Documente Academic

Documente Profesional

Documente Cultură

Specifications of Concrete Works

Încărcat de

nicoleta_cristian4798Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Specifications of Concrete Works

Încărcat de

nicoleta_cristian4798Drepturi de autor:

Formate disponibile

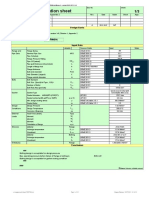

Contractor:

FRAMEWORK AGREEMENT FOR ENGINEERING,

PROCUREMENT SERVICES AND

CONSTRUCTION MANAGEMENT FOR SURFACE

FACILITIES

Framework Agreement no.:

Company Job. No.:

Contractor doc. no.:

Contractor Job. No.:

11J01917-CIV-SP-000-001

Sheet

84600146009

DJ1784

11J01917

of

45

Company:

Company doc. no.:

PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION

FOR

EXECUTION OF CONCRETE WORKS

F0

D0

C0

05-11-2012

19-10-2012

29-06-2012

REV.

DATE

Final Issue

Issued for Company Approval

Issued for Company Review

File name: PE-D-DJ1784-CS-SPC-001-F0-E

REVISION TITLE

N. Cristian

N. Cristian

N. Cristian

EN. PREP.

M. Popa

M. Popa

A. Tomescu

W. Ricciatti

W. Ricciatti

W. Ricciatti

EN. CHECK.

EN. APP.

COMP. APP.

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

Rev.:

C0

D0

Sheet

F0

2

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

INDEX

1

2

Preface .........................................................................................................................................4

General .........................................................................................................................................5

2.1

Scope of Document ...............................................................................................................5

2.2

Definitions ..............................................................................................................................5

2.3

Applicable Codes and Standards ...........................................................................................6

2.4

Conflicting Requirements, Exceptions....................................................................................7

2.5

Unit of Measurement .............................................................................................................7

2.6

Language...............................................................................................................................7

3 Specification for Concrete Works ..................................................................................................8

3.1

General..................................................................................................................................8

3.2

Important Category and Class of concrete works ...................................................................8

3.3

Cement for Mortar and Concrete ...........................................................................................9

3.4

Aggregates ............................................................................................................................9

3.5

Water ...................................................................................................................................10

3.6

Additives and additions ........................................................................................................10

3.7

Technical Characteristics of Concrete..................................................................................11

3.7.1

General.........................................................................................................................11

3.7.2

Concrete Preparation ....................................................................................................11

3.7.3

Concrete Verify .............................................................................................................12

3.7.4

Concrete Transportation ...............................................................................................14

3.7.5

Conditions for Pouring Concrete ...................................................................................14

3.7.6

Concrete temperature ...................................................................................................15

3.8

Concrete Compacting ..........................................................................................................15

3.9

Further Treatment of Concrete.............................................................................................16

3.10 Joint Working and Water-stop ..............................................................................................16

3.11 Execution of Concrete in Cold Weather ...............................................................................16

3.12 Execution of Foundations ....................................................................................................17

3.12.1 General conditions ........................................................................................................17

3.12.2 Grouting ........................................................................................................................18

3.12.3 Anchor Bolts .................................................................................................................19

3.13 Execution of Vertical Elements ............................................................................................19

3.14 Execution of Beams and slabs .............................................................................................19

3.15 Precast Elements.................................................................................................................20

3.15.1 General Data ................................................................................................................20

3.15.2 Execution of installation and joints ................................................................................21

3.15.3 Joint execution of precast elements ..............................................................................21

3.15.4 Checking and reception of mounting works for precast elements..................................22

4 Reinforcement Bars ....................................................................................................................23

4.1

General provisions ...............................................................................................................23

4.2

Reinforcement Bending .......................................................................................................24

4.3

Checking and Reception of Mounted Reinforcement ...........................................................24

4.4

Concrete covering................................................................................................................25

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

Rev.:

C0

D0

Sheet

F0

3

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

4.5

Replacement Reinforcement................................................................................................25

5 Formwork....................................................................................................................................27

5.1

General................................................................................................................................27

5.2

Acceptable Deviations to Formwork Installing ......................................................................27

5.3

Checking and Reception of Formwork and Its Supports.......................................................28

5.4

Casting Made in Land Areas ................................................................................................29

5.4.1

General.........................................................................................................................29

5.4.2

Permissible deviations for casting spaces made in the field are the followings: ............29

5.4.3

Checking of casting spaces made in the field is performed to: ......................................29

5.5

Previously and necessary conditions during execution of formwork and their supports ........30

6 Labor Safety per Categories of Work ..........................................................................................31

6.1

General provisions ...............................................................................................................31

6.2

Loading, unloading and storage of materials........................................................................31

6.3

Preparation and transport of concrete and mortar ................................................................32

6.4

Pouring and compacting concrete ........................................................................................32

6.5

Cutting, bending and mounting reinforcing steel armatures .................................................33

6.6

Casings, platforms, scaffolding, ladders ...............................................................................33

6.7

Handling, transport and mounting of reinforced and concrete elements ...............................34

7 Geometric Tolerances.................................................................................................................35

8 The Quality Control and Works Reception ..................................................................................36

8.1

General Provisions ..............................................................................................................36

8.2

Check Classes .....................................................................................................................38

8.3

Checking of input elements in the work execution................................................................39

8.4

Checking of works execution ...............................................................................................40

8.5

Reception of concrete and reinforcement concrete works ....................................................42

9 Embedded Pieces in Concrete....................................................................................................43

10 Quality tracking program concept ...............................................................................................44

10.1 General................................................................................................................................44

10.2 Quality Tracking Program Concept of Civil Works................................................................44

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

Rev.:

C0

D0

Sheet

F0

4

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

1 PREFACE

This specification has been prepared by Contractor within a standardization program that has

been introduced by Company with the aim of harmonising the design of concrete works for all

the FRD Oil Projects.

Being not submitted for approval to the Company Committee, this specification CAN NOT be

considered as Company Standards and its validity is therefore limited to the FRD Oil Projects,

for which it has been prepared, that will be developed by Contractor within the Framework

Agreement Contract.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

11J01917-CIV-SP-000-001

C0

D0

Sheet

F0

5

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

GENERAL

2.1

Scope of Document

This Specification defines general requirements for the supply, construction, testing, delivery,

operation and inspection of concrete works to be realized in OMV Petrom S.A. production facilities in

Romania.

The concrete foundations, concrete structures, pipes support foundations and concrete platforms

shall be designed, manufactured, inspected, tested and supplied in accordance with this specification

and the referenced applicable codes and standards. This specification shall be read in conjunction

with the latest revision of the applicable project documents.

The General Contractor has to demonstrate the capabilities of supplying of concrete works as per this

specification; any deviation from this specification and all norms and standards in force shall be

clearly declared. These Specifications were developed in accordance with Law 10/1995 on the quality

of construction works to achieve adequate quality.

2.2

Definitions

The following definitions will be used in this document without the need of any further

explanation:

Company/Principal:

OMV Petrom S.A.

Contractor:

ENERECO Spa. The Engineering Firm awarded by the

Company for the Framework Agreement for Engineering,

Procurement Services and Construction Management for

Surface Facilities

Contract:

the Framework Agreement for Engineering, Procurement

Services and Construction Management for Surface

Facilities

Project:

is any FRD Oil Project who this specification applies to.

Job:

is any Job within the FRD Oil Project who this

specification applies to.

Package Contractors:

any third Party/Entity that will be charged by Company for

the Design, Fabrication, Site Erection, Commissioning

and Start-Up of packaged process units and utility

systems.

Supplier/Vendor:

any third Party/Entity that will be awarded by the

Company for manufacturing and/or supplying of

equipment and goods for the Project.

General Contractor:

any third Party/Entity that will be charged by Company for

the Construction, Commissioning and Start-Up of the

Balance of Plant (BOP), being this to be intended as the

part of the Project not covered by the Package

Contractors.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

2.3

Rev.:

C0

D0

Sheet

F0

6

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Applicable Codes and Standards

SR EN 1990:2004 Eurocod: Bases of structures design

SR EN 1990:2002/A1:2005 Bases of structures design, Annex 1

SR EN 1990/NA Bases of structures design, National Annex

SR EN 1992-1-1 & SR EN 1992-1-1/NB Eurocod 2: Design of concrete structures. Part 1-1:

General rules and rules for buildings & National Annex

SR EN-1998-1 & SR EN 1998-1/NA Eurocod 8: Design of structures for earthquake

resistance. Part 1: General rules, seismic actions and rules for buildings.

SR EN-1998-5 & SR EN 1998-5/NA Eurocod 8: Design of structures for earthquake

resistance. Part 5: Foundations, retaining structures and geotechnical aspects

P100-1/2006 Code of structures design for earthquake resistance

NP112 2004 Code for the structure design of directly founded

NE 012-1 2007 Code of practice for execution of concrete, reinforced concrete and prestressed

NE012/2 2010 Normative for concrete production and works execution of poor concrete,

reinforced concrete and pre-stressed concrete. Part 2: Execution of concrete works

NE 013 2002 Code of practice for execution of precast elements from concrete, reinforced

and pre-stressed

SR EN 197-1:2011 Cement Part 1: Composition, specifications and conformity criteria for

common cements

SR 388 -1995 Portland Cement

C155-1989 Normative regarding preparation and use of concrete with lightweight aggregate

SR EN 12350:2009 Test on fresh concrete

SR EN 13450:2003 Natural aggregates for road and railway works. Methods of

determination

STAS 4606 - 1980 Heavy natural aggregates for concrete and mortars with mineral binders.

Testing methods.

SR EN 12620:2003 Aggregates for concrete

SR EN 13055-1:2003 Lightweight aggregates. Part 1: Lightweight aggregates for concrete,

mortar and grout

SR EN 1008:2003 Water for concrete and mortar

SR EN 934-2:2003 Additives for concrete, mortar and grout. Part 2: Additives for concrete

STAS 438-1/89 Steel products for reinforcement of concrete. Hot rolled steel. Grades and

technical requirements of quality

SR 438-3-98 Steel products for reinforcement of concrete. Welded fabric

C56-1985 & C56-2002 Standard for quality check and reception of construction works and

related equipment

C16/84 Norms for the working in cold time and related facilities.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

7

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

2.4 Conflicting Requirements, Exceptions

The General Contractor shall notify the Company of any conflict between this specification,

the Codes and Standards and any other specification included as part of the procurement

documentation for any equipment.

2.5 Unit of Measurement

The International System (SI) shall be used. When necessary for a specific application,

alternative units may be indicated in brackets behind the SI units.

Length:

m; mm

Area:

m2; mm2

Force:

kN; N

Mass:

kg

Pressure:

kN/m2; MPa

Specific Weight:

kN/m3

2.6 Language

All documents will be done in English language excluding the manuals which must be in

English language.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

8

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

SPECIFICATION FOR CONCRETE WORKS

3.1

General

This specification establishes the technical requirements of the works of concrete and concrete

materials for the production, transport and pouring of the concrete.

In addition to the provisions obtained in these specifications, the contractor shall comply with all

STAS's and standards.

Execution of concrete and reinforced concrete works shall be in accordance with NE 012-1:2007 and

NE 012/2-2010.

Class of compressive strength after 28 days will be required under the project.

Exposure class, defined in standard NE 012-1:2007 is different depending by element, position,

exposure, climatic data and others.

Usually, exposure classes are:

-

Concrete Structures:

Foundations:

Sidewalk slab:

Ditches:

XC1; XF1

XC2

XF3

XC4

Exposure classes shall be determined by project.

Concrete purchased will be accompanied by quality certificates and test bulletins issued by the

concrete supplier.

Contractor is obliged to make the application design engineer and beneficiary checks of work mark,

machine control and enforcement of the concrete, additional tests and any additional measures as

deemed necessary during construction.

For each object will be completed by the contractor a book of concrete. This will be reconciled with

physical progress achieved to date by checking the project supervisor and this will be recorded in the

statements of facts.

During execution of works will not make any derogation from this specification without prior approval

in writing of the design engineer. If they see that deviations from these specifications, which can

change the strength or stability conditions the design engineer and the beneficiary will interrupt the

work.

Contractor is responsible for all changes and damage that may result from these interruptions.

3.2

Important Category and Class of concrete works

Important Category, as per HG 766/1997 is C

Important Class, as per Cod P100-1/2006 is III.

For a construction that complies with a higher category than above, shall be prepared an Annex to

this specification with specific requirements of that category.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

3.3

D0

Sheet

F0

9

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Cement for Mortar and Concrete

General skill of use is fixed for cements according to SR EN 197-1. For other cements that are not

included in SR EN 197-1, general skill of use must be based on the provisions of other European

standards for cements, of national standards SR 3011, SR 755, STAS 10092, elaborated considering

the recognised principles and procedures in accordance with SR EN 197-1.

For the preparation of poor concrete shall be used CEM II A-S32,5 N cement and for preparation of

reinforced cement shall be used CEM II A-S32.5 N. If to use other cements, must be decided by the

designer.

Reception of cement will be in factory as per actual standards, at the site being made only check the

status of conservation, the setting time and determine the constant volume according to STAS 227/186, SR 227-2 and EN 196 -8:2004.

Technical conditions of reception, delivery and control of cement must comply with those standards.

During transport from factory to site (or intermediate storage), handling and storage on site, cement

shall be protected from moisture and contamination with foreign matter.

Storage of cement will be made only after finding quality certificate. Shelf life of cement shall not

exceed 45 days from date of shipment by the manufacturer.

Cement remained in storage for a long time cant be used only after checking the conservation of

mechanical resistance to 2 (7) days. Cement which will lower mechanical strength prescribed limits

that mark will be downgraded and used.

Cement is established that to be altered dispose banned for use to preparation of concrete or mortars.

Evacuation will be at the expense of the contractor.

3.4

Aggregates

For production of concrete shall be used aggregates or gravel following to check the quality of these

units through preliminary laboratory trials.

General skill of use is determined for:

Aggregates having normal density and hard aggregates in accordance with SR EN 12620.

Lightweight aggregate in accordance with SR EN 13055-1.

Recommended granulometric curves for the preparation of concrete are shown in Annex K, NE 012-1:

2007 for various nominal maximum sizes of aggregates 0/8mm, 0/22mm, 0/32mm and 0/64mm.

For concrete preparation with apparent density between 2201 - 2500 Kg / cm, are used heavy

aggregates, resulting from natural breaking or crushing rocks.

Aggregates should be from stable rock, meaning unalterable in the air, water or frost; should not be

used aggregates from Feld spathic rocks or schist. Aggregates must be inert and do not cause harm

to the cement used to prepare concrete or mortar.

The sand must be coarse to the touch. High sand will be used only on special prescriptions.

Fine and coarse aggregates will be separated by permanent substantial partitions in the store.

It is forbidden to store aggregates directly on the ground or on ballast platforms.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

3.5

D0

Sheet

F0

10

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Water

For water used to prepare concrete and mortar, the checking will be done by a specialist laboratory to

start work. In site it will prevent that water to be polluted with detergents, organic matter, vegetable

oils, clays, etc.

General skill of use is determined for mixing water and wash water recovery from concrete

manufacturing, according to SR EN 1008.

3.6

Additives and additions

General skill of use is determined for additive, according to SR EN 934-2. Compatibility of the

additives with used cements should be checked by preliminary tests.

General aptitude to use the addition of type I is determined for:

Fillers, according to SR EN 12620.

Pigments, according to SR EN 12878.

General aptitude to use the addition of type II is determined for:

Fly ashes, according to SR EN 450.

Ultrafine silica, according to SR EN 13263.

Total quantity of additives used must not exceed the maximum dosage recommended by the

manufacturer of additives and should not be greater than 50 g of additive per kg of cement.

Conditions of additives use are stipulated in the below table:

Item

1

2

Concrete type, technology and

pouring conditions

Strength concrete with class

between C8/10 and C30/37

inclusive

Exposed concrete to repeated

freeze-thaw

Recommended additive

Plasticizer

As appropriate:

super-plasticizer

Coach air

Concrete having low

permeability

Water reducer / plasticizer

Exposed concrete to conditions

of intense and very intense

aggression

Water reducer / plasticizer

Concrete made monolithic

having C35/45

Super-plasticizer /

intensive water reducing

Fluid concrete

Super-plasticizer

Massive concrete

Concrete cast by special

technology (self-compacting)

Concrete cast in hot weather

(Plasticizer)

Super-plasticizer + cement

retarder

Cement retarder + superplasticizer (Plasticizer)

File name: PE-D-DJ1784-CS-SPC-001-F0-E

Observations

As appropriate:

intensive water reducing /

super-plasticizer

waterproofing

As appropriate:

intensive water reducing /

super-plasticizer

corrosion inhibitor

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

11

45

PE-D-DJ1784-CS-SPC-001-F0-E

Counter-freeze +

accelerating admixture

Setting accelerators

without chlorides

Concrete cast in cold weather

10

High strength concrete with

short time

3.7

Technical Characteristics of Concrete

3.7.1

Company doc. no.:

of

General

Preparation and verification of concrete characteristics is properly defined on the Code NE 0121:2007.

The uniformity is ensured by mixing uniformity, consistency and density. For technical compliance

including homogeneity will meet:

Composition of concrete and concrete recipe.

The conditions of preparation, transportation and commissioning work.

Apparent density.

Workability.

Conditions of workability (granulometry, aggregates, temperature, density and air occlusive) will be

checked at concrete station. If the results fall within acceptable limits, preparation of concrete will be

stopped and will be established the necessary technological measures.

3.7.2

Concrete Preparation

Preparation will not start until after the establishment of definitive prescriptions will be based on

quality aggregates, technology preparation, conditions of carriage, handling and installation. These

prescriptions will be approved laboratory.

Concrete will be prepared with maximum 32mm aggregate with grain. Concrete will be made by

mechanical mixing of all constituents simultaneously in the cement mixer. Aggregates will be

introduced into the mixer in the following order:

with the large aggregates (16-32 mm)

cement

sand

the smallest aggregates (8-16 mm)

water

For dosing of the component materials for concrete, are permitted following deviations:

aggregates

cement and water

additions

3%

2%

3%

The main characteristics for different types of used concrete as per NE-012-1:2007:

Reinforced Concrete, Grade C25/30

Cement type

CEM II A-S 32.5N

Minimum dosage of cement

300 kg/m3

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

12

Company doc. no.:

of

Maximum Ratio water/cement

0.45

Maximum aggregate size

22 mm

45

PE-D-DJ1784-CS-SPC-001-F0-E

Precast Concrete, Grade C30/37

Cement type

CEM II A-S 42.5N

Minimum dosage of cement

300 kg/m3

Maximum Ratio water/cement

0.47

Maximum aggregate size

16 mm

Lean Concrete, Grade C12/15

Cement type

CEM II A-S 32.5N

Minimum dosage of cement

260 kg/m3

Maximum Ratio water/cement

0.65

Maximum aggregate size

32 mm

Concrete class is defined based on characteristic strength fck cil (fck cub), which is compressive

strength in N/mm2, determined on cylinders with dimensions 150/300 mm (or on cubes having length

150 mm) having 28 days age. The used classes are followings:

Grade C12/15, fck cil = 12 N/sqm:

- lean concrete

Grade C25/30, fck cil = 25 N/sqm:

- Foundation mats and footings

- Equipment foundation with relevant pedestals

- Pump and compressor foundations

- Retaining walls

- Structures for building and for process equipment

- Basins, pits and sewer manholes

- Pipes supports

Grade C30/37, fck cil = 30 N/sqm:

- Precast concrete elements

- Precast concrete trenches

- Reinforced concrete chimneys and other elevated

structures higher than 15 meters.

3.7.3

Concrete Verify

In order to verify the correctness of concrete manufacture, will be made components control of

concrete, fresh and strengthened concrete according to NE012-1:2007. At the start of concrete work

it will be done compressive strength tests for each type of concrete at 7 days.

The workability of concrete will be measured by the method of settlement.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

D0

Sheet

11J01917-CIV-SP-000-001

F0

13

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Concrete consistency should be determined by trials using one of the following methods:

Checking of settlement, according to SR EN 12350-2.

Vebe trying, according to SR EN 12350-3.

Determining the degree of compacting, according to SR EN 12350-4.

Trying with mass of propagation, according to SR EN 12350-5.

Specific testing methods that have been the subject of an agreement between specification

owner and concrete manufacturer, for concrete intended for some special applications.

Recommended test methods to methods consistency are:

Spreading method (according to SR EN 12350-5) - for fluids concrete

Compaction method (according to SR EN 12350-5) - for consistent concrete

When must determine the consistency of concrete, this requirement will be applied when using

concrete or when the concrete is ready for using and in delivery time. Consistency can be specified by

reference to a class of consistency, according to NE 012-1, paragraph 4.2.1 or in particular cases, by

a specified value. In this case, the tolerances are given in the following table:

Settlement

Range of specified values,

in mm

40

From 50 to 90

100

Tolerances, in mm

10

20

30

Range of specified values,

in s

11

From 10 to 6

Tolerances, in s

1.26

From 1.25 to

1.11

1.1

0.10

0.08

0.05

Vebe Time

Degree of compaction

Range of specified values

Tolerances

Propagation (stretching)

Range of specified values,

in mm

Tolerances, in mm

All values

30

Verifications are performed:

During the execution for all categories of work before coverage becomes hidden works.

The end of work stages.

The preliminary reception of objects.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

3.7.4

D0

Sheet

F0

14

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Concrete Transportation

Concrete transportation must be done taking measures to prevent the segregation, loss or

contamination of concrete components.

The vehicles must be sealed to prevent grout loss. During the heat or rain, concrete surface must be

protected so as to avoid altering the characteristics of concrete.

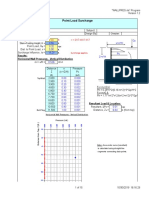

The maximum time for transportation depending exterior conditions is presented in the below table.

Maximum time of concrete transport using self-mixers

Concrete mix temperature (0C)

Maximum time for transport (minutes)

Cements class 32.5

Cements class 42.5

100 < t 300

50

35

T < 100

70

50

3.7.5

Conditions for Pouring Concrete

Before the starting of pouring concrete will be verify:

Corresponding formwork dimensions, horizontally and vertically, in accordance with the

project.

Horizontality and flatness formwork.

Measures to fixing of formwork elements.

Strength and stability of existing support elements and the correct assembling and supporting,

existing failures or other means of moulding.

Proper disposal of fittings and correspondence of diameters and number in accordance with

project, fittings solidarity between them (by tying, welding, party), the existence of sufficient

number of spacers.

Installation according to the project documents, the plates that will remain embedded in

concrete or creating holes.

Before starting concreting, formwork and reinforcing steel will be clean from any foreign materials,

mortar remained from the previous pouring, loose rust, etc and will proceed to closing windows

cleaning.

After performing the checks and measures mentioned above, it will proceed to record the findings in a

report of hidden works.

Concrete should be put in opera before setting (determined in the laboratory).

The beneficiary shall fix a maximum time period for enforcement of the concrete after its manufacture,

taking into account the provisions norm NE 012-2007. Concrete will not be put into practice within

determined or which will prove that started setting will be removed from the site.

Concrete must be protected from segregation at the time of the opera. If during transport has not

been mixed, it can be mixed by hand at the place of use before casting.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

15

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

On resumption of concreting, reinforced concrete surface is pinched if necessary and well cleaned.

The surface is abundant wet, so the old concrete should be saturated before being placed in contact

with fresh concrete.

The pouring will take into account the following rules:

Formwork shall be cleaned of old concrete and wetted 2-3 hours before pouring concrete,

excess water will be removed.

Height of free fall concrete shall not exceed 1.5 m.

Concrete is spread evenly inside the elements, aiming at making layers.

Concreting will be working continuously until the joints provided in the documentation.

Not allowed to overstep time of vibration and achieve formwork with vibrator forbid. Immediately after

de-moulding will be control of concrete surfaces for finding any pouring defects.

3.7.6

Concrete temperature

Fresh concrete temperature should not be less than 50C at the time of delivery. Generally, fresh

concrete temperature should not exceed 300C, unless special measures were taken to overcome

temperature.

Concrete temperature must not be less than +50C, if the air temperature is between +50C and -30C.

Concrete temperature should be less than +100C at the place of execution, where cement content is

less than 240 kg/m3 or if using cement with low hydration heat (e.g. class 32.5 N).

For air temperature lower than -30C, concrete temperature should not be less than +100C. In cold

weather should be taken adequate measures for pouring consisting in frost protection of concrete.

It is recommended to use cement with high release of heat and/or additives to accelerate the

hardening and antifreeze. It is not recommended casting of concrete at air temperature below -100C.

Where need another requirement on the maximum or minimum temperature for fresh concrete, it

must be specified, giving the tolerances. All requirements for artificial cooling or heating of the

concrete should be agreed between manufacturer and user.

3.8

Concrete Compacting

Concrete compacting is performed by mechanical vibration, in the case of impossibility of further

compaction by vibration (vibrator damage, power outages, etc.), pouring concrete shall be continued

until the position corresponding to a point, manually compacting the concrete.

Workability of concrete compacted by internal vibration is recommended to be L 3 or L 3 / L 4.

The external signs after which recognizes that concrete vibration is finished, are the following:

the concrete does not compact;

concrete surface is horizontal and slightly glossy;

stop of air bubbles on the surface appearance of concrete and reduce their diameter.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

3.9

D0

Sheet

F0

16

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Further Treatment of Concrete

Protection of concrete will be made with materials that must remain wet. Watering will begin after 2-12

hours of the casting, depending by type of cement used and ambient temperature, but immediately

after the concrete is sufficiently strong to result not cement paste. Spraying should be repeated every

2-6 hours so that the surface to remain permanently wet.

If the ambient temperature is below +50, it will not do the watering, but will apply to materials with

protective films.

3.10 Joint Working and Water-stop

As far as it is possible shall be avoided working joints, because these generate poor resistance of

areas, execution of pouring concrete shall be done without interruption on that level or between

expansion joints.

When joints cant be avoided, their position must be established, taking into account the size of

solicitations from various sections of the construction elements and the possibilities of organizing work

to rule. They will be provided in areas where solicitations are minimal.

When joints are not indicated in the project, their position will be determined by the constructor before

the start of concreting.

The maximum allowable period for interruptions of pouring shall not exceed the starting time of the

concrete plug, without taken special measures to resume pouring. In the absence of laboratory

determinations, this time will be considered at 2 hours after preparation of concrete for cement with

admixtures and 1.5 hours for cements without addition.

Water-stop material shall be polyvinyl chloride or rubber as approved or decided by the Company.

Where not specified otherwise water-stops of the integral type shall be to the approval of the

Company and have a minimum width of 230mm and a minimum web thickness of 10mm.

Surface type water-stops, where not specified, shall be to the approval of the Company and have a

minimum width of 230mm and at least four (4) integral flanged ribs.

Site jointing of water-stops shall be strictly in accordance with the manufacturer's instructions and

shall preferably be done using equipment provided by the material manufacturer.

3.11 Execution of Concrete in Cold Weather

For work performed in cold weather, shall comply with provisions of Normative C16-84 and NE0121:2007. The specific measures to be adopted during the cold weather shall be established taking into

account:

Real thermo-climatic regime existing on site during the preparation of transport, pouring and

concrete protect

Size and massiveness or thinness of elements which will be poured

Exposure degree of the works - area and time - to action of cold weather during strengthening

concrete

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

17

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

In the minutes of hidden works shall be mentioned the measures adopted for the protection of works

and findings regarding their efficiency.

Formwork should be well cleaned of snow and ice. It is recommended that immediately before

concrete to do the final cleaning with a jet of hot air or steam.

Storage of reinforcement shall be preferably in the available covered areas and in their absence,

reinforcement shall be protected in order to avoid falling snow or ice formation on the surface of the

bars. Reinforcement bending shall be made only up positive temperatures using, if necessary, heated

spaces.

Defrosting by flame is prohibited.

Concrete recipe displayed at the place of concrete preparation must indicate the followings:

Water temperature from mixed depending on the temperature of aggregates in day of concrete

preparation.

Concrete temperature from download from mixer, which should be between +150C and +300C.

During transporting of concrete, measures will be taken to limit damage to the minimum heat of

concrete by:

Avoid large transport distances, of the stationary and concrete transhipment.

Shovels and dumper will be covered with tarpaulins.

Before loading new concrete quantities shall be checked if inside of used vehicle there are ice or

frozen concrete. They will be carefully removed if it exists, using a hot water jet.

Concrete compacting is mandatory using mechanical vibration. Concrete protection after pouring

must ensure temperature of min. +50C, on whole period until to reach a resistance of min. 50daN/cm2,

when the cold weather can not affect concrete quality.

The minimum time of protection keeping for resistance achieving 50daN/cm2 is called pre-hardening

time and is determined by:

Type of cement used and the ratio value W/C.

The average temperature of the concrete from work.

3.12 Execution of Foundations

3.12.1 General conditions

The execution of concrete and reinforced concrete foundations shall be comply with the provisions

contained in Code NE 012-1:2007. The execution of foundations will be considered following:

The materials utilized in the project must comply with instructions and prescriptions of

manufacturing standards and rules in force.

Execution of foundations cant begin if not in advance did the foundation excavation control.

Foundation will be performed as much as possible, without interruption on the distance

between two joints of settlement, in the case when this condition could not be respected shall

be proceed according to the "Working Joints".

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

11J01917-CIV-SP-000-001

C0

D0

Sheet

F0

18

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Maximum allowable period of interruption of concrete, for which special measures are taken to

resume concreting, will be between 1.5 and 2 hours.

Where the joint work of the foundation cant be avoided, it will be made vertically.

Strips pouring of foundation shall be made in horizontal layers of 30-50 cm, and overlapping

the next upper layer of concrete will be required before the cement plug in the lower layer.

Joints shall not be admitted working in foundations or in isolated areas with maximum

concentrations of effort.

The pouring will be replay after joint surface preparation:

o

Joint working surface should be well cleaned and washed with plenty of water

immediately before pouring fresh concrete.

In case of interruption with longer durations, the surface treatment of reinforced

concrete will be started with long watering (8-10 hours) before concreting and cleaning

with wire brush, air blow.

Before foundation pouring, shall be checked the number of reinforcing bars, position, diameter,

length, distance, etc., as well as the measures to maintain the verticality bars for vertical elements.

Shall be checked also, the formwork in the correspondence with the project regarding the position and

size, if properly cleaned and thickness of cover layer and dimensions of covering, whose minimum

thickness will be:

For foundation sitting on lean concrete layer, for bottom reinforcement ............ 35 mm

For foundation faces in contact with earth........................................................... 50 mm

Allowable deviations for dimensions of covering layer ..................................... +10 mm

If the concrete elements are exposure to humidity, shall be respected all regulations included by

project and according to NE-012-1:2007, regarding minimum class of concrete, ratio of water-cement

and cement dosage to assure required non-permeability.

3.12.2 Grouting

High strength grout for precision support of machine base and soleplates, including equipment subject

to thermal movement, tanks, column base plates, bridge seats, anchor bolts and dowels, etc., shall be

a non-shrink, ready-to-use, fluid precision grout material, proportioned, premixed and packaged at the

factory, delivered to the job site to be placed with only the addition of water, formwork, and curing

shall be as specified.

Before depositing new concrete on or against concrete that has set, existing surfaces shall be

thoroughly roughened and cleaned of laitance, foreign matter and loose particles. Forms shall be retightened and existing surfaces slushed with a grout coat of mortar consisting of cement and fine

aggregate in the same proportion in the mix, but not leaner than one (1) part cement to two (2) parts

fine aggregate, after the existing surface has been moistened. New concrete shall be placed before

the grout has attained initial set.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

D0

Sheet

11J01917-CIV-SP-000-001

F0

19

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

3.12.3 Anchor Bolts

Anchor bolts for the columns fixed on foundation shall be made from steel of quality minimum class

4.6. For very large loads, which would lead to complicated solutions for column base plates, is

acceptable to use anchor bolts with physical and mechanical characteristics of class as 8.8 (low alloy

steel with heat treatment of normalization).

Anchor Bolts will be fitted with two nuts and a washer. Minimum distance of the centre of the anchor

bolts to the edge of the pedestal will be 100 mm or for times the bolt diameter which is greater.

All anchor bolts will be the embedded type, that is, placed in forms before the concrete poured. For

particular installations, anchor bolts will be placed after construction of the foundations, in this case,

adequate pockets will be provided in the foundation (before concreting), for anchor bolts to be

installed later. Pockets will be used filled using non-shrink grout.

All instances will be specifically noted on the drawings. Anchor bolts and inserts will be set accurately

with respect to position, orientation, verticality and projection.

Tolerance of anchor bolts for single equipment base frames will be:

distance between the bolts: maximum 2.0 mm

level of bolts:

maximum 15.0mm

Anchor bolts will be protected throughout the construction works from physical damage and corrosion,

until the installation of the supported facilities is complete.

The anchor plates are part of the concrete structure supply. On the steel structure drawing, the

centre-line and the top edge of the anchor plate is taken from the foundation drawings

3.13 Execution of Vertical Elements

Execution of vertical elements - columns, walls, for all elements having maximum 3 m height is

permitted to provide the formwork on all sides and height. Concreting is permitted starting to top of

item if concrete vibration is not hampered by small thickness of the element or reinforcement

distances. The first layer of concrete will have a consistency to maximum allowable limit by the

execution procedure and shall not exceed a height of 30 cm.

3.14 Execution of Beams and slabs

The concreting of beams and slabs shall respect the following additional specifications:

Pouring of beams and slabs will start after 1-2 hours from pouring end of columns or walls that

supports, if the execution procedure does not contain any specifications.

Beams and slabs that come in contact will usually pour simultaneously. It is admitted to create

a working joint having from 1/5 to 1/3 of slab length and then later its pouring.

To pouring slabs will be used benchmarks ordered to maximum distance of 2 m, to ensure

compliance the designed thickness.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

20

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

3.15 Precast Elements

3.15.1 General Data

Precast elements will be made in accordance with the prescriptions of Code NE 013-2002.

Cement, aggregates and water used in precast pre-stressed to achieve, should meet the

requirements of NE Code 013 - 2002 and standards in force.

Items for paving and drainage ditches will have the following characteristics:

Class of exposure to environmental action:

XC4

Freeze-thaw attack phenomenon:

XF3

Resistance class:

CEM II/A-S42.5 N

Compressive strength class:

C30/37

According to code NE 013-2002 prescriptions, selecting components and setting concrete

composition shall be designed by precast unit based on preliminary mixes established and verified by

authorized laboratory. The composition of concrete mixtures preliminary conditions must be

established for real work.

Works for formwork, reinforcing and concrete pouring shall follow prescriptions of Code NE 013-2002.

On site, before downloading precast visual control is required. For accepting of elements, it shall be

making verification immediately, after receiving their transportation, control being performed according

to NE 012-2002.

Mounting of precast elements is performed based on data from project. Depending on the complexity

of mounting works, through project shall be provided necessity of technological project design and

elaboration of specification by designer.

The project will include at least the following:

a) The quantity of items to install, for each sort;

b) Transport to the installing place;

c) On-site storage location and conditions of installing and supporting (if installation is not

executed directly from the means of transport);

d) Methods of installation, necessary equipment and its location;

e) Development order of the installation operations;

f) Working teams required for installation;

g) The graphic of work for the transport and mounting of precast elements, prepared in

accordance with mounting order of elements and considering the required time for hardening

of fill joints, if any;

h) The preparation of filling zones and areas on which will be leaned the items;

i) The positioning and rules for verifying the installation permissible deviations;

j) The measures necessary for provisional fixation elements;

k) Order of welds execution and technical condition of quality that must be fulfilled welds;

l) Steps which is necessary a partial reception of mounting works or of joint and other secondary

works;

m) Allowable deviations from mounting.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

Rev.:

C0

D0

Sheet

F0

21

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

In determining the measures required for provisional fixing of elements shall be considered the

standards SR EN 1991-1-6 and SR EN 1991-1-6/NB.

Succession of assembly operations is considered by the possibility of definitive joints execution, which

should not be hampered by further elements that are mounted or in performing other works.

3.15.2 Execution of installation and joints

Before installation must be performed as follows:

a) Surfaces checking coming into contact and those who come into joint, particularly the following:

compliance with conditions for dimensions and shape (flatness, roughness and so on), as

applicable

adequate processing (eg. brushing with a wire brush and plenty of washing if coming into

contact with joint concrete or mortar), if applicable

the position and shape of the reinforcements or other pieces entering in joint

cleanliness

b) Detail marking of seating position, with benchmarks of the setting areas and on the elements which

are mounted.

c) Verification of seating surfaces elevation that are mounted elements.

d) Preparation of temporary means to ensure the stability of mounted element pending final joint, if is

necessary.

For installation of precast elements shall be used equipment to ensure a safe installation. For lifting

the precast elements shall be executed a prior temporary lifting up to approx. 20 mm height for

checking of items catching in hook.

Items will be realised from hook only after correct achievement of bearing. It is mandatory to ensure

stable balance of all mounted elements or which resting on them.

It is forbidden the installation of items on other elements that were not permanently fixed (except as

provided by project).

Permanent joints must be performed as soon as possible after assembly.

3.15.3 Joint execution of precast elements

Filling joints between precast elements can be done by:

Pouring concrete in large spaces (100 ... 200 mm)

Epoxy paste, in which case the joint thickness should not exceed 1 mm; resins used will be

done based on legal technical documents and on supplier provisions.

Other special methods based on technical legal documents.

After items placing in assembly position and joints filling shall be take measures to prevent dirt to the

inside face of joints.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

Rev.:

C0

D0

Sheet

F0

22

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Before filling joints with mixtures based on cement, those faces of the panels will be wetted with

water, taking the necessary measures to remove water from the joints.

3.15.4 Checking and reception of mounting works for precast elements

Checking for precast installation works include:

Check position into plan and height and verify whether into admissible deviations for each

mounted element.

Verification by direct visual observation of bearing for simple bearing on mortar layer.

To groups of non-structural elements, direct examination can be made by survey.

Reception is performed for both precast elements provided by the manufacturer on order, as well as

those made by executing in own workshops or on site (pre-cast) and shall be noted into the minutes

of quality reception.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

11J01917-CIV-SP-000-001

C0

D0

Sheet

F0

23

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

REINFORCEMENT BARS

4.1

General provisions

Reinforcing steel must meet technical conditions prescribed in STAS 438/1-89, 438/2-91, STAS

438/3, 4-98, STAS 6482/2, 3-80.

Types currently used in reinforced concrete elements and their application areas are complying with

Code NE 012/2-2010:

Meshes for reinforced concrete Class S 440 (symbol STNB), constructive or strength

reinforcement, as per SR 438-3/4.

Reinforcing steel with regularly profile Class S 355 (symbol PC 52), strength reinforcement.

Flat steel Class S 235 (symbol OB 37), constructive and strength reinforcement.

Delivery reinforcing steel according to the site is in force accompanied by quality certificate issued by

the manufacturer (if the delivery does the manufacturer).

Bars for reinforcement shall be stored on the types of diameters.

For bending, reinforcement must be clean and straight, for this purpose must be removed:

Traces of oil, paint, soil, mortar or other impurities;

Adhering rust is off by hitting with hammer;

Rust adhesion, friction wire brush.

Shaping and mounting bars and mesh reinforcement shall be in accordance with the project

execution.

Cut and shaped bars are stored in packages labelled by type, in such a way as to avoid confusion

and to preserve their shape and clean up when mounting.

It prohibits shaping reinforcement above 100C. Profile bars with regular diameters greater than 25 mm

will dress warm.

Reinforcement will finish with or without beaks according to the project. If reinforcement flat with a

diameter "d" beak bend to 1800 having a inner radius 1.25 d and right end portion of at least 3 d.

For reinforcement with periodic profile, beak bends to 900, with inner radius of at least 2 d and right

end portion of at least 7 d.

Mounting reinforcement can begin only after receiving the quality of formwork.

Reinforcement shall be mounted in the position covered by the project, taking measures to ensure its

maintenance during concrete pouring (spacers, clips, caps, etc.).

Spacers can be of cement mortar in the form of prisms set with a wire armature to be related to, or

made of plastic.

It is forbidden to use the spacers to the reinforcing steel coupons.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

11J01917-CIV-SP-000-001

C0

D0

Sheet

F0

24

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Anchor bars and steel plate embedded points will be fixed by welding of reinforcement element, or be

connected with wire casing or reinforcement, ensuring maintenance of their correct position during

pouring.

Overlaps reinforcement shall be in accordance with the project requirements.

In the event that the project does not indicate where and how to splice the bars, its position will be

established so that a section has no more than 50% bars. Overlaps reinforcement over 25 mm

diameter shall be welded (required from 32 mm diameter), according to paragraph 8.4, NE 012-2.

Minimum length of overlap for reinforcements which are spliced shall be as per SR EN 1992-1-1 & SR

EN 1992-1-1/NB.

Reception of reinforcement, welds and pieces embedded shall be recorded after verification by

Authorization Site Checker and beneficiary in the minutes of work which are becoming hidden.

4.2

Reinforcement Bending

Reinforcement bending can be done by General Contractor (into own workshops and / or on-site) or

by commissioning it by General Contractor to a specialized manufacturing into reinforcement bending.

Reinforcement bending shall be in accordance with the laws in force in terms of technological

equipment used and the personnel performing the work.

Reinforcement bending should be performed under the following conditions:

Bending does not run below - 100C.

Bending of rolled bars will be done only slowly, using two-speed machines.

Bending bars are made with slow moving, with uniform speed, without shocks.

Diameter of used mandrels for bars bending used should be:

o

for bars having nominal diameter less than or equal to 16 mm, at least four times the

diameter of the bar

for bars having nominal diameter greater than 16 mm, at least seven times the diameter of

the bar

Shape and size hooks at the bars ends shall be according to the applicable technical

regulations and shall be specified in the project.

Bending radius for inclined bars and stirrups / clips will be also those specified in applicable

technical regulations. They must be specified in the project.

Tolerance classes for reinforcement bending shall be applied in compliance with the requirements of

Annex C, NE 012-2.

4.3

Checking and Reception of Mounted Reinforcement

Checking and reception of mounted reinforcement shall be:

a) At finished reinforcement works, for a working stage, when is done also, work reception.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

25

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

b) Immediately before concrete pouring, when shall be perform a new checking.

Checking of mounted reinforcement shall be made by direct examination and simple measurements,

which refers to the following:

The type, class and traceability, by visual observation and confrontation with the documents

on those products.

Diameters and respecting of tolerances concerning the dimensions and positions, by direct

measurement at least two sections, in each area where reinforcement is different, particular

attention being given to distance from formwork (concrete cover).

Overlaps position, by visual observation and direct measurement.

Reinforcement linking to cross and existence of spacers, by visual observation and

appreciation.

Reinforcement status, by visual observation and measurement, as appropriate, regarding:

o

Clean: reinforcement surface should not be covered with materials that prevent

adhesion (earth, grease, etc.)

The state of corrosion

Reception of mounted reinforcement represents the confirmation of compliance with the project and

provisions of applicable technical regulations, on the checks carried out. It will sign a minutes of

qualitative reception on phases (for works becoming hidden), with the participation of the Beneficiary;

for reinforcement reception of structural elements will be involving the designer.

4.4

Concrete covering

To ensure the designed covering shall be proper provide of plastic or mortar spacers. It is forbidden to

use spacers made by steel or wood coupons.

For the elements made monolith in site, minimum thickness of concrete cover layer of reinforcement

is:

Slabs or dense ribs of slabs

- 10 mm, but not less 1.2 bar diameter on the first layer

Structural walls:

- 15 mm, but not less 1.2 bar diameter on the first layer

Beams, columns, wall bulbs of structural walls:

Foundations

- 25 mm

- 35 mm for side, this is in contact with lean concrete or formwork

- 50 mm for side, this is in contact directly with earth.

Minimum thickness of the cover layer for longitudinal reinforcement must respect the above values,

but to be at least equal to 1.2 times diameter of longitudinal bars.

Maximum thickness of the cover layer is limited to 50 mm.

4.5

Replacement Reinforcement

Unless have the assortment and diameter specified in the project, it can proceed to replace them only

with the designer approval.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

Rev.:

C0

D0

Sheet

F0

26

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Replacement of reinforcement provided in the project will follow the execution drawings which are

submitted to Construction Book.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

11J01917-CIV-SP-000-001

Rev.:

C0

D0

Sheet

F0

27

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

FORMWORK

5.1

General

The composition and assembling formwork should be such as to ensure the necessary stability under

the action of loads that appear in the execution. It must also securing shape, size and degree of finish

to the project for items to be made complying with the allowable deviations required by Code NE 0121:2007.

Calculation of formwork and their support shall take into account the normative provisions NE 0122007. Can be used formwork of wood materials (tego, boards), removable metallic formwork, made

from the recyclable items or subassemblies at a number of reusing (the tapes).

Before installing the panels, check invariably only rehabilitate formwork, taking into consider the

following:

Not allowed re-lining panels with discontinuous.

Not allowed re-using formwork that system resistance weakened, loose mounting lifting lugs,

loose or damaged.

Before installing formwork used previously will be taken that they be cleaned from inside the

adherent mortar or other foreign objects, recommending wax emulsion lubrication panel, to be

applied shortly before concreting.

Formwork must be caught its drip grout and mortar.

Geometric deviations at the formwork assembling from fixed dimensions by the project will be to enrol

in the allowable limits (tolerances complying) with the specified in normative NE 012-1:2007).

When removing the formwork shall be taken all measures and precautions required to avoid damage

to or destruction poured concrete formwork.

Formwork removal is forbidden by beating, forcing or striking the allegations.

Minimum time removing the formwork will be indicative of NE 012-1: 2007 and in any case there will

be less time needed to achieve the following resistances:

At least 50 daN/cm for lateral sides

Minimum of 75 daN/ cm for openings.

At least 50% of mark for length up to 2 m

At least 70% of mark for length 2 m and 8 m.

5.2

Acceptable Deviations to Formwork Installing

Tolerances for formwork assembly refer to the following categories:

Dimensions of space for formwork

Elevations (for formwork bottom, concreting height, etc.)

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

11J01917-CIV-SP-000-001

C0

D0

Sheet

F0

28

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Axes position, in plan and height (including straightness and perpendicularity or provided

angle, if any)

Surface form (including flatness and local bump as appropriate)

Acceptable deviations for dimensions, elevations and axes position, if they are not express included in

the project, will be provided for those items.

5.3

Checking and Reception of Formwork and Its Supports

Checking of formwork and its supports is performed:

At the end of formwork works, for one work step, when it is performed formwork reception.

Immediately, before placing of concrete, when it is performed a new checking.

Checking of formwork and its supports shall be made by direct examination, simple measurements

and measurements using equipment.

Checking of formwork and its supporting, by direct observation and simple measurements refers to

following:

Comparing with the provisions of the technological project and / or provisions manufacturer

regarding:

o

the composition of assembly by visual

the types of materials and them integrity by visual and analysis their quality records,

dimensions by measurement

joints (fasteners and contact between elements in joint): visual and application by

hand, have no stake in joint

Corresponding placement of items / formwork panels themselves, from the base of the

boundary and between them, by visual - position and no empty spaces between them

Support or punctual link elements (struts, inclined bracing, interior links etc.) are fixed: by

application with hand, do not have the play, interior connections are correctly mounted, by

visual observation

Cleanliness, by visual

Application of de-moulding agents, by visual

Sizes with at least 2 sections for each element and the holes and their relative position, by

direct measurement

Tracing of the concreting height, by direct measurement towards the bottom formwork, or to

other existing surfaces

The general appearance of the surface which comes into contact with concrete, by visual.

Nonconformities, either in terms of compiling and assembly, either overcoming tolerances (allowable

deviation) on sizes and / or position shall be recorded and shall be resolved by the General

Contractor.

Checking formworks and their support shall be made again during the 24 hours before installing

reinforcement, if necessary, before starting concrete work, if between these operations has passed a

longer period. This second check is performed by direct observation and simple measurements.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

C0

11J01917-CIV-SP-000-001

D0

Sheet

F0

29

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Reception of formworks and their supports represents the confirmation of compliance with the project

and provisions of applicable technical regulations, on the checks carried out. It will sign a minutes of

qualitative reception on phases (for works becoming hidden), with the participation of the Beneficiary;

for reception of special formworks and scaffolds will be involving the designer which prepared the

specifications.

5.4

Casting Made in Land Areas

5.4.1

General

A. Casting areas made in land (case of holes for foundations pouring or pouring on horizontal

and inclined surfaces are, in generally formed from earth works. The main conditions for the

space execution of casting in these cases refer to the following:

Ground / embankment status

Axes, dimensions and levels

The surface

B. Conditions of ground or embankment status include:

Ground status for casting directly in excavation

The embankment status

C. Conditions of axes, dimensions and levels include:

Axes and dimensions in plan and height: to comply with the allowable deviations

included in the project, or the specific requirements.

Cases where, given the nature ground or other conditions, the execution excavation

have resulted in some areas, larger, leading to additional consumption of concrete: to

provide, where appropriate, formwork on those areas.

Levels: will be assigned in the allowable deviations included in the project, noting that

for embankments, quotas are the results after taking embankment.

D. Conditions of form surfaces include:

flatness or, where appropriate, curved form of the excavation

local irregularities, which should not affect the sizes or elevations

5.4.2

Permissible deviations for casting spaces made in the field are the followings:

Where the elements, which will be poured are reinforcement elements and thickness of

concrete cover to reinforcement is taken into consideration:

- 0 mm +50 mm

In other cases:

- 24 mm +50 mm

5.4.3

Checking of casting spaces made in the field is performed to:

Axes verification and framing of tolerances, in plan and height, if applicable: with

adequate equipment.

File name: PE-D-DJ1784-CS-SPC-001-F0-E

FRD OIL PROJECTS STANDARDS

GENERAL SPECIFICATION FOR EXECUTION OF CONCRETE WORKS

Contractor doc. no.:

Rev.:

11J01917-CIV-SP-000-001

C0

D0

Sheet

F0

30

Company doc. no.:

of

45

PE-D-DJ1784-CS-SPC-001-F0-E

Checking dimensions and their relative position towards the axes and checking of

classification in tolerance: by direct measurement in least two sections for each

element.

Checking the surface appearance and if appropriate, flatness: by direct measurement.

Checking the cleanliness of the space: by visual observation.

Reception consists in approval of compliance work in a report for quality reception on phases (for

works that are hidden).

5.5 Previously and necessary conditions during execution of formwork and their supports

Previously conditions refer, mainly, to the following: