Documente Academic

Documente Profesional

Documente Cultură

MVINC-CO-X-M-x-x: User Manual

Încărcat de

Abdul_SamadTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MVINC-CO-X-M-x-x: User Manual

Încărcat de

Abdul_SamadDrepturi de autor:

Formate disponibile

MVINC-CO-X-M-x-x

User Manual

Author: JKA

File: MVINC-CO-X_user_manual_2_04

SW: 2.17

Version:2.04

Modified: 11.12.2006 16:16

MVINC-CO-X-M user manual

User Manual

Version 2.04

Table of Contents

1.VERSION HISTORY...........................................................................................................................4

2.GENERAL.............................................................................................................................................5

2.1ABBREVIATIONS AND TERMS...................................................................................................................6

3.SUMMARY OF TECHNICAL SPECIFICATIONS........................................................................ 7

4.ORDER CODES................................................................................................................................... 9

4.1FOR INCLINOMETER MODULES............................................................................................................... 9

4.2FOR ACCESSORIES................................................................................................................................ 9

5.INTEGRATING THE DEVICE INTO THE APPLICATION...................................................... 11

5.1MEASURING AXIS AND ZERO ANGLE LEVELS............................................................................................ 11

5.2DIMENSIONS OF THE MVINC MODULE ............................................................................................... 15

5.3CONNECTORS..................................................................................................................................... 15

5.3.1Spring load PCB connector ................................................................................................. 16

5.3.2Housing connectors............................................................................................................... 16

5.3.2.1MIL4................................................................................................................................................16

5.3.2.2MIL6................................................................................................................................................17

5.4CAN BUS CABLING............................................................................................................................ 17

5.5ACCESSORIES..................................................................................................................................... 18

5.5.1Assembly sets......................................................................................................................... 18

5.5.2Mating Connectors.................................................................................................................19

5.5.3Termination stubs...................................................................................................................20

5.5.4Cables.................................................................................................................................... 20

6.SOFTWARE UPDATES.................................................................................................................... 21

6.1PROGRAMMING CABLE......................................................................................................................... 21

6.2INSTRUCTIONS TO HANDLE SOFTWARE UPGRADES ..................................................................................22

6.2.1General.................................................................................................................................. 22

6.2.2Update Procedure..................................................................................................................22

7.PROFILE AND MANUFACTURER SPECIFIC FEATURES .................................................... 24

7.1INCLINOMETER RELATED

FUNCTIONS AND CONFIGURATIONS.......................................................................26

7.1.1General.................................................................................................................................. 26

7.1.2Angle resolution..................................................................................................................... 26

7.1.3Angle inverse and offset configurations.................................................................................27

7.1.4Procedure to configure resolution, inversion and offset....................................................... 30

Copyright Axiomatic Technologies Oy

2/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

7.1.5Internal timing ...................................................................................................................... 31

7.1.6Angular rate and acceleration outputs ................................................................................. 31

7.2COMMUNICATION CONFIGURATIONS .......................................................................................................32

7.2.1Device type (0x1000)............................................................................................................. 32

7.2.2Device identity (0x1018)........................................................................................................ 32

7.2.3Emergency messages............................................................................................................. 33

7.2.4CAN bus baudrate..................................................................................................................33

7.2.5Node ID.................................................................................................................................33

7.2.6PDO configurations............................................................................................................... 34

7.2.7The boot up print....................................................................................................................37

7.2.8The RS232 prints...................................................................................................................38

7.2.9The RS232 command set ...................................................................................................... 40

8.CANOPEN MANUAL AND SUPPORTED DS301 SPECIFIC OBJECTS .................................43

8.1HOW TO READ A CAN MESSAGE SEEN WITH A SIMPLE CAN TOOL............................................................43

8.2OBJECT DICTIONARY (OD).................................................................................................................. 43

8.3NETWORK MANAGEMENT (NMT).........................................................................................................43

8.4PROCESS DATA OBJECT (PDO).............................................................................................................44

8.4.1PDO COB ID......................................................................................................................... 45

8.4.2Disabling And Enabling a PDO............................................................................................ 46

8.4.3PDO transmissions................................................................................................................ 47

8.4.4PDO mappings.......................................................................................................................48

8.5SERVICE DATA OBJECT (SDO)............................................................................................................. 49

8.6SAVING THE OBJECT DICTIONARY PARAMETERS........................................................................................ 50

8.7RESTORING THE DEFAULT VALUES TO THE OBJECT DICTIONARY...................................................................51

8.8SPECIAL FUNCTIONS AND OBJECTS......................................................................................................... 51

8.8.1Boot-up message.................................................................................................................... 52

8.8.2Synchronization object (Sync)................................................................................................52

8.8.3Error Control ( Heartbeat Features).....................................................................................53

8.9LAYER SETTING SERVICE LSS.............................................................................................................. 54

8.9.1Protocol for setting the baudrate...........................................................................................54

8.9.2Protocol for setting the node ID............................................................................................ 55

9.OBJECT DICTIONARY................................................................................................................... 56

Copyright Axiomatic Technologies Oy

3/63

MVINC-CO-X-M user manual

1.

User Manual

Version 2.04

VERSION HISTORY

Versio

n

Date

Initials

Description

2.03

Nov.13th 2006

JKA

-PDO default values corrected to the PDO configurations chapter

-Version history chapter added

-Some layout corrections

-Module dimension drawing added

-Measuring axis drawings for units having MIL connectors added

2.04

Dec.11th 2006

JKA

-Filter delay spesified more preciously

-dimension and measuring axis drawings added

Copyright Axiomatic Technologies Oy

4/63

MVINC-CO-X-M user manual

2.

User Manual

Version 2.04

GENERAL

MVINC inclinometer module measures the angles of slope, elevation or inclination of an

item with respect to gravity. Measured values are provided both via CANopen and RS232

interface. The CANopen interface fullfills the CIA's communication profile DS301 and the

inclinometer profile DS410.

Depending on the module it has 1 or two measuring axis. Nominal measuring range is

0...180 degrees for MVINC-CO-1-180 (single axis) and MVINC-CO-2-180 (dual axis)

model. MVINC-CO-1-360 is capable to measure angles from 0 ...360 degrees.

Sensor elements are MEMS based which guaranties fast response time and good tolerance

against interference caused for instance by motor vibrations. Module provides also

sophisticated digital filtering which stabilizes the signal noise level below +-0.02 degrees.

The MVINC-CO-1-360 model provides additional protection against interference caused by

rotational accelerations. More information about this can be found in Integrating the device

into the application chapter.

In addition of angle data the MVINC

provides also rate and acceleration data

per each measuring axis.

MVINC modules are temperature

compensated which means that the full

accuracy of +-0.2 degrees is available

over whole temperature range.

Module is availeable with different

connector options such as 4 and 6 pin

MIL conenctors and PG outlets.

Drawing 1: MVINC-CO-x-x-PG11-2

Axiomatic Technologies provides vast variety of accessories to ease the intergration task:

Assembly sets, CAN bus termination stubs, mating connectors and cable sets are available.

More information can be found from accesories chapter.

Product highlights:

Several versions:

MVINC-CO-1-180 : single axis with meassuring range of 0...180 degrees

MVINC-CO-1-360 : single axis with meassuring range of 0...360 degrees

MVINC-CO-2-180 : dula axis with meassuring ranges of 0...180 degrees / per

axis

Operation voltage 9...35V

Fullfils CAN open DS301 ver 4.2 communication specification and inclinometer

profile 1.1

IP65 protection class

Accuracy +-0.2 degrees over whole temperature and accurate measuring range.

Applications:

Boom angle measurements (in excavators, lifts etc)

Levelling applications

Copyright Axiomatic Technologies Oy

5/63

MVINC-CO-X-M user manual

2.1

User Manual

Version 2.04

Abbreviations and terms

Abbrevation

description

CAN

Lower layer CAN protocol for upper layer CAN protocols like CAN OPEN,

J1939 and device net-

CANopen

Upper layer protocol for CAN networks

CIA

CAN in Automation, CAN open standardization organization

(www.canorg.net)

CAN ID

ID of the CAN message seen on the bus. Consists of 11 or 29 bits. Part of the

COB ID which can be found in object dictionary

COB ID

Consists of CAN ID and some control and informative bits. Found in object

dictionary

Object

Variable in obejct dictionary

Object Dictionary

Consists of objects, Accessable from CAN bus with SDO writ and read

operations

OD

Object dictionary

DS410 ver 1.1

The CAN open device profile for inclinometers. Version 1.1 is published 1.st

of January 2005

DS301 ver 4.1

The general communication profile for CAN open devices. This version is

published 21.st February 2006

MVINC-CO-1-180-x-x-x

Type of the inclinometer, single axis with accurate measuring range of +- 85

degrees, connectors and potting not defined

MVINC-CO-1-360-x-x-x

Type of the inclinometer, single axis with accurate measuring range of 360

degrees ,connectors and potting not defined

MVINC-CO-2-180-x-x-x

Type of the inclinometer, dual axis with accurate measuring range of +- 85

degrees for both axis,connectors and potting not defined

PCB

Printed circuit board

Accurate measuring range

In MVINC-CO-1-180 and MVINC-CO-2-180 modules the accurate measuring

range isn't equal to the full measuring range. Accurate range starts from +5 and

ends to + 175 degrees.

Table 1: Abbreviations and terms

Font

italic

Bold and italic

Meaning

internal inks, names of the tables and drawing

Names of the objects

Table 2: fonts and their meanings

Copyright Axiomatic Technologies Oy

6/63

MVINC-CO-X-M user manual

3.

User Manual

Version 2.04

SUMMARY OF TECHNICAL SPECIFICATIONS

All specifications typical at nominal input voltage (24 V) and 25 C unless otherwise

specified.

Operating voltage

(power supply

requirement)

Reverse polarity

protection

Current consumption

9 to 35 VDC

RS232

CAN

Baudrates up to 115200 kbits/sec, RS232 level

Philips TJA1050 Transceiver

Baudrates 50kB to 1MB

Measuring range

MVINC-CO-x-180 : 180 degrees, accurate range 5... 175 degrees.

MVINC-CO-x-360 : 360 degrees, accurate range 0...360 degrees

Accuracy

(over whole

temperature range)

MVINC-CO-x-180 :

In accurate range : +-0,2

otherwise : +-0.7 degrees

MVINC-CO-x-360 :

tilt between -30 ... +30 degrees : +-0,3 over whole measuring range

tilt between -60 ... -30 or +30 ... +60 : +-0,4 degrees

tilt between -85 ... -60 or +60 ... +85 : +-0.6 degrees

MVINC-CO-1-360: less than +-30 degrees to maintain the best accurary

between -60 ... -30 or +30 ... +60 : +-0.4 degrees

between -85 ... -60 or +60 ... +85 : +-0.6 degrees

absolute maximum allowed tilt angle is +-85 degrees

MVINC-CO-1-180: less than +-70 degrees to maintain the best accurary

between -70 ... -80 or +70 ... +80 : +-0.4 degrees

absolute maximum tilt is +-85 degrees

0.1 as default. SW adjustable between 0.01 and 1 degrees

70 250ms, depending on the module type and ave filter configuration

70ms (MVINC-2-X-CO or MVINC-1-360 with zero AVE)

Maximum tilt angle

(tilted perpendicural

to the measuring axis

Resolution

Delay

Provided

70mA with 24volts

Table 3: Electrical Specifications

Copyright Axiomatic Technologies Oy

7/63

MVINC-CO-X-M user manual

Operating conditions

Declaration of

conformity (CE)

Communications

LED indicators

Electrical connections

EMC compatibility

User Manual

Version 2.04

-40 to +85C (-40 to 185F)

Yes

CAN bus: CANopen

RS232

Inside the module: green power led and red/green status led.

4 and 6 pin military, PG outlets or customer spesific,

Fulfills the requirements of the heavy industrial environment.

Emissions:

EN61000-6-4:2001

Immunity:

EN61000-6-2:1999

Protection class

Vibration

Weight

IP65

Vibration compliance is suitable for mobile equipment and industrial applications.

Fully potted (MIL connector variants)

Half potted (PG outlet and MIL connector variants)

Packaging and

dimensions

Aluminium housing.

75 x 79 x 58 mm (W x L x H), mounting brackets and connectors excluded

Table 4: General specifications

Specifications are subject to update without notice.

Copyright Axiomatic Technologies Oy

8/63

MVINC-CO-X-M user manual

4.

User Manual

Version 2.04

ORDER CODES

4.1

For Inclinometer Modules

MVINC -

CO

180

MIL4

Can protocol

Amount of

measuring

axis

Measuring range per

axis

Conector type

Amount of

connectors

CO =

CANopen

1 = single

180 = nominal

range +-90 degrees

per axis, accurate

range +-88

MIL4 = 4 pin

military C5015

1 = one

2 = dual

360 = 360 degrees

MIL6= 6 -pin

military KPSE

2 = two

PG11 = PG11

outlet

Table 5: MIVINC order codes

4.2

For Accessories

C1

MIL4

D1

B1

90

250

B2

D2

C2

Connector type

Connector

dust cap

Cable boot

angle

Cable lenght in

centimeters

Cable boot

angle

Connector

dust cap

Connect

or type

MIL4 : 4 pin

military C5015

D:

dust cap

provided

90 : 90 degrees

0...20000

See B1

options

See D1

options

See C1

options

MIL6 : 6 -pin

military KPSE

0 : without

cap

0 : 0 degrees

Dust cap

selected

90 degrees

boot

2.50 meters

No boot

No cap

Free

end

0 = free end

MIL 4 connector

selected

Table 6: Order codes for cable sets

Copyright Axiomatic Technologies Oy

9/63

MVINC-CO-X-M user manual

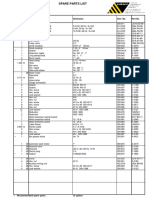

Order Code

User Manual

Part description

Version 2.04

Supplied

quantity

AS-1

Assembly set #1

AS-2

Assembly set #2

WP

welding plate

MP-HW

Mounting plate with high sides walls

MP-LW

Mounting plate with low sides walls

CT-270

Cable tie 4*270mm

M8-ND

M8 nordlock

M8-NUT

M8 Nut

M8-25-HEX-SOCKET

M8 * 25mm Hexagon Socket Screw

MIL4-F-W

Wire connector MIL4 female , 4 pins

MIL6-F-W

Wire connector MIL6 female, 6 pins

BOOT-90

Cable boot 90 degrees angle

BOOT-0

Cable boot straight

RS232-D9F-Free

RS232 programming cable. Cable length

is 1 meter.

CAN-T_STUB-MIL4-F

120 ohm CAN termination stub in MIL4

female connector

CAN-T_STUB-MIL6-F

120 ohm CAN termination stub in MIL6

female connector

CAN-TR-120-7W

120 ohm 7 Watts termination resistor

Table 7: Order codes for accessories excluding cable sets

Copyright Axiomatic Technologies Oy

10/63

MVINC-CO-X-M user manual

5.

5.1

User Manual

Version 2.04

INTEGRATING THE DEVICE INTO THE APPLICATION

Measuring axis and zero angle levels

The drawings below describe the zero levels as well as measuring axis and the positive

direction of measuring axis for all the inclinometer types. Offset and inversion functions are

not used.

Long corresponds to the longitudal axis (object 0x6010)

Lat corresponds to the latitudal axis (object 0x6020)

The MVINC-CO-1-360-x-x module is intended to be mounted on side so that the cover

points to the side.

Illustration 1: MVINC-CO-1-360-PG-x module mounted on its side

Copyright Axiomatic Technologies Oy

11/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

Illustration 2: MVINC-CO-1-360-MIL4-1

Copyright Axiomatic Technologies Oy

12/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

MVINC-CO-2-180-x-x module should be installed so that the cover points upwards.

Illustration 3: MVINC-CO-2-180-PG11-x mounted on bottom

Illustration 4: MVINC-CO-2-180-MIL4-1 measuring axis

Copyright Axiomatic Technologies Oy

13/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

The MVINC-CO-1-180-x-x module should be mounted on its side or so that the cover

points upwards.

Illustration 5: MVINC-CO-1-180-PG11-X module mounted on side

Illustration 6: MVINC-CO-1-180-PG11-X module mounted on its bottom

Copyright Axiomatic Technologies Oy

14/63

MVINC-CO-X-M user manual

5.2

User Manual

Version 2.04

Dimensions of the MVINC Module

Illustration 7: Dimensions and mounting holes of MVINC housing

5.3

Connectors

The MVINC module can be connected to CAN bus with MIL connectors or spring loaded

connector terminals depending on the selected connector type (MIL-4, MIL-6 or PG). All

connector types allow connecting the device to the bus as a chained node or with a drop

line.

In addition of CAN bus connection module provides also RS232 interface as data output.

RS232 connection is also used for software upgrades. RS232 signals are normally available

in spring load connector block, though in case of MIL6 connector they are also available in

housing connector.

Connector pinouts are described in the following sub chapters. The following signal types

are used:

Copyright Axiomatic Technologies Oy

15/63

MVINC-CO-X-M user manual

Abbrev.

User Manual

Version 2.04

Meaning

PWR

Power supply signal

GND

Ground level signal

CAN

CAN bus signal (ISO 11898)

RS232

RS-232 signals

Table 8: Signal Types

5.3.1

Spring load PCB connector

The PCB connector consists of ZFKKDS-5.08 spring load terminal blocks and which are

manufactured by Phonix Contacts.

Maximum allowed wire size is 1.5mm2 (AWG 16)

Pin

Signal

Type

Function

CAN sh

CAN

CAN shield

V supply

PWR

Power supply

GND

GND

Power supply ground

CAN hi

CAN

CAN bus hi signal

CAN lo

CAN

CAN bus lo signal

Table 9: Connector J1 signals

Power supply voltage range is 9...35 V.

CAN bus signals withstand short circuits to 40V and GND.

5.3.2

Housing connectors

There are two standard options for housing connector: MIL4 and MIL6. Others are

available on request. Both of twose connector types are designed to be used in harsh

environment and they are IP67 rated. Axiomatic Technologies has used them several years

succesfully in various mobile and military applications.

5.3.2.1

MIL4

ITT Cannon CA3102E14S-14S-2P-F80 , 4 pins, male, IP67

Mating connector is TT Cannon CA3106E14S-14S-2P-F80-DN , 4 pins, female, IP67, cable

clamp provided.

Copyright Axiomatic Technologies Oy

16/63

MVINC-CO-X-M user manual

Pin

User Manual

Signal

Type

Version 2.04

Function

V supply

PWR

Power supply

GND

GND

Power supply ground

CAN hi

CAN

CAN bus hi signal

CAN lo

CAN

CAN bus lo signal

Table 10: MIL4 Connector pinnout

Power supply voltage range is 9...35 V.

CAN bus signals withstand short circuits to 40V and GND.

5.3.2.2

MIL6

ITT Cannon KPSE02E10-6P

Mating connector ITT Cannon KPSE6E10-6SDN or KPSE6E10-6SDZ

Pin

Signal

Type

Function

V supply

PWR

Power supply

GND

GND

Power supply ground , used also as

RS232 GND

CAN hi

CAN

CAN bus hi signal

CAN lo

CAN

CAN bus lo signal

RS232_TX

RS232

RS232 transmit

RS232_TX

RS232

RS232 transmit

Table 11: MIL6 connector pinnout

5.4

CAN bus cabling

The bus should be routed continuously from one module to another. Though drop lines with

specified length are allowed. Maximum lenghts are specified in table below. A 120 ohms

terminating resistor must be attached to both ends of the bus. It is recommended to use at

least 7W resistors to ensure that they withstands short circuits to power supply lines.

Baudrate

Max total

bus length

Max stub length

Max accumulated

stub length

1 Mbit/s

25m

1,5m

7,5m

800 kbit/s

50m

2,5m

12,5m

500 kbit/s

100m

5,5m

27,5m

250 kbit/s

250m

11m

55m

125 kbit/s

500m

22m

110m

50 kbit/s

1000m

55m

275m

Table 12: Baudrates, bus and stub lengths

Copyright Axiomatic Technologies Oy

17/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

The grounds of all modules must be toed together using low impedance cabling. It is

recommended to use a system ground point to which all ground lines are connected.

Common ground wires for devices consuming lot of current should also be avoided.

Otherwise potential differences may become too big.

5.5

Accessories

5.5.1

Assembly sets

There are 2 different assembly sets available. The main difference between them is the

shape of the mounting plate. Mounting plate provided in set #1 provides more protection

against mechanical impacts. All parts of the assembly sets are also available separately.

Order code

Reference in

Part name

Provided

Drawing

Quantity In

Drawing #

Set #1

Set #2

WP

Welding plate

MP-HW

Mounting plate with high sides walls

MP-LW

Mounting plate with low sides walls

CT-270

Cable Tie 4*270mm

M8-ND

M8 nordlock

M8-NUT

M8 Nut

M8-25-HEX-SOCKET

M8 * 25mm Hexagon Socket Screw

Table 13: Assembly set part lists

Illustration 8: MVINC with M4 connector(s) and

Copyright Axiomatic Technologies Oy

Assembly set #1

18/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

Illustration 9: MVINC-CO-1-360-MIL4-2 with assembly set 2

5.5.2

Order

Code

Mating Connectors

The following mating connector are available:

Description

Part #

Order Codes for Mating

Dust cap

Cable Boot

MIL4-F-W

4 pin female, AWG max

CA3106E14S-14S-2P-F80-DN

DC-MIL4-F

BOOT-0, BOOT-90

MIL6-F-W

6 pin female, AWG max

KPSE6E10-6SDN

DC-MIL6-F

BOOT-0, BOOT-90

Table 14: Mating connectors, dust caps and cable boots

Mating connectors are supplied with the crimps.

Crimping should be accomplished with particular crimping tool.

Order code for the crimping tool is

Boots

Copyright Axiomatic Technologies Oy

19/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

90 degrees angle :

Manufacturer Raychem, part #222K132-25/225-0, order code BOOT-90

Straight:

Manufacturer Raychem, part # 202K132-25/225-0, order code BOOT-0

Dust caps

5.5.3

Termination stubs

TBD

5.5.4

Cables

Axiomatic Technologies is also able to provide custom cable sets which fit to the MVINC

housing connectors.

Feature

Description

Cable type

Wire count

4 or 6

Temperature

range

-40...125 degrees of celsius

Oil resistant

Yes

Minimum

bend radius

Copyright Axiomatic Technologies Oy

20/63

MVINC-CO-X-M user manual

6.

User Manual

Version 2.04

SOFTWARE UPDATES

Module contains a serial interface for software downloads. The interface utilises RS232

protocol.

Serial port (COM1)

Power supply 12 / 24V

PC

MVINC

J4

J1, J2, X1

or X2

Illustration 10: Setup for software updates

6.1

Programming cable

Particular programming cable is not required. Connecting RS signals (RX, TX , GND) to

the computer's RS232 port is all what is needed. Programming cables are available from

Axiomatic Technologies Oy with order code RS232-D9M-Free

D9 Female

MVINC: connector, pin

Signal

R1, 3

GND

R2, 5

txd

R1, 5

rxd

Table 15: Programming cable pin outs

Copyright Axiomatic Technologies Oy

21/63

MVINC-CO-X-M user manual

6.2

User Manual

Version 2.04

Instructions to Handle Software Upgrades

6.2.1

General

Usually the best way to handle sw upgrades is to send module to Axiomatic Technologies.

However it's possible in some cases that customer handles the update by himself. Contact

Axiomatic Technologies for new SW versions.

Note that sw upgrade results often restoring the settings to factory default values! Factory

calibration data won't normally get lost but other setting are restored!

6.2.2

Update Procedure

Software can be upgraded via RS232 interface.

What is needed :

1. PC with terminal software, for example the HyperTeminal, or the preferred one,

Teraterm

2. Programming cable. See instructions on chapter 6.1.1

.

The HyperTerminal software is found normally in the Windows Start menu ->

Programs -> Accessories -> Communications -> HyperTerminal.

The initial settings in HyperTerminal are done using the following steps:

1. Start HyperTerminal. New connection window opens, where you can type a name for

the connection. Type here MVINC sw download and press Ok.

2. Connect window opens. Select from the drop-down box at the bottom of the window

(Connect using) the serial port you have available on your PC, for example Direct to

COM1.

3. Serial port settings window opens. Enter the following values:

Bits per second:

115200

Data bits:

8

Parity:

None

Stop bits:

1

Flow control: XON/XOFF

4. Now the actual terminal window opens. Press the 'd' button down and power up the

MVINC module. The terminal window should show text Send S file. If you don't see

anything, check the connection of the serial cable, and that the COM port you have

selected is really available on your PC, and try again.

5. Now you can download new software by clicking File -> Send file. File browsing

window pops up. Select correct elf.S -file and click OK. You may also just drag and

drop the file into terminal window.

6. Reboot the module after succesfull download.

7. The bootup print should state that the SW version has changed and settings are restored

to factory defaults

sr-ldr 1.3-5mv

PORInitializing timer...done.

Initializing adc...done.

Initializing ext eeprom...done.

Init I/O...

Reading parameters...

MAGIC: 81680100 SW: 215

285 bytes in EEPROM, reading checksum

Checksum ok, loading parameters from EEPROM

Loading parameters...done.

msCAN: Node ID = 127

msCAN: Baudrate = 125 kbit/s

msCAN: Creating rx-buffer...

msCAN: Creating tx-buffer....

Copyright Axiomatic Technologies Oy

22/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

msCAN: Adding id 7E5 to receive list

Initializing PDO 0, type 2...

Alloc.mem. @0x05D0, size 22 bytes

COB 00004000

-> ID: 1FF, type 254

-> Mapped objs: 4

map obj:1A00 sub:0-> Mapping index 6010, sub 00, size 10

map obj:1A00 sub:1-> Mapping index 2000, sub 00, size 08

map obj:1A00 sub:2-> Mapping index 2000, sub 00, size 08

map obj:1A00 sub:3-> Mapping index 2001, sub 00, size 10

Initializing PDO 1, type 2...

Alloc.mem. @0x05E8, size 22 bytes

COB 0000C000

-> ID: 2FF, type 254

-> Mapped objs: 2

map obj:1A01 sub:0-> Mapping index 5515, sub 00, size 20

map obj:1A01 sub:1-> Mapping index 5516, sub 00, size 20

msCAN: Adding id 67F to receive list

msCAN: Adding id 77F to receive list

msCAN: Adding id 080 to receive list

msCAN: Adding id 000 to receive list

msCAN: Setting 2nd ID filter...done

Sync to CAN...OK

Axiomatic MVINC-CO-1-360 V2.15,RT_t_calib

Released 9.Aug.2006 16:00

SN:0

of:17108 se:13753 tar:-90.0 st:2000 min

0.4422149 ->RAW:3354

of:17108 se:13753 tar:-80.0 st:2800 min

0.0061035 ->RAW:3565

of:17108 se:13753 tar:-60.0 st:4000 min

0.0036621 ->RAW:5198

of:17108 se:13753 tar:-30.0 st:8000 min

0.0009155 ->RAW:10231

of:17108 se:13753 tar:30.0 st:22000 min

0.0009155 ->RAW:23984

of:17108 se:13753 tar:60.0 st:27000 min

0.0036621 ->RAW:29018

of:17108 se:13753 tar:80.0 st:28000 min

0.0061035 ->RAW:30651

of:17108 se:13753 tar:90.0 st:32000 min

0.4422149 ->RAW:30862

of:17108 se:13753 tar:-90.0 st:2000 min

0.4422149 ->RAW:3354

of:17108 se:13753 tar:-80.0 st:2800 min

0.0061035 ->RAW:3565

of:17108 se:13753 tar:-60.0 st:4000 min

0.0036621 ->RAW:5198

of:17108 se:13753 tar:-30.0 st:8000 min

0.0009155 ->RAW:10231

of:17108 se:13753 tar:30.0 st:22000 min

0.0009155 ->RAW:23984

of:17108 se:13753 tar:60.0 st:27000 min

0.0036621 ->RAW:29018

of:17108 se:13753 tar:80.0 st:28000 min

0.0061035 ->RAW:30651

of:17108 se:13753 tar:90.0 st:32000 min

0.4422149 ->RAW:30862

FIR_ORDER:141

ave:delay:50ms

1.0000 (0.00) 1.0002 (0.01) 1.0000 (0.02) 1.0000 (0.03) 1.0000 (0.04) 0.0000 (0.05) 0.9999 (0.06) 0.9999 (0.07)

0.9999 (0.08) 0.9998 (0.09) 0.9998 (0.10)

0.9998 (0.1) 0.9993 (0.2) 0.9985 (0.3) 0.9974 (0.4) 0.9959 (0.5) 0.9941 (0.6) 0.9920 (0.7) 0.9896 (0.8) 0.9868

(0.9) 0.9838 (1.0)

-0.1 (1) -0.5 (2) -1.3 (3) -2.4 (4) -3.8 (5) -5.9 (6) -8.6 (7) -12.5 (8) -19.1 (9) -100.0 (10)

-15.9 (17) -19.3 (27) -21.1 (37) -21.8 (47)

MAIN_LOOP

8. Give #SSt! and #CSa! commands to save the restored settings to nonvolatile memory

9. Reboot the application and reconfigure the module!

Copyright Axiomatic Technologies Oy

23/63

MVINC-CO-X-M user manual

7.

User Manual

Version 2.04

PROFILE AND MANUFACTURER SPECIFIC FEATURES

This chapter describes the device profile and manufacturer specific features of the MVINC

inclinometer modules. DS301 specific objects and features are described mainly in CAN

open chapter.

MVINC-CO-a-m (a= number of measuring axis, m = measuring range per each axis)

modules implements the CIA's device profile for single and dual axis inclinometers

(DS410). Modules support all mandatory and some optional objects that the profile

specifies.

Module provides almost all DS410 specific features also through RS232 interface,

including angle values, preset and offset functions, inversion etc.

M: mandatory, C : conditional (ie. required if something else is supported), O : optional

Copyright Axiomatic Technologies Oy

24/63

MVINC-CO-X-M user manual

Index

(Hex)

Name

User Manual

size

Type

Provided

only in

co-1360

1000

co_device_ type

U32

ro

1018

co_identity

2000

co_temperature

record

I8

ro

ro

2002

co_ave_size

U16

5001

co_manuf_1

5002

Version 2.04

Notes

Available in

RS232

co-2180

-

in boot up print

Temperature inside the module

in degrees Celsius

#STt!

rw

Size of additional ave filter

I16

ro

Manufacturer use only

co_print_cmd

U32

rw

Commads RS232 debug print

on and off

#P! ,#STf, STt!

5005

co_manuf_2

I16

rw

Manuf. use only

5009

co_manuf_3

array

ro

Manuf. use only

5010

co_manuf_4

I16

ro

Manuf. use only

5011

co_manuf_5

I16

ro

Manuf. use only

5012

co_manuf_6

array

ro

Manuf. use only

5013

co_manuf_7

array

ro

Manuf. use only

5015

co_manuf_8

array

ro

Manuf. use only

5019

co_manuf_9

array

ro

Manuf. use only

5020

co_manuf_10

I16

ro

Manuf. use only

5021

co_manuf_11

I16

ro

Manuf. use only

5022

co_manuf_12

array

ro

Manuf. use only

5023

co_manuf_13

array

ro

Manuf. use only

5025

co_manuf_14

array

ro

Manuf. use only

5515

co_slope_ long_rate

I32

ro

5516

co_slope_ long_acceleration

I32

ro

5525

co_slope_ lat_rate

I32

ro

5526

co_slope_ lat_acceleration

I32

ro

6000

co_resolution

U16

rw

#SERvvvv!

6010

co_slope_ long16

I16

ro

#STt!

6011

co_slope_

long16_oper_param

U8

rw

6012

co_slope_ long16_preset_val

I16

rw

#SEPxvvvvv!

6013

co_slope_ long16_offset

I16

rw

#SZ!

6014

co_slope_ long16_diff_offset

I16

rw

#SEDOxvvvv!

6020

co_slope_ lat16

I16

ro

6021

co_slope_ lat16_oper_param

U8

rw

6022

co_slope_ lat16_preset_val

I16

rw

#SEPyvvvvv!

6023

co_slope_ lat16_offset

I16

rw

#SZ!

6024

co_slope_ lat16_diff_offset

I16

rw

#SEDOyvvvv!

#STt!

#STt!

*

x

*

#STt!

x

#STt!

#SEIxt!, #SEIxf!

#SESxt!, #SESxf!

#STt!

Copyright Axiomatic Technologies Oy

#STt!

#SEIyt!, #SEIyt!

#SESyt!, #SESyf!

25/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

Table 16: Supported objects defined in the encoder profile DS406

7.1

Inclinometer related functions and configurations

7.1.1

General

Sensor provides inclination angle, rate and acceleration rata of each of its measuring axis.

User is able to configure angle resolution, inversion and offsets. Reolution is allways

common for both axis (in case of MVINC-CO-2-x) but other parameters are set individually

for each axis.

Illustration Illustration 11: angle , rate and acceleration calculations describes how sensor

output variables are calculated.

Illustration 11: angle , rate and acceleration calculations

All parameters and sensor output variables are described in their own sub chapter.

The last sub chapter [Procedure to configure resolution, inversion and offset] describes the

correct procedure to configure module's inclinometer related parameters.

7.1.2

Angle resolution

Output angle resolution is configurable with object co_resolution (0x6000). Acceptable

values are 10, 100 and 1000 and the default value is 100. Note that 0,01 degrees is not

accepted in case of MVINC-CO-1-360 module. Resolution can be set also from RS232 with

#SERvvvv! command where vvvv corresponds the same resolution set values that are user

with co_resolution object.

Copyright Axiomatic Technologies Oy

26/63

MVINC-CO-X-M user manual

Value of

co_resolution object

User Manual

Version 2.04

Resulting

resolution

(degrees)

Notes

1000

100

0.1

50

NON STANDARD VALUE!! Acts as scaling.

Example real angle 12.24 -> on bus : 245

10

0.01

Not possible with MVINC-CO-1-360

0.001

Not supported

Table 17: relationship between value in resolution object and actual resolution

co_resolution

Value range of the co_slope_long or co_slope_lat

1000

-90 ... 90 , 0 ...359

100

-900 ... 900 , 0...3599

10

-9000 ... 9000 , 0...35999

Table 18: Relationship between co_resolution and sensor output

Note that the resolution does't change the unit of acceleration or rate output!

7.1.3

Angle inverse and offset configurations

Angle output can be inversed and offset can be added through the object dictionary. In

addition same functionality is available through RS232 interface. Corresponding RS232

commands can be found in chapter

Inversion can be activated from co_slope_long16_oper_param

lat16_oper_param objects by setting the bit 0 as 1.

and

co_slope_

Angle output is calculated according to the following equation in case or longitudal angle or

single axis 360 degrees sensor:

co_slope_long16 = INVERSE_IF_NEEDED( measured_long16 ) + co_slope_long16_offset +

co_slope_long16_diff_offset

User is able to adjust both co_slope_long16_offset and co_slope_long16_diff_offset

variables.

co_slope_long16_offset is intended to be set through preset_value object (co_slope_

long16_preset_val ). User should write the actual angle that he wants the output to be at the

moment to the preset_value object. Module calculates the needed offset and writes it to the

co_slope_long16_offset. Offset can be zeroed by writing 0 to the offset object

co_slope_long16_offset.

Preset method suits well to mounting offset calibration, which means that user sets zero

level after mounting the module to the application. The actual offset is not needed to be

known; for instance in case of an excavator it's enough to drive boom to level and write

then 0 to the preset_val object to get the zero level set.

Equation along which

co_slope_lat16_offset :

Copyright Axiomatic Technologies Oy

module

calculates

the

co_slope_long16_offset

and

27/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

co_slope_long16_offset = co_slope_long16_preset_val INVERSE_IF_NEEDED( measured_long16 ) - co_slope_long16_diff_offset

User is also able to set the offset with the diff_offset objects (co_slope_long16_diff_offset

and co_slope_lat16_diff_offset). Module uses both offsets in paraller in output angle

calculation as stated in equation given above.

Note that the offset values have to be defined after configurateing the resolution and

reconfigured after changing resolution. Example: Initial resolution is 100 (0.1 degrees) and

value in co_slope_lat16_offset is 123 (12,3 degrees). Resolution is then changed to 10

(0.01 degrees) without reseting the offset value. Effective offset is now 1.23 degrees!

Offset objects are ignored unless the scaling is enabled in co_slope_long16_oper_param

and co_slope_ lat16_oper_param objects. Feature is active if bit 1 (second lowest bit) is

set as 1.

The value range of the co_slope_long16_preset_val, co_slope_lat16_preset_var,

co_slope_long16_diff_offset and co_slope_lat16_diff_offset objects is

(measuring_range_low_end) ... ( measuring_range_high_end)

for MVINC-CO-x-180 and

(-1 *measuring_range_high_end) ... ( measuring_range_high_end)

in case of MVINC-CO-x-360 module the value range is then

-3599 ... 3599 ( 359,9) with resolution of 0.1 degrees

and for MVINC-CO-x-180 with resolution of 0.01 degrees

-9000.... 9000 (-90,00 ... 90,00 )

Copyright Axiomatic Technologies Oy

28/63

MVINC-CO-X-M user manual

True physical

angle

User Manual

Value of

co_diff_offset

or co_offset

Version 2.04

Value of

co_slope_long16

MCINVCO-x-180

Notes

MCINVCO-x-360

400 (40.0)

201 (20.1)

601 (60.1)

601 (60.1)

400 (40.0)

-2002 (-200.2)

Unacceptable

offset value

1998(199.8)

400 (40.0)

901 (90.1)

1301 (130.1)

1301(130.1)

1000 (100.0)

3599 (359.9)

True angle

out of range

999 (99.9)

1000 (100.0)

4000 (400.0)

True angle

out of range

Unacceptabl

e offset

value

-622 (-62.2)

700 (70.0)

78 (7.8)

True angle

out of range

2212 (221.2)

1800 (180.0)

True angle

out of range

412 (41.2)

2212 (221.2)

-1800 (-180.0)

True angle

out of range

412 (41.2)

2212 (221.2)

2800 (280.0)

True angle

out of range

1412 (141.2)

2212 (221.2)

-2800 (-280.0)

True angle

out of range

3012 (301.2)

Used to shift the measuring range of MVINC

180 from +-90 to 0..180

Note that the good accuracy range is now

between 2...178 degrees. And sensor is most

accurate when the output is close to 90 degrees

Table 19: Examples of offsets and resulting output angles

True physical

angle

400 (40.0)

Value of

co_slope_long16 while inverse bit is on

MCINV-CO-x-180

MCINV-CO-x-360

-400 (-40.0)

3200 (320.0)

-405 (-40.5)

-405 (40.5)

True angle out of range

3014 (301.4)

True angle out of range

586 (58.6)

-1111 (-111.1)

True angle out of range

248.9 (248.9)

Table 20: Examples on how the inversion bit affects to the output angle

Copyright Axiomatic Technologies Oy

29/63

MVINC-CO-X-M user manual

index Type

Acc.

User Manual

Name

Version 2.04

notes

0x6000

UNSIGNED16

rw

co_resolution

0x6010

INTEGER16

ro

co_slope_ long16

Longitudal angle

0x6011

UNSIGNED8

rw

co_slope_ long16_oper_param

Bit 0 controls inversion

Bit 1 controls offset features

0x6012

INTEGER16

rw

co_slope_ long16_preset_val

Sets output angle to this value

0x6013

INTEGER16

rw

co_slope_ long16_offset

Offset that corresponds to given preset angle

0x6014

INTEGER16

rw

co_slope_ long16_diff_offset

Indipendent offset

0x6020

INTEGER16

ro

co_slope_ lat16

0x6021

UNSIGNED8

rw

co_slope_ lat16_oper_param

0x6022

INTEGER16

rw

co_slope_ lat16_preset_val

0x6023

INTEGER16

rw

co_slope_ lat16_offset

0x6024

INTEGER16

rw

co_slope_ lat16_diff_offset

Following are used only in dual MVINC-CO-2-X

Latitude angle

Table 21: Objects related to the angle inversion and offset configuration

7.1.4

Procedure to configure resolution, inversion and offset

The following order must be obeyed:

1.

To avoid false angle, rate and acceleration values command the module to the preoperational state by sending a NMT command (instructions available in network

management chapter)

2.

Configure the resolution (if non default value is used) with the co_resolution

( 0x6000) object.

3.

Set inverse mode if needed by setting bit 0 of co_operating_params ( 0x6011 and

0x6021) object as 1

4.

Set the offset by co_preset_value and /or co_diff_offset objects

1. Allow scaling by setting co_operating_params ( 0x6011 and 0x6021) bit 1 as

logic 1.

2. Set current angle as something else with co_preset_value object if needed.

3. Use co_diff_offset object to add known offset.

5.

Test that the settings are OK.

6.

Save setting to the nonvolatile memory by sending save all objects command to

the module. See instructions from chapter Saving the object dictionary

parameters.

Copyright Axiomatic Technologies Oy

30/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

Illustration 12: Configuration procedure

NOTES:

If an upper level parameter is changed all lower level parameters have to be reconfigured

aswell! This means that offsets have to be reconfigured if resolution is changed.

Particular save command is needed to store setting to nonvolatile memory

(co_store_params object or #CSa! RS232 command, more information in CANopen

chapter).

7.1.5

Internal timing

Module calculates new angle, rate and acceleration values every 10th millisecond. 10 ms is

also minimum PDO send interval.

7.1.6

Angular rate and acceleration outputs

Device provides also angular rate (speed) and acceleration information. The angular rate is

available in co_slope_ long_rate and co_slope_ lat_rate objects. Acceleration values can be

found in co_slope_ long_acceleration and co_slope_ long_acceleration objects. All of

them can also be found from RS232 normal data print.

Copyright Axiomatic Technologies Oy

31/63

MVINC-CO-X-M user manual

index

User Manual

type

access

Version 2.04

variable

description

0x5515

INTEGER32

ro

co_slope_ long_rate

Longitudal angular speed

0x5516

INTEGER32

ro

co_slope_ long_acceleration

Longitudal angular acceleration

0x5525

INTEGER32

ro

co_slope_ lat_rate

Latitudal angular speed

0x5526

INTEGER32

ro

co_slope_ lat_acceleration

Latitudal angular acceleration

Table 22: rate and acceleration related objects

Rate is always given as degrees per second. Thee lowest numbers form the decimal part.

1234567 corresponds then 1234.567 degrees/ second. Value of the resolution object

(co_resolution) doesn't affect to the resolution of rate or acceleration objects.

Acceleration is given as degrees/ sec2. Value contains also decimal part which is formed by

three lowest numbers. 2345 corresponds then 2,345 degrees.

To use the rate and acceleration values in real time user should activate the second PDO and

in case of MVINC-CO-2-x also the third PDO. PDO chapter describes how this can be

done.

7.2

Communication configurations

7.2.1

Device type (0x1000)

The device type object (0x1000) identifies the type of the product. Data in the lower 4 bytes

0x019A ( 410 as decimal number) tells that the module fulfills the CIA inclinometer profile

DS410. Data in the four upper bytes tells the amount of measuring axis and measuring

ranges.

index

0x1000

sub

1

type

U32

Acc.

RO

variable

co_device_type

values

notes

0x1801019A

MVINC-CO-1-180

0x3601019A

MVINC-CO-1-360

0x1802019A

MVINC-CO-2-180

Table 23: The device type object

7.2.2

Device identity (0x1018)

Device identity object identifies the module vendor, vendors product code and product

revision number. Modules unic serial number is also provided in sub 4. It can also be read

from the RS232 boot up print.

Copyright Axiomatic Technologies Oy

32/63

MVINC-CO-X-M user manual

index

0x1018

sub

User Manual

type

Acc.

variable

co_identity

values

Version 2.04

notes

U32

RO

U32

RO

0x55

Vendor ID (0x55 = Axiomatic

Technologies Oy)

U32

RO

0x2000

Product code

0x2000: MCINC-CO-1-180

0x2005: MCINC-CO-1-360

0x2010: MCINC-CO-2-180

U32

RO

Revision number

Bits 0-15

Application sw ver.

number

Bits 16-31

CAN behaviour ver

number

Example: 0x01020211 == CAN 1.02 ,

Application 2.17

4

U32

RO

Serial number. 0 if not set

Table 24: The device identity object

7.2.3

Emergency messages

MVINC doesn't support emergency (EMCY) messages.

7.2.4

CAN bus baudrate

Every device connected to the CAN bus has to use same baudrate. Baudrate can be changed

with the LSS protocol ( a CAN open sub protocol) or trough RS232 interface with a #SBvv!

command. The LSS protocol is described in details in CANopen manual chapter.

The serial protocol command is #SBvv! where xx is serial command index. Supported

baudrate values and correlated indexes for LSS and serial commands are listed in table

below. Baudrate of an unconfigurated device is 125 kbit/s.

baubrate

LSS index

Serial command index

Supported

1 Mbit/s

0x00

1000

800 kbit/s

0x01

800

500 kbit/s

0x02

500

250 kbit/s

0x03

250

125 kbit/s

0x04

125

50 kbit/s

0x06

50

Table 25: Supported command indexes for baudrate setup

7.2.5

Node ID

Each module connected to the same CAN bus must have an unique node ID. System

integrator may change device's node ID through CAN interface with the LSS protocol, or

through RS232 with #SNvvv! command.

Range for node IDs is 1 to 127. Usually 127 states that the node is unconfigurated.

Copyright Axiomatic Technologies Oy

33/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

CANopen manual chapter provides more information about the LSS protocol. The RS232

command for adjusting the node ID is #SNvvv! where vvv is the node ID as a decimal

number.

Note that the node ID changed via object dictionary won't be used until the communication

parameters are saved and module is reseted! This should be done immediately after

configuring the node ID.

Note that the PDO CAN IDs should be checked after changing the node ID with LSS

protocol. PDO CAN ids are set to the default values if RS232 #SNvvv! command is used.

System configurator should take account that Node IDs defines PDOs' priorities in case that

the default IDs are used. This means that the smaller node ID the higher priority its

messages have.

7.2.6

PDO configurations

MVINC has up to three transmit PDOs (process data object) which deliver the measurement

data from the inclinometer module to other modules connected to the CAN bus. Dual axis

sensor (MVINC-CO-2-X) provides 3 usable PDOs while other modules provide 2 usable

PDOs.

The PDO subchapter in CANopen manual chapter provides more information about the

PDOs and how they can be configured. However PDO's default settings' are described in

tables below. Default transmission types for all PDOs are asynchronous.

Note that each module type (MVINC-CO-1-180, MVINC-CO-2-180 and MVINC-CO-1360 ) has slightly different communication and mapping parameters!

index

0x1800

sub type

0

Acc.

RO

variable

co_tpdo_comm_par[0]

Def. values

notes

U32

RW

0x4000180 +

node id

PDO's CAN id is 180 + node id,

No RTR.,11 bits IDs,

PDO enabled

U8

RW

0xFE

Transmission type: Event driven,

message will be sent when the event

timer triggers

U16

RW

Inhibit time, not supported

U8

RW

Reserved

U16

RW

Event timer: 0 -> PDO is not send in

case of 0xFE transmission type.

Table 26: TPDO1's communication parameters

Copyright Axiomatic Technologies Oy

34/63

MVINC-CO-X-M user manual

index

0x1A00

sub

type

User Manual

Acc.

RW

variable

co_map_comm_par[0]

Version 2.04

Def.values

notes

Number of mapped objects.

Can be edited to leave

unnecessary data out.

U32

RW

0x60100010

Mapped object: 0x6010, subindex

0, 16 bits. (long angle)

U32

RW

0x20000008

Mapped object: 0x2000, subindex

0, 8 bits. (temperature)

U32

RW

0x20010010

Mapped object: 0x2001, subindex

0, 16 bits. (aux input)

Table 27: MVINC-CO-1-180 TPDO1 mapping parameters

index

0x1A00

sub

type

Acc.

RW

variable

co_map_comm_par[0]

Def. values

notes

Number of mapped objects

U32

RW

0x60100010

Mapped object: 0x6010, subindex

0, 16 bits. (long angle)

U32

RW

0x20000008

Mapped object: 0x2000, subindex

0, 8 bits. (temperature)

U32

RW

0x20010010

Mapped object: 0x2001, subindex

0, 16 bits. (aux input)

U32

RW

0x20000008

Mapped object: 0x2000, subindex

0, 8 bits. (temperature)

Table 28:MVINC-CO-1-360 TPDO1 mapping parameters

index

0x1A00

sub

type

Acc.

RW

variable

co_map_comm_par[0]

Def.values

notes

Number of mapped objects

U32

RW

0x60100010

Mapped object: 0x6010,

subindex 0, 16 bits. (long angle)

U32

RW

0x60200010

Mapped object: 0x6020,

subindex 0, 16 bits. (lat angle)

U32

RW

0x20000008

Mapped object: 0x2000,

subindex 0, 8 bits. (temperature)

U32

RW

0x20010010

Mapped object: 0x2001,

subindex 0, 16 bits. (aux input)

Table 29: MVINC-CO-2-180 TPDO1 mapping parameters

Copyright Axiomatic Technologies Oy

35/63

MVINC-CO-X-M user manual

index

0x1801

sub

type

User Manual

Acc.

RO

variable

co_tpdo_comm_par[1]

Version 2.04

Def. values

notes

U32

RW

0xC000280 +

node id

PDO's CAN id is 280 + node id

No RTR, PDO disabled

U8

RW

0xFE

Transmission type: Event driven,

message will be sent when the event

timer triggers

U16

RW

Inhibit time, not supported

U8

RW

Reserved

U16

RW

Event timer: 0 -> PDO is not send in

case of 0xFE transmission type.

Table 30: TPDO2's communication parameters

index

0x1A01

sub

type

Acc.

RW

variable

Def.values

co_map_comm_par[1]

notes

Number of mapped objects

U32

RW

0x55150020

Mapped object: 0x5515 subindex

0, 32 bits. (long rate)

U32

RW

0x55160020

Mapped object: 0x5516 subindex

0, 32 bits. (long acceleration)

Table 31: TPDO2 mapping parameters for all types

The third PDO is usable only with dual axis module (MVINC-CO-2-X). Single axis module

with 180 degrees measuring range (MVINC-CO-1-180) doesn't have it at all and in

MVINC-CO-1-360 it's a dummy PDO which can't be used.

index

0x1802

sub

type

access

RO

variable

co_tpdo_comm_par[2]

Def. values

notes

U32

RW

0xC000380 +

node id

PDO's CAN id is 380 + node id

No RTR, PDO disabled

U8

RW

0xFE

Transmission type: Event driven,

message will be sent when the

event timer triggers

U16

RW

Inhibit time, not supported

U8

RW

Reserved

U16

RW

Event timer: 0 -> PDO is not send

in case of 0xFE transmission type.

Table 32: MVINC-CO-2-180 TPDO3 communication parameters

index

0x1A02

sub

type

Acc.

RW

variable

co_map_comm_par[2]

Def. values

notes

Number of mapped objects

U32

RW

0x55250020

Mapped object: 0x5525 subindex

0, 32 bits. (lat rate)

U32

RW

0x55260020

Mapped object: 0x5526 subindex

0, 32 bits. (lat acceleration)

Table 33: TPDO3 mapping parameters for MVINC-CO-2-180

Copyright Axiomatic Technologies Oy

36/63

MVINC-CO-X-M user manual

index

0x1802

sub

type

User Manual

Acc.

RO

variable

co_tpdo_comm_par[2]

Version 2.04

Def.values

notes

U32

RO

0xC000380 +

node id

PDO's CAN id is 380 + node id

No RTR, PDO disabled

U8

RO

0xFE

Transmission type: Event driven,

message will be sent when the event

timer triggers

U16

RO

Inhibit time, not supported

U8

RO

Reserved

U16

RO

Event timer: 0 -> PDO is not send in

case of 0xFE transmission type.

Table 34: MVINC-CO-1-360 TPDO3 communication parameters

index

0x1A02

sub

type

Acc

RO

variable

Def. values

co_map_comm_par[2]

notes

Number of mapped objects

U32

RO

0x55250020

Mapped object: 0x5525 subindex

0, 32 bits. (lat rate)

U32

RO

0x55260020

Mapped object: 0x5526 subindex

0, 32 bits. (lat acceleration)

Table 35: TPDO3 mapping parameters for MVINC-CO-1-360

7.2.7

The boot up print.

The following print comes through RS232 port when module is powered. The last line is

printed after module has been commanded to the operational state.

sr-ldr 1.3-5mv

PORInitializing timer...done.

Initializing adc...done.

Initializing ext eeprom...done.

Init I/O...

Reading parameters...

MAGIC: 81680100 SW: 215

285 bytes in EEPROM, reading checksum

Checksum ok, loading parameters from EEPROM

Loading parameters...done.

msCAN: Node ID = 127

msCAN: Baudrate = 125 kbit/s

msCAN: Creating rx-buffer...

msCAN: Creating tx-buffer....

msCAN: Adding id 7E5 to receive list

Initializing PDO 0, type 2...

Alloc.mem. @0x05D0, size 22 bytes

COB 00004000

-> ID: 1FF, type 254

-> Mapped objs: 4

map obj:1A00 sub:0-> Mapping index 6010, sub 00, size 10

map obj:1A00 sub:1-> Mapping index 2000, sub 00, size 08

map obj:1A00 sub:2-> Mapping index 2000, sub 00, size 08

map obj:1A00 sub:3-> Mapping index 2001, sub 00, size 10

Initializing PDO 1, type 2...

Alloc.mem. @0x05E8, size 22 bytes

COB 0000C000

-> ID: 2FF, type 254

-> Mapped objs: 2

map obj:1A01 sub:0-> Mapping index 5515, sub 00, size 20

Copyright Axiomatic Technologies Oy

37/63

MVINC-CO-X-M user manual

User Manual

Version 2.04

map obj:1A01 sub:1-> Mapping index 5516, sub 00, size 20

msCAN: Adding id 67F to receive list

msCAN: Adding id 77F to receive list

msCAN: Adding id 080 to receive list

msCAN: Adding id 000 to receive list

msCAN: Setting 2nd ID filter...done

Sync to CAN...OK

Axiomatic MVINC-CO-1-360 V2.15,RT_t_calib

Released 9.Aug.2006 16:00

SN:0

of:17108 se:13753 tar:-90.0 st:2000 min

0.4422149 ->RAW:3354

of:17108 se:13753 tar:-80.0 st:2800 min

0.0061035 ->RAW:3565

of:17108 se:13753 tar:-60.0 st:4000 min

0.0036621 ->RAW:5198

of:17108 se:13753 tar:-30.0 st:8000 min

0.0009155 ->RAW:10231

of:17108 se:13753 tar:30.0 st:22000 min

0.0009155 ->RAW:23984

of:17108 se:13753 tar:60.0 st:27000 min

0.0036621 ->RAW:29018

of:17108 se:13753 tar:80.0 st:28000 min

0.0061035 ->RAW:30651

of:17108 se:13753 tar:90.0 st:32000 min

0.4422149 ->RAW:30862

of:17108 se:13753 tar:-90.0 st:2000 min

0.4422149 ->RAW:3354

of:17108 se:13753 tar:-80.0 st:2800 min

0.0061035 ->RAW:3565

of:17108 se:13753 tar:-60.0 st:4000 min

0.0036621 ->RAW:5198

of:17108 se:13753 tar:-30.0 st:8000 min

0.0009155 ->RAW:10231

of:17108 se:13753 tar:30.0 st:22000 min

0.0009155 ->RAW:23984

of:17108 se:13753 tar:60.0 st:27000 min

0.0036621 ->RAW:29018

of:17108 se:13753 tar:80.0 st:28000 min

0.0061035 ->RAW:30651

of:17108 se:13753 tar:90.0 st:32000 min

0.4422149 ->RAW:30862

FIR_ORDER:141

ave:delay:50ms

1.0000 (0.00) 1.0002 (0.01) 1.0000 (0.02) 1.0000 (0.03) 1.0000 (0.04) 0.0000 (0.05) 0.9999 (0.06) 0.9999 (0.07)

0.9999 (0.08) 0.9998 (0.09) 0.9998 (0.10)

0.9998 (0.1) 0.9993 (0.2) 0.9985 (0.3) 0.9974 (0.4) 0.9959 (0.5) 0.9941 (0.6) 0.9920 (0.7) 0.9896 (0.8) 0.9868

(0.9) 0.9838 (1.0)

-0.1 (1) -0.5 (2) -1.3 (3) -2.4 (4) -3.8 (5) -5.9 (6) -8.6 (7) -12.5 (8) -19.1 (9) -100.0 (10)

-15.9 (17) -19.3 (27) -21.1 (37) -21.8 (47)

MAIN_LOOP

CO: OPERATIONAL

7.2.8

The RS232 prints

The measurement data can be achieved through the RS232 interface in addition of the CAN

interface. Printing can be controlled both with object table and RS232 commands. From

Rs232 #P! command inits the debug print and #STt! normal data print. #STf! ends the

normal data print. Interval of the data print can be adjusted with #STivvvvv! command

where the send interval (vvvvv) is given as milliseconds.

Object co_print_cmd (0x5002) controls the printing from CAN bus. Writing 0x1234vvvv

to that object inits the debug print and 0xvvvv5678 inits the normal data print. vvvv tagged

numbers are ignored. All other values stops printing. Using 0x0000 is recommended

though.

RS232 Baudrate can also be adjusted with #STbvvvv! command where vvvv is the

suggested baudrate.

Note that setting won't be stored to nonvolatile memory unless save command is given

(#CSa! from RS232 or correct SDO write to the 0x1010 sub 1 from CAN). Some

parameters requires #SSt! command to get stored. See table Table 37: RS232 commands

which controls RS232 printing for further information.

index

0x5002

sub

0

type

U8

access

RW

variable

co_print_cmd

values

notes

Controls serial printing

0xYYYY5678 -> debug printing is on

0x1234YYYY -> normal data printing

is on

Table 36: Object dictionary variable related to RS232 printing

Copyright Axiomatic Technologies Oy

38/63

MVINC-CO-X-M user manual

Command

Value

range

User Manual

Default

value

Available

via CAN

Description

#P!

#STx!

f ,t

#STixxx!

10, 20 ...

100000

200

No

Sets the print interval for

normal printing

#STbxx!

19200

38400

57600

115200

115200

No

#CDx!

f ,t

#SSt!

Version 2.04

Notes

Saving to

nonvolatile

memory

Restore

command

co_print_cmd

Turns the debug prints on

#CSa! ,CAN

#CRa! ,CAN

co_print_cmd

Turns the normal printing

on and off

#CSa! ,CAN

#CRa! ,CAN

#SSt!

#SRt!

Sets the baudrate for

RS232 interface

#SSt!

#SRt!

No

turns the CAN info

prints the on and off

#SSt!

#SRt!

No

Saves print interval and

baud rate to nonvolatile

memory

Multiplies of

10 ms

10 ==10ms,

100==100ms

Table 37: RS232 commands which controls RS232 printing

A print example while normal print mode is chosen. Current resolution is 0.1 degrees

long:

264 (22814) rate:

0.0 acc:

0.00, lat: -148 (13322) rate:

-0.5 acc:

-0.55, temp: 35

long:

264 (22814) rate:

0.0 acc:

0.00, lat: -148 (13323) rate:

0.0 acc:

-0.55, temp: 35

long:

264 (22814) rate:

0.0 acc:

0.00, lat: -148 (13324) rate:

0.0 acc:

0.00, temp: 35

long:

264 (22814) rate:

0.0 acc:

0.00, lat: -148 (13323) rate:

0.0 acc:

0.00, temp: 35

long:

264 (22812) rate:

-0.5 acc:

-0.55, lat: -148 (13323) rate:

0.0 acc:

0.00, temp: 35

long:

264 (22811) rate:

0.0 acc:

0.00, lat: -148 (13321) rate:

0.0 acc:

0.00, temp: 35

long:

264 (22812) rate:

0.0 acc:

0.00, lat: -148 (13322) rate:

0.0 acc:

0.00, temp: 35

long:

264 (22812) rate:

0.0 acc:

0.00, lat: -148 (13323) rate:

0.0 acc:

0.00, temp: 35

Debug print:

long(X): O:16810 S:13502 ang:

15346.2 rate:

long(X): O:16810 S:13502 ang:

15346.7 rate:

-6.07

0.0 accl: 0.00lat(Y): O:16773 S:13488 ang:

-6.07

7.5% t: 35.0 co 35

0.02

16817.0 rate:

0.0 accl: 0.00lat(Y): O:16773 S:13488 ang:

-6.07

7.7% t: 35.0 co 35

0.02

16817.6 rate:

0.0 accl: 0.00lat(Y): O:16773 S:13488 ang:

-6.07

0.02

7.6% t: 35.0 co 35

16818.6 rate:

0.0 accl: 0.00 -irq:

Copyright Axiomatic Technologies Oy

0.0 accl: 0.00lat(Y): O:16773 S:13488 ang:

7.6% t: 35.0 co 35

16816.9 rate:

0.0 accl: 0.00 -irq:

long(X): O:16810 S:13502 ang:

15347.2 rate:

0.02

0.0 accl: 0.00 -irq:

long(X): O:16810 S:13502 ang:

15346.6 rate:

16816.5 rate:

0.0 accl: 0.00 -irq:

long(X): O:16810 S:13502 ang:

15346.5 rate:

0.02

0.0 accl: ss0.00 -irq:

0.0 accl: 0.00lat(Y): O:16773 S:13488 ang:

-6.07

7.6% t: 35.0 co 35

39/63

MVINC-CO-X-M user manual

7.2.9

User Manual

Version 2.04

The RS232 command set

Module supports quite many RS232 commands providing then almost same functionality

for both RS232 and CANopen. All value arguments (vvv ) are given as INTEGER16

without any leading zeroes.

Copyright Axiomatic Technologies Oy

40/63

MVINC-CO-X-M user manual

Command

Value

range

User Manual

Def.

value

Available

trough CAN

interface

Description

Version 2.04

notes

Saving to

nonvolatile

memory, A ->

automatically

#SNvvv!

1-127

127

LSS protocol

Sets the node ID.

New node ID will be effective after

module is reseted. Sets the PDO

CAN ids as default

#SBvvv!

125, 250,

800, 500,

1000

125

Through the LSS

protocol

Sets the baudrate.

Will be effective after next reset.

#P!

off

co_print_cmd

Toggles the debug

prints on and off

#CSa! , CAN

#STv!

f ,t

co_print_cmd

Turns the normal data

prints on and off

#CSa! , CAN

#STivvv!

10, 20 ...

100000

200

No

Sets the print interval

for normal printing

#STbvvv!

19200

38400

57600

115200

115200

No

Sets the baudrate for

RS232 interface

#SSt!

#CDv!

f ,t

Turns the CAN

information prints on

and off

#SSt!

#CRa!

co_restore_params

sub 1

Restores object table to Protected objects (P) are not

factory defaults.

restored. No calibration data is lost.

#CSa!

co_store_params sub

1

Stores all object table

objects to nonvolatile

memory.

#SRt!

Restores the RS232

baudrate and normal

print intervals to

factory defaults.

#SSt!

#RO!

Multiplies of 10 milliseconds

10 ==10ms, 100 == 100ms

Doesn't save the setting

automatically to the nonvolatile

memory.

#SSt!

#SSt!

Stores the print settings

described above to

nonvolatile memory

Prints the object table

#SERvvv!

10,100,

1000

100

co_resolution

To set the resolution

#CSa! , CAN

#SEIav!

v : f, t

a: x, y

co_slope_

long16_oper_param

co_slope_

lat16_oper_param

Controls the inversion

bit of given axis

#CSa! , CAN

#SESav!

v : f, t

a: x, y

co_slope_

long16_oper_param

co_slope_

lat16_oper_param

Controls the scaling bit

of given axis

(argument a)

#CSa! , CAN

#SEPavv!

v:

measuring_r

ange

a: x, y

co_slope_

long16_preset_val

co_slope_

lat16_preset_val

Preset angle function

for given axis

#CSa! , CAN

#SZ!

co_slope_

long16_preset_val

co_slope_

Preset angle function

for all axis with preset

angle of 0 degrees.

#CSa! , CAN

Copyright Axiomatic Technologies Oy

41/63

MVINC-CO-X-M user manual

Command

Value

range

Def.

value

User Manual

Available

trough CAN

interface

Description

lat16_preset_val

co_slope_

long16_oper_param

co_slope_

lat16_oper_param

Enables also scaling

from operating params

Version 2.04

notes

Saving to

nonvolatile

memory, A ->

automatically

#SECOa!

a: x, y

co_slope_

long16_offset

co_slope_

lat16_offset

Clears the offset of

given axis

#CSa! , CAN

#SEDOavvv!

v:

measuring_r

ange

a: x, y

co_slope_

long6_diff_offset

co_slope_

lat16_diff_offset

Differential slope

function.

#CSa! , CAN

Table 38: Supported RS232 commands

Copyright Axiomatic Technologies Oy

42/63

MVINC-CO-X-M user manual

8.

User Manual

Version 2.04

CANOPEN MANUAL AND SUPPORTED DS301 SPECIFIC OBJECTS

CANopen is a CAN-based higher layer protocol. It was developed as a standardized

embedded network with highly flexible configuration capabilities. CANopem was targeted

for motion-oriented machine control networks, such as handling systems. By now it is used

in many various fields such as excavators mining equipment and military vehicles.

Standardized profiles developed by CiA members simplify system designer's integration

task. CANopen is flexible and open enough to allow both manufacturer specific

functionality and the generic functionality described in the device profiles to be integrated

in very same device.

CANopen provides standardized communication objects for real-time data transfers

(Process Data Objects, PDO), configuration data (Service Data Objects, SDO), and special

functions (Time Stamp, Sync message, and Emergency message) as well as network

management data (Boot-up message, NMT message, and Error Control).

8.1

How to read a CAN message seen with a simple CAN tool

The message below is a SDO read message seen with a simple CAN tool. Message is

addressed to module which node ID is 0x0A (10d). The type of CAN messages is little

endian (INTEL type).

CAN ID

Length

60A

40

00

18

01

00

00

00

00

Table 39: An example of CAN message seen with a simple CAN tool

Data corresponds to the following in human readable format:

00 00 00 00 18 01 00 40

8.2

Object dictionary (OD)

The object dictionary provides access to the application program of the device in terms of