Documente Academic

Documente Profesional

Documente Cultură

Tooling Mold

Încărcat de

Anonymous kYcX3YENDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tooling Mold

Încărcat de

Anonymous kYcX3YENDrepturi de autor:

Formate disponibile

Tooling And Mold Design

Autodesk Inventor Professional helps automate key aspects of

the design of injection molds for plastic parts. This allows you

to quickly create and validate complete mold designs, reducing

errors and improving mold performance.

With its intuitive mold

design workflow,

Inventor software guides

you through the mold

design process in a way

that is natural for the

experienced user, while at

the same time supportive

for the novice.

Streamline the design of plastic injection molds

Autodesk Inventor software includes easy-touse mold design features that work directly

from Inventor 3D models of plastic parts. Full

associativity to the Inventor digital model helps

make sure that any changes to the model are

automatically reflected in the mold design. Inventor

guides you through the mold design process and

automates a number of complex operations, such

as capping openings and runoff/shutoff surface

generation. The result is higher quality products and

faster time to market.

Part

Part Preparation

Gain access to extensive material property

information by selecting part material from the

Autodesk Moldflow material database, the

worlds largest material database for injection

plastic molding. Interactively define the parting

direction. A default work piece size is recommended

by the system based on the part dimensions. You

can also easily edit the settings, if necessary. Any

information added to the part model is reused in the

mold design process.

Patch and Parting Surface Creation

Accelerate mold design by creating surfaces

automatically. Close multiple openings in your part

model using automated patch surface creation. And

generate parting surfaces automatically based on

the defined parting direction.

Automated Core and Cavity Design

Core and cavity design is time consuming with traditional CAD tools, but the mold design knowledge

in Inventor software saves you time and reduces

rework. With Inventor, you can split the work piece

to generate the core and cavity halves based on the

parting surface definition. Create side core designs

to match the mold assembly, and incorporate old

side core designs into existing mold assemblies. For

multicavity mold designs, easily define the mold

configuration layout as circular, rectangular, or

variable. And use automated core and cavity design

tools to create family molds.

11

Core/Cavity

Intelligent Patching

Tooling And Mold Design

Autodesk Inventor Professional includes Moldflow plastic flow

analysis tools. Use them to determine material flow rates, ideal

gate locations, shrinkage, and process parameters.

Runner and Gate Design

Reduce mold design lead time with automated

runner and gate design tools. Facilitate the

efficient distribution of molten plastic from the

machine nozzle to the mold cavities by designing

the complete runner system, including the sprue,

runners, and gates. Gate location analysis tools

help you determine gate locations accurately and

efficiently. Preconfigured shapes allow you to

quickly create gate points, gates, runners, sprues,

and cold wells.

Cooling Channel Design

Reduce the time it takes to add cooling channels

to the mold base while avoiding errors and

inconsistencies. With Inventor Mold Design, you

can quickly design cooling channels for the mold

base through an intuitive user interface. Enforce

consistency and reduce mistakes by selecting

cooling components, such as connectors and pipe

plugs, sealing plugs, and O-rings, from a standard

catalog.

Moldability Analysis

Avoid costly mistakes by detecting moldability

issues early in the design cycle. With Inventor

software, you can analyze the part model before

starting the mold design process. You quickly

enhance your understanding of the plastic filling,

sink marks, cooling efficiency, gate location, and

optimum molding window.

12

Tooling And Mold Design

Autodesk Inventor Professional provides an extensive collection

of vendor catalogs of standard mold bases and components so

you wont have to spend time modeling them.

Mold Base Libraries

Reuse standard mold base components across the

organization, allowing you to avoid duplicate work

while taking advantage of proven design knowledge.

Inventor software supports a wide range of mold

base catalogs, including DME, Futaba, HASCO,

LKM, Pedrotti, Polimold, Rabourdin, and Strack.

A single database stores and delivers easy access

to standard components. When required, you can

efficiently customize standard mold bases to suit

your needs.

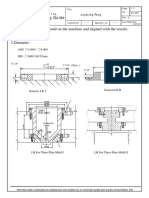

Standard Mold Base Parts

Improve productivity and avoid errors by reusing

existing mold design knowledge as you create the

detailed mold design in 3D. Begin by selecting mold

base components from standard catalogs, including

Meusburger, Misumi, National, Progressive, Punch,

and Sideco. Design or modify standard components,

such as sliders, lifters, ejectors, sprue bushings, and

locating rings. When you have standard mold base

components that meet your needs, you can export

them as templates for future use.

Documentation

Reduce mold design lead time by generating

drawings and BOMs automatically. Inventor allows

you to automatically create 2D drawings of mold

designs and related BOMs for use in documentation

or manufacturing. When you make changes to the

3D design model, Inventor automatically updates

the drawings and BOMs.

13

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Graham HoltDocument4 paginiGraham HoltTung NguyenÎncă nu există evaluări

- BMath3 ProjectDocument6 paginiBMath3 ProjectRainbow VillanuevaÎncă nu există evaluări

- Mold SimulationDocument1 paginăMold SimulationAnonymous kYcX3YENÎncă nu există evaluări

- Cutting OulineDocument1 paginăCutting OulineAnonymous kYcX3YENÎncă nu există evaluări

- Pricelist Produk AlamicoidDocument7 paginiPricelist Produk AlamicoidAnonymous kYcX3YENÎncă nu există evaluări

- CuttingDocument1 paginăCuttingAnonymous kYcX3YENÎncă nu există evaluări

- Katalog Produk AlamicoidDocument32 paginiKatalog Produk AlamicoidAnonymous kYcX3YENÎncă nu există evaluări

- AssyDocument1 paginăAssyAnonymous kYcX3YENÎncă nu există evaluări

- 24Document4 pagini24Anonymous kYcX3YENÎncă nu există evaluări

- Biznet Inspire Edisi July 2014Document29 paginiBiznet Inspire Edisi July 2014silver8700Încă nu există evaluări

- Pricelist Produk AlamicoidDocument7 paginiPricelist Produk AlamicoidAnonymous kYcX3YENÎncă nu există evaluări

- IHT Process Design Sheet RGBDocument2 paginiIHT Process Design Sheet RGBAnonymous kYcX3YENÎncă nu există evaluări

- Lesson 5 Making Design Changes: SolidworksDocument19 paginiLesson 5 Making Design Changes: Solidworkskijimoshi_777Încă nu există evaluări

- Moldmaking GuideDocument2 paginiMoldmaking GuideAnonymous kYcX3YENÎncă nu există evaluări

- Katalog Produk AlamicoidDocument32 paginiKatalog Produk AlamicoidAnonymous kYcX3YENÎncă nu există evaluări

- Moldmaking Guide: 1.the Fixed Side EjectionDocument5 paginiMoldmaking Guide: 1.the Fixed Side EjectionAnonymous kYcX3YENÎncă nu există evaluări

- 16Document22 pagini16Anonymous kYcX3YENÎncă nu există evaluări

- 24Document4 pagini24Anonymous kYcX3YENÎncă nu există evaluări

- 29Document6 pagini29Anonymous kYcX3YENÎncă nu există evaluări

- Moldmaking Guide: Used For Maintaining The Mold Temperature and A Faster Molding Cycle. 2. Basic GuidelineDocument13 paginiMoldmaking Guide: Used For Maintaining The Mold Temperature and A Faster Molding Cycle. 2. Basic GuidelineAnonymous kYcX3YENÎncă nu există evaluări

- 23Document6 pagini23Anonymous kYcX3YENÎncă nu există evaluări

- 24Document4 pagini24Anonymous kYcX3YENÎncă nu există evaluări

- Moldmaking GuideDocument1 paginăMoldmaking GuideAnonymous kYcX3YENÎncă nu există evaluări

- Moldmaking GuideDocument1 paginăMoldmaking GuideAnonymous kYcX3YENÎncă nu există evaluări

- Moldmaking Guide: 1.screw SupplierDocument2 paginiMoldmaking Guide: 1.screw SupplierAnonymous kYcX3YENÎncă nu există evaluări

- 24Document4 pagini24Anonymous kYcX3YENÎncă nu există evaluări

- 19Document20 pagini19Anonymous kYcX3YENÎncă nu există evaluări

- Moldmaking GuideDocument1 paginăMoldmaking GuideAnonymous kYcX3YENÎncă nu există evaluări

- Moldmaking Guide: 1.used For Attaching Mold To The Plate of Injection MachineDocument1 paginăMoldmaking Guide: 1.used For Attaching Mold To The Plate of Injection MachineAnonymous kYcX3YENÎncă nu există evaluări

- CNC ProgrammingDocument49 paginiCNC Programmingasil_turk100% (6)

- Moldmaking Guide: 1.used As The Clearance Holes For K.O. Retainer. 2.the Location and Size of Knockout HolesDocument1 paginăMoldmaking Guide: 1.used As The Clearance Holes For K.O. Retainer. 2.the Location and Size of Knockout HolesAnonymous kYcX3YENÎncă nu există evaluări

- 01Document12 pagini01Anonymous kYcX3YENÎncă nu există evaluări

- HP SMART ARRAY 641 USER GUIDEDocument69 paginiHP SMART ARRAY 641 USER GUIDEMichele BarbaÎncă nu există evaluări

- Jillin ExplosionDocument10 paginiJillin ExplosionArjun ManojÎncă nu există evaluări

- Worksheet (Time and Motion) Answer KeyDocument7 paginiWorksheet (Time and Motion) Answer Keykatira rashmiÎncă nu există evaluări

- Fluid Mechanics 4Document3 paginiFluid Mechanics 4Pugao SpikeÎncă nu există evaluări

- Fun33 LCNVDocument6 paginiFun33 LCNVnehalÎncă nu există evaluări

- Types of Evidence DLPDocument9 paginiTypes of Evidence DLPMary Joy IgnacioÎncă nu există evaluări

- Siddique, Tashfeen Coverletter 20170320Document1 paginăSiddique, Tashfeen Coverletter 20170320Anonymous liUNtnyÎncă nu există evaluări

- TAFJ-AS JBossInstall v5.2 EAP PDFDocument33 paginiTAFJ-AS JBossInstall v5.2 EAP PDFrameshÎncă nu există evaluări

- Muhammad Adnan Sarwar: Work Experience SkillsDocument1 paginăMuhammad Adnan Sarwar: Work Experience Skillsmuhammad umairÎncă nu există evaluări

- NSTP ReportDocument8 paginiNSTP ReportMary Grace MendeÎncă nu există evaluări

- HR Associate - Job Description VFinalDocument2 paginiHR Associate - Job Description VFinalPamela CardozoÎncă nu există evaluări

- CalibrationDocument9 paginiCalibrationLuis Gonzalez100% (1)

- PROII Data Transfer System User GuideDocument91 paginiPROII Data Transfer System User Guidemfruge7Încă nu există evaluări

- Doppler Weather RadarDocument35 paginiDoppler Weather RadarjosefalguerasÎncă nu există evaluări

- NBA AwarenessDocument39 paginiNBA AwarenessRaja SekarÎncă nu există evaluări

- Talon Star Trek Mod v0.2Document4 paginiTalon Star Trek Mod v0.2EdmundBlackadderIVÎncă nu există evaluări

- Manual ViscosimetroDocument55 paginiManual ViscosimetroLUIS XV100% (1)

- 4D Asp: Wall Tiling 4D - PG 1Document3 pagini4D Asp: Wall Tiling 4D - PG 1Vlaho AlamatÎncă nu există evaluări

- S6a S13 GX RX InterfacesDocument4 paginiS6a S13 GX RX Interfacessyedsajjad68Încă nu există evaluări

- Verification ofDocument14 paginiVerification ofsamuel-kor-kee-hao-1919Încă nu există evaluări

- Neil Bryan N. Moninio: Professional GoalDocument3 paginiNeil Bryan N. Moninio: Professional GoalNeil Bryan N. MoninioÎncă nu există evaluări

- Stone ColumnDocument116 paginiStone ColumnNur Farhana Ahmad Fuad100% (1)

- 2 Gentlemen of VeronaDocument12 pagini2 Gentlemen of VeronaAaravÎncă nu există evaluări

- Theories and Paradigms in SociologyDocument10 paginiTheories and Paradigms in SociologyAngel KimÎncă nu există evaluări

- The Scientific Method Is An Organized Way of Figuring Something OutDocument1 paginăThe Scientific Method Is An Organized Way of Figuring Something OutRick A Middleton JrÎncă nu există evaluări

- Sustainability Indicators and Indices: An OverviewDocument22 paginiSustainability Indicators and Indices: An OverviewRigoberto ToprresÎncă nu există evaluări

- Listening - Cot4thDocument6 paginiListening - Cot4thmichel.atilanoÎncă nu există evaluări

- DCR-DVD810: DVD Handycam® Camcorder NEWDocument2 paginiDCR-DVD810: DVD Handycam® Camcorder NEWraynaldoÎncă nu există evaluări