Documente Academic

Documente Profesional

Documente Cultură

Acs 1

Încărcat de

Arvind KumarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Acs 1

Încărcat de

Arvind KumarDrepturi de autor:

Formate disponibile

ACS550

Quick Start Guide

ACS550-01 Drives (0.75160 kW),

IP21 / UL Type 1 Enclosure

Prepare for installation

WARNING! The ACS550 should ONLY be

installed by a qualified electrician.

Unpack the drive

REMOVE the front cover

MOUNT the drive

INSTALL wiring

REINSTALL the cover

APPLY power

START-UP

Application

This guide provides a quick reference for

installing ACS550-01 drives having a standard

enclosure.

Note: This guide does not provide detailed

installation, safety or operational

instructions. See ACS550 Users Manual for

complete information.

Nominal power ____________________

Tools required

Screwdrivers, wire stripper, tape measure,

mounting screws or bolts and drill.

Refer to Users Manual and confirm that all

preparations are complete.

Remove the front cover

Drive identification

ACS550-01-08A8-4

U1

3~ 380...480 V

I2N/ I2hd 8.8/6.9 A

Serno

PN/Phd 4.0/3.0 kW

*2030700001*

Use the following chart to interpret the type

code found on the drive label.

AC, Standard Drive 550 series

Construction (region specific)

01 = Setup/parts for IEC install./compliance

U1 = Setup/parts for US install./compliance

Output current rating

See Ratings in Users Manual for details

Voltage rating

2 = 208240 V AC

4 = 380480 V AC

6 = 500600 V AC

Options

Examples of options:

No specification = IP21 / UL type 1

B055 = IP54 / UL type 12

UL type 12 is not available for type

ACS550-01-290A-4.

0J400 = No control panel

J404 = ACS-CP-C Basic Control Panel

1. Remove the

control panel, if

attached.

2

2. Loosen the

captive screw

at the top.

1

3. Pull near the

top to remove

the cover.

2. Install the cable clamps for

the power/motor cables.

1

3. On the input power cable,

X0004

strip the sheathing back far

enough to route individual wires.

4. On the motor cable,

7

strip the sheathing

6

back far enough to

expose the copper wire 7

4

shield so that the

3

shield can be twisted

into a bundle. Keep the 8

IP2001

bundle not longer than

five times its width to minimize noise radiation.

360 grounding under the clamp is

recommended for the motor cable to minimize

noise radiation. In this case, remove the

sheathing at the cable clamp.

5. Route both cables through the clamps.

Nominal speed ____________________

Wiring Follow local codes for wiring, circuit

protection and EMC requirements.

Suitable environment Drive requires heated,

indoor controlled environment that is suitable

for the selected enclosure.

ACS550-01-08A8-4+J404+

CHECK installation

1. Open the appropriate

knockouts in the gland box.

The drive requires a

smooth, vertical, solid

surface, free from heat and

moisture, with free space for

air flow 200 mm (8 in)

above and below.

1

1. Mark the mounting points

using the template.

2. Drill the mounting holes.

Motor compatibility Motor type, nominal

current, frequency and voltage range must

match drive specifications.

PREPARE mounting location

Voltage __________________________

Prepare the mounting location

Check

PREPARE for installation

Wiring power

Nominal frequency _________________

1. Unpack the drive.

2. Check for any damage.

3. Check the contents against the order / shipping

label.

The installation of the ACS550 adjustable

speed AC drive follows the outline below.

Collect the following data from the motor

nameplate for later use in the ACS550 startup:

Nominal motor current ______________

Note: Lift the ACS550 by its chassis and not by its

cover.

Overview

Install the wiring

Collect motor data

6. Connect the bundle created from the motor

cable shield to the GND terminal.

7. Strip and connect the power/motor wires and

the power ground wire to the drive terminals

using the torques given in the table below. See

Power connections below or, for more detail,

see Users Manual.

X0002

IP2000

Frame Tightening torque

size Nm

lbft

R1, R2 1.4

1

R3

2.5

1.8

R4

5.6; PE: 2 4; PE 1.5

R5

15

11

R6

40; PE: 8 30; PE: 6

X0005

8. Install conduit/gland box and tighten the cable

clamps.

Mount the drive

1. Position the ACS550 and

use screws or bolts to

securely tighten all four

corners.

Note: Lift the ACS550 by its

metal chassis.

WARNING! To disconnect the internal EMC

filter, remove the screws marked with -, or

replace the screws marked with with the

provided polyamide screws, depending on

the frame size.

System type

2. Non-English speaking

IP2002

locations: Attach a

warning sticker in the appropriate language

over the existing warning on the top of the

module.

R1...R3

R4

R5...R6

EM1 EM3 EM1 EM3 F1 F2

IT system

Corner grounded TN

system

- -

9. Install the cable clamp(s) for

the control cable(s). (Power/

motor cables and clamps

not shown in the figure.)

9

X0006

Wiring the controls

Frame size R1R4

EM3

1. Strip control cable sheathing

and twist the copper shield

into a bundle.

3

4

Check installation

2. Route control cable(s)

through clamp(s) and tighten

clamp(s).

EM1

PE

GND

X0033

Power input

(U1, V1, W1)

Power output to motor

(U2, V2, W2)

See table Optional

braking below.

Frame size R5

F1

See table Optional

braking below.

F2

Before applying power, perform the following

checks.

3. Connect the ground shield

bundle for digital and analog

I/O cables at X1-1. (Ground

only at the drive end.)

X0035

Power input

(U1, V1, W1)

Power output to motor

(U2, V2, W2)

Frame size R6

F2

See table

Optional braking

below.

F1

X0013

5. Install the conduit/gland box cover (1 screw).

The drive is properly grounded.

X1

1

2

3

4

5

6

7

8

9

SCR

AI1

AGND

10V

AI2

AGND

AO1

AO2

AGND

Signal cable shield (screen)

Ext. freq. ref. 1: 010 V

Analog input com.

Ref. voltage 10 V DC

Not used

Analog input com.

Output freq.: 020 mA

Output current: 020 mA

Analog output com.

10

11

12

13

14

15

16

17

18

24V

GND

DCOM

DI1

DI2

DI3

DI4

DI5

DI6

Aux. volt. output +24 V DC

Aux. volt. common

Digital input com. for all

Start/Stop: Active = start

Fwd/Rev: Active = rev. dir.

Constant speed sel.2

Constant speed sel.2

Ramp pair: Active = 2nd ramp pair.

Not used

19

20

21

22

23

24

25

26

27

RO1C

RO1A

RO1B

RO2C

RO2A

RO2B

RO3C

RO3A

RO3B

Relay output 1

Default operation:

Ready = 19/21 connected

Relay output 2

Default operation:

Running = 22/24 connected

Relay output 3

Default operation:

Fault(-1) =25/27 connected

(Fault => 25/26 connected)

Frame

size

R1, R2

R3R6

Terminal

Brake options

labels

BRK+, BRK- Brake resistor

UDC+, UDC- Braking unit

Chopper and resistor

or

J1

ON

Optional braking

J1

ON

Power output to motor

(U2, V2, W2)

1 2

GND

ON

PE

AI1: 010 V

AI2: 0(4)20 mA

Note 2. Code: 0 = open, 1 = connected

DI3 DI4

Output

0

0

Reference through AI1

1

0

CONSTANT SPEED 1 (1202)

0

1

CONSTANT SPEED 2 (1203)

1

1

CONSTANT SPEED 3 (1204)

Always reinstall the front cover before turning

power on.

WARNING! The ACS550 will start up

automatically at power up, if the external run

command is on.

Note: Before increasing motor speed, check that

the motor is running in the desired direction.

The motor and driven equipment are ready for start.

For IT systems and corner grounded TN systems:

The internal EMC filter is disconnected (see the table

in Wiring power).

Input power (mains) voltage matches the drive

nominal input voltage.

Note 1. Jumper setting (two switch types possible):

Power input

(U1, V1, W1)

The drive is mounted securely.

Proper cooling space around the drive.

ABB Standard macro

GND

Environment conforms to specifications.

4. Strip and connect the individual

IP2003

control wires to the drive

terminals. Use a tightening torque of 0.4 Nm (0.3

lbft). See Control connections below or, for more

information, see Users Manual.

Apply power

1. Apply input power.

When power is applied to the ACS550, the

green LED comes on.

Check

Control connections

PE

WARNING! The maximum voltage for digital

inputs is 30 V.

The input power (mains) terminals, U1, V1, W1, are

connected and tightened as specified.

The input power (mains) fuses are installed.

The motor terminals, U2, V2, W2, are connected and

tightened as specified.

Motor cable is routed away from other cables.

NO power factor compensation capacitors are in the

motor cable.

Control terminals are wired and tightened as

specified.

NO tools or foreign objects (such as drill shavings)

are inside the drive.

NO alternate power source for the motor is

connected no input voltage is applied to the output

of the drive.

In start-up, enter motor data (collected earlier)

and, if needed, edit parameters that define how

the drive operates and communicates.

Assistant Control Panel

The Start-up Assistant steps through typical

start-up selections, and runs automatically

upon the initial power up. At other times, use

the steps below to run the Start-up Assistant.

1. Use the MENU key to

access the Main menu.

2. Select ASSISTANTS.

3. Select Start-up Assistant.

4. Follow the screen

instructions to configure the

system.

49.1Hz

400RPM

LOC

LOC

49.RPM

1 Hz

1200

12.40.

A5 A

405

10.dm3/s

7 %

DIR

DIR

12:45

00:00

MENU

MENU

Note: For common parameters and menu items,

use the Help key ? to display

descriptions.

If you encounter alarms or faults, use the

Help key or refer to chapter Diagnostics in

Users Manual.

Reinstall the cover

1. Align the cover

and slide it on.

2. Tighten the

captive screw.

3. Install the control

panel.

Start-up

1

2

Basic Control Panel

3

IP2009

The Basic Control Panel does not

include the Start-up Assistant. Refer to

section How to start up the drive in

Users Manual and manually enter any

parameter changes desired.

Code: 3AFE68243513 REV E / EN

Effective: 2009-07-07

Supersedes: 2007-04-16

Power connections

S-ar putea să vă placă și

- UHF RFID Reader Plus Protocol Application Example V1 3 - ENDocument14 paginiUHF RFID Reader Plus Protocol Application Example V1 3 - ENArvind KumarÎncă nu există evaluări

- ASDA-B2 Anual PDFDocument311 paginiASDA-B2 Anual PDFALEXANDRU ZANOAGAÎncă nu există evaluări

- EnMS Worksheet for Corrective & Preventive Action RequestsDocument1 paginăEnMS Worksheet for Corrective & Preventive Action RequestsArvind KumarÎncă nu există evaluări

- DG Synchronizing PanelDocument33 paginiDG Synchronizing PanelArvind KumarÎncă nu există evaluări

- 12Document34 pagini12Rafael GagoÎncă nu există evaluări

- InvoiceDocument1 paginăInvoiceArvind KumarÎncă nu există evaluări

- HMI Template en PDFDocument37 paginiHMI Template en PDFCao Minh ToànÎncă nu există evaluări

- HMI Template en PDFDocument37 paginiHMI Template en PDFCao Minh ToànÎncă nu există evaluări

- ASDA-B2 Anual PDFDocument311 paginiASDA-B2 Anual PDFALEXANDRU ZANOAGAÎncă nu există evaluări

- Project/Activity - 01 Journey To Industry 4.0: (Dept.: Electronics Maintenance/Utilities)Document21 paginiProject/Activity - 01 Journey To Industry 4.0: (Dept.: Electronics Maintenance/Utilities)Arvind KumarÎncă nu există evaluări

- InvoiceDocument1 paginăInvoiceArvind KumarÎncă nu există evaluări

- 12Document34 pagini12Rafael GagoÎncă nu există evaluări

- Manual JX PDFDocument263 paginiManual JX PDFArvind KumarÎncă nu există evaluări

- Project/Activity - 01 Journey To Industry 4.0: (Dept.: Electronics Maintenance/Utilities)Document21 paginiProject/Activity - 01 Journey To Industry 4.0: (Dept.: Electronics Maintenance/Utilities)Arvind KumarÎncă nu există evaluări

- Energy Council Reviews Utility Consumption and Savings ProjectsDocument14 paginiEnergy Council Reviews Utility Consumption and Savings ProjectsArvind KumarÎncă nu există evaluări

- Easy Start Guide LS IC5Document15 paginiEasy Start Guide LS IC5Arvind KumarÎncă nu există evaluări

- Proposal For Mpet Winding Machine-OEE CalculationDocument3 paginiProposal For Mpet Winding Machine-OEE CalculationArvind KumarÎncă nu există evaluări

- Predialysis Education PresentationDocument99 paginiPredialysis Education PresentationArvind KumarÎncă nu există evaluări

- CX Server RuntimeDocument91 paginiCX Server RuntimeArvind KumarÎncă nu există evaluări

- Exceutive Meet PresentationDocument21 paginiExceutive Meet PresentationArvind KumarÎncă nu există evaluări

- Technical Specifications: Enviropol Engineers Pvt. LTDDocument17 paginiTechnical Specifications: Enviropol Engineers Pvt. LTDArvind KumarÎncă nu există evaluări

- Basic Drive Programing - PF753Document68 paginiBasic Drive Programing - PF753Arvind KumarÎncă nu există evaluări

- Allen Bradley PLC Input/Output Chart for DG Automation ProjectDocument17 paginiAllen Bradley PLC Input/Output Chart for DG Automation ProjectArvind KumarÎncă nu există evaluări

- Introduction To Factorytalk View Software Tool.: LaboratoryDocument24 paginiIntroduction To Factorytalk View Software Tool.: LaboratoryArvind KumarÎncă nu există evaluări

- Index 01Document1 paginăIndex 01Arvind KumarÎncă nu există evaluări

- Drives ManualDocument12 paginiDrives ManualArvind KumarÎncă nu există evaluări

- 5 Allocation of Buffer Memories (BFM) 3 Installation and WiringDocument8 pagini5 Allocation of Buffer Memories (BFM) 3 Installation and WiringArvind KumarÎncă nu există evaluări

- New Microsoft PowerPoinPLC PRESENTATIONt PresentationDocument16 paginiNew Microsoft PowerPoinPLC PRESENTATIONt PresentationArvind KumarÎncă nu există evaluări

- Revised PLC Drawing 250812Document14 paginiRevised PLC Drawing 250812Arvind KumarÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Curriculum Vitae: Name: Email ID: MOBILE: +91 9361265029Document4 paginiCurriculum Vitae: Name: Email ID: MOBILE: +91 9361265029Shankker KumarÎncă nu există evaluări

- Fujitsu ACDocument16 paginiFujitsu ACNora SmithÎncă nu există evaluări

- Module Title:-Cable Calculation: o o o o o oDocument13 paginiModule Title:-Cable Calculation: o o o o o ocbradley87Încă nu există evaluări

- 12V DC To 220V AC Inverter CircuitDocument6 pagini12V DC To 220V AC Inverter CircuitAnonymous e3XZzQ100% (1)

- Epm 07 07S enDocument5 paginiEpm 07 07S enWojciech WróbelÎncă nu există evaluări

- SIP5CC 7SX800 V08.70 Manual C003-1 enDocument1.630 paginiSIP5CC 7SX800 V08.70 Manual C003-1 enSamÎncă nu există evaluări

- CSF 110Document46 paginiCSF 110damanchurw210Încă nu există evaluări

- Duroplast Switch System PricelistDocument1 paginăDuroplast Switch System PricelistAntonio Vergara RuizÎncă nu există evaluări

- Reactor de NeutroDocument7 paginiReactor de NeutroJosePaen100% (2)

- Manual Generador ENGGADocument20 paginiManual Generador ENGGAmanuel100% (2)

- 8407 Slides Topic8 OtherDocument6 pagini8407 Slides Topic8 OtherhuydktdÎncă nu există evaluări

- X Cable To BS6004: H07V-R/H07V-UDocument3 paginiX Cable To BS6004: H07V-R/H07V-UVinay PallivalppilÎncă nu există evaluări

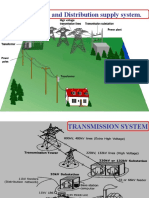

- Transmission and Distribution Supply SystemDocument108 paginiTransmission and Distribution Supply SystemAshok Kumar100% (1)

- Sizing and Installing CUMMINSDocument52 paginiSizing and Installing CUMMINSTTIBCCAÎncă nu există evaluări

- S202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereDocument5 paginiS202M-K16UC: Miniature Circuit Breaker - S200MUC - 2P - K - 16 AmpereMary RoshmaÎncă nu există evaluări

- Chapter4-Synchronous MachinesDocument55 paginiChapter4-Synchronous MachinesDuydo Bui100% (2)

- STATCOM - Working Principle, Design and Application - Electrical ConceptsDocument7 paginiSTATCOM - Working Principle, Design and Application - Electrical ConceptsJunaid BhattiÎncă nu există evaluări

- Substation Monitoring System: Prof. Kunal V.Ranvir, Mayuri A. Solanke, Rohit P. Ratnaparkhi, Ashvini N. SableDocument3 paginiSubstation Monitoring System: Prof. Kunal V.Ranvir, Mayuri A. Solanke, Rohit P. Ratnaparkhi, Ashvini N. SableerpublicationÎncă nu există evaluări

- Tariff Technical ReportDocument9 paginiTariff Technical ReportREXGODÎncă nu există evaluări

- Optidrive P2 User Guide V3.09Document88 paginiOptidrive P2 User Guide V3.09Mulata Comida y caféÎncă nu există evaluări

- Magneti Marelli: Active Industrial Solutions Job# A0862 Op5035Document23 paginiMagneti Marelli: Active Industrial Solutions Job# A0862 Op5035Christian TorresÎncă nu există evaluări

- App X-Ray Multiphos 10 PlusDocument8 paginiApp X-Ray Multiphos 10 PlussamarÎncă nu există evaluări

- BAE146AVRO 146 RJ Maintenance Training Manual: Engine Starting ATA 80-00Document30 paginiBAE146AVRO 146 RJ Maintenance Training Manual: Engine Starting ATA 80-00Ale Torrico TamayoÎncă nu există evaluări

- Metravi 1811 ELCB Tester CatalogueDocument2 paginiMetravi 1811 ELCB Tester CatalogueKishore KumarÎncă nu există evaluări

- PowerGeneration S4000 Diesel BrochureDocument9 paginiPowerGeneration S4000 Diesel BrochureVoltgent GeneratorÎncă nu există evaluări

- Transmission and Distribution Design Old QuestionsDocument10 paginiTransmission and Distribution Design Old QuestionsHarry ChaudharyÎncă nu există evaluări

- EEE 4227: Power Electronics: InvertersDocument52 paginiEEE 4227: Power Electronics: InvertersMd. Abu Hossain MahadyÎncă nu există evaluări

- TP 6783Document60 paginiTP 6783FredÎncă nu există evaluări

- Current and Voltage Controls Current Transformer, 1-Phase AC Type TAD 2, TAD 3Document2 paginiCurrent and Voltage Controls Current Transformer, 1-Phase AC Type TAD 2, TAD 3Naeem MemonÎncă nu există evaluări

- Astronergy CHSM6612P 3BB 40mm Frame 20151014Document2 paginiAstronergy CHSM6612P 3BB 40mm Frame 20151014J AAÎncă nu există evaluări