Documente Academic

Documente Profesional

Documente Cultură

Calculation of Overspeed Trip Mechanism Linkage Forces

Încărcat de

Jhon DonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Calculation of Overspeed Trip Mechanism Linkage Forces

Încărcat de

Jhon DonDrepturi de autor:

Formate disponibile

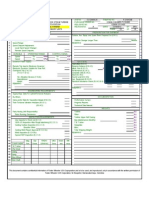

ATTACHMENT 9.

ENGINEERING CALCULATION COVER PAGE

Sheet 1 of 2

F- ANO-1

E] ANO-2

[I GGNS

LI IP-2

El IP-3

IZ JAF

[I

El RBS

El VY

E] W3

LI NP-GGNS-3

FI NP-RBS-3

PNPS

CALCULATION

1)EC #

31177,

(2)

Page 1 of

Z PLP

3.4

COVER PAGE

(3)Design Basis Calc.

F-1 YES

Z NO

E-- EC Markup

(4) Z CALCULATION

Calculation No: EA-EC31177-01

) Revision: 0

(7)

Title: Calculation of Overspeed Trip Mechanism Linkage Forces

(9)

System(s): AFW

('0) Review Org (Department):

(11) Safety Class:

Editorial

E] YES Z NO

Sys Eng

(8)

(12) Component/Equipment/Structure

Type/Number:

er8

pump

Z Safety / Quality Related

Quality Program

F-I Augmented

Mi Non-Safety Related

(13)

(14)

Turbine

K-8

Document Type: Record

Keywords (Description/Topical

Codes):

Overspeed, Trip, AFW, Spurious

Grease, Greasing, Latch, Linkage,

Knife Edge

REVIEWS

(15)

Name/Signature/Date

(16)

MPR Associates /11-30-11

Responsible Engineer

Name/Sinatu re/ ate

<&..& 41t(-'O-,

E-1

Design Verifier

(17)

Name/Sign ture/Date

Supervisor/Approval

Z Reviewer

__

Comments Attached

-- Comments Attached

EN-DC-126 REV 4

ATTACHMENT 9.4

RECORD OF REVISION

Sheet 1 of 1

Initial issue.

0

*1*

EN-DC-126 REV 4

ATTACHMENT

9.3

CALCULATION REFERENCE SHEET

Sheet 1 of 3

CALCULATION

REFERENCE SHEET

CALCULATION NO:

REVISION: 0

EA-EC31177-01

I. EC Markups Incorporated (N/A to NP calculations)

1. N/A

2.

3.

4.

5.

II. Relationships:

Sht

Rev

2.

3.

Impact

Y/N

Tracking

No.

l]

El

El

El

EJ

4.

5.

Ill.

Output

Doc

[]

N/A

1.

Input

Doc

_0

0[]

0

CROSS REFERENCES:

1. Palisades Condition Report CR-PLP-2011-02350 "Auxiliary Feedwater P ump P-8B

Tripped on Overspeed"

2. Elliott Turbomachinery Technical Manual 10OM for Elliott DYRT Turbine,

B902105MOD.1

3. Machinery Handbook, Oberg, Jones, Horton and Ryffel, 2 5 th ed. Industrial Press

1996

4.

5.

IV.

SOFTWARE USED:

N/A

Title:

V.

N/A

Disk/CD No.

Version/Release

N/A

Disk/CD No. N/A

DISK/CDS INCLUDED:

N/A

Title:

VI.

N/A

Version/Release:

OTHER CHANGES:

N/A

EN-DC-126 REV 4

VENDOR DOCUMENT REVIEW STATUS

ATTACHMENT 9.1

Sheet 1 of 1

Sv~ntrsn/ENTERGY NUCLEAR MANAGEMENT MANUAL

EntergyEN-DC-1

49

VENDOR DOCUMENT REVIEW STATUS

Z]

LIIPEC

El

FOR ACCEPTANCE

[] JAF

PLP

[] PNPS

Document No.: 0098-1103-0171-00

VY

FOR INFORMATION

[-

ANO

[] GGNS

[] RBS

IW3 L

NP

Rev. No.4

Document Title: Calculation of Overspeed Trip Mechanisim Linkage Forces

Purchase Order No.

EC No.: 31177

(N/A for NP)

STATUS NO:

1. Z ACCEPTED, WORK MAY PROCEED

2. F-1 ACCEPTED AS NOTED RESUBMITTAL NOT REQUIRED, WORK MAY PROCEED

3. F-1 ACCEPTED AS NOTED RESUBMITTAL REQUIRED

4. I1 NOT ACCEPTED

Acceptance does not constitute approval of design details, calculations, analyses, test methods, or materials

developed or selected by the supplier and does not relieve the supplier from full compliance with contractual

negotiations.

Responsible Engineer

SGKupka

/

Sig dat

Print Name

Engineering Supervisor

THFouty

Print Name

-74V

Signa

Date

I I/3o//

re

Date

EN-DC-149 REV 6

MPR Associates, Inc.

*M

320 King Street

Alexandria, VA 22314

CALCULATION TITLE PAGE

Client:

Palisades Nuclear Plant

Page 1 of 30

Project:

Task No.

Overspeed Trip Mechanism Evaluation

0098-1103-0171-00

Title:

Calculation No.

Calculation of Overspeed Trip Mechanism Linkage Forces

Preparerf/ Date

0098-0171-01

Checker / Date

Reviewer & Approver / Date

Rev. No.

Patrick Butler

August 5, 2011

Amber Su

August 9, 2011

Ben Frazier

August 9, 2011

Ben Frazier

August 31, 2011

Joseph Konefal

August 31, 2011

Robert Keating

August 31, 2011

Patrick Butler

November 14, 2011

Mark Staley

November 15, 2011

Ben Frazier

November 15, 2011

Ben Frazier

November 15, 2011

Patrick Butler

November 17, 2011

Ben Frazier

November 18, 2011

Ben Frazier

November 18, 2011

Patrick Butler

November 30, 2011

Ben Frazier

November 30, 2011

Ben Frazier

November 30, 2011

MPR Associates, Inc.

320 King Street

PR

*M

Alexandria, VA 22314

RECORD OF REVISIONS

Calculation No.

0098-0171-01

Revision

Prepared By

Checked By

Page:

Pae"eUcrLpi

JAffected Pages

Description

All

Initial Issue

All

Added a summary of the critical variable calculations to Section 2.0. This

change is indicated by a revision bar.

Revision note was removed from the body of the calculation.

All

Changed the modeling of the linkage to specifically address mass of the

Resetting Lever, force from Backseat Spring on Resetting Lever, moment of

torsional spring on Hand Trip Lever.

Revised the model of the Hand Trip Lever to include the complete lever.

Used vibration data during turbine operation taken at the end of the Resetting

Lever instead of older vibration data from the Governor

Added a modal analysis of the linkage to determine the natural frequencies,

mode shapes and modal participation of modes near frequencies where

vibration peak accelerations were measured.

All

Changes made to incorporate Energy comments as follows:

"

"

*

"

"

All

Discussion of Knife Edge/Latch contact area added

Assumption regarding horizontal acceleration added

Added clarification regarding iterative process used in calculation

Change in location of measured force associated with torsional spring

Additional clarifications and corrections.

Revised Figures 3-4, 3-5 and 3-9 to be more readable. Eliminated redundant

page 19.

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

WM PR

Calculation No.

0098-0171-01

Prepared By

Vh

"f

,,

Checked By

Page:

Revision:

Table of Contents

1.0

Purpose.........................................................................................................

2.0

Sum m ary of Results ...........................................................................

3.0

Discussion........................................................................................................

4.0 Assum ptions....................................................................................................

5.0

6.0

.............. 4

Calculation......................................................................................................

17

5 .1

Ap p ro ach .....................................................................................................................

17

5.2

Calculation of Knife Edge Forces .........................................................................

18

5.3

Knife Edge Latch Contact ...................................................................................

22

5.4

Vibration M easurements .......................................................................................

22

5.5

M otion of Resetting Lever in Horizontal Plane ...................................................

24

5.6

M odal Analysis of Trip Linkage ...........................................................................

26

References......................................................................................................

30

MPR Associates, Inc.

*M

320 King Street

Alexandria, VA 22314

0098-0171-01

1.0

"V

"x4

Page: 4

Checked By

Prepared By

Calculation No.

Revision: 4

PURPOSE

During a routine plant surveillance test of Auxiliary Feedwater Pump P-8B, the turbine overspeed

trip mechanism actuated resulting in a trip of the feed pump. As documented in Entergy Condition

Report CR-PLP-2011-02350 (Reference 1), the pump was declared inoperable. Investigations

determined that during recent maintenance of the turbine, lubricant was applied to the mating knife

edge surfaces of the trip linkage. These surfaces are not intended to be lubricated. This

calculation determines the applied forces and resulting moments on the trip linkage components.

In addition, this calculation determines if addition of the lubricant to the knife edge sufficiently

reduces friction at the knife edge such that a trip would be expected at Resetting Lever vibration

levels measured during normal operation of the pump.

2.0

SUMMARY OF RESULTS "

The results of this calculation show that the given typical coefficient of friction values of 0.8

associated with dry conditions, 0.16 associated with lubricated conditions and a coefficient of

friction of zero, the geometry of the linkage is such that the following combined vertical and

horizontal accelerations are needed to overcome the friction and trip the linkage.

Coefficient of Friction

Required Combined Vertical and Horizontal

Acceleration required to Trip Linkage

0.8

36.14 g left and 36.14 g upward

0.16

36.4 g left and 36.4 g upward

1.85 g left and 1.85 g downward

MPR Associates, Inc.

P R

320 King Street

Alexandria, VA 22314

Calculation No.

Prepared By

0098-0171-01

Vakdo

Checked By

,

Page:

Revision: 4

Measured values of horizontal and vertical acceleration and displacement of the Resetting Lever

near the knife edge during operation of the pump are as follows:

Direction

Peak

Acceleration

Complete

Frequency

Peak Spectral

Acceleration

Value (g)

Frequency at

Peak Spectral

Acceleration (Hz)

Displacement (in)

2.77

.85

1400

0.0068

8.11

3.39

2200

0.0052

Range (g)

Horizontal

(perpendicular to

Resetting Lever

Axis)

Vertical

The measured values of acceleration are below those expected to cause trip of the linkage under

lubricated conditions. Further, the frequencies at which the measured peak accelerations occur are

sufficiently high that resulting displacements are significantly below the displacements required to

trip the linkage.

Finally, modal analysis of the trip linkage showed that fundamental frequencies of the Hand Trip

Lever and the Resetting Lever start at 230 Hz and that the 9th and 11th fundamental frequencies at

1489 Hz and 2023 Hz, respectively are close to the measured frequencies of 1400Hz and 2200Hz.

The mass participation of each of these modes is a generally small (on the order of 2 to 8 percent)

although in the Z direction, mass participation is approximately 30%. However, the high

frequency of these modes does not result in significant response of the linkage. The mass

participation of each of these modes is a small percentage of the overall mass (i.e., less than 0.2%)

and these modes are not expected to result in significant response of the linkage.

In summary, the geometry of the linkage is such that large accelerations are needed to cause it to

trip, the actual measured accelerations are small relative to those required to cause trip and the

measured displacements on the order of 0.007 inches are too small to move the Hand Trip Lever

the approximate 0.125" (Reference 2, page 4-15) required to cause it to trip.

3.0

DISCUSSION

The AFW pump turbine overspeed trip mechanism is illustrated in Figure 3-1. As shown in the

figure, the end of the pump turbine shaft includes a spring loaded Overspeed Trip Pin Assembly

inside of it. If the rotational speed exceeds a specified value, the pin will extend from the shaft,

strike the Plunger Assembly and will cause the Hand Trip Lever to rotate counter-clockwise. The

*M

Calculation No.

0098-0171-01

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

Prepared By

1VX o

"TNlL,

Checked By

A

t_. 7

Page: 6

Revision: 4

Knife Edge of the Resetting Lever will disengage from the Latch of the Hand Trip Lever and the

Closing Springs will rotate the Resetting Lever counter-clockwise. The Trip Valve will close,

steam supply to the turbine will be cut off, and the turbine will stop.

To allow calculation of the forces acting on the various components of the Overspeed Trip

Mechanism (OTM), a walkdown was performed and dimensions of the components were obtained.

The dimensions taken for the Hand Trip Lever and Resetting Lever are shown in Figures 3-2 and

3-3, respectively. The dimensions for the Hand Trip Lever and Resetting Lever were obtained

during walkdowns of the Auxiliary Feedwater Pump performed on May 19, 2011 and October 25,

2011. Solid CAD models were made from the walkdown dimensions and the solid models were

used to determine the locations of the centroids and the masses of both components. The locations

of the centroids for the Hand Trip Lever and the Resetting Lever relative to their pivot points are

provided in Figure 3-4.

The Solidworks solid modeling program was used to determine that the volume of material in the

Hand Trip Lever is 11.07 cubic inches. Assuming that Hand Trip Lever is cast carbon steel with a

density of 0.29 lbm/in3 , the mass of the Hand Trip Lever is 3.21 Ibm. In addition, the Solidworks

software was used to determine that the centroid of the Hand Trip Lever is 1.06 inches above its

pivot in the vertical direction and is 0.82 inches to the left of its pivot point, as shown in Figure 34.

The dimensions for the Resetting Lever on Figure 3-3 were used to build a solid model of the

Resetting Lever using the Solidworks CAD software. Solidworks was used to determine that the

volume of material in the Resetting Lever is 22.43 cubic inches. Assuming that Resetting Lever is

cast carbon steel with a density of 0.29 lbm/in 3 , the mass of the Resetting Lever is 6.49 Ibm. In

addition, the Solidworks software was used to determine that the centroid of the Resetting Lever is

10.73 inches from the knife edge and is 0.52 inches below the centerline of the circular section of

the arm, as shown in Figure 3-4. Note that as documented in Reference 6, weight and center of

gravity measurements taken for the Resetting Lever by Palisades maintenance personnel were 6.56

Ibm and 10 3/4 inches from the knife edge.

To allow calculation of the forces on the OTM and to assess the impact of addition of lubricant to

the mating Knife Edge and Latch, free body diagrams for the Hand Trip Lever and Resetting Lever

were prepared as shown in Figure 3-5.

As shown in the exploded view in Figure 3-7, there is a torsional spring (Item 32) that is installed

on the Hand Trip Lever. The torsional spring applies a moment in the clockwise direction (as

viewed in Figure 3-1) and prevents the Hand Trip Lever from disengaging from the Resetting

Lever. Measurements were taken by Palisades maintenance personnel that indicated that with the

Hand Trip Lever in its set position, a force of 3.65 lbf applied at the centerline of the Resetting

Lever is needed to overcome the spring force.

MPR Associates, Inc.

IIM PR

320 King Street

Alexandria, VA 22314

Calculation No.

0098-0171-01

Prepared By

,V"

Checked By

L,

Page: 7

Revision: 4

While vibrations measurements are taken during surveillance testing of the AFW pump, the

vibration instrumentation is attached to the governor housing and results obtained may not be

representative of vibration of the OTM mechanism components. To address this, Palisades ran the

AFW pump with vibration instrumentation attached directly to the Resetting Lever near the Knife

Edge as shown in Figure 3-6. Tests were run with the pump in recirculation mode as well as when

providing flow to the steam generators. Since the vibration data taken while the pump was in

recirculation mode is greater, it will be used in this calculation and is provided for the vertical and

horizontal directions in Figure 3-8. The measurement data is from Reference 7.

To address concerns over lateral motion of the Resetting Lever, the lateral motion will be

evaluated. Free body diagrams for the Resetting Lever for lateral motion was prepared as shown

in Figure 3-9.

4.0

ASSUMPTIONS

1.

The measured accelerations are assumed to be sinusoidal. This allows use of a factor of

1.414 to convert root-mean-square acceleration to peak acceleration. This is a reasonable

assumption and introduces no bias into the calculation.

2.

Accelerations measured when the pump was operated in recirculation mode bound

accelerations measured when the pump was operated with flow to the steam generator as

existed during the spurious trip.

3.

The material for the Resetting Lever and the Hand Trip Lever is assumed to be cast carbon

steel. This assumption introduces no bias into the calculation because the material is clearly

metallic and will have a density close to the 0.29 lb/in 3 value assumed. If this assumption is

determined to be in error, the impact on the material density will be small and is not

expected to change the results of the calculation.

4.

The calculation that determines the vertical acceleration and the horizontal acceleration in

the direction of the Resetting Lever necessary to overcome various coefficients of friction

assumed that the magnitudes of the horizontal and vertical accelerations were equivalent.

The intent of the calculation is to provide an estimate of the acceleration value needed to

cause the linkage to trip and as such is reasonable. Further, the measured value of

acceleration in the vertical direction was significantly larger than the acceleration in the

horizontal direction perpendicular to the Resetting Lever and is expected to also be larger

than the acceleration in the horizontal direction parallel to the Resetting Lever, which was

not measured.

*M PR

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

Calculation No.

Prepared By

0098-0171-01

" L

Checked By

4

, LM.

-,

FIGURE

ITEM

NUMBER

4-7-1

2

3

4

5

6

7

8

9

10

11

12

4.

OVERSPEED

TRIP PIN ASSEMBLY

DESCRIPTION

Page:

Revision:

0aUANTITY

TRIP PIN

TRIP SPRING

"U" LOCK STAPLE

ADJUSTING NUT

WASHER

AUXILIARY WEIGHT

PLUNGER ASSEMBLY

JACKSCREW

JAM NUT

JAM NUT

SET SCREW

INSPECTION PLUG

1

I

1

2

1

1~

1

1

1

1

*Indicates part not used on all turbines or

variable quantities.

Figure 3-1. AFW Pump Turbine Overspeed Trip Mechanism

MPR Associates, Inc.

FIM PR

320 King Street

Alexandria, VA 22314

Calculation No.

Prepared By

")k

0098-0171-01

Checked By

4

Page:

Revision: 4

UO 7.5

-1

1R.

..

4.76

Figure 3-2. Dimensions of Hand Trip Lever

75

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

Calculation No.

0098-0171-01

Prepared By

-VX"

Checked By

TNA

"'Yj/4J-,

L

.25,

=--

Inu

6.75

__uu

I7,

.K---i- 1.5Figure 3-3 Dimensions of Resetting Lever

Page:

Revision:

10

4

MPR Associates, Inc.

WMPR

320 King Street

Alexandria, VA 22314

Calculation No.

0098-0171-01

Prepared By

"e

,h

, "'

Checked By

L.

Page:

Revision:

-.25

-.82

DETAIL

A

SCALE I : I

Figure 3-4. Overspeed Trip Mechanism - Resetting Lever & Hand Trip Lever Centroid

Locations (Dimensions in Inches)

11

4

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

*MPR

Calculation No.

Prepared By

Checked By

Page:

2 4 4$J4L5UAt

0098-0171-01

Revision:

12

4

Fke

0/

Figure 3-5. Free Body Diagrams for Resetting Lever and Hand Trip Lever

MPR Associates, Inc.

OM PR

Calculation No.

0098-0171-01

320 King Street

Alexandria, VA 22314

Prepared By

"Vk"

TUAL

Checked By

A147'

Figure 3-6 Locations of Vibration Transducers on Resetting Lever

Page:

13

Revision: 4

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

*MPR

Calculation No.

0098-0171-01

Prepared By

hecked By

Page:

14

Revision: 4

Figure 3-7 Exploded View Showing Torsional Spring on Hand Trip Lever (Item 32)

(note - the Resetting Lever, Item 11, in the figure has a slightly different

configuration than the actual component)

WMP3R

MPR Associates, Inc.

King Street

Alexandria, VA 22314

Calculation No.

Prepared By

0098-0171-01

"VX

Checked By

," T4

T."

t.,

Page:

A..''-

Revision: 4

Pm,

- P48 -.. ,b Do~l MIW

0.174

Trnd 2D.w

0100e

O-M w40e

I

0144

0

at

00

12

Is

D~p:

2&4d.1

2640-11 T.

07

01

MCC. IJ

LOAV- 1410

am . 360 f4

433 H14

OR

0.1

02

0

00

240

am0

1210

4450

26040 li 14A924

12

"RU.An0

0

I:

~~

P45

OWOwpu.dTWL.V41

0-05 Vlo&210

0444o

GIN4

03

811

11414

zi

ZA

2840.4

20

UA2

I

1.2

CA

0

we0

low

1200

No4

II

4005

PP. 322

]1

CREW-1214

05

we0

40*

Tm...

39IO

.1....

1....

T-

."M

15

s1

=4

Figure 3-8 Recirculation Mode Vibration Measurements for Resetting Lever Near Knife

Edge (Reference 7)

MPR Associates, Inc.

M P R

320 King Street

Alexandria, VA 22314

Calculation No.

Prepared By

0098-0171-01

V"

0.

T? W

Checked By

,

Page:

Revision:

Figure 3-9 Free Body Diagrams for Lateral Motion of Resetting Lever

16

4

MPR Associates, Inc.

*M

Calculation No.

0098-0171-01

5.0

5.1

320 King Street

Alexandria, VA 22314

Checked By

Prepared By

T:II

Page:

17

Revision: 4

CALCULATION

Approach

This calculation will estimate the magnitude of acceleration required to cause the Hand Trip

Lever to disengage from the Reset Lever and trip the Auxiliary Feedwater Pump. Equivalent

static methods will be used. Moments will be summed about the pivot point for the Hand Trip

Lever to determine the acceleration where the resulting inertial moments exceed the moment

associated with the friction force. Since the friction force is a function of the normal force at

the knife edge/latch interface, and since that normal force is also a function of the

acceleration, an iterative process will be used as follows.

A free body diagram of the Reset Lever will be used to sum the moments about the

1.

Reset Lever pivot point to determine the normal force between the knife edge of the Reset

Lever and the latch plate of the Hand Trip Lever. Assumed values of acceleration on the

Reset Arm will be used to determine the normal force. For simplicity, the horizontal

acceleration and the vertical acceleration will be assumed to be equal. The directions of the

accelerations will be chosen such that the resulting moments on the Hand Trip Lever are

counterclockwise (i.e., disengagement direction).

2.

Given the calculated normal force, a friction force between the knife edge and latch will

be calculated using three assumed values of -', tdry =0.8, Plub=0. 1 6 and Itmin= 0 , which

correspond to un-lubricated, lubricated and zero friction conditions.

Moments about the pivot point of the Hand Trip Lever will be taken using the assumed

3.

values of acceleration. The assumed values of acceleration will be iterated until the

acceleration values for each of the assumed values of la is determined where the sum of the

moments about the pivot point is zero. The acceleration value where the moments equal zero

is the acceleration required to overcome the friction force and trip the hand lever.

The calculated values of acceleration will be compared to measured values of

4.

acceleration to determine if the measured values are sufficient to result in trip of the

mechanism. (Note that in this calculation, the iterative process will not be document, i.e., the

final acceleration values will be assumed and the iteration to arrive at these values will not be

shown.)

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

Checked By

Prepared By

Calculation No.

0098-0171-01

-&

T)UA

ACLd

Page:

18

Revision: 4

Calculationof Knife Edge Forces

5.2

To determine the spring force, Fs, on the Resetting Lever, the free lengths and spring rate of the

two springs in parallel must be used with the installed spring length.

spring free length, Ref. 4

lsfree:= 3.5625in

lf

35. 65

k,.

measured outer spring rate, Ref.

6, page 4

in

k,.2 :

f

3

3.1

measured inner spring rate, Ref.

6, page 5

in

s.installed :=6.875in

Fs,:= (Isinstalled

F=

installed spring length, Ref. 5

sfree) (k,.I + k,. 2 )

161.48/bf

To determine the spring force from the spring that backseats the shutoff valve disc, Fsb, the free

length and the spring rate must be used with the installed length of the backseat spring.

lsb.free := 3.125in

ksb := 47.85lbf

in

lsb.installed :=

1.75in

Fsb := (lsbfree - lsb.installed ) ksb

Fsb = 65.791bf

The mass of the Resetting Lever, mr, equals:

mr :- 6.491b

back seat spring free length,

Ref. 6

backseat spring rate, Ref. 6

installed backseat spring

length, (measured during

walkdown 10/25)

UMPR

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

Checked By

Prepared By

Calculation No.

-ea.hakoIL "1,

0098-0171-01

-n -

Page:

19

Revision: 4

The coefficients of friction that will be used are 0.8 for dry, unlubricated conditions (Ref. 3), 0.16 for

lubricated conditions (Ref. 3) and zero.

0.8

u:=

0. 16

0

Assumed values of acceleration in the downward, avd,and upward, avu, directions will be as

follows:

1000g

avd :=

37

36.14 1g

'

a,, :=

.52g

"

36.35g

38.07g

1.85g

There are two opposing effects associated with the vertical acceleration. The first effect is that an

upward vertical acceleration will reduce the normal force and as a result will reduce the friction

force resisting trip. An upward vertical force will also, however, result in a clockwise moment on

the Hand Trip Lever which increase the total moment resisting trip. Since these two effects

oppose, it is not clear if a upward vertical force is most limiting or a downward vertical force is

most limiting. Accordingly, both directions will be evaluated. Note that the most limiting

direction for the horizontal acceleration will always be to the left.

Downward Vertical Force

The forces acting on the Resetting Lever can be determined by summing forces and moments

shown on the first Free Body Diagram on Figure 3-5.

The force on the Knife Edge of the Resetting Lever for downward acceleration, Fked, can be

determined by summing moments about Z at the pin at the right end of the Resetting Lever.

Y moments on Resetting Lever about Z = 0 (counterclockwise is positive)

Fked

+ m ra vd .0.57 .in

+ mr 'avd8.40 "in

F s.9. 13 in + F b .4.63.in+ m 1.- .g.8.40.in

=lO~10in+

9.13.in-.07in - .12.n

2

3160.46

Fked

lbf

211.46

102.17

MPR Associates, Inc.

*M

320 King Street

Calculation No.

Alexandria, VA 22314

Prepared By

.Vk I

0098-0171-01

Checked By

"TNA1,

Page: 20

Revision:

Using the Free Body Diagram for the Hand Trip Lever on Figure 3-5, the moments about the

pivot point can be calculated and the inertial accelerations in the x and y directions

respectively, avx and avy, that will overcome the friction force between the knife edge and

latch can be calculated.

mh :3.211b

mass of the hand trip lever as calculated from the solid

model

Ft, :3.651bf

Fts is the force from the torsional spring that engages the

Hand Trip Lever with the Resetting Lever. As identified in

Reference 6, torque provided by this spring was equivalent

to a force of 3.65 lbf applied at the centerline of the

Resetting Lever (shown in Figure 3-4).

Summing the moments about the pivot of the Hand Trip Lever gives:

-10675.87

-Ft, .7.14in - (/'Fked))6. 75in + Fkd "{0.25in- .07in + mh avd .0.

82in + mh "ad"

1.06in + mh lg.

2 in)

8 2 in

The equation above shows that for assumed V of:

r 0.8

p =

coefficient of friction dry

coefficient of friction lubricated

0.16

0

coefficient of friction of zero

left horizontal and downward vertical accelerations of:

1000 N

avd

37.52 g

1.85 1

-0

-0

in.lbf

MPR Associates, Inc.

*M

PR

320 King Street

Alexandria, VA 22314

Calculation No.

Prepared By

0098-0171-01

-VX "

Checked By

W1

pA

Page: 21

.;-

Revision: 4

are needed to cause the Hand Trip Lever to disengage and trip the Auxiliary Feedwater

Pump Turbine. Note that for the assumed value of lt of 0.8, there is no value of

acceleration that will cause the Hand Trip Lever to trip. This is because increased

acceleration values needed to put sufficient moment on the Hand Trip Lever to

disengage it also increase the applied moment on the Resetting Lever, in turn increasing

the normal force, Fke, and the friction force tFke, resisting disengagement.

Upward Vertical Acceleration

The moment equations for vertical upward acceleration are provided below.

Fkeu :

Fs.9.13.in + Fsb .4.63.in + mr.1.g.8.40.in - mravu.8.40.in + mr.avu.0.57.in

.12.

lOin+ 9.13.in

-. O7in - -- n

-F,s7.14in - (/.Fkeu) .6.75in + Fkeu,0.25in

-.

07in - 2-mi

82 in

+ mh'au, 1.06 in - Mh -*lg..

-m

0av'O.

82in ...

0

0

in.IbJ

-0

The equation above shows that for assumed p of:

(O.8

S= ]0.16

coefficient of friction dry

coefficient of friction lubricated

coefficient of friction of zero

left horizontal and upward vertical accelerations of:

(36.14

avu =

36.35 g

,.38.07)

are needed to cause the Hand Trip Lever to disengage and trip the Auxiliary Feedwater Pump

Turbine.

MPR Associates, Inc.

2MPR

King Street

Alexandria, VA 22314

0098-0171-01

5.3

Checked By

Prepared By

Calculation No.

'V

"l,

,L

Page: 22

Revision: 4

Knife Edge Latch Contact

The Knife Edge and Latch overlap approximately 0.12 inches as shown in Detail A of Figure 3-4.

In the process of inspecting the Knife Edge and Latch, bluing was applied to the Latch to

determine the percentage of the Knife Edge that was in contact with the Latch. As documented in

Reference 6 (attachment page 3 of 8) only 45% of the Knife Edge overlapping surface was

engaged with the Latch. As documented in the attachment to Reference 6, 90% to 100% is

considered acceptable. The calculation of forces necessary to trip the linkage in Section 5.2 and

the calculation of lateral motion of the Resetting Lever in Section 5.5 of this calculation do not

address the degraded contact surface identified in the inspection. The contact is not a variable in

these calculations because they are force balances and the calculated forces will be independent of

the contact area. The contact pressure between the Knife Edge and Latch, will, however, be

impacted by the contact area. The contact area with the as-found 45% contact area will be twice

the value of the contact area if the contact area was the desired 90 to 100%. A literature search

regarding the impact of contact pressure on the coefficient of friction showed that the coefficient of

friction typically increases with increased contact pressure. Accordingly, the increased contact

pressure associated with the reduced contact area is expected to make the linkage less likely to trip

because the coefficient of friction is increased.

5,4

Vibration Measurements

Vibration measurements were taken during operation of the AFW pump turbine.

Measurements were taken with the pump in recirculation mode as well as in operating

mode (with the pump providing normal flow to the steam generators). The vibration

measurements involved application of transducers to the reset arm as shown in Figure 3-6.

Two transducers were employed. The first was put on the top of the end of the Resetting

Lever near the knife edge to measure vibration in the vertical direction. In addition, a

transducer was placed on the side of the Resetting Lever near the knife edge to measure the

vibration in the horizontal plane perpendicular to the axis of the Resetting Lever. The data

from the operation of the pump in recirculation mode was used because it bounds the data

from operation with flow to the steam generators.

The measured vertical overall root mean square acceleration over the complete frequency

range, av.meas.rms, was:

dv.meas.rms :

5. 74 g

The measured horizontal overall root mean square acceleration over the complete frequency

range, ah.meas.rms, was:

aj7 mfeas rmns:1.96g

MPR Associates, Inc.

*M

320 King Street

PR

Alexandria, VA 22314

Checked By

Prepared By

Calculation. No.

0098-0171-01

Page:

Revision: 4

"'4.4,,

Assuming that the vibration was sinusoidal, the peak acceleration is 1.414 times the

RMS acceleration.

1. 414 av.meas.rms

av.meas.peak

av.meas.peak =

8.1 2 g

ah.measpeak

1.414 ah.meas.rms

77

ah.meas.peak = 2. g

The highest vertical acceleration at a given frequency occurred at a frequency of 2200 Hz.

This RMS vertical spectral acceleration, av.2200 was:

av.2200.rms := 2.4g

As shown on the plots, the total peak (+/-) displacement of the Resetting Arm

associated with the vertical vibration was 0.0052 in. Assuming that the vibration was

sinusoidal, the peak acceleration is 1.414 times the RMS acceleration.

1.414.av.2200.rms

av2200.peak

av.2200.peak

3.39g

The highest horizontal acceleration at a given frequency occurred at a frequency of 1400

Hz. This RMS vertical spectral acceleration, ah. 1400 was:

6

ah.14OO.ms := 0. g

As shown on the plots, the total peak (+/-) displacement of the Resetting Arm associated

with the horizontal vibration was 0.0068 in. Assuming that the vibration was sinusoidal,

the peak acceleration is 1.414 times the RMS acceleration.

ah.1400.peak := 1.

ah.1400.peak =

14.ah.1400.rms

0-85g

23

MPR Associates, Inc.

FIM PR

320 King Street

Alexandria, VA 22314

Calculation No.

Prepared By

0098-0171-01

5.5

"B/iji,

Checked By

L,

'L 4

,4

Page: 24

"-

Revision: 4

Motion of Resetting Lever in HorizontalPlane

Due to concerns identified by the NRC regarding lateral movement of the Resetting Lever

in the horizontal plane in the direction perpendicular to the axis of the Resetting Lever, the

measurements identified in Section 5.4 above were taken. The lateral displacement of the

Resetting Lever was measured to be 0.0068 inches. Deflection of this magnitude is not

significant enough to result in tripping of the mechanism.

To estimate the acceleration required to cause differential relative motion between the

Resetting Arm and the Hand Trip Lever, the free body diagrams in Figure 3-9 are

used. By summing moments about the pivot point of the Resetting Lever, the

acceleration needed to exceed the friction for is calculated.

The acceleration in the horizontal direction perpendicular and parallel to the Resetting

Lever axis and the vertical axis are assumed to be the equal and will all be denoted by,

av.h.

Since the normal force, Fkeh and the inertial force on the Resetting lever are a

function of av.h, a value of av.h will be assumed then iterated to determine the

appropriate value. Note that for Fkeh, the accelerations acting on the Resetting

Lever are assumed to be acting upward and to the right in order to minimize Fkeh.

(14.51g

av.h :=4.596g

.Og

F, .9.13.in + Fsb .4.63-in + mr.-1 .g.8.40.in - mr'av.h. 8 . 4 0in - mrav~hO.5 7 .in

Fke

1O.in + 9.13.in - .07in - "12.n

r52.04

Fkeh =

82.42

96.5

fbf

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

UM PR

Calculation No.

0098-0171-01

Prepared By

Checked By

.4"1i

"j9g,'

,-

,0

(it.Fkeh). 19.13.in -. O7in -

1inj

-mr'av.h'

.40"in= -0

inilbf

The results indicate that assuming a coefficient of friction of 0.8 associated with dry,

unlubricated conditions, a lateral acceleration of 14.51 g is needed to overcome

friction between the knife edge and the latch. Assuming a coefficient of 0.16

associated with lubricated conditions, the lateral acceleration needed is 4.60g.

Obviously, with a coefficient of friction of 0, there will be relative lateral motion

between the knife edge and latch.

It is important to note that the above calculations are performed on an equivalent

static basis and do not account for effects of the frequency at which the accelerations

are applied. As documented in Section 5.4, the first peak horizontal acceleration

measured at the knife edge occurred at a natural frequency of 1400 Hz. This

frequency is so high that the acceleration changes direction 1400 times per second.

Accordingly, displacement of the knife edge under accelerations at this frequency are

very small because before the knife edge can move any significant distance, the

acceleration changes direction and results in an inertial force acting in the opposite

direction. This is consistent with the measured total acceleration of 0.0068 inches

documented in Section 5.4.

Page: 25

Revision: 4

MPR Associates, Inc.

*M

PR

320 King Street

Alexandria, VA 22314

Calculation No.

0098-0171-01

5.6

Prepared By

"VX"

"-5U

Checked By

147.;-

Page: 26

Revision: 4

Modal Analysis of Trip Linkage

A modal analysis of the trip linkage was performed to determine its natural frequencies and

determine if it had any fundamental modes near the measured peak vibrations documented in

Section 5.3. The model shown in Figure 5-1 was used. It included the Hand Trip Lever and the

Resetting Lever. Both levers were given cylindrical supports at their pivot points. The cylindrical

supports were constrained in the axial and radial directions, but not the tangential directions (i.e.,

the cylindrical surfaces could not translate, but could rotate about their axis). The constraint

provided by the nested springs and backseat spring on the Resetting Lever and the constraint from

the torsional spring on the Hand Trip Lever were not modeled. Note that the modal analysis is

linear and treats the interface between the knife edge and latch as bonded. This is valid provided

acceleration forces are not sufficient to overcome friction forces. These limiting accelerations are

calculated in Sections 5.2 and 5.4.

2 2}

-.--- ~----

6MS

KO--yh4" ,q--

Figure 5-1 Model for Modal Analysis

The modal analysis determined that the first 25 natural frequencies of the linkage are as follows:

PIM

MPR Associates, Inc.

PR

320 King Street

Alexandria, VA 22314

Calculation No.

0098-0171-01

MODE

1

2

3

4

5

6

7

a

9

10

11

12

13

14

15

16

17

10

19

20

21

22

23

24

25

FREQUENCY(ERITZ)

229.8966169259

261.9191436496

425.7514337450

596.5167758342

624.6537654084

965.0003802196

993.5813602176

1202.745849543

1489.231005222

1681.107744664

2202.627494749

2384.383469861

2474.200972974

2578.803556520

2873.830461892

2914.930806782

3009.936830063

3356.535287805

3480.042667251

3525.019649366

3645.234284341

4313.071367665

4832.755577439

4981.113018642

5696.331441148

Prepared By

"4

"

Checked By

'i!.

Page:

27

Revision: 4

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

WMPR

Calculation No.

0098-0171-01

Prepared By

"VX

Checked By

15UA

I.

Page: 28

Revision: 4

The 9th and 11th modes at 1489 Hz and 2203 Hz, respectively are closest to the measured peak

accelerations. The mode shapes for the 9th and 11 th modes are shown below in Figures 5-2 and 53.

--

~---

Figure 5-2. 9th Mode Shape at 1489Hz

T20

Figure 5-3. 11lth Mode Shape at 2203Hz

Review of the mass participation for the 9th and 11 th modes indicates that the following

percentages of the total mass are participating in each of these nodes.

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

Calculation No.

0098-0171-01

Prepared By

"

Checked By

"DUA

Page:

Revision:

Mass Participation (participating mass/total mass)

x-direction

y-direction

z-direction

9th

11th

.44xl 0'

.33x10-

'

.027

.0078

.30

.079

29

4

1IM

MPR Associates, Inc.

320 King Street

Alexandria, VA 22314

0098-0171-01

Checked By

Prepared By

Calculation No.

-"

TUA

Xe"-

Page: 30

Revision: 4

6.0

REFERENCES

1.

Entergy Palisades Condition Report CR-PLP-2011-02350

2.

Elliott Technical Manual Prepared for Consumers Power Company for Elliott DYRT

Turbine, Revised 5/91.

3.

Oberg, Jones, Horton and Ryffel, Machinery's Handbook, 25th Edition, Industrial Press,

1996.

4.

Email from S. Kupka (Entergy Operations) to P. Butler (MPR) dated 6/27/2011, "Aux Feed

Pump Data."

5.

Email from S. Kupka (Entergy Operations) to P. Butler (MPR) dated 6/30/2011, "AFW

Pump Trip at Palisades."

6.

Email from R. Schmidt (Entergy Operations) to P. Butler (MPR) dated 10/26/2011,

10:02PM, "FW: Scan from a Xerox 4112/4127."

7.

Email from J. Jerz (Entergy Operations) to P. Butler (MPR) dated 10/22/2011, 3:13PM,

"RE: AFW Pump P-8B Resetting Lever Vibration Data."

S-ar putea să vă placă și

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979De la EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonÎncă nu există evaluări

- Scanned Manual: Cooper Nuclear Station Vendor Manual Mfr. Byron Jackson Pump DivisionDocument77 paginiScanned Manual: Cooper Nuclear Station Vendor Manual Mfr. Byron Jackson Pump DivisionEdison Marin MuñozÎncă nu există evaluări

- d200318x012 PDFDocument12 paginid200318x012 PDFLimuel EspirituÎncă nu există evaluări

- 3-1 Operation of Cooling TowersDocument12 pagini3-1 Operation of Cooling TowersHassan SamiÎncă nu există evaluări

- Process & Gas Solutions: Centrifugal Air & Gas CompressorsDocument10 paginiProcess & Gas Solutions: Centrifugal Air & Gas CompressorsVăn Tuấn NguyễnÎncă nu există evaluări

- Dyrhh Steam Turbine: High Back-Pressure, Large Frame Single-Stage Steam TurbineDocument2 paginiDyrhh Steam Turbine: High Back-Pressure, Large Frame Single-Stage Steam Turbineameya natuÎncă nu există evaluări

- Fisher 8580 Rotary Valve PDFDocument24 paginiFisher 8580 Rotary Valve PDFARMANDOÎncă nu există evaluări

- Efficiency and Operating Characteristics of Centrifugal and Reciprocating Compressors - Pipeline & Gas JournalDocument6 paginiEfficiency and Operating Characteristics of Centrifugal and Reciprocating Compressors - Pipeline & Gas JournalAnargha BhattacharyaÎncă nu există evaluări

- Density Measurement - System OverviewDocument20 paginiDensity Measurement - System OverviewLuis MayorgaÎncă nu există evaluări

- Valve CV Flow Rate FormlaeDocument1 paginăValve CV Flow Rate Formlaelatasharma79Încă nu există evaluări

- GT 6B Gas Fuel Inlet Pressure 96FG-2ABC False Indication - Automation & Control Engineering Forum PDFDocument1 paginăGT 6B Gas Fuel Inlet Pressure 96FG-2ABC False Indication - Automation & Control Engineering Forum PDFnboulegrouneÎncă nu există evaluări

- IGB016.E1-Centrifugal Fan New PDFDocument13 paginiIGB016.E1-Centrifugal Fan New PDFSusan LamÎncă nu există evaluări

- Api StandartDocument2 paginiApi Standartyg89Încă nu există evaluări

- Fisher ET and EAT Easy-E Valves CL125 Through CL600 PDFDocument48 paginiFisher ET and EAT Easy-E Valves CL125 Through CL600 PDFARMANDOÎncă nu există evaluări

- Hydraulic Valves AnalyticsDocument8 paginiHydraulic Valves Analyticspartha6789Încă nu există evaluări

- MincoTs103A 3Document18 paginiMincoTs103A 3Jeff AyersmanÎncă nu există evaluări

- ET ValveDocument48 paginiET ValveDaniel SantillanÎncă nu există evaluări

- A Pump Performance CurveDocument6 paginiA Pump Performance CurveOcta RioÎncă nu există evaluări

- ms-03-19 HoseDocument8 paginims-03-19 HoseBowo Edhi WibowoÎncă nu există evaluări

- CCI Control Valves For Fossil ApplicationsDocument2 paginiCCI Control Valves For Fossil ApplicationsGabrieldiazÎncă nu există evaluări

- Performance and Mechanical Running Tests of Centrifugal Compressors PDFDocument9 paginiPerformance and Mechanical Running Tests of Centrifugal Compressors PDFDaniel Key Bordin100% (1)

- Liquid Level Switches Asme B31.1 ConstructionDocument36 paginiLiquid Level Switches Asme B31.1 Constructionsamer8saifÎncă nu există evaluări

- US SootblowerDocument40 paginiUS SootblowerAlex EduardoÎncă nu există evaluări

- Control Chapter 5 - RemoteDocument87 paginiControl Chapter 5 - RemoteJhonny PerezÎncă nu există evaluări

- Speed (%) Vs Time (Min) : Gas Turbine Starting CurveDocument2 paginiSpeed (%) Vs Time (Min) : Gas Turbine Starting CurveAdy FardyÎncă nu există evaluări

- System DescriptionDocument28 paginiSystem DescriptionGloria HamiltonÎncă nu există evaluări

- MK6e Control System ChecksDocument4 paginiMK6e Control System ChecksAugustine Owo Ukpong100% (1)

- Forbes Marshall Turbine Bypass ValvesDocument28 paginiForbes Marshall Turbine Bypass Valveser_sanjaypatelÎncă nu există evaluări

- 1 Servo Working PrincipleDocument8 pagini1 Servo Working PrinciplegminayasÎncă nu există evaluări

- Main Steam Turbine Controls Retrofit ISA FinalDocument13 paginiMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- 8C Throttle Trip ValvesDocument4 pagini8C Throttle Trip Valvesjr110livecom100% (1)

- Power Plant Familiar Is at Ion V - IIIDocument164 paginiPower Plant Familiar Is at Ion V - IIISiva Kumar Tutika100% (2)

- Masinloc Power Partners Co., LTDDocument1 paginăMasinloc Power Partners Co., LTDariyakkannaaÎncă nu există evaluări

- Product Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Document12 paginiProduct Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Sakthi Sekar CbiÎncă nu există evaluări

- Control Chapter 5 - RemoteDocument86 paginiControl Chapter 5 - RemoteWilmar Antonio Zuluaga ArangoÎncă nu există evaluări

- 945 Cci 100dpc Drag Production Wellhead Choke New ConstructionDocument4 pagini945 Cci 100dpc Drag Production Wellhead Choke New ConstructionAnderson SiqueiraÎncă nu există evaluări

- Draft (1) RevDocument2 paginiDraft (1) RevLeelanandaÎncă nu există evaluări

- Kop Flex General CatalogDocument72 paginiKop Flex General CataloglerplataÎncă nu există evaluări

- Mitsubishi CompressorsDocument5 paginiMitsubishi Compressorsstavros7100% (1)

- Control Valve CharacteristicsDocument3 paginiControl Valve CharacteristicsgifitrianggraeniÎncă nu există evaluări

- Masoneilan Transfer ValveDocument4 paginiMasoneilan Transfer Valveiviji81Încă nu există evaluări

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 paginăApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilÎncă nu există evaluări

- Buku Pintar GTG&HRSG 1Document25 paginiBuku Pintar GTG&HRSG 1Prasetyo RaditaÎncă nu există evaluări

- 6 Konitzer2Document32 pagini6 Konitzer2mchramziÎncă nu există evaluări

- Turbine Servo-Positioner-Contro Woodward SPCDocument4 paginiTurbine Servo-Positioner-Contro Woodward SPCWalid FattahÎncă nu există evaluări

- Variable-Area FlowmeterDocument15 paginiVariable-Area FlowmeterhotnatkapoorÎncă nu există evaluări

- Turbo SupervisionDocument140 paginiTurbo SupervisionRamalingamÎncă nu există evaluări

- Calibration Procedure For BFP-T Turbine Rotor Expansion SensorDocument9 paginiCalibration Procedure For BFP-T Turbine Rotor Expansion Sensornaresh977977Încă nu există evaluări

- Boiler Feed Pumps and Standard Values For Boiler Feed and Circulating WaterDocument3 paginiBoiler Feed Pumps and Standard Values For Boiler Feed and Circulating WaterAshrafMostafaÎncă nu există evaluări

- CONTROL VALVES Complete Study PDFDocument99 paginiCONTROL VALVES Complete Study PDFMubarik AliÎncă nu există evaluări

- Centrifugal Compressor Surge and Speed ControlDocument14 paginiCentrifugal Compressor Surge and Speed ControlWaqas AhmedÎncă nu există evaluări

- Docslide - Us Servo Valve CalibrationDocument19 paginiDocslide - Us Servo Valve CalibrationnboulegrouneÎncă nu există evaluări

- Improved Level Control of A Feed Water ValveDocument7 paginiImproved Level Control of A Feed Water ValveAli Bari100% (1)

- Woodward Governor: Presented By: Saraswati Je/Dsl/GocDocument42 paginiWoodward Governor: Presented By: Saraswati Je/Dsl/GocTirthankar DasÎncă nu există evaluări

- Control and Condition Monitoring of Reciprocating CompressorDocument2 paginiControl and Condition Monitoring of Reciprocating CompressorPedro DiazÎncă nu există evaluări

- Speed TronicDocument3 paginiSpeed Tronicscribdkhatn0% (1)

- Sample Pipe Stress ReportDocument15 paginiSample Pipe Stress Reportpipinguser100% (4)

- Case New Holland Kobelco Iveco Komatsu F4CE F4DE F4GE F4HE Service Repair Manual For Engine Overhaul (Mechanical Injection and Electronic Common Rail) PDFDocument277 paginiCase New Holland Kobelco Iveco Komatsu F4CE F4DE F4GE F4HE Service Repair Manual For Engine Overhaul (Mechanical Injection and Electronic Common Rail) PDFpckey100% (46)

- 240K-C2-ES-15-001-1 Structural PDFDocument14 pagini240K-C2-ES-15-001-1 Structural PDFWaldomiroCanoÎncă nu există evaluări

- Hydraulic Modeling of Torque ConvertersDocument8 paginiHydraulic Modeling of Torque Convertersserf007100% (1)

- 2012 Influence of Blank Holding Force On The Forming Limits of DP590 SteelDocument6 pagini2012 Influence of Blank Holding Force On The Forming Limits of DP590 SteelJhon DonÎncă nu există evaluări

- 2 SolidWorks BasicsDocument8 pagini2 SolidWorks BasicsJhon DonÎncă nu există evaluări

- Dynamics of Asymmetric Rotors Using Solid ModelsDocument6 paginiDynamics of Asymmetric Rotors Using Solid ModelsOlivia MendozaÎncă nu există evaluări

- Civil Seminar InfoDocument89 paginiCivil Seminar InfoNagesh BhargavÎncă nu există evaluări

- Stress Analysis of Front Axle of JD 955 Combine Harvester Under Static LoadingDocument3 paginiStress Analysis of Front Axle of JD 955 Combine Harvester Under Static LoadingRajendra PraharajÎncă nu există evaluări

- Welcome To Computer-Aided Drawing and Fabrication: Fall 2011Document29 paginiWelcome To Computer-Aided Drawing and Fabrication: Fall 2011Jhon DonÎncă nu există evaluări

- Finite Element Formulation For BeamsDocument27 paginiFinite Element Formulation For BeamsPalash JainÎncă nu există evaluări

- Motion Analysis SW0809NXDocument66 paginiMotion Analysis SW0809NXJhon DonÎncă nu există evaluări

- An Inverse Analysis of The Erichsen Test Applied For The Automatic Identification of Sheet Materials BehaviorDocument6 paginiAn Inverse Analysis of The Erichsen Test Applied For The Automatic Identification of Sheet Materials BehaviorJhon DonÎncă nu există evaluări

- Design of Underground Reservoir - 03Document21 paginiDesign of Underground Reservoir - 03Engr SwapanÎncă nu există evaluări

- Rectangular Ground Water TankDocument26 paginiRectangular Ground Water TankJhon DonÎncă nu există evaluări

- Call For Papers 2011 OverseasDocument2 paginiCall For Papers 2011 OverseasJhon DonÎncă nu există evaluări

- (Buckling) Analysis of A Submarine With Hull ImperfectionsDocument81 pagini(Buckling) Analysis of A Submarine With Hull ImperfectionsJhon DonÎncă nu există evaluări

- Can CrusherDocument81 paginiCan CrusherJhon Don100% (1)

- Concrete Silo DesignDocument19 paginiConcrete Silo DesignSnehendu Biswas50% (2)

- Engineering GraphicsDocument19 paginiEngineering GraphicsFranCanavÎncă nu există evaluări

- Hardness TestDocument6 paginiHardness TestJhon DonÎncă nu există evaluări

- Arvind Gupta-Toy Treasures-Eklavya, Bhopal, IndiaDocument35 paginiArvind Gupta-Toy Treasures-Eklavya, Bhopal, IndiaAndreea GradinaruÎncă nu există evaluări

- Experimental Stress Analysis - Photo Elastic - Strain Measurement - Britlle Coating - Hani Aziz AmeenDocument47 paginiExperimental Stress Analysis - Photo Elastic - Strain Measurement - Britlle Coating - Hani Aziz AmeenHani Aziz AmeenÎncă nu există evaluări

- Implementation of Robust Design in ANSYSDocument118 paginiImplementation of Robust Design in ANSYSJhon DonÎncă nu există evaluări

- 3-d Finite Element Modelling of Granular Flow in SilosDocument8 pagini3-d Finite Element Modelling of Granular Flow in SilosJhon DonÎncă nu există evaluări

- Powder MechanicsDocument43 paginiPowder MechanicsJhon DonÎncă nu există evaluări

- Build A Generator From A Lawn Edger MotorDocument13 paginiBuild A Generator From A Lawn Edger Motorصفوان التلÎncă nu există evaluări

- Motion Simulation and Analysis Tutorial UniversityDocument16 paginiMotion Simulation and Analysis Tutorial UniversityVega R JoseÎncă nu există evaluări

- Ansys Best PracticesDocument126 paginiAnsys Best PracticesJhon DonÎncă nu există evaluări

- Beam Diagrams and Formulas by 1. Simple Beam-Uniformly Distributed LoadDocument22 paginiBeam Diagrams and Formulas by 1. Simple Beam-Uniformly Distributed Loadlucadeldiablo100% (2)

- Beam Diagrams and Formulas by 1. Simple Beam-Uniformly Distributed LoadDocument22 paginiBeam Diagrams and Formulas by 1. Simple Beam-Uniformly Distributed Loadlucadeldiablo100% (2)

- On A Diagonal Crack Numerical Model of RC Beam With No Shear ReinforcementDocument6 paginiOn A Diagonal Crack Numerical Model of RC Beam With No Shear ReinforcementJhon DonÎncă nu există evaluări

- ISO 18436 Category II Vibration Analyst Training TopicsDocument1 paginăISO 18436 Category II Vibration Analyst Training TopicsDean LofallÎncă nu există evaluări

- Sound NotesDocument9 paginiSound Notes시야KpopMDNÎncă nu există evaluări

- ICSE Class 10 Physics Question Paper Solution 2017 PDFDocument19 paginiICSE Class 10 Physics Question Paper Solution 2017 PDFHardikÎncă nu există evaluări

- Thomas Hewlett Puente Del Alamillo TeamgeckoDocument10 paginiThomas Hewlett Puente Del Alamillo Teamgeckoapi-284149698Încă nu există evaluări

- ME 7360 Theory of Vibration Assignment 2: Department of Mechanical EngineeringDocument2 paginiME 7360 Theory of Vibration Assignment 2: Department of Mechanical EngineeringSAGI RATHNA PRASAD me14d210Încă nu există evaluări

- Guide Asce 7Document116 paginiGuide Asce 7Eduardo Morales100% (3)

- Broch Samceflinear AnDocument4 paginiBroch Samceflinear AnAnonymous KdnOsd9Încă nu există evaluări

- D 4015 - 92 R00 Rdqwmtu - 2 PDFDocument21 paginiD 4015 - 92 R00 Rdqwmtu - 2 PDFLuthfiÎncă nu există evaluări

- Propagation and Attenuation Characteristics of Various Ground VibrationsDocument12 paginiPropagation and Attenuation Characteristics of Various Ground VibrationsTony Christian Canahua ChoquezaÎncă nu există evaluări

- Flywheel Housing & AlternatorsDocument9 paginiFlywheel Housing & AlternatorsLukman ChairkiandraÎncă nu există evaluări

- Jonathon Goldman - A Summary of Sound Therapy and Vibrational Healing ConceptsDocument52 paginiJonathon Goldman - A Summary of Sound Therapy and Vibrational Healing ConceptsSantiago Marcelino Leon Luis75% (4)

- Pet-Cal-Std-033 Bruel & Kjar 4294Document2 paginiPet-Cal-Std-033 Bruel & Kjar 4294CALIBRATION TRACKINGÎncă nu există evaluări

- Condition Monitoring System - Brochure GEDocument12 paginiCondition Monitoring System - Brochure GEAli AbdurrahmanSungkar0906631036Încă nu există evaluări

- Brochure Under Ballast Mats enDocument12 paginiBrochure Under Ballast Mats enÜmit KukulaÎncă nu există evaluări

- 2100 AMMe P3Document122 pagini2100 AMMe P3RolffoTelloÎncă nu există evaluări

- Wind Loading On Tall BuildingsDocument14 paginiWind Loading On Tall BuildingsHarish T S GowdaÎncă nu există evaluări

- Civil Engineering Applications of Vibration Control (Structural Control)Document19 paginiCivil Engineering Applications of Vibration Control (Structural Control)Naeem SheykhÎncă nu există evaluări

- As 7240.5-2004 Fire Detection and Alarm Systems Point Type Heat Detectors (ISO7240!5!2003 MOD)Document10 paginiAs 7240.5-2004 Fire Detection and Alarm Systems Point Type Heat Detectors (ISO7240!5!2003 MOD)SAI Global - APACÎncă nu există evaluări

- 2012 B-04-01-11.mNBC 649.div B 4.1.7.MS.06-06-2016.NS.03-18-2016.MSDocument25 pagini2012 B-04-01-11.mNBC 649.div B 4.1.7.MS.06-06-2016.NS.03-18-2016.MSDavide MartiniÎncă nu există evaluări

- The Science of Musical SoundsDocument308 paginiThe Science of Musical Soundsfictitious30Încă nu există evaluări

- IBIS FB BrochureDocument2 paginiIBIS FB BrochureFranco Armando Salgado BazanÎncă nu există evaluări

- Vibrodrivers: For Pile Driving and Deep FoundationsDocument24 paginiVibrodrivers: For Pile Driving and Deep FoundationsRomanÎncă nu există evaluări

- Article - Determination of Poisson Ratio in Gypsum MaterialsDocument7 paginiArticle - Determination of Poisson Ratio in Gypsum MaterialsPablo de SarasateÎncă nu există evaluări

- Civil 3rd PDFDocument48 paginiCivil 3rd PDFGautam NarulaÎncă nu există evaluări

- The Effect of Weight On Bit On The Contact Behavior of Drill String and WellboreDocument7 paginiThe Effect of Weight On Bit On The Contact Behavior of Drill String and Wellboreansoe21Încă nu există evaluări

- Dynamic Balancing and Shaft AlignmentDocument34 paginiDynamic Balancing and Shaft AlignmentLalit Mohan100% (2)

- = 2 π f = 2 π (3.98) =25 rad /s: Assignment No 1 ProblemDocument3 pagini= 2 π f = 2 π (3.98) =25 rad /s: Assignment No 1 ProblemAtul KhodeÎncă nu există evaluări

- Identification of Multiple Cracks in A Beam Using Natural Frequencies, Lee, 2009Document9 paginiIdentification of Multiple Cracks in A Beam Using Natural Frequencies, Lee, 2009masi1975Încă nu există evaluări

- Wave Motion and Its ApplicationsDocument24 paginiWave Motion and Its ApplicationsDivya SoodÎncă nu există evaluări