Documente Academic

Documente Profesional

Documente Cultură

Scope and Limitation

Încărcat de

Dianne Bernadeth Cos-agonDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Scope and Limitation

Încărcat de

Dianne Bernadeth Cos-agonDrepturi de autor:

Formate disponibile

SCOPE AND LIMITATION

This research is mainly concern about the fiber content of water

lilies fibers that can be an ingredient or additive in making a gysum board.

The proposal also covers the acceptability of this water lily fiber in the

production of better. The following are the materials to be used for this

research and its description.

Gypsumchemically known as calcium sulfate dihydrate, gypsum

contains calcium, sulfur bound to oxygen, and water. Gypsum is an

abundant mineral and takes forms including alabastera material

used in decoration and construction as far back as ancient Egypt.

The White Sands National Monument in New Mexico is the worlds

largest gypsum dunefield. This non-toxic mineral can be helpful to

humans, animals, plant life, and the environment. While the

majority of gypsum produced in North America is used to

manufacture gypsum board or building plasters, gypsum is used in

many other ways.

Drywall (also known as plasterboard, wallboard, gypsum board) - is

a panel made of gypsum plaster pressed between two thick sheets

of paper. It is used to make interior walls and ceilings. Drywall

construction became prevalent as a speedier alternative to

traditional lath and plaster. In many places, the product is sold

under the trademarks SheetrocGyproc.

Common

gypsum

board

have

the

following

advantages

and

disadvantages:

Ease of installation

Gypsum board building systems are easy to install for

several reasons. Gypsum board panels are relatively large

compared to other materials. They come in 48- and 54-inch wide

sheets and in lengths of 8, 10, or 12 feet, so they quickly cover

large wall and ceiling areas. Gypsum board assemblies require only

a few tools for their construction. Gypsum board can be cut with

either a utility knife or a variety of saws, and it can be attached with

a variety of fasteners, including screws, nails, and staples. It can

also be adhesively attached to many substrates. Gypsum board is

a lightweight material. Two workers can easily handle most panels

and cover large areas in very short time periods. Gypsum board is

easily finished using either a few hand tools or relatively modest

machines. Gypsum board installers can quickly learn most

application techniques in a few hours.

Fire resistance

Gypsum board is an excellent fire-resistive building material.

In North America, it is the most commonly used interior finish where

fire resistance classifications are required. Its noncombustible core

contains nearly 21% chemically combined water, as described

earlier, which, under high heat, is slowly released as steam.

Because steam will not exceed 212 degrees F under normal

atmospheric pressure, it very effectively retards the transfer of heat

and the spread of fire. Even after complete calcination, when all the

water has been released from its core, gypsum board continues to

serve as a heat-insulating barrier. Moreover, tests conducted in

accordance with ASTM E 84 show that gypsum board has a low

flame-spread index and a low smoke-density index. When installed

in combination with other materials in laboratory-tested wall and

ceiling assemblies, gypsum board serves to effectively protect

building elements from fire for prescribed time periods.

Sound isolation

Preventing the transfer of unwanted sound to adjoining

areas is a key consideration when designing a building, specifically

when taking into account the intended activities of the occupants in

the various parts of the building. For example, a building containing

office spaces adjacent to manufacturing facilities requires more

noise-reducing features than are typically necessary in a building

that has only office space in it. Gypsum board wall and ceilings

systems effectively help control sound transmission

Durability

Gypsum board is used to construct strong, high quality walls

and ceilings that offer excellent dimensional stability and durability.

Surfaces created using gypsum board are easily decorated and

refinished.

Economy

Gypsum board is readily available and easy to apply. It is an

inexpensive wall surfacing material that provides a fire resistant

interior finish. Gypsum board building systems can generally be

installed at significantly lower labor costs than most alternate

systems.

Versatility

Gypsum board satisfies a wide range of architectural requirements

for design. Ease of application, performance, ease of repair,

availability, and its adaptability to all forms of decoration combine to

make gypsum board unmatched by any other surfacing product.

DEFINITION OF TERMS

Gypsum

Chemically known as calcium sulfate dihydrate, gypsum contains

calcium, sulfur bound to oxygen, and water. Gypsum is an abundant

mineral

and

takes

forms including alabastera

material

used in

decoration and construction as far back as ancient Egypt. The White

Sands National Monument in New Mexico is the worlds largest gypsum

dunefield. This non-toxic mineral can be helpful to humans, animals, plant

life, and the environment. While the majority of gypsum produced in North

America

is

used

to

manufacture

gypsum

board

or

building

plasters, gypsum is used in many other ways.

Gypsum Board

Also known as plasterboard, wallboard, dry wall is a panel made

of gypsum plaster pressed between two thick sheets of paper. It is used to

make interior walls and ceilings. [1] Drywall construction became prevalent

as a speedier alternative to traditional lath and plaster.

Water Lily (Nymphaeaceae)

Is a family of flowering plants.Members of this family are commonly

called water lilies and live as rhizomatous aquatic herbs in temperate

and tropical climates around the world.

S-ar putea să vă placă și

- Practical Guide to Historic Roof ConservationDocument22 paginiPractical Guide to Historic Roof ConservationmjdscribeÎncă nu există evaluări

- SEC Corp e-mail mobile submissionDocument1 paginăSEC Corp e-mail mobile submissionDianne Bernadeth Cos-agonÎncă nu există evaluări

- Nursing Care PlansDocument10 paginiNursing Care PlansGracie S. Vergara100% (1)

- Interior Finishing Materials GuideDocument14 paginiInterior Finishing Materials GuideRicha ChamariaÎncă nu există evaluări

- GYP547 ResGuide 2011 - 557fDocument56 paginiGYP547 ResGuide 2011 - 557fduckman2009Încă nu există evaluări

- Suspended Ceiling SystemDocument12 paginiSuspended Ceiling SystemcruxifixoÎncă nu există evaluări

- Use Acupressure to Conceive FasterDocument15 paginiUse Acupressure to Conceive Fastersale18100% (1)

- Module A Specimen Questions January2020 PDFDocument5 paginiModule A Specimen Questions January2020 PDFShashi Bhusan SinghÎncă nu există evaluări

- Roadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostDocument4 paginiRoadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostJanel Castillo Balbiran33% (3)

- Mr. Raman Sapru, Executive Vice President - Engineering, Oberoi Realty - Dry Wall Technique PresDocument10 paginiMr. Raman Sapru, Executive Vice President - Engineering, Oberoi Realty - Dry Wall Technique PresJnanamÎncă nu există evaluări

- Ancon Wall TiesDocument28 paginiAncon Wall TiesDawit Solomon0% (1)

- Durra Wall System - Strong Eco-Friendly Internal WallsDocument1 paginăDurra Wall System - Strong Eco-Friendly Internal WallstallerautorepÎncă nu există evaluări

- 09250.517.gypsum DrywallDocument7 pagini09250.517.gypsum DrywallNguyen BachÎncă nu există evaluări

- Wall FinishDocument12 paginiWall FinishAidi Amar0% (1)

- Construction Technology WallsDocument24 paginiConstruction Technology WallsAsish Seeboo100% (1)

- Presentation CTT Research Proposal FinalDocument23 paginiPresentation CTT Research Proposal FinalbegosewÎncă nu există evaluări

- Gypsum Drywall Wastes Reuse As Subgrade Road StabilizerDocument52 paginiGypsum Drywall Wastes Reuse As Subgrade Road StabilizertiteÎncă nu există evaluări

- Glossary of Wind Terms Used in ConstructionDocument36 paginiGlossary of Wind Terms Used in Constructionqatarstructz30Încă nu există evaluări

- Chapter 10wallfinishesplasteringpointingpainting 180117080527Document61 paginiChapter 10wallfinishesplasteringpointingpainting 180117080527Jude Acepcion100% (1)

- Determining Wind Actions in Kenya According to EurocodesDocument7 paginiDetermining Wind Actions in Kenya According to Eurocodespatrick chegeÎncă nu există evaluări

- Roof CoveringDocument26 paginiRoof CoveringNaresh SankuruÎncă nu există evaluări

- 14 Masonry ConstructionMethodsDocument78 pagini14 Masonry ConstructionMethodsMaverick LastimosaÎncă nu există evaluări

- Polycarbonate Sheet BenefitsDocument12 paginiPolycarbonate Sheet Benefitsirfan_haider_2Încă nu există evaluări

- Disadvantages of WPC BoardDocument32 paginiDisadvantages of WPC BoardvidhiÎncă nu există evaluări

- CIB 271 - Towards Sustainable RoofingDocument33 paginiCIB 271 - Towards Sustainable RoofingAndon Setyo WibowoÎncă nu există evaluări

- Australia Triboard Construction Manual (Aug02)Document112 paginiAustralia Triboard Construction Manual (Aug02)keithjonathan100% (1)

- Building Construction Lecture Note.Document31 paginiBuilding Construction Lecture Note.Umar Bello NuhuÎncă nu există evaluări

- Wood Products GuideDocument35 paginiWood Products GuideMin Htet MyintÎncă nu există evaluări

- Curtain Walling and CladdingDocument58 paginiCurtain Walling and CladdingRicha ShahÎncă nu există evaluări

- 1.1 Concept of Prefabrication StructureDocument20 pagini1.1 Concept of Prefabrication StructureAkriti VashishthaÎncă nu există evaluări

- Roof Types1Document34 paginiRoof Types1Shah Swara100% (1)

- Precast ConcreteDocument5 paginiPrecast ConcreteSurya TejÎncă nu există evaluări

- Investigate cracks in buildingsDocument11 paginiInvestigate cracks in buildingsRohit BhamareÎncă nu există evaluări

- GlazingsDocument23 paginiGlazingsKinkar BhattacharjeeÎncă nu există evaluări

- Precast Concrete Aesthetic SolutionsDocument20 paginiPrecast Concrete Aesthetic SolutionsMohammed IkramaliÎncă nu există evaluări

- Building DefcetsDocument13 paginiBuilding Defcetsvartika100% (1)

- SuperstructureDocument39 paginiSuperstructureaang100% (1)

- KIOT Building Construction LectureDocument26 paginiKIOT Building Construction Lecturebini1221Încă nu există evaluări

- Tapered Insulation For Roof Slope DrainageDocument34 paginiTapered Insulation For Roof Slope DrainagebatteekhÎncă nu există evaluări

- Floor and Roof Connections To Masonry WallsDocument4 paginiFloor and Roof Connections To Masonry WallsChris FindlayÎncă nu există evaluări

- Glued Laminated TimberDocument25 paginiGlued Laminated Timberpametnica21Încă nu există evaluări

- Built in Gutter Design and Detailing: Levine & Company, Inc Ardmore, PennsylvaniaDocument17 paginiBuilt in Gutter Design and Detailing: Levine & Company, Inc Ardmore, Pennsylvaniathe conquerorÎncă nu există evaluări

- Cracks in Building: Er Gurudev Singh, IDSEDocument51 paginiCracks in Building: Er Gurudev Singh, IDSEAnonymous ciKyr0t100% (3)

- Façade System: 18AR35 Atif MominDocument11 paginiFaçade System: 18AR35 Atif MominAtif MominÎncă nu există evaluări

- Prefabricated ConcreteDocument17 paginiPrefabricated ConcreteNishimaÎncă nu există evaluări

- Timber A Sustainable Construction MethodDocument15 paginiTimber A Sustainable Construction MethodOluwaseyi AdegokeÎncă nu există evaluări

- Facade TreatmentDocument11 paginiFacade TreatmentfakemasterkgpÎncă nu există evaluări

- KNAUF Plasterboard Installation Guide June18 WEBDocument76 paginiKNAUF Plasterboard Installation Guide June18 WEBBryanÎncă nu există evaluări

- Window, Door and Skylights-Residential, Sold in Canada-ENERGY STAR Technical SpecificationsDocument53 paginiWindow, Door and Skylights-Residential, Sold in Canada-ENERGY STAR Technical SpecificationsBaoNguyenÎncă nu există evaluări

- HNC Design Principles Ass 2 June 2010Document19 paginiHNC Design Principles Ass 2 June 2010fever7Încă nu există evaluări

- Nutec Flat Sheets Product GuideDocument52 paginiNutec Flat Sheets Product GuideMilu OberoiÎncă nu există evaluări

- Wall FinishDocument10 paginiWall FinishMunindra MohantaÎncă nu există evaluări

- Air Leakage Control Materials and TechniquesDocument15 paginiAir Leakage Control Materials and TechniquesAbubakkar Siddiq100% (1)

- Types of WallsDocument9 paginiTypes of WallsjarihÎncă nu există evaluări

- What are roofs and their typesDocument66 paginiWhat are roofs and their typespravin100% (1)

- Curtain WallsDocument27 paginiCurtain Wallsgau100% (1)

- Why To Provide Control Joints in Cement PlasterDocument2 paginiWhy To Provide Control Joints in Cement Plastermp_babu_2Încă nu există evaluări

- Ceiling Options 15Document12 paginiCeiling Options 15M VIJAYA SIMHA REDDYÎncă nu există evaluări

- What Is Building Envelope ?: Function and PerformanceDocument7 paginiWhat Is Building Envelope ?: Function and PerformanceSumi MathewÎncă nu există evaluări

- Plastering Pointing PDFDocument35 paginiPlastering Pointing PDFMumtahina MouliÎncă nu există evaluări

- CONCRETEDocument70 paginiCONCRETEMichelle MarquezÎncă nu există evaluări

- Monolithic Membrane 6125: PremiumDocument8 paginiMonolithic Membrane 6125: PremiumSam YoonÎncă nu există evaluări

- Using Gypsum BoardDocument138 paginiUsing Gypsum BoardkeitÎncă nu există evaluări

- GypsumDocument6 paginiGypsumarsabanÎncă nu există evaluări

- Tagufa vs. LumabanDocument7 paginiTagufa vs. LumabanDianne Bernadeth Cos-agonÎncă nu există evaluări

- People Vs RachoDocument14 paginiPeople Vs RachoDianne Bernadeth Cos-agonÎncă nu există evaluări

- Accretion Abandoned River BedDocument1 paginăAccretion Abandoned River BedDianne Bernadeth Cos-agonÎncă nu există evaluări

- Po Vs PoDocument23 paginiPo Vs PoDianne Bernadeth Cos-agonÎncă nu există evaluări

- Chung Jr. vs. MondragonDocument1 paginăChung Jr. vs. MondragonDianne Bernadeth Cos-agonÎncă nu există evaluări

- G.R. No. 210435 People Vs SONNY RAMOS y BUENAFLORDocument9 paginiG.R. No. 210435 People Vs SONNY RAMOS y BUENAFLORDianne Bernadeth Cos-agonÎncă nu există evaluări

- Manquil vs. MoicoDocument5 paginiManquil vs. MoicoDianne Bernadeth Cos-agonÎncă nu există evaluări

- Tappa Vs BacusDocument10 paginiTappa Vs BacusDianne Bernadeth Cos-agonÎncă nu există evaluări

- People vs. MERVIN GAHIDocument11 paginiPeople vs. MERVIN GAHIDianne Bernadeth Cos-agonÎncă nu există evaluări

- Cta 00 CV 05289 D 1999may27 Ref PDFDocument13 paginiCta 00 CV 05289 D 1999may27 Ref PDFDianne Bernadeth Cos-agonÎncă nu există evaluări

- Cta 00 CV 05289 D 1999may27 Ref PDFDocument13 paginiCta 00 CV 05289 D 1999may27 Ref PDFDianne Bernadeth Cos-agonÎncă nu există evaluări

- Lecture CVL LWDocument24 paginiLecture CVL LWDianne Bernadeth Cos-agonÎncă nu există evaluări

- Accretion (Along Rivers, Creeks, ETC) : 1. ApplicantDocument2 paginiAccretion (Along Rivers, Creeks, ETC) : 1. ApplicantDianne Bernadeth Cos-agonÎncă nu există evaluări

- Poli 2017Document12 paginiPoli 2017BrunxAlabastroÎncă nu există evaluări

- Mock Bar - RemDocument6 paginiMock Bar - RemDianne Bernadeth Cos-agonÎncă nu există evaluări

- Estimated Duties and Taxes for 1.8 Million Euro ShipmentDocument1 paginăEstimated Duties and Taxes for 1.8 Million Euro ShipmentDianne Bernadeth Cos-agonÎncă nu există evaluări

- Rule 41 Section 1: No Appeal Shall Be Taken From: 8 Ddidaset-Ows An Order of Execution Is Not Appealable, Except: 6 VcestiDocument1 paginăRule 41 Section 1: No Appeal Shall Be Taken From: 8 Ddidaset-Ows An Order of Execution Is Not Appealable, Except: 6 VcestiDianne Bernadeth Cos-agonÎncă nu există evaluări

- Estimated Duties and Taxes PDFDocument1 paginăEstimated Duties and Taxes PDFDianne Bernadeth Cos-agonÎncă nu există evaluări

- Checklist of ObjectionsDocument5 paginiChecklist of ObjectionsCha Hope100% (3)

- Insurance Law Case Digests For CommrevDocument18 paginiInsurance Law Case Digests For CommrevDianne Bernadeth Cos-agonÎncă nu există evaluări

- Lip Case Digests 3b Ay2016-2017Document38 paginiLip Case Digests 3b Ay2016-2017Dianne Bernadeth Cos-agonÎncă nu există evaluări

- Due Process Ichong v. HernandezDocument6 paginiDue Process Ichong v. HernandezDianne Bernadeth Cos-agonÎncă nu există evaluări

- Manila Port Charges - NEWDocument1 paginăManila Port Charges - NEWDianne Bernadeth Cos-agonÎncă nu există evaluări

- Marital Validity AnalysisDocument2 paginiMarital Validity AnalysisDianne Bernadeth Cos-agonÎncă nu există evaluări

- Vda Dela Rosa vs. Heirs of RustiaDocument3 paginiVda Dela Rosa vs. Heirs of RustiaDianne Bernadeth Cos-agon100% (1)

- NEGOTIABLE INSTRUMENTS LAW DIGESTSDocument22 paginiNEGOTIABLE INSTRUMENTS LAW DIGESTSDianne Bernadeth Cos-agonÎncă nu există evaluări

- Table of Crimes Per TitleDocument7 paginiTable of Crimes Per TitleDianne Bernadeth Cos-agonÎncă nu există evaluări

- Table of Crimes Per TitleDocument7 paginiTable of Crimes Per TitleDianne Bernadeth Cos-agonÎncă nu există evaluări

- Lip Case Digests 3b Ay2016-2017Document38 paginiLip Case Digests 3b Ay2016-2017Dianne Bernadeth Cos-agonÎncă nu există evaluări

- FINALS REVIEWER ENVI ENGG Topic 1Document8 paginiFINALS REVIEWER ENVI ENGG Topic 1As ReÎncă nu există evaluări

- Sigma monitor relayDocument32 paginiSigma monitor relayEdwin Oria EspinozaÎncă nu există evaluări

- Carpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesDocument105 paginiCarpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesVinod KumarÎncă nu există evaluări

- Puskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListDocument98 paginiPuskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListLaboratorium PKM 23 IlirÎncă nu există evaluări

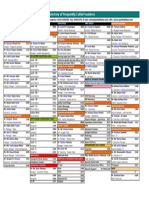

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 paginăDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoÎncă nu există evaluări

- Proper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle JDocument15 paginiProper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle Jjoannamhay ceraldeÎncă nu există evaluări

- Valvula de Leve MasterDocument20 paginiValvula de Leve Masterguillermo trejosÎncă nu există evaluări

- Siemens MV Gas Insulated Switch GearDocument14 paginiSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VÎncă nu există evaluări

- Đề cương ôn tập tiếng anh 9Document28 paginiĐề cương ôn tập tiếng anh 9Nguyễn HoaÎncă nu există evaluări

- ERS M22 PC4 FerryDocument2 paginiERS M22 PC4 FerryouakgoodÎncă nu există evaluări

- Grade 3 science syllabus 1st and 2nd semesterDocument2 paginiGrade 3 science syllabus 1st and 2nd semesterelyzabeth SibaraniÎncă nu există evaluări

- Cot 1 Vital SignsDocument22 paginiCot 1 Vital Signscristine g. magatÎncă nu există evaluări

- Consumer Behaviour: Group ProjectDocument5 paginiConsumer Behaviour: Group ProjectAanchal MahajanÎncă nu există evaluări

- FinalsDocument8 paginiFinalsDumpÎncă nu există evaluări

- Disinfecting Water Wells Shock ChlorinationDocument3 paginiDisinfecting Water Wells Shock ChlorinationmayaÎncă nu există evaluări

- Clinical Case Report No 2Document11 paginiClinical Case Report No 2ملک محمد صابرشہزاد50% (2)

- EP Series User Manual PDFDocument40 paginiEP Series User Manual PDFa.elwahabÎncă nu există evaluări

- C. Drug Action 1Document28 paginiC. Drug Action 1Jay Eamon Reyes MendrosÎncă nu există evaluări

- Request Baha Alert PPMPDocument3 paginiRequest Baha Alert PPMPLö Räine AñascoÎncă nu există evaluări

- Canada's Health Care SystemDocument11 paginiCanada's Health Care SystemHuffy27100% (2)

- Ic Audio Mantao TEA2261Document34 paginiIc Audio Mantao TEA2261EarnestÎncă nu există evaluări

- AAR Maintenance 001Document3 paginiAAR Maintenance 001prakash reddyÎncă nu există evaluări

- The National Building Code of The PhilippinesDocument390 paginiThe National Building Code of The PhilippinesJohn Joseph EstebanÎncă nu există evaluări

- Completed Manuscript 1 5Document52 paginiCompleted Manuscript 1 5SAMANTHA LACABAÎncă nu există evaluări

- Growing Turmeric: Keys To SuccessDocument4 paginiGrowing Turmeric: Keys To SuccessAnkit ShahÎncă nu există evaluări

- Tumors of The Central Nervous System - VOL 12Document412 paginiTumors of The Central Nervous System - VOL 12vitoÎncă nu există evaluări