Documente Academic

Documente Profesional

Documente Cultură

SK 140 HDLC

Încărcat de

alsief1951Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SK 140 HDLC

Încărcat de

alsief1951Drepturi de autor:

Formate disponibile

STANDARD EQUIPMENT

OPTIONAL EQUIPMENT

ENGINE

Engine, MITSUBISHI D04F, Diesel engine with turbocharger and intercooler

Automatic engine deceleration

Auto Idle Stop (AIS)

Removable clean-out screen for radiator

Automatic engine shut-down for low engine oil pressure

Engine oil pan drain valve

Double element air cleaner

Pre-air cleaner

CONTROL

Working mode selector (H-mode and S-mode)

Power Boost

SWING SYSTEM & TRAVEL SYSTEM

Swing rebound prevention system

Straight propel system

Two-speed travel with automatic shift down

Sealed & lubricated track links

Grease-type track adjusters

Automatic swing brake

HYDRAULIC

Arm regeneration system

Aluminum hydraulic oil cooler

MIRRORS & LIGHTS

Two rearview mirrors

Four front working lights

Swing flasher

CAB & CONTROL

Two control levers, pilot-operated

Tow eyes

Horn, electriic

Integrated left-right slide-type control box

Cab, all-weather sound suppressed type

Cab light (interior)

Coat hook

Luggage tray

Large cup holder

Detachable two-piece floor mat

Double slide seat

Retractable seatbelt

Headrest

Handrails

Heater and defroster

Intermittent windshield wiper with double-spray washer

Skylight

Tinted safety glass

Pull-type front window and removable lower front window

Easy-to-read multi-display monitor

Automatic air conditioner

Emergency escape hammer

Wide range of buckets

Various optional arms

Wide range of shoes

Additional hydraulic circuit

Note: Standard and optional equipment may vary. Consult your KOBELCO dealer for specifics.

Bucket Capacity:

0.6 0.7m3 ISO heaped

Engine Power:

69.2 kW/2,000 min-1 (ISO 9249)

74 kW/2,000 min-1 (ISO 14396)

Operating Weight:

13,100 kg

Note: This catalog may contain attachments and optional equipment that are not available in your area. And it may contain photographs of machines

with specifications that differ from those of machines sold in your areas. Please consult your nearest KOBELCO distributor for those items you require.

Due to our policy of continuous product improvements all designs and specifications are subject to change without advance notice.

Copyright by

No part of this catalog may be reproduced in any manner without notice.

Inquiries To:

H-200, Sector-63, Noida, Distt: G.B. Nagar, U.P. - 201 307, INDIA

Tel : +91-120-4079900 Fax : +91-120-4079999

www.kobelconet.in/

Hydraulic Excavators

Announcing ACERA GEOSPEC and the Concept of Beautiful Performance.

Sturdy Construction &

Built-in Durability

The Power Wave of Change

Efficient Performance

When we set out to design our new hydraulic excavators,

Easy Maintenance

we kept our eyes on the big picture.

Comfort and Safety

Of course we wanted machines with greater digging capacity.

But they also had to be fuel-efficient and economical,

while imposing less of a burden on the local and global environments.

Applying our advanced technologies,

E E

we developed KOBELCOs new ACERA GEOSPEC series,

an entirely new kind of excavator that beautifully balances

all the demands of todays construction industry.

NEXT-3E

Pursuing the Three Es

Lean and efficient with capacity to spare,

these sleek powerhouses bring a whole new style to the worksite while

setting new standards for environmental responsibility.

The Perfection of Next-Generation, Network Performance

Enhancement

Greater Performance Capacity

New hydraulic circuitry minimizes pressure loss

High-efficiency,electronically controlled

Common Rail Fuel Injection Engine

Powerful travel and arm/bucket digging force

Sturdy Construction

GEOSCAN Remote Monitoring System

Economy

Environment

Improved Cost Efficiency

Features That Go Easy on the Earth

Advanced power plant that reduces fuel

consumption

Easy maintenance that reduces upkeep costs

High structural durability and reliability that

retain machine value longer

Meets the latest exhaust emission standards

Auto Idle Stop as standard equipment

Noise reduction measures (with improvement of

the sound quality) minimize noise and vibration

ACERA GEOSPEC

The GEO in GEOSPEC expresses our deep respect for our planet, and for the solid ground where excavators are in their element.

This is accompanied by SPEC, which refers to the performance specifications needed to get the job done efficiently as we carry

on the tradition of the urban-friendly ACERA series.

Reliability and Durability

Sturdy Construction & Built-in Durability

Stable Attachment Strength

Enhanced Upper Carbody Strength

Forged and cast components are used throughout. The arm

tip's cross-sectional coefficient is 15 % higher that previous

models, giving the arm the same strength as the 3-faced

reinforced arm that was offered only as an option before. The

strength of the boom foot has also been increased by 18 %.

The structure of the lower portion of the upper frame has been

reassessed and the undercover area has been minimized. Also,

the side decks cross-sectional strength has been boosted by

50 %.

Rock guard (optional)

Forged steel arm

foot boss

Integrated cast steel

boom top

Reinforced boom center boss

Cast steel boom foot boss

Durability That Retains Machine Value Five and

Ten Years in the Future

Emergency Acceleration (Dial) Permits Continued

Operation in the Unlikely Event of Malfunction

Improved heat resistance in the swing motor, cylinders and

other hydraulic components

New operators seat covered in durable material

High-quality urethane paint

Easily repaired bolted hand rails

If unexpected trouble is experienced

with the ITCS mechatronic control

system, the machine can still be

operated using the emergency acceleration system. Digging modes are

also automatically relayed to an

emergency system so that digging

can continue temporarily until a service person arrives to repair

the primary system.

Pre-air cleaner

Engine throttle

Mechatronic

controller

Engine

Pump

Engine ECU

Emergency acceleration

Newly designed MCU

Vertical alignment and sealed cover

gives better protection from water and

dust

Integration in base plate boosts assembly quality

Reliable fixture to base plate

New MCU

Conventional

MCU

Countermeasures Against Electrical System Failure

All elements of the electrical system, including controller, have

been designed for enhanced reliability.

Reinforced upper and lower frames

The front section of the upper frame and the entire lower

frame are constructed of thicker steel plate. As a result, the

durability of the machine body is higher than other KOBELCO

machines in the 13 ton class.

Reinforced Crawler Shoes

The diameter of the track

link pins has been made a

size larger for even greater

strength.

Durable forged steel shoe

Stronger casing for travel motor

Performane

Efficient Performance

Amazing Productivity with 10% Saving in

Fuel Consumption and Top-Class Cost Performance

Fuel Consumption*

10%

improvement in fuel efficiency when performing more work volume (S-Mode)

3%

NEXT-3E Technology

New Hydraulic System

Next-Generation Electronic Engine Control

Rigorous inspections for pressure loss are performed on all

components of the hydraulic piping, from the spool of the

control valve to the connectors. This regimen, combined with

the use of a new, high-efficiency pump, cuts energy loss to a

minimum.

The high-pressure, common-rail fuel-injection engine features

a cooled EGR (Exhaust Gas Recirculation) device that lowers

the air intake temperature to keep the oxygen concentration

down.

Air intake

increase in work volume using the same

amount of fuel. (H-Mode)

Top-Class Powerful Digging

Max. arm crowding force:

Max. bucket digging force:

71.9kN{7.3tf}

89.2kN{9.1tf}

Powerful Travel

Travel speed:

Drawbar pulling force:

5.6/3.4km/h

139kN{14.2tf}

Greater Swing Power, Shorter Cycle Times

39.9kN

11.0min

Swing torque:

Swing speed:

-1

Significant Extension of Continuous Working Hours

The combination of a large-capacity fuel tank and excellent

fuel efficiency delivers an impressive 37 % increase in continuous operation hours.

NEXT-3E Technology

Total Tuning Through Advanced ITCS Control

The next-generation engine control is governed by a new

version of ITCS, which responds quickly to sudden changes in

hydraulic load to ensure that the engine runs as efficiently as

possible with a minimum of wasted output.

ITCS (Intelligent Total Control System)

is an advanced, computerized system that provides comprehensive

control of all machine functions.

Simple Select: Two Digging Modes

For heavy duty when a higher performance level is required.

For normal operations with lower fuel consumption.

Mode

Mode

Optional N&B (crusher and breaker)

The operator selects the desired mode from

inside the cab, and the selector valve automatically configures the machine accordingly.

Auto Idle Stop Provided as Standard Equipment

Pull up safety lock lever

37%

Light Lever Operation

It takes 10% less effort to move the control

levers, so that operators can work longer

hours with less fatigue.

10%Less

Alarm

Engine deceleration

Engine rpm

Fuel tank:

Exhaust

Water-cooled

EGR

Electronic control

EGR valve

Work Volume*

NEXT-3E Technology

12 sec

Shut-off

4 sec

55 sec

Engine stops

60 sec

Elapsed time

This function saves fuel and cuts emissions by shutting down

the engine automatically when the safety lock lever is pulled

up. It also stops the hourmeter, which helps to retain the

machines asset value.

*The value shows results from actual measurements taken by KOBELCO when

compared with previous KOBELCO models.

Engine speed is automatically reduced

when the control lever is placed in

neutral, effectively saving fuel and

reducing noise and exhaust emissions.

The engine quickly returns to full speed

when the lever is moved out of neutral.

Engine Speed

Automatic Acceleration/Deceleration Function

Reduces Engine Speed

Lever Off (Neutral)

Lever On

Lever Stroke

Maintenance

Easy Maintenance

Pre-air Cleaner

Comfortable "On the Ground" Maintenance

The pre-air cleaner prolongs a

replacement cycle of main air

cleaner.

The machine layout

was designed with

easy inspection and

maintenance in mind.

1

Access Through the Left Side Cover

Parallel Cooling Units Are Easy to Clean

Air cleanerr

Air conditioner condenser

Access Through the Right Side Cover

A new fuel filter has been installed in a convenient, readily

accessible location. It now has two pre-fuel filters (with

built-in water separator), and a high-efficiency main fuel

filter.

Oil cooler

Radiator

Intercooler

2

Main fuel filter

Third filter Pre-fuel filter

(with built-in water separator)

Main fuel filter

Highly Durable Super-fine Filter

Quick Oil Drain Valves for Quick Maintenance

A quick drain valve, which requires no

tools, is provided as standard equipment.

The high-capacity hydraulic oil filter incorporates glass fiber with superior cleaning power

and durability. With a replacement cycle of

1,000 hours and a construction that allows

replacement of the filter element only, its both

highly effective and highly economical.

Super-fine filter

Double-Element Air Cleaner as Standard

Quick drain valve

To facilitate fuel tank cleaning, the fuel

drain valve was made larger and fitted with

a flange on the bottom.

Fuel drain valve

Air cleaner (double element)

More Efficient Maintenance Inside the Cab

Drain Detachable

Detachable two-piece

floor mat with handles

for easy removal.

Hour meter can be

checked while standing

on the ground.

The large-capacity element features a double-filter structure

that keeps the engine running clean even in dusty environments.

Easy-access fuse box.

Air conditioner filter can

be easily removed.

Large-capacity tool box.

Monitor Display with Essential Information for

Accurate Maintenance Checks

Displays only the maintenance information

thats needed, when its needed.

Self-diagnostic function that provides

early-warning detection and displayof electrical

system malfunctions.

Record previous breakdowns, including irregular

and transient malfunctions.

Choice of 16 Languages for Monitor Display

With messages including those requiring urgent action displayed in the local

language, users in all parts of the

world can work with greater peace of

mind.

Comfort and Safety

Comfort and Safety

Spacious, Comfortable Cab

Low Noise Level and Mild Sound Quality

Designed for safety, the cab meets ISO standards, and also

offers a spacious interior and plenty of foot room, with levers

and other controls ideally positioned for easy operation.

The electronically controlled common-rail engine has a unique

fuel injection system that runs quietly.

A long wiper covers a wide area for a broad view in bad weather.

Back mirrors provide a safe view of the rear.

Reinforced green glass windows meet European standards.

Meets EMC (Electromagnetic Compatibility)

Standards in Europe.

Wide-Access Cab Ensures Smooth Entry and Exit

Measures have been taken to ensure that the GEOSPEC

machines do not cause electro-magnetic interference.

The left control box lifts

up with the safety lock

lever to add 10 to the

cab entry angle for easy

entrance and exit.

Bracket for Attaching a Head Guard Provided as

Standard Equipment

A bracket is provided as standard equipment that allows the

optional head guard to be simply bolted on.

Safety Features That Take Various Scenarios into

Consideration

10

Plenty of Foot Room

The rigid cab construction and liquid-filled viscous cab mounts

minimize cab vibration. In addition, the use of new lower

rollers on the crawlers cuts travel vibration in half compared

with previous models.

In-Cab Noise is Reduced by 3dB Compared with

Previous Models.

Firewall separates the pump

compartment from the engine

Hammer for emergency exit

Newly Designed Information Display Prioritizes

Visual Recognition

The analog gauge provides information

thats easy to read regardless of the

operating environment. The information display screen has been enlarged,

and a visor is attached to further

enhance visibility.

Swing flasher

Thermal guard prevents contact with hot components during engine inspections

Hand rails meet European standards

Retractable seatbelt requires no manual adjustment

Creating a Comfortable Operating Environment

Double slide seat

Powerful automatic air

conditioner

Spacious luggage tray

Two-speaker FM radio

with station select

(Optional)

New interior design

and materials create an

elegant feel

Seat can be reclined to horizontal position

One-touch lock release

simplifies opening and

closing the front window

Large cup holder

GEOSCAN

Specifications

Remote Monitoring for Peace of Mind

Engine

GPS

Travel System

Model

MITSUBISHI D04FR

Type:

Direct injection, water-cooled, 4-cycle diesel

engine with turbocharger, intercooler

No. of cylinders:

Bore and stroke:

Displacement:

4

102 mm X 130 mm

4.249 L

74 kW/ 2,000 min -1 (ISO14396:2002)

69.2 kW/2,000 min-1 (ISO9249:2007)

375 Nm/1,600 min-1 (ISO14396:2002)

359 Nm/1,600 min-1 (ISO9249:2007)

Rated power output:

Base station

Max. torque:

Hydraulic excavator

Hydraulic System

Cab

All-weather, sound-suppressed steel cab mounted on the silicon-sealed

viscous mounts and equipped with a heavy, insulated floor mat.

Control

Two hand levers and two foot pedals for travel

Two hand levers for excavating and swing

Electric rotary-type engine throttle

Pump

Type:

KOBELCO service personnel/dealer/customer

GEOSCAN is the remote monitoring system for Acera Geospec series excavators. When a hydraulic excavator is

fitted with this system, data on the machines operation, such as operating hours, location, fuel consumption, and

maintenance status can be obtained remotely.

Direct Access to Operational Status

Accurate location data can be obtained

even from sites where communications

are difficult.

Fuel Consumption Data

Data on fuel consumption and idling

times can be used to indicate improvements in fuel consumption.

Maintenance Data and Warning Alerts

Machine Maintenance Data

Provides maintenance status of separate machines operating at multiple

sites.

Maintenance data is also relayed to

KOBELCO service personnel, for more

efficient planning of periodic servicing.

Max. discharge flow:

Relief valve setting

Boom, arm and bucket:

Travel circuit:

Swing circuit:

Control circuit:

Pilot control pump:

Main control valves:

Oil cooler:

Brake:

Parking brake:

Swing speed:

Tail swing radius:

Min. front swing radius:

Fuel consumption

Operating Hours

Graph of Work Content

A comparison of operating times of

machines at multiple locations shows

which locations are busier and more

profitable.

Operating hours on site can be

accurately recorded, for running time

calculations

needed

for

rental

machines, etc.

The graph shows how working hours

are divided among different operating

categories, including digging, idling,

traveling and optional operations

(N&B).

Security System

Engine Start Alarm

The system can be set an alarm if the

machine is operated outside designated

time.

Area Alarm

It can be set an alarm if the machine is

moved out of its designated area to another location.

Work status

34.3 MPa {350 kgf/cm2}

34.3 MPa {350 kgf/cm2}

28.0 MPa {285 kgf/cm2}

5.0 MPa {50 kgf/cm2}

Gear type

8-spool

Air cooled type

Boom, Arm & Bucket

Boom cylinders:

Arm cylinder:

Bucket cylinder:

100 mm X 1,092 mm

115 mm X 1,120 mm

95 mm X 903 mm

Refilling Capacities & Lubrications

Axial-piston motor

Hydraulic; locking automatically when the

swing control lever is in the neutral position

Hydraulic disc brake

11.0 min-1 {rpm}

2,190 mm

2,620 mm

Fuel tank:

Cooling system:

Engine oil:

Travel reduction gear:

Swing reduction gear:

275 L

14 L

18.5 L

2 X 2.1 L

1.65 L

Hydraulic oil tank:

101 L tank oil level

172 L hydraulic system

Attachments

Maintenance

Backhoe bucket and combination

Alarm for outside of reset area

Backhoe bucket

Normal digging

Use

Bucket capacity

Struck

Opening width

ISO heaped

m3

m3

With side cutter

mm

Without side cutter mm

No. of bucket teeth

Bucket weight

2.09 m short arm

Recommended

Daily report

Two variable displacement pumps +

1 gear pump

2 X 130 L/min, 1 X 20 L/min

Swing System

Swing motor:

Latest location

2 X axial-piston, two-step motors

Hydraulic disc brake

Oil disc brake per motor

46 each side

5.6/3.4 km/h

139 kN {14.2 tf} (ISO 7464)

70 % {35}

440 mm

Cab & Control

web server

Location Data

Travel motors:

Travel brakes:

Parking brakes:

Travel shoes:

Travel speed:

Drawbar pulling force:

Gradeability:

Ground clearance:

kg

Earth work digging

0.6

0.43

1,100

1,000

5

410

0.7

0.5

1,100

1,100

5

550

Specifications

Lifting Capacities

Working Ranges

Boom

4.68 m

Arm

Range

a- Max. digging reach

Short

2.09 m

8.04

b- Max. digging reach

at ground level

7.89

cdef-

5.23

8.27

5.85

2.53

Max. digging depth

Max. digging height

Max. dumping clearance

Min. dumping clearance

Rating over front

Rating over side or 360 degrees

A - Reach from swing centerline to bucket hook

B - Bucket hook height above/below ground

C - Lifting capacities in kilograms

Max. discharge pressure: 34.3 MPa (350 kg/cm2)

Short Arm: 2.09 m Bucket: 0.6 m3 ISO heaped 410 kg Shoe: 500 mm

SK140HDLC

A

1.5 m

3.0 m

4.5 m

6.0 m

At max. reach

Radius

g- Max. vertical wall

digging depth

4.68

h- Min. swing radius

2.61

i - Horizontal digging stroke

at ground level

6.0 m

kg

*2,950

*2,950

*1,810

*1,810

5.20 m

2.45

4.5 m

kg

*3,220

*3,220

*2,500

1,940

*1,730

*1,730

6.22 m

Bucket capacity ISO heaped m3

0.6

3.0 m

kg

*5,950

5,890

*4,050

3,040

3,090

1,860

*1,790

1,490

6.75 m

1.5 m

kg

*6,900

5,070

4,740

2,760

2,960

1,750

*1,990

1,370

6.91 m

Digging Force (ISO 6015)

Arm length

Bucket digging force

Arm crowding force

Unit: kN (tf)

Short

2.09 m

89.2 {9.1}

71.9 {7.3}

G.L.

kg

*7,020

4,840

4,540

2,580

2,870

1,660

2,390

1,380

6.72 m

-1.5 m

kg

*5,890

*5,890

*8,760

4,850

4,480

2,530

2,840

1,640

2,720

1,570

6.17 m

-3.0 m

kg

*9,310

*9,310

*7,470

5,000

4,550

2,600

3,720

2,150

5.11 m

Notes:

1. Do not attempt to lift or hold any load that is greater than these lift capacities at their

specified lift point radius and heights. Weight of all accessories must be deducted from the

above lift capacities.

2. Lift capacities are based on machine standing on level, firm, and uniform ground. User must

make allowance for job conditions such as soft or uneven ground, out of level conditions,

side loads, sudden stopping of loads, hazardous conditions, experience of personnel, etc.

3. Bucket lift hook defined as lift point.

4. The above lifting capacities are in compliance with ISO 10567. They do not exceed

Short Arm

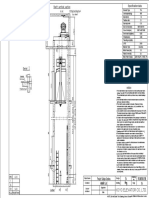

Dimensions

Unit: mm

A

B

C

D

E

F

Arm length

Short

2.09 m

Distance from center of

G

swing to rear end

2,180

Overall length

Overall width

Overall height (to top of cab)

Ground clearance of rear end*

Ground clearance*

Tail swing radius

7,510

2,490

2,870

910

440

2,190

H Tumbler distance

I Overall length of crawler

J Track gauge

K Shoe width

L Overall width of upperstructure

3,040

3,750

1,990

500

2,490

* Without including height of shoe lug.

Operating Weight & Ground Pressure

In standard trim, with short boom, 2.09 m arm, and 0.6 m 3 ISO heaped bucket

Shaped

Shoe width

Overall width

Ground pressure

Operating weight

mm

mm

kPa (kgf/cm 2)

kg

Triple grouser shoes (even height)

500

2,490

39 {0.40}

13,100

87% of hydraulic lifting capacity or 75% of tipping load. Lifting capacities marked with an

asterisk (*) are limited by hydraulic capacity rather than tipping load.

5. Operator should be fully acquainted with the Operators and Maintenance Instructions

before operating this machine. Rules for safe operation of equipment should be adhered to

at all times.

6. Lift capacities apply to only machine as originally manufactured and normally equipped by

KOBELCO CONSTRUCTION MACHINERY CO., LTD.

7. The above figures indicate machine capacity, but in practice the machine should not be used

for lifting loads.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Manual of Information: RIFE Hydraulic RamDocument19 paginiManual of Information: RIFE Hydraulic RamSean100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Acert 2007 CATDocument29 paginiAcert 2007 CATalsief1951100% (1)

- U-STO Parametre Kılavuzu V1.00 TRDocument38 paginiU-STO Parametre Kılavuzu V1.00 TRSalah Salah100% (1)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- GET Parts CaterpillarDocument917 paginiGET Parts Caterpillaralsief195167% (3)

- Cat Forklift Gc25 Schematic Service ManualDocument27 paginiCat Forklift Gc25 Schematic Service Manualfrankstewart270488qny99% (83)

- Elevator Control Wiring and Simple Configuration: Button ModeDocument7 paginiElevator Control Wiring and Simple Configuration: Button ModeAgnelo FernandesÎncă nu există evaluări

- Testing Commissioning Document For ElevatorsDocument5 paginiTesting Commissioning Document For ElevatorsAmin AlbadawiÎncă nu există evaluări

- Raymond Model 8210 and 8250 Pallet Trucks Maintenance ManualDocument320 paginiRaymond Model 8210 and 8250 Pallet Trucks Maintenance ManualMantenimiento CH Reportes100% (1)

- Lifts: Building Material and Construction TechnologyDocument18 paginiLifts: Building Material and Construction TechnologyVala Vraj M.Încă nu există evaluări

- Designing A Hydraulic Ram Pump: Water For The WorldDocument25 paginiDesigning A Hydraulic Ram Pump: Water For The Worldsms19100% (2)

- SM W190 ENDocument508 paginiSM W190 ENBaciu Nicolae100% (5)

- Body Mechanics and Transfer TechniquesDocument90 paginiBody Mechanics and Transfer TechniquesTina Talmadge100% (1)

- Universal Joint 2014 GMBDocument49 paginiUniversal Joint 2014 GMBalsief195171% (7)

- Gidronasosy Serii PMV10Document48 paginiGidronasosy Serii PMV10alsief1951Încă nu există evaluări

- HTM 82-Health CareDocument39 paginiHTM 82-Health CareAbraham JyothimonÎncă nu există evaluări

- Accessibility by Design Handbook Syf41 42Document60 paginiAccessibility by Design Handbook Syf41 42Ats ByÎncă nu există evaluări

- 7 Frame and WheelDocument12 pagini7 Frame and Wheelalsief1951Încă nu există evaluări

- Wa200-5 Aess643-00Document12 paginiWa200-5 Aess643-00alsief1951100% (4)

- Serq4103 NTS4Document75 paginiSerq4103 NTS4alsief1951100% (1)

- ACERT™ 2007: Variable Nozzle TurbochargerDocument37 paginiACERT™ 2007: Variable Nozzle Turbochargeralsief1951Încă nu există evaluări

- A35769EDocument44 paginiA35769Ealsief1951Încă nu există evaluări

- Wa380 5Document12 paginiWa380 5alsief1951100% (3)

- Main Hydraulic Pump PDFDocument12 paginiMain Hydraulic Pump PDFalsief1951Încă nu există evaluări

- Agriculture CatalogueDocument44 paginiAgriculture Cataloguealsief1951Încă nu există evaluări

- 432E - Hyd ComponentsDocument2 pagini432E - Hyd Componentsalsief1951100% (2)

- SectionDocument180 paginiSectionalsief1951Încă nu există evaluări

- Hydraulic Oil TankDocument3 paginiHydraulic Oil Tankalsief1951Încă nu există evaluări

- Variable Vane Pump PDFDocument4 paginiVariable Vane Pump PDFalsief1951Încă nu există evaluări

- 7 14 PDFDocument4 pagini7 14 PDFJames MÎncă nu există evaluări

- Altivar LIFT - 2010 ENDocument2 paginiAltivar LIFT - 2010 ENzkucanÎncă nu există evaluări

- Paper Tray Unit (Machine Code: D331) Service Manual: March, 2007 Subject To ChangeDocument29 paginiPaper Tray Unit (Machine Code: D331) Service Manual: March, 2007 Subject To ChangeДмитрий РазуваевÎncă nu există evaluări

- Koyo Elevator Co,.Ltd.: Specification DataDocument4 paginiKoyo Elevator Co,.Ltd.: Specification DataFelipe Raul Chumpitaz GÎncă nu există evaluări

- Mini Super Cub RTF ManualDocument26 paginiMini Super Cub RTF Manualjesuspca2004@yahoo.comÎncă nu există evaluări

- Sam Higginbottom University of Agriculture Technology & Sciences Department of Civil EngineeringDocument63 paginiSam Higginbottom University of Agriculture Technology & Sciences Department of Civil EngineeringPraveen SinghÎncă nu există evaluări

- Wormgeared Motor NMRVDocument39 paginiWormgeared Motor NMRVCRISTIANÎncă nu există evaluări

- Zigler Katalog PL (En) 2016Document40 paginiZigler Katalog PL (En) 2016Rajib Sarkar100% (1)

- CFS Lift Product RangeDocument9 paginiCFS Lift Product RangeRajen RaghwaniÎncă nu există evaluări

- Transferring of ClientsDocument5 paginiTransferring of ClientsJavieÎncă nu există evaluări

- GE MR480 Voyager 1.5TDocument8 paginiGE MR480 Voyager 1.5TkhamsenglÎncă nu există evaluări

- AOT Safety Clamps Type CDocument2 paginiAOT Safety Clamps Type CCarlig Radu MihaiÎncă nu există evaluări

- DCE 80-100E: Publ. No IDCE01.03GBDocument52 paginiDCE 80-100E: Publ. No IDCE01.03GBEdson GoncalvesÎncă nu există evaluări

- National Building CodeDocument29 paginiNational Building Codeवात्सल्य कृतार्थÎncă nu există evaluări

- Safe Job Procedures SJPDocument49 paginiSafe Job Procedures SJPapi-317342021Încă nu există evaluări

- 2 Post Lifter - ManualDocument24 pagini2 Post Lifter - ManualRyan EncomiendaÎncă nu există evaluări

- Shear Wall Analysis and DesignDocument7 paginiShear Wall Analysis and DesigndaniÎncă nu există evaluări

- 2011 Ref GuideDocument47 pagini2011 Ref GuidejillianixÎncă nu există evaluări