts.

(Deg. F)

True vapor pressure of storage liquid at the

storage temperature (Ts) in Pisa

Molecular weight of vapor in storage tank

at 82oF , (lb/lb mole)

H1-6

Facility: ______

Initials: ______

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

(b). Floating Roof Tanks: (insert more columns if necessary)

Floating Roof tanks

Tank Identification No.

Total number of identical tanks

Name of material stored in the tank

Type of tank (Internal floating/ External

floating roof)

Type of seal (Fill as per Note-1)

Tank Diameter (Ft)

Color

a) Roof

b)Shell

Condition of shell (light rust/ Dense rust

/Gunite lined)

Number of columns (for Int. fl. Tanks)

Effective column diameter (Ft) (= Column

perimeter/ 3.14)

Tank Capacity (gallons)

Total throughput per year (gallons)

Number of turnover per year

Avg. temperature of storage liquid , Ts. ( Deg.

F)

True vapor pressure of storage liquid at the

storage temperature (Ts) in Pisa

Average density of the liquid stored (lb/gallon)

Molecular weight of vapor in storage tank at

60oF (lb/lb mole)

Note 1: A - Metallic shoe seal with primary seal only

B - Metallic shoe seal with shoe mounted secondary seal

C - Metallic shoe seal with rim mounted secondary seal

D - Liquid mounted resilient seal with primary seal only

E - Liquid mounted resilient seal with weather shield

F - Liquid mounted resilient seal with rim mounted secondary

seal

H1-7

Facility: ______

Initials: ______

Royal Commission Environmental Regulations-2010

RCER-2010,Volume II, Environmental Permit Program, Form PA-H1 Hazardous Substance Handling & Storage

seal

G - Vapor mounted resilient seal with primary seal only

H - Vapor mounted resilient seal with weather shield

I - Vapor mounted resilient seal with rim mounted secondary

(c). Internal Floating Roof Tanks (insert more columns if necessary)

Deck fittings

Deck fitting type (Fill as per Note -2)

Number of such deck fittings

Total length of deck seams (ft)

Area of Deck (ft2)

Note 2 : A - Access hatch, Bolted cover, Gasketed

B - Access hatch, Unbolted cover, Gasketed

C - Access hatch, Unbolted cover, Ungasketed

D - Automatic gauge float well, Bolted cover, Gasketed

E - Automatic gauge float well, Unbolted cover, Gasketed

F - Automatic gauge float well, Bolted cover, Ungasketed

G - Column well , Built-up column-sliding cover, Gasketed

H - Column well , Built-up column-sliding cover, Ungasketed

I - Column well , Pipe column-flexible fabric sleeve seal

J - Column well , Pipe column-sliding cover, Gasketed

K - Column well , Pipe column-sliding cover, Ungasketed

L - Ladder well, Sliding cover, Gasketed

M - Ladder well, Sliding cover, Ungasketed

N - Roof leg or hanger well, Adjustable

O - Roof leg or hanger well, Fixed

P - Sample pipe or well, Slotted pipe-sliding cover, Gasketed

Q - Sample pipe or well, Slotted pipe-sliding cover, Ungasketed

R - Sample pipe or well, Sample well-slit fabric seal, 10% open

area

S - Stb drain, 1 Inch diameter

T - Vacuum breaker, Weighted mechanical actuation, Gasketted

U - Vacuum breaker, Weighted mechanical actuation

H1-8

Facility: ______

Initials: ______

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Case Studies in Fracture MechanicsDocument475 paginiCase Studies in Fracture MechanicsBenjamin Rohit100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Law of AntiquitiesDocument9 paginiLaw of AntiquitiesWellfroÎncă nu există evaluări

- TRA of Lifting of EquipmentsDocument3 paginiTRA of Lifting of EquipmentsandreÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- 2004 Corolla Air Conditioning Wiring DiagramDocument4 pagini2004 Corolla Air Conditioning Wiring Diagramjldamasceno100% (2)

- John Deere Attachment MatrixDocument24 paginiJohn Deere Attachment Matrixforge_monkeyÎncă nu există evaluări

- Cranes and DerricksDocument15 paginiCranes and DerricksAl Hamra AyashofiyaÎncă nu există evaluări

- Anand's Human Anatomy For Dental Students, 3rd EditionDocument762 paginiAnand's Human Anatomy For Dental Students, 3rd Editionviaerea100% (4)

- San Francisco-Oakland Bay Bridge East Span Seismic Safety ProjectDocument18 paginiSan Francisco-Oakland Bay Bridge East Span Seismic Safety ProjectWellfroÎncă nu există evaluări

- Southwest Case Study SolutionDocument12 paginiSouthwest Case Study SolutionGaurav SharmaÎncă nu există evaluări

- ProjectClosureReport-v1 0Document83 paginiProjectClosureReport-v1 0WellfroÎncă nu există evaluări

- Crane Design and CalculationDocument28 paginiCrane Design and Calculationodim7370% (23)

- 15-MHR Intl-Module 15 Mechanical Plumbing and ElectricalDocument94 pagini15-MHR Intl-Module 15 Mechanical Plumbing and ElectricalSony JsdÎncă nu există evaluări

- Climate Report Saudi Arabia 2017Document5 paginiClimate Report Saudi Arabia 2017WellfroÎncă nu există evaluări

- Stakeholder SeminarDocument80 paginiStakeholder SeminarWellfro100% (1)

- CementDocument40 paginiCementanteid3100% (1)

- Risk Assessment Example - Mobile Offshore Unit (MOU) Relocation Operations PDFDocument18 paginiRisk Assessment Example - Mobile Offshore Unit (MOU) Relocation Operations PDFWellfro0% (1)

- Ambient air quality and exposure assessment study of the Gulf Cooperation Council countries_ A critical review (Science of The Total Environment, vol. 636) (2018)Document8 paginiAmbient air quality and exposure assessment study of the Gulf Cooperation Council countries_ A critical review (Science of The Total Environment, vol. 636) (2018)WellfroÎncă nu există evaluări

- Control of Resuspended Sediments in Dredging ProjectsDocument12 paginiControl of Resuspended Sediments in Dredging ProjectsWellfroÎncă nu există evaluări

- Jones_etal2015Document26 paginiJones_etal2015WellfroÎncă nu există evaluări

- Artificial Lighting at Night in Estuaries PDFDocument22 paginiArtificial Lighting at Night in Estuaries PDFWellfroÎncă nu există evaluări

- Dubai_Creek_from_commercial_dock_to_straDocument4 paginiDubai_Creek_from_commercial_dock_to_straWellfroÎncă nu există evaluări

- Silt Curtain EffectivenessDocument2 paginiSilt Curtain EffectivenessWellfroÎncă nu există evaluări

- Silt Curtain Selection GuideDocument6 paginiSilt Curtain Selection GuideWellfroÎncă nu există evaluări

- Project Description and MethodologyDocument14 paginiProject Description and MethodologyWellfroÎncă nu există evaluări

- Ozone Depleting SubstancesDocument7 paginiOzone Depleting SubstancesWellfroÎncă nu există evaluări

- Stakeholder Analysis ToolDocument8 paginiStakeholder Analysis ToolRichard Thodé JrÎncă nu există evaluări

- Marpol Suplement 2015Document48 paginiMarpol Suplement 2015CvitaCvitićÎncă nu există evaluări

- TorqueDocument1 paginăTorqueAnonymous oWDHhPÎncă nu există evaluări

- Refrigerator: Owner S Instructions SR-17NFB SR-19NFB SR-22NFBDocument18 paginiRefrigerator: Owner S Instructions SR-17NFB SR-19NFB SR-22NFBjchunga_lauÎncă nu există evaluări

- The Impact of Supply Chain CostDocument18 paginiThe Impact of Supply Chain CostGab ColobongÎncă nu există evaluări

- Case Study: Helge Ingstad - Sola TSDocument19 paginiCase Study: Helge Ingstad - Sola TSakshayvÎncă nu există evaluări

- Italy GuideDocument54 paginiItaly Guidehahmed78Încă nu există evaluări

- Bradford T (2018) - The Energy System Technology Economics Markets and Policy - TOCDocument12 paginiBradford T (2018) - The Energy System Technology Economics Markets and Policy - TOCArif GokakÎncă nu există evaluări

- Speeding Mitigation PlanDocument2 paginiSpeeding Mitigation PlanAnonymous Pb39klJÎncă nu există evaluări

- CMR Groupings-PCO May 31-June 4, 2021Document4 paginiCMR Groupings-PCO May 31-June 4, 2021Kim Howard CastilloÎncă nu există evaluări

- Pantaloon ReportDocument16 paginiPantaloon ReportHimanshu Rastogi100% (1)

- Catalogue From Zhejiang Groupstar 20231205Document44 paginiCatalogue From Zhejiang Groupstar 20231205sergio.lopez100% (1)

- MIM-WMS-03 - 2018 PESB Equipment Lifting Method StatementDocument8 paginiMIM-WMS-03 - 2018 PESB Equipment Lifting Method StatementSatrioÎncă nu există evaluări

- Captain Vartul DixitDocument40 paginiCaptain Vartul DixitAman GautamÎncă nu există evaluări

- Caterpillar Performance Handbook 49 62020 Partie3Document4 paginiCaterpillar Performance Handbook 49 62020 Partie3ali alilouÎncă nu există evaluări

- Modul 1 Peraturan Yang Berlaku Untuk SPUKTA (9 Sep 22) V3 PDFDocument103 paginiModul 1 Peraturan Yang Berlaku Untuk SPUKTA (9 Sep 22) V3 PDFAdmin PT PLN UPT MakassarÎncă nu există evaluări

- Manual - V-Drive 2021Document184 paginiManual - V-Drive 2021AngelÎncă nu există evaluări

- Physiology and Neurobiliogy 2275 UCONN Test 3Document8 paginiPhysiology and Neurobiliogy 2275 UCONN Test 3sin117Încă nu există evaluări

- In The Neighborhood I: Upn, Pasión Por Transformar VidasDocument24 paginiIn The Neighborhood I: Upn, Pasión Por Transformar VidasNirvana HornaÎncă nu există evaluări

- BoQ Underpass LP7 - Juni 2010 PDFDocument7 paginiBoQ Underpass LP7 - Juni 2010 PDFalmirÎncă nu există evaluări

- Wa0000 PDFDocument76 paginiWa0000 PDFSumitÎncă nu există evaluări

- Engineering Vol 69 1900-03-30Document31 paginiEngineering Vol 69 1900-03-30ian_newÎncă nu există evaluări