Documente Academic

Documente Profesional

Documente Cultură

1 Input Data: WWW - Hilti.co - Uk

Încărcat de

ihpeterTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 Input Data: WWW - Hilti.co - Uk

Încărcat de

ihpeterDrepturi de autor:

Formate disponibile

Profis Anchor 2.5.

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

2/26/2015

Specifier's comments:

1 Input data

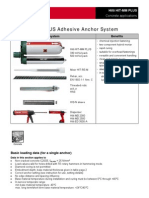

Anchor type and diameter:

HIT-HY 200-A + HIT-V (8.8) M20

Effective embedment depth:

hef,act = 350 mm (hef,limit = - mm)

Material:

8.8

Evaluation Service Report:

ETA 11/0493

Issued I Valid:

8/8/2012 | 12/23/2016

Proof:

Design method ETAG BOND (EOTA TR 029)

Stand-off installation:

eb = 0 mm (no stand-off); t = 30 mm

Anchor plate:

gr275; E = 200000.00 N/mm2; fyk = 275.00 N/mm2; gMs = 1.100

lx x ly x t = 450 mm x 350 mm x 30 mm; (Recommended plate thickness: calculated)

Profile:

Advance UKB; (L x W x T x FT) = 251 mm x 146 mm x 9 mm x 9 mm

Base material:

uncracked concrete, C40/50, fcc = 50.00 N/mm2; h = 10000 mm, Temp. short/long: 0/0 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

with longitudinal edge reinforcement d >= 12 + close mesh (stirrups, hangers) s <=

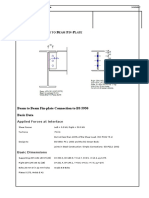

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

2

2/26/2015

2 Load case/Resulting anchor forces

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Shear force x

Anchor

1

0.000

12.750

12.750

2

66.158

12.750

12.750

3

0.000

12.750

12.750

4

66.158

12.750

12.750

max. concrete compressive strain:

0.31 []

max. concrete compressive stress:

9.42 [N/mm2]

resulting tension force in (x/y)=(175/0):

132.316 [kN]

resulting compression force in (x/y)=(-200/0): 124.316 [kN]

3

Shear force y

0.000

0.000

0.000

0.000

x

Tension

Compression

3 Tension load (EOTA TR 029, Section 5.2.2)

Load [kN]

66.158

Capacity [kN]

130.667

Utilization bN [%]

51

Status

OK

Combined pullout-concrete cone failure**

132.316

257.818

52

OK

Concrete Breakout Strength**

132.316

188.446

71

OK

132.316

374.224

36

OK

Steel Strength*

Splitting failure**

* anchor having the highest loading

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

196.000

gM,s

1.500

NRd,s [kN]

130.667

NSd [kN]

66.158

3.2 Combined pullout-concrete cone failure

Ap,N [mm2]

493686

A0p,N [mm2]

426667

2

tRk,ucr,25 [N/mm ]

20.00

scr,Np [mm]

653

ccr,Np [mm]

327

yc

1.000

2

tRk,ucr [N/mm ]

20.00

k

3.200

yg,Np

1.034

yg,Np

1.011

ec1,N [mm]

0

yec1,Np

1.000

ec2,N [mm]

0

yec2,Np

1.000

ys,Np

0.902

N0Rk,p [kN]

439.823

NRk,p [kN]

464.072

gM,p

1.800

NRd,p [kN]

257.818

NSd [kN]

132.316

cmin [mm]

220

yre,Np

1.000

3.3 Concrete Breakout Strength

Ac,N [mm2]

968500

A0c,N [mm2]

1102500

ccr,N [mm]

525

scr,N [mm]

1050

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

0

yec2,N

1.000

N0Rk,c [kN]

467.637

gM,c

1.800

NRd,c [kN]

188.446

NSd [kN]

132.316

Ac,N [mm2]

541500

A0c,N [mm2]

490000

ccr,sp [mm]

350

scr,sp [mm]

700

yh,sp

1.467

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

0

yec2,N

1.000

ys,N

0.889

N0Rk,c [kN]

467.637

gM,sp

1.800

NRd,sp [kN]

374.224

NSd [kN]

132.316

ys,N

0.826

yre,N

1.000

k1

10.100

yre,N

1.000

k1

10.100

3.4 Splitting failure

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

2/26/2015

4 Shear load (EOTA TR 029, Section 5.2.3)

Load [kN]

12.750

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Capacity [kN]

78.400

Utilization bV [%]

17

Status

OK

N/A

N/A

N/A

N/A

Pryout Strength**

51.000

664.746

OK

Concrete edge failure in direction x+**

51.000

106.740

48

OK

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel Strength (without lever arm)

VRk,s [kN]

98.000

VRd,s [kN]

78.400

gM,s

1.250

VSd [kN]

12.750

4.2 Pryout Strength (Concrete Breakout Strength controls)

Ac,N [mm2]

1423500

A0c,N [mm2]

1102500

ccr,N [mm]

525

scr,N [mm]

1050

k-factor

2.000

k1

10.100

ec1,V [mm]

0

yec1,N

1.000

ec2,V [mm]

0

yec2,N

1.000

ys,N

0.826

yre,N

1.000

N0Rk,c [kN]

467.637

gM,c,p

1.500

VRd,c1 [kN]

664.746

VSd [kN]

51.000

a

0.126

b

0.062

yec,V

1.000

4.3 Concrete edge failure in direction x+

hef [mm]

350

dnom [mm]

20.0

k1

2.400

c1 [mm]

220

Ac,V [mm2]

300300

A0c,V [mm2]

217800

ys,V

1.000

yh,V

1.000

ya,V

1.000

ec,V [mm]

0

V0Rk,c [kN]

116.123

gM,c

1.500

VRd,c [kN]

106.740

VSd [kN]

51.000

yre,V

1.000

5 Combined tension and shear loads (EOTA TR 029, Section 5.2.4)

bN

0.702

a

bV

0.478

a

1.500

Utilization bN,V [%]

92

Status

OK

bN + bV 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

49.006 [kN]

dN

0.134 [mm]

VSk

18.889 [kN]

dV

0.756 [mm]

dNV

0.767 [mm]

dN

0.223 [mm]

dV

1.133 [mm]

dNV

1.155 [mm]

Long term loading:

NSk

49.006 [kN]

VSk

18.889 [kN]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

2/26/2015

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Checking the transfer of loads into the base material is required in accordance with EOTA TR 029, Section 7!

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of EOTA TR029! For larger

diameters of the clearance hole see Chapter 1.1. of EOTA TR029!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Bore hole cleaning must be performed according to instructions for use (blow twice with oil-free compressed air (min. 6 bar), brush twice,

blow twice with oil-free compressed air (min. 6 bar)).

Characteristic bond resistances depend on short- and long-term temperatures.

Please contact Hilti to check feasibility of HIT-V rod supply.

Longitudinal reinforcement along the edge of the member shall be provided!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

2/26/2015

8 Installation data

Anchor plate, steel: gr275; E = 200000.00 N/mm2; fyk = 275.00 N/mm2

Profile: Advance UKB; 251 x 146 x 9 x 9 mm

Hole diameter in the fixture: df = 22 mm

Plate thickness (input): 30 mm

Recommended plate thickness: calculated

Cleaning: Premium cleaning of the drilled hole is required

Anchor type and diameter: HIT-HY 200-A + HIT-V (8.8) M20

Installation torque: 0.150 kNm

Hole diameter in the base material: 22 mm

Hole depth in the base material: 350 mm

Minimum thickness of the base material: 394 mm

8.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Compressed air with required

accessories to blow from the bottom of

the hole

Proper diameter wire brush

y

225

50

225

Setting

Dispenser including cassette and mixer

Torque wrench

250

175

175

2

50

50

350

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

-175

175

-175

175

y

-125

-125

125

125

c-x

-

c+x

570

220

570

220

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

50

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

2/26/2015

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

S-ar putea să vă placă și

- 2005-07 Ranger 500 EFI 2X4 4X4 Service ManualDocument345 pagini2005-07 Ranger 500 EFI 2X4 4X4 Service ManualBrian Cook100% (5)

- Tem 3413354 0101Document67 paginiTem 3413354 0101Kolawole KehindeÎncă nu există evaluări

- Assign 3Document9 paginiAssign 3Yudha PP0% (1)

- Group 2 (ME 03) - Hoa Phat GroupDocument42 paginiGroup 2 (ME 03) - Hoa Phat GroupLê Thành DanhÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Nauticus 3D BeamDocument114 paginiNauticus 3D BeamMinca AndreiÎncă nu există evaluări

- Safety Inventory ExercisesDocument12 paginiSafety Inventory ExercisesParnabho KunduÎncă nu există evaluări

- Lecture 09 Value Chain AnalysisDocument29 paginiLecture 09 Value Chain AnalysisDavid HermanÎncă nu există evaluări

- Maxstar140str (KK013519)Document52 paginiMaxstar140str (KK013519)mrtans0% (1)

- 1 Input Data: Profis Anchor 2.4.6Document6 pagini1 Input Data: Profis Anchor 2.4.6Naresh KumarÎncă nu există evaluări

- Pipe Rack Hilti Bolt CalculationsDocument6 paginiPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVÎncă nu există evaluări

- Beam End Connection ReportDocument6 paginiBeam End Connection ReportHibri HalimÎncă nu există evaluări

- Canopy M16 HIT-RE500Document5 paginiCanopy M16 HIT-RE500marchus09Încă nu există evaluări

- Hilti AnchorDocument5 paginiHilti AnchorGopi KrishnanÎncă nu există evaluări

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 paginiPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15Încă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.6Document6 pagini1 Input Data: Profis Anchor 2.6.6Collin NguÎncă nu există evaluări

- H 200mm Thick Slab - Pa2Document6 paginiH 200mm Thick Slab - Pa2ihpeterÎncă nu există evaluări

- 1 Input Data: WWW - Hilti.inDocument5 pagini1 Input Data: WWW - Hilti.inpudumaiÎncă nu există evaluări

- Base CHS X 10tDocument7 paginiBase CHS X 10tCollin NguÎncă nu există evaluări

- 290mm Thick Slab and 540mm EcenDocument6 pagini290mm Thick Slab and 540mm EcenihpeterÎncă nu există evaluări

- Hilti AnchorDocument6 paginiHilti AnchorantonioÎncă nu există evaluări

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 paginiPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.2.4Document6 pagini1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinÎncă nu există evaluări

- PROFIS Anchor 2.0.7Document4 paginiPROFIS Anchor 2.0.7Miky CastenÎncă nu există evaluări

- 1 Input Data: WWW - HiltiDocument5 pagini1 Input Data: WWW - HiltiCibotaru MihaiÎncă nu există evaluări

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocument6 paginiPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007Încă nu există evaluări

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 paginiPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguÎncă nu există evaluări

- Hilti Bolt DesignDocument7 paginiHilti Bolt Designcheligp1981Încă nu există evaluări

- PROFIS Anchor 2.0.7: WWW - Hilti.usDocument5 paginiPROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiÎncă nu există evaluări

- 250x16 Shs Column Base - Pa2123Document5 pagini250x16 Shs Column Base - Pa2123ihpeterÎncă nu există evaluări

- Connection d01 1Document6 paginiConnection d01 1Win ThanÎncă nu există evaluări

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 paginiPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliÎncă nu există evaluări

- PES Hilti M10 HSA ReportDocument4 paginiPES Hilti M10 HSA ReportCollin NguÎncă nu există evaluări

- PES Hilti M10 HSA Report RunnerDocument4 paginiPES Hilti M10 HSA Report RunnerCollin NguÎncă nu există evaluări

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 paginiPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliÎncă nu există evaluări

- Rowad Debugging MachineDocument6 paginiRowad Debugging MachineRonnie De Joya AguirreÎncă nu există evaluări

- Anchor Design - Hilti (HP)Document6 paginiAnchor Design - Hilti (HP)Harikrishnan PÎncă nu există evaluări

- Machine RoomDocument6 paginiMachine RoomRonnie De Joya AguirreÎncă nu există evaluări

- SAMPLE HILTI SolutionDocument6 paginiSAMPLE HILTI SolutionJester AbucayÎncă nu există evaluări

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 paginiShaft B, Hb1 Kempinski 11-1-17.pa2sobhiÎncă nu există evaluări

- Profis Rebar ReportDocument5 paginiProfis Rebar ReportSowmya MajumderÎncă nu există evaluări

- Hilti - Profis Anchor Design Report 594Document5 paginiHilti - Profis Anchor Design Report 594Madhu GuptaÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.5.2Document5 pagini1 Input Data: Profis Anchor 2.5.2jasekan.dcÎncă nu există evaluări

- Hilti Connection ReportDocument7 paginiHilti Connection ReportFrancisco BonillaÎncă nu există evaluări

- Kempinski Hilti Rc-ODocument6 paginiKempinski Hilti Rc-OsobhiÎncă nu există evaluări

- Hilti - Hit Hy 150 Max Cu Hit TZ - 1Document12 paginiHilti - Hit Hy 150 Max Cu Hit TZ - 1Mihnea-Bogdan NicolaescuÎncă nu există evaluări

- 44 - HVZ Adhesive AnchorDocument14 pagini44 - HVZ Adhesive AnchorHuan VoÎncă nu există evaluări

- CAL01 Rev 00Document55 paginiCAL01 Rev 00NiemÎncă nu există evaluări

- Offcon DNV Zorro SkidDocument7 paginiOffcon DNV Zorro SkidRAMSINGH CHAUHANÎncă nu există evaluări

- WIT-PE 500 Design Manual RBDocument24 paginiWIT-PE 500 Design Manual RBMadusha TisseraÎncă nu există evaluări

- Hilti HIT HY 150 MAX With RebarDocument14 paginiHilti HIT HY 150 MAX With RebarNelly BuquironÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 78Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 78danieldumapitÎncă nu există evaluări

- HeavyWeight 3.5 25.58lbs NC-38Document3 paginiHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаÎncă nu există evaluări

- Hilti Hit Hy 150 Max Con Barra CorrugadaDocument20 paginiHilti Hit Hy 150 Max Con Barra Corrugadalandsv01Încă nu există evaluări

- Mazeikiai Residual Hydrocracking Unit (RHCU) - PL-6Document11 paginiMazeikiai Residual Hydrocracking Unit (RHCU) - PL-6shraddhaÎncă nu există evaluări

- Entwürfe - DMD Standard - Beton - 15. Mai 2023Document9 paginiEntwürfe - DMD Standard - Beton - 15. Mai 2023der.holger.bollÎncă nu există evaluări

- Hilti HIT MM Plus 1Document14 paginiHilti HIT MM Plus 1Mihnea-Bogdan NicolaescuÎncă nu există evaluări

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDocument21 paginiHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisÎncă nu există evaluări

- X BT Brochure en W3987Document68 paginiX BT Brochure en W3987Paul RobbinsÎncă nu există evaluări

- 1 Input Data: Hilti PROFIS Engineering 3.0.81Document8 pagini1 Input Data: Hilti PROFIS Engineering 3.0.81Zaido Al HalabiÎncă nu există evaluări

- Technische Dokumentation Technical Documentation: Fully Lined Flanged Filters & Strainers (DIN Version), Type Y101, PN 16Document5 paginiTechnische Dokumentation Technical Documentation: Fully Lined Flanged Filters & Strainers (DIN Version), Type Y101, PN 16peroooÎncă nu există evaluări

- 4597 AAB SC 07 Addendum 2 R0v0 74Document1 pagină4597 AAB SC 07 Addendum 2 R0v0 74danieldumapitÎncă nu există evaluări

- Flupec Catalog Etansari Translatie PDFDocument446 paginiFlupec Catalog Etansari Translatie PDFRadu VasileÎncă nu există evaluări

- Schoeck Isokorb T Type CO Technical Manual (8631)Document7 paginiSchoeck Isokorb T Type CO Technical Manual (8631)theoÎncă nu există evaluări

- MachinaDocument14 paginiMachinaHSY79Încă nu există evaluări

- Anclaje Quimico HILTIDocument84 paginiAnclaje Quimico HILTIWuceirÎncă nu există evaluări

- Hilti Hit Hy 200 With Hit VDocument18 paginiHilti Hit Hy 200 With Hit VRobinReyndersÎncă nu există evaluări

- 11Document3 pagini11ihpeterÎncă nu există evaluări

- Connections UB457 191x98xconnDocument3 paginiConnections UB457 191x98xconnihpeterÎncă nu există evaluări

- Hilti Design Report PDFDocument6 paginiHilti Design Report PDFihpeterÎncă nu există evaluări

- Anchor Bolt CheckDocument1 paginăAnchor Bolt CheckihpeterÎncă nu există evaluări

- Connections UB457 191x98xconnDocument3 paginiConnections UB457 191x98xconnihpeterÎncă nu există evaluări

- Anchor Bolt CheckDocument1 paginăAnchor Bolt CheckihpeterÎncă nu există evaluări

- SBBDocument3 paginiSBBihpeterÎncă nu există evaluări

- 20180923Document13 pagini20180923ihpeterÎncă nu există evaluări

- 20170303Document4 pagini20170303ihpeterÎncă nu există evaluări

- Expo Favoriteroom 5Document1 paginăExpo Favoriteroom 5ihpeterÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.1Document6 pagini1 Input Data: Profis Anchor 2.6.1ihpeterÎncă nu există evaluări

- Portal Output 20180718 R2Document60 paginiPortal Output 20180718 R2ihpeterÎncă nu există evaluări

- Circular Skylight Splice DetailDocument1 paginăCircular Skylight Splice DetailihpeterÎncă nu există evaluări

- UB457 End PlateDocument4 paginiUB457 End PlateihpeterÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.4Document6 pagini1 Input Data: Profis Anchor 2.6.4ihpeterÎncă nu există evaluări

- UB 457 152 52 B B F - P: X X EAM TO EAM IN LateDocument6 paginiUB 457 152 52 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- Reaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZDocument1 paginăReaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZihpeterÎncă nu există evaluări

- Conn DetailDocument1 paginăConn DetailihpeterÎncă nu există evaluări

- RRDocument6 paginiRRihpeterÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.4Document6 pagini1 Input Data: Profis Anchor 2.6.4ihpeterÎncă nu există evaluări

- UB 356 171 45 B B F - P: X X EAM TO EAM IN LateDocument6 paginiUB 356 171 45 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- Conn ForcesDocument2 paginiConn ForcesihpeterÎncă nu există evaluări

- SHS120 Post FixingDocument6 paginiSHS120 Post FixingihpeterÎncă nu există evaluări

- ADocument7 paginiAihpeterÎncă nu există evaluări

- ADocument9 paginiAihpeterÎncă nu există evaluări

- SHS120 Post FixingDocument6 paginiSHS120 Post FixingihpeterÎncă nu există evaluări

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocument7 paginiUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocument7 paginiUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- ADocument7 paginiAihpeterÎncă nu există evaluări

- ADocument2 paginiAihpeterÎncă nu există evaluări

- Tay Township User Fees and Service Charges BylawDocument27 paginiTay Township User Fees and Service Charges BylawMidland_MirrorÎncă nu există evaluări

- Risk Assess T-17 - Using Portable Hand ToolsDocument4 paginiRisk Assess T-17 - Using Portable Hand ToolsMAB AliÎncă nu există evaluări

- Control Panel STD Design PDFDocument71 paginiControl Panel STD Design PDFDuy ThaiÎncă nu există evaluări

- A Vocational Training Presentation On: "Computer Numerical Control Machine"Document15 paginiA Vocational Training Presentation On: "Computer Numerical Control Machine"karan2015Încă nu există evaluări

- RISC Vs CISCDocument13 paginiRISC Vs CISCBehin SamÎncă nu există evaluări

- Flextronics FINALDocument25 paginiFlextronics FINALAnkit GauravÎncă nu există evaluări

- EVI DC Inverter Technical Manual 2 Capacity TableDocument67 paginiEVI DC Inverter Technical Manual 2 Capacity TableMouyed Al QasemÎncă nu există evaluări

- Slum FinalDocument46 paginiSlum FinalSanghita Bhowmick83% (6)

- ViO80 1A PDFDocument2 paginiViO80 1A PDFTomislav1998Încă nu există evaluări

- Guide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsDocument12 paginiGuide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsMauricio Javier León TejadaÎncă nu există evaluări

- Pure Sine Wave Inverter For House BackupDocument44 paginiPure Sine Wave Inverter For House BackupKrista Jackson100% (1)

- GC120 Outline Rev SGDocument2 paginiGC120 Outline Rev SGsong perezÎncă nu există evaluări

- 010 Zircoat MDocument3 pagini010 Zircoat MvsdeepakchandraÎncă nu există evaluări

- Li-Fi Industries Communication Using Laser Media in Open SpaceDocument61 paginiLi-Fi Industries Communication Using Laser Media in Open SpaceVinothKumar100% (1)

- Mooring SystemsDocument6 paginiMooring SystemsVinicius PessottiÎncă nu există evaluări

- E4-E5 CM (3G Operational Issues)Document42 paginiE4-E5 CM (3G Operational Issues)VIKAS NIGAMÎncă nu există evaluări

- Un 2 Terrazzo FlooringDocument6 paginiUn 2 Terrazzo FlooringRÎncă nu există evaluări

- Foaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingDocument27 paginiFoaming of Friction Stir Processed Al /mgco3 Precursor Via Ame HeatingArshad SiddiqueeÎncă nu există evaluări

- RA 7920 Section 33Document1 paginăRA 7920 Section 33Renz Emil ReyesÎncă nu există evaluări

- SNO-I-DS-001 - 0 Instrument Data Sheet For Shutdown and Blowdown Valves (Revise)Document174 paginiSNO-I-DS-001 - 0 Instrument Data Sheet For Shutdown and Blowdown Valves (Revise)ono_czeÎncă nu există evaluări

- Guinness Case StudyDocument3 paginiGuinness Case StudyMunyaradzi T HotoÎncă nu există evaluări

- c02 Scrubber User ManualDocument30 paginic02 Scrubber User ManualJomhel CalluengÎncă nu există evaluări