Documente Academic

Documente Profesional

Documente Cultură

Lasers Introduction

Încărcat de

Farooq ShahTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lasers Introduction

Încărcat de

Farooq ShahDrepturi de autor:

Formate disponibile

Solid-state lasers have the active medium held in an insulating

dielectric crystal or amorphous glass.

The lasing action comes from energy jumps between discrete

electronic energy levels of the dopant such as rare earth ions or

transition ions with unfilled outer shells.

The main industrial solid-state lasers include Nd3+:YAG,

Er3+:YAG, Yb3+:YAG, ruby (Cr3+:Al2O3), titanium sapphire

(Ti3+:Al2O3) and alexandrite (Cr3+:BeAl2O4)

The host material for the neodymium or other rare earth

element may be YAG (Y3Al5O12), yttrium lithium fluoride (YLF),

yttrium aluminium perovskite (YAP; YAlO3), yttrium vanadate

(YVO4) or phosphate or silica glass.

Solid-state lasers have the advantage of relatively long

lifetimes for the excited states.

which allows higher energy storage than for gas lasers and

hence allows them to be Q-switched to give very high peak

powers in short pulses.

Q Switching

Q switching is a technique for obtaining energetic short (but

not ultrashort) pulses from a laser by modulating the

intracavity losses and thus the Q factor of the laser resonator.

The technique is mainly applied for the generation of

nanosecond pulses of high energy and peak power with solidstate bulk lasers.

Initially, the resonator losses are kept at a high level. As lasing

cannot occur at that time, the energy fed into the gain medium

by the pumping mechanism accumulates there.

Then, the losses are suddenly (with active or passive means, see

below) reduced to a small value, so that the power of the laser

radiation builds up very quickly in the laser resonator.

Once the temporally integrated intracavity power has reached

the order of the saturation energy of the gain medium, the gain

starts to be saturated.

The energy of the generated pulse is typically higher than the

saturation energy of the gain medium and can be in the millijoule range even for small lasers.

In most cases, Q-switched lasers generate regular pulse trains

via repetitive Q switching.

Lasers to which the Q-switching technique is applied are called Qswitched lasers

3

Pure Y3Al5O12 is a colourless optically isotropic crystal with the

cubic structure of garnet.

If around 1% of the yttrium rare earth is substituted by the

alternative rare earth neodymium, the lattice will then contain Nd3+

ions. These ions can undergo the transitions shown in Figure 1.24.

Other solid-state lasers for material processing include

Nd:YVO4 operating at 1.06 m, Yb:YAG operating at 1.03m

and Er:YAG operating in the eye-safe region of 1.54 m.

eye-safe means the radiation will be absorbed on the

cornea and not penetrate to the retina with a 105 times

amplification in intensity.

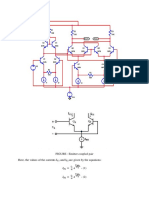

The overall construction of a Nd:YAG laser is shown in Figure

1.27 for pumping by a lamp or diode.

The Nd:glass lasers have the same energy diagram for Nd3+ as

the YAG laser but the energy conversion is better in glass.

However, the cooling problems are more severe owing to the

poor conductivity of glass

so the Nd:glass lasers are confined to slow repetition rates,

approximately 1 Hz.

At higher repetition rates the beam divergence (or ease of

focusing) becomes unacceptable for material processing.

The beam froma glass laser is more spiked than that froma YAG

laser as seen in Figure 1.28. It is more prone to burst mode

operation.

There is a problem with flash-lamp-pumped Nd:YAG lasers, in

that only a few percent of the flash lamp power is actually

absorbed by the Nd3+ ions and so used in the lasing action;

the waste energy heats up the YAG rod, causing distortion and

variations in the refractive index.

This leads to poor pulse-to-pulse consistency (approximately

1015% variation) and low beam quality.

The lamps have a lifetime of a few hundred hours and require

substantial power supplies to drive them.

These problems can be eliminated by using diode lasers

instead of flash lamps to excite the Nd3+, as illustrated in

Figure 1.27.

The wall plug efficiency of diodes is around 3040% and all

the light is emitted centred on a strong absorption line of

Nd3+ at 808 nm.

The power supply and cooling requirements are greatly

reduced

The remaining problem is the cost of the high-powered

diodes required to do the pumping.

As the size of market for laser diodes increases, so the price is

likely to fall.

10

One version of a diode-pumped solid-state laser is a disc geometry

in which a coin shaped YAG crystal doped with ytterbium forms the

lasing medium.

A disc, 0.3mmthick and 7mmin diameter, doped with ytterbium up

to 25% can produce over 500Wof high-quality beam from the top

surface of the coin at 1.03 m wavelength.

The reason for the high power and quality is the superior cooling

and higher dopant rates possible with this geometry, as well as the

cavity design

11

Meanwhile, diode-pumped fibre lasers are being developed, these

lasers are doped plastic or glass fibres that are end- or side-pumped

by diode lasers.

IPGPhotonics is marketing a 2-kW CW fibre laser based on ytterbium

operating at 1,085 nm.

It has a beam quality 10 times better than that of a standard Nd:YAG

laser.

The fibre can be very thin, 100 m, and hence the only way

oscillations can be contained is by wave guiding within the fibre as

Gaussian beam.

The wall plug efficiency is stated as 20 %,whereas the lifetime for the

pumping diodes is reckoned to be 100,000 h, indicating several years

of maintenance-free operation.

The 700-W version of a fibre

laser was able to cut through 50mm of steel. The 2-kW version could

weld steel from several metres distance.

With this sort of performance these lasers appear to have much to

offer

12

13

These lasers are becoming the most important laser material

processing tool both for pumping solid-state lasers and for direct

application to surface heating and welding.

They have the advantages of being compact, efficient, with a quick

modulation response and reliability.

Diode lasers [17] are currently the most efficient devices for

converting electrical into optical energy.

Their wall plug efficiency may reach up to 50%.

In a diode laser the excited state is that of the electrons in the

conduction band.

The two states, electrons and holes, come together in an active

region set at a pn junction in a semiconductor material.

A current flow induces electrons to jump from the conduction band

down to the valence band and give up the energy difference

between these two Fermi levels as radiation (hv).

14

15

Dye lasers are one of the most readily tunable lasers [16].They

can also operate at high powers with pulse lengths from CW

to femtoseconds.

They are, however, extremely inefficient.

They work through the absorption of a pumping laser and

emit over a wide range of wavelengths, which can be selected

by cavity tuning, changing the concentration of the dye and

changing the pressure.

The range of wavelengths and some of the dyes that have

been studied are shown in Figure 1.33.

16

17

The free-electron laser does not depend on excited states but

depends on synchrotron radiation.

Synchrotron radiation is emitted when an electron changes

direction; the energy involved appears as radiation

The laser consists of a circuit for relativistic electrons streaming

around in a ring.

As part of the circuit there is a magnetic wiggler, which is a shortwavelength magnetic field that causes the electrons to make a

wiggly path, emitting photons on each turn in the same direction as

the travelling electrons.

These machines can generate radiation from deep infrared to Xradiation.

Owing to the velocity distribution within the flow stream, there is

considerable spectral spread in the output beam.

It is sometimes known as a rainbow laser.

18

19

S-ar putea să vă placă și

- 1 Introduction To Research MethodologyDocument49 pagini1 Introduction To Research MethodologyFarooq ShahÎncă nu există evaluări

- Verb - List - Irregular (Appendix 6.10.1)Document4 paginiVerb - List - Irregular (Appendix 6.10.1)Nur AmaliaÎncă nu există evaluări

- Chacha Chakan by Imtiaz Ali TajDocument115 paginiChacha Chakan by Imtiaz Ali TajSaghirÎncă nu există evaluări

- 300 McqsDocument18 pagini300 McqsFarooq ShahÎncă nu există evaluări

- Astm d638 Type VDocument1 paginăAstm d638 Type VFarooq Shah100% (1)

- Pak Study MCQsDocument10 paginiPak Study MCQsFarooq ShahÎncă nu există evaluări

- A Steam EngineDocument3 paginiA Steam EngineFarooq ShahÎncă nu există evaluări

- REPORTED SPEECH EXAMPLESDocument5 paginiREPORTED SPEECH EXAMPLESFarooq ShahÎncă nu există evaluări

- LAB#4 To Study The Creep Phenomenon in Given Material and To Obtain A Time-Extension CurveDocument2 paginiLAB#4 To Study The Creep Phenomenon in Given Material and To Obtain A Time-Extension CurveFarooq ShahÎncă nu există evaluări

- Traditional Ceramic MaterialsDocument2 paginiTraditional Ceramic MaterialsFarooq ShahÎncă nu există evaluări

- Scientific InstrumentsDocument5 paginiScientific InstrumentsFarooq ShahÎncă nu există evaluări

- REPORTED SPEECH EXAMPLESDocument5 paginiREPORTED SPEECH EXAMPLESFarooq ShahÎncă nu există evaluări

- Foreign Policies During Zulfiqar Ali Bhutto EraDocument20 paginiForeign Policies During Zulfiqar Ali Bhutto EraFarooq Shah67% (3)

- Science Mixed MCQsDocument14 paginiScience Mixed MCQsFarooq ShahÎncă nu există evaluări

- SOAP FormatDocument2 paginiSOAP FormatFarooq ShahÎncă nu există evaluări

- Pakistan's Foreign PolicyDocument107 paginiPakistan's Foreign PolicyFarooq ShahÎncă nu există evaluări

- Universal Testing MachineDocument3 paginiUniversal Testing MachineFarooq Shah100% (1)

- REPORTED SPEECH EXAMPLESDocument5 paginiREPORTED SPEECH EXAMPLESFarooq ShahÎncă nu există evaluări

- CNC G & M Codes in Machining Introductory Lab ReportDocument3 paginiCNC G & M Codes in Machining Introductory Lab ReportFarooq ShahÎncă nu există evaluări

- X Ray DiffractionDocument63 paginiX Ray DiffractionFarooq ShahÎncă nu există evaluări

- Crystal Systems&MillerIndicesDocument8 paginiCrystal Systems&MillerIndicesFarooq ShahÎncă nu există evaluări

- SEM Imaging and Microanalysis TechniquesDocument42 paginiSEM Imaging and Microanalysis TechniquesFarooq ShahÎncă nu există evaluări

- Screw and Edge DislocationsDocument5 paginiScrew and Edge DislocationsFarooq ShahÎncă nu există evaluări

- Transmission Electron MicroscopeDocument21 paginiTransmission Electron MicroscopeFarooq ShahÎncă nu există evaluări

- Basic Laser OpticsDocument29 paginiBasic Laser OpticsFarooq ShahÎncă nu există evaluări

- Laser CladdingDocument9 paginiLaser CladdingFarooq ShahÎncă nu există evaluări

- Transmission Electron MicroscopeDocument20 paginiTransmission Electron MicroscopeFarooq ShahÎncă nu există evaluări

- Lecture 1 Introduction To Lasers Design and ApllicationsDocument38 paginiLecture 1 Introduction To Lasers Design and ApllicationsFarooq ShahÎncă nu există evaluări

- STL GenerationDocument11 paginiSTL GenerationFarooq ShahÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- A New Physical Design Flow For A Selective State Retention Based ApproachDocument15 paginiA New Physical Design Flow For A Selective State Retention Based ApproachJoseph HuangÎncă nu există evaluări

- Power Controllers E-SAFEDocument2 paginiPower Controllers E-SAFEEliasÎncă nu există evaluări

- GLP21 CH tx-32lx60 PDFDocument56 paginiGLP21 CH tx-32lx60 PDFBoKi PoKiÎncă nu există evaluări

- NIC Components NAZJ SeriesDocument4 paginiNIC Components NAZJ SeriesNICCompÎncă nu există evaluări

- Nontraditional Manufacturing Processes: Mf30604: Aknath Lecture No.-1 Introduction To NtmpsDocument14 paginiNontraditional Manufacturing Processes: Mf30604: Aknath Lecture No.-1 Introduction To NtmpsNishant PrabhakarÎncă nu există evaluări

- (Codientu - Org) - (Codientu - Org) - AV 21F7 mn1873287 nn5198kDocument10 pagini(Codientu - Org) - (Codientu - Org) - AV 21F7 mn1873287 nn5198kGioVoTamÎncă nu există evaluări

- Turbovisory InstrumentsDocument21 paginiTurbovisory InstrumentsSupratim Pal100% (5)

- IES - Electronics Engineering - Analog Electronic CircuitsDocument71 paginiIES - Electronics Engineering - Analog Electronic CircuitsVishwanath MalakarÎncă nu există evaluări

- LED Seminar PPT By, Er. Swapnil V. KawareDocument14 paginiLED Seminar PPT By, Er. Swapnil V. Kawareswapnil50% (2)

- Bruker Axs Saxs Webinar XRDDocument119 paginiBruker Axs Saxs Webinar XRDhafizalÎncă nu există evaluări

- Energy Storage Systems For Advanced Power ApplicationsDocument41 paginiEnergy Storage Systems For Advanced Power ApplicationsJr ManiÎncă nu există evaluări

- HOOSEKI Campur 1Document12 paginiHOOSEKI Campur 1Anugrah Prihantoro Amd T100% (3)

- BJT Gibert MultiplierDocument5 paginiBJT Gibert MultiplierJyoti GoyalÎncă nu există evaluări

- Description: Technical DataDocument17 paginiDescription: Technical DataDhivya NÎncă nu există evaluări

- Transistor Catalog 2005Document24 paginiTransistor Catalog 2005Angelo PalamingÎncă nu există evaluări

- Mass Action Law:: in N-Type SemiconductorDocument10 paginiMass Action Law:: in N-Type Semiconductordheeraj rajÎncă nu există evaluări

- Quick Charge Device List PDFDocument20 paginiQuick Charge Device List PDFEnoÎncă nu există evaluări

- TP 6Document45 paginiTP 6EngrAneelKumarAkhaniÎncă nu există evaluări

- Keypad Interfacing With ARM7 SlickerDocument15 paginiKeypad Interfacing With ARM7 SlickerDenise NelsonÎncă nu există evaluări

- Plessey Radar and Radio Communications IC Handbook 1980Document445 paginiPlessey Radar and Radio Communications IC Handbook 1980Roberto BernerÎncă nu există evaluări

- High Voltage Fast-Switching NPN Power Transistor: General FeaturesDocument10 paginiHigh Voltage Fast-Switching NPN Power Transistor: General FeaturesAlf HdezÎncă nu există evaluări

- 1959 A First Course in Electrical Engineering Clement & JohnsonDocument3 pagini1959 A First Course in Electrical Engineering Clement & JohnsonAntonioAguiarÎncă nu există evaluări

- BPW17N Data SheetsDocument5 paginiBPW17N Data SheetssegalignoÎncă nu există evaluări

- Impulse Testing of TransformersDocument20 paginiImpulse Testing of TransformersSantosh VardhanÎncă nu există evaluări

- Details PDF: Image Part Number Description Manufacturer QtyDocument1 paginăDetails PDF: Image Part Number Description Manufacturer QtySamsung J2Încă nu există evaluări

- Auspy DatasheetDocument2 paginiAuspy Datasheet2006ashokÎncă nu există evaluări

- UV Spectroscopy: Principles and ApplicationsDocument20 paginiUV Spectroscopy: Principles and ApplicationsAMOGH DAHITULEÎncă nu există evaluări

- Magnetic Balance and Magnetising (Excitation) Current Test - A Effective Diagnostic ToolDocument13 paginiMagnetic Balance and Magnetising (Excitation) Current Test - A Effective Diagnostic ToolVishal Mahire80% (10)