Documente Academic

Documente Profesional

Documente Cultură

Power Team Manual Valves - Catalog

Încărcat de

TitanplyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Power Team Manual Valves - Catalog

Încărcat de

TitanplyDrepturi de autor:

Formate disponibile

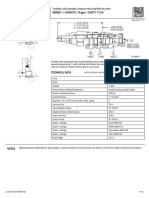

9628

Valves

HYDRAULIC PUMP MOUNTED

(STRESS PORT) A B (RETURN PORT)

X POS. B

5,800

6,400

psi

RETURN PORT B De s ig n e d f o r us e

CENTER

with Power Te a m

Manual

STRESS PORT A

POS. A

a i r, gasoline and

electric power e d

P T

hy d r a u l ic p um p s .

Port B Port A

4-WAY/3-POSITION (TANDEM 3. Valve is placed in “B” position,

CENTER) MANUAL VALVE which is pressure controlled and will

not exceed 6,400 psi. “Return”

Application – Single strand, double-

portion of stressing tool is

acting stressing jacks with Power

pressurized and will release “A” port

Wedge seater.

10,000 psi., 3/8" ports, 5 gpm max

when pressure reaches

Actuation – Lever operated, detent

flow rate.

approximately one-half the “A” port

positioned.

pressure. “A” port remains open as

Operation –

long as this pressure differential is

1. With valve in center position, pump

maintained.

is started.

4. Pump is stopped, valve is placed in

P U M P S / VA LV E S

2. Cable is inserted into stressing tool,

“A” position, releasing “B” port

valve is placed in “A” position. “Pull”

pressure. * These pumps may have reduced first

portion of stressing tool is

Used on these pumps: PA17*, flow stage characteristics due to

pressurized to specified level for

PA46*, PA55, PE17*, PE21*, PE30, internal valve restrictions.

proper cable tensioning (“A” port is

PE46*, PE55, PE60, PE84, PE120, No. 9628 – Post tensioning valve for

checked internally, can only be

PE200, PE400, PG30*, PG55, PG120, 10,000 psi (max.) single-

released by building pressure

PG400, PQ60 and PQ120 series. acting/Power Wedge seater.

in “B” position).

Wt., 5.4 lbs.

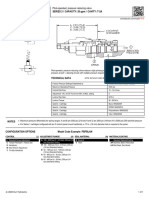

“TWIN” 4-WAY/3-POSITION position. Seating portion of cylinder PG30*, PG55, PG120, PG400, PQ60

(TANDEM CENTER) MANUAL will be pressurized to seating and PQ120 series.*

VALVE pressure controlled by “Seat” relief * These pumps may have reduced first

valve (factory set to 3,900 psi). flow stage characteristics due to

Application – Multi-strand, double-acting 4. Valve “B” is shifted to “Return” internal valve restrictions.

stressing jacks with an auxiliary seating position, which is pressure controlled No. 9632 – Post tensioning valve for

cylinder. and will not exceed 2,200 psi. “Return” 10,000 psi (max.) double-acting

Actuation – Dual lever operated, detent portion of stressing tool should be systems. Wt., 13.6 lbs.

positioned. pressurized and will release “Stress” 9632

Operation – port when pressure reaches 15% of

1. With valves “A” and “B” in center “Stress” port pressure. CENTER

SEAT RETURN

position, pump is started; cable is 5. “Stress” port will remain open and

inserted into stressing tool. cylinder will return as long as VALVE B VALVE B

2. Valve “A” is placed in “Stress” pressure differential is maintained. CENTER

Stress VALVE A

position; cylinder extends to tension “Stress” and “Seat” ports are open Return STRESS

cable. Pump pressure controls force to reservoir. Seat

exerted by tensioning cylinder in this 6. When cylinder has fully returned, both STRESS RETURN SEAT

1,900 3,800

psi psi

position. “Stress” port is checked valves are shifted to “Center” position

2,000 4,000

internally, and can only be released by and oil will be directed to reservoir. VALVE B

building pressure in the valve “B” Maximum pressure setting for the

return position. “Seat” relief valve is 6,000 psi.

3. When desired cable tension is Used on these pumps: PA17*, PA46*,

achieved, valve “A” is placed in valve PA55, PE17*, PE21*, PE30, PE46*,

VALVE A

P T

“B” position and valve “B” in “Seat” PE55, PE84, PE120, PE200, PE400, Pump mounted, 6-position detented 5-

way manual dual valve. Rated pressure to

valve “A” is 10,000 psi and valve “B” is

6,000 psi. Case pressure is 500 psi max.

CAUTION: To prevent sudden, uncontrolled descent of a load as it is being lowered, use a No. 9596 Load Lowering Valve or No. 9720

Counter Balance Valve (see page 132) in conjunction with the directional valve used in your application.

IMPORTANT: Conversion kit 251528 must be used when mounting any of the valves on this page on PA17 or PE17 pumps.

IMPORTANT: When ordering any valve for a PE30 or PG30 series pump, 1/2" longer mounting screws are required. For valves 9569, 9570

and 9579, order four 10856 cap screws. For valves 9552, 9572 and 9592, order four 12001 cap screws.

Page 6 Page 12 Page 61 Page 116 Page 120

www.powerteam.com 57

S-ar putea să vă placă și

- Pneumatic Actuator ElementsDocument49 paginiPneumatic Actuator Elementsdk.vermaÎncă nu există evaluări

- Chapter 2 Hyd PumpDocument8 paginiChapter 2 Hyd PumpManuelÎncă nu există evaluări

- Dual Pressure SwitchDocument2 paginiDual Pressure SwitchRakibul HassanÎncă nu există evaluări

- Pump Unload Pilot Valve SUN QPABDocument2 paginiPump Unload Pilot Valve SUN QPABankesh_ghoghariÎncă nu există evaluări

- Accumulator Charging Valve: 1 Product DescriptionDocument6 paginiAccumulator Charging Valve: 1 Product DescriptionVagabond HuynhÎncă nu există evaluări

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 paginiModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareÎncă nu există evaluări

- High Pressure Logic Valves: Mechanical and PilotDocument6 paginiHigh Pressure Logic Valves: Mechanical and PilotMohamed MusaÎncă nu există evaluări

- Service Training 2005Document76 paginiService Training 2005Heidi Cuevas Venegas100% (1)

- Model 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityDocument2 paginiModel 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityGamal El Deen KamalÎncă nu există evaluări

- 106 206 RPS LHDocument3 pagini106 206 RPS LHral75Încă nu există evaluări

- Safety and reliability of hydraulics check valvesDocument6 paginiSafety and reliability of hydraulics check valvesJessica Tatiana Muñoz OrtizÎncă nu există evaluări

- Brake System FunctionDocument6 paginiBrake System FunctionNguyen Vu BuiÎncă nu există evaluări

- 03 CPPDocument25 pagini03 CPPNur 07T48Încă nu există evaluări

- Infusion Pumps Training-Converted1Document79 paginiInfusion Pumps Training-Converted1Trương DuyÎncă nu există evaluări

- Canon AE1 SPT Canon AE1 Program GuideDocument13 paginiCanon AE1 SPT Canon AE1 Program Guideหนึ่ง ทุ่งฟายหายÎncă nu există evaluări

- Manual 820-Pp AsDocument12 paginiManual 820-Pp AsjabalpuramitÎncă nu există evaluări

- HLIW145-EB AdjustmentsDocument38 paginiHLIW145-EB AdjustmentsBastian Bazaes100% (1)

- Bomba Hidráulica FestoDocument8 paginiBomba Hidráulica FestoAlex TamayoÎncă nu există evaluări

- $RLHCG0FDocument107 pagini$RLHCG0FChomiÎncă nu există evaluări

- Damcos JDPGDocument6 paginiDamcos JDPGAlan Stone RebeloÎncă nu există evaluări

- Dkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpenDocument2 paginiDkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpensnsnagarajanÎncă nu există evaluări

- Series Parallel Pumps PDFDocument4 paginiSeries Parallel Pumps PDFMarc Danielle G Josue IIÎncă nu există evaluări

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document22 paginiWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Рома БлошенкоÎncă nu există evaluări

- Chapt 6 AntijamDocument6 paginiChapt 6 AntijamManuelÎncă nu există evaluări

- ZIEGLER Brochure UP4 Eng B3202-8!2!0519 WebDocument8 paginiZIEGLER Brochure UP4 Eng B3202-8!2!0519 WebJhonatas QuintanillhaÎncă nu există evaluări

- Arca Valve Manual - 830 POSITIONERDocument13 paginiArca Valve Manual - 830 POSITIONERAtul bhabad0% (1)

- RPGC Full en Us A4Document2 paginiRPGC Full en Us A4zapchasty29Încă nu există evaluări

- Áp TH y L C Trên Main Ngáng DRF450Document1 paginăÁp TH y L C Trên Main Ngáng DRF450Nguyễn Văn HùngÎncă nu există evaluări

- P03MSV PDR Pressure ReducingRelieving Valve Form 1013019 Rev. 12 19Document6 paginiP03MSV PDR Pressure ReducingRelieving Valve Form 1013019 Rev. 12 19moonstarÎncă nu există evaluări

- ValveDocument1 paginăValveKUMAR RAGHUVANSHAMÎncă nu există evaluări

- Preset Reactor RegulatorDocument2 paginiPreset Reactor RegulatorLuis Landin MontapertoÎncă nu există evaluări

- Bendix - Master-Vac - Power Brake Service Manual - OCR - 8 PagesDocument8 paginiBendix - Master-Vac - Power Brake Service Manual - OCR - 8 Pagesgreg titanÎncă nu există evaluări

- Directional Control ValvesDocument68 paginiDirectional Control ValvesRasoolKhadibiÎncă nu există evaluări

- Huong Dan Lap Dat Va Su Dung Van Chong Va PDFDocument4 paginiHuong Dan Lap Dat Va Su Dung Van Chong Va PDFDONGTA123Încă nu există evaluări

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDocument2 paginiModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalÎncă nu există evaluări

- Pressure Switch Data SheetDocument4 paginiPressure Switch Data SheetSam WildÎncă nu există evaluări

- Kimray SMT 1400 (Control Valve)Document7 paginiKimray SMT 1400 (Control Valve)CARLOS SARMIENTOÎncă nu există evaluări

- Catalogo de Bombas de Caudal Variable PDFDocument29 paginiCatalogo de Bombas de Caudal Variable PDFJMÎncă nu există evaluări

- Direct-acting relief valve technical data and configuration optionsDocument2 paginiDirect-acting relief valve technical data and configuration optionsJustinÎncă nu există evaluări

- PVDB Full en Us LetterDocument2 paginiPVDB Full en Us LetterIsrael RuizÎncă nu există evaluări

- Condor 46N 92179Document264 paginiCondor 46N 92179Pedro Alberto BenitesÎncă nu există evaluări

- Piston Pump PVDocument16 paginiPiston Pump PVtreinamentoÎncă nu există evaluări

- B046E-HQ-HQCN Pressure SwitchDocument2 paginiB046E-HQ-HQCN Pressure Switch123ertyugfÎncă nu există evaluări

- Conveyor Tensioning Device: TP501 Festo DidacticDocument9 paginiConveyor Tensioning Device: TP501 Festo DidacticGiang TônÎncă nu există evaluări

- Chapt 2 PumpsDocument6 paginiChapt 2 PumpsManuelÎncă nu există evaluări

- Pittsburgh (Harbor Freight) 92649 A-C Manifold Gauge Set Quick ReferenceDocument4 paginiPittsburgh (Harbor Freight) 92649 A-C Manifold Gauge Set Quick ReferenceRick McGuire0% (1)

- Pilot Circuits: Service Training Manual CM 760/780Document5 paginiPilot Circuits: Service Training Manual CM 760/780victor laraÎncă nu există evaluări

- A2vk PDFDocument10 paginiA2vk PDFMohar SinghÎncă nu există evaluări

- A2VKDocument10 paginiA2VKsalelg1980Încă nu există evaluări

- A2vk PDFDocument10 paginiA2vk PDFMohar SinghÎncă nu există evaluări

- DP40Document11 paginiDP40Yoyoo SusantoÎncă nu există evaluări

- PBFB en Us A4Document1 paginăPBFB en Us A4operacion hydratekÎncă nu există evaluări

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedDocument2 paginiModel 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedVinit ChoudharyÎncă nu există evaluări

- SV Equipment - Standard and High Pressure Portables Manual v1Document32 paginiSV Equipment - Standard and High Pressure Portables Manual v1Ussapitiya HeritageÎncă nu există evaluări

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveDocument2 paginiModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinÎncă nu există evaluări

- DOCUMENTCMYK Pilot Operated Pressure Relief ValveDocument10 paginiDOCUMENTCMYK Pilot Operated Pressure Relief ValveDipti BhanjaÎncă nu există evaluări

- Electro-Prop ValveDocument2 paginiElectro-Prop Valvemaikel.mÎncă nu există evaluări

- Hyva Valvula Volvo Volcadora PDFDocument2 paginiHyva Valvula Volvo Volcadora PDFricardo bueraÎncă nu există evaluări

- Power Team Inline Valves Page 2 - CatalogDocument1 paginăPower Team Inline Valves Page 2 - CatalogTitanplyÎncă nu există evaluări

- Power Team Gauges - CatalogDocument2 paginiPower Team Gauges - CatalogTitanplyÎncă nu există evaluări

- Power Team Pump Mounted Valves - CatalogDocument1 paginăPower Team Pump Mounted Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Manual Pilot Valves - CatalogDocument1 paginăPower Team Manual Pilot Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Hydraulic Oil - CatalogDocument1 paginăPower Team Hydraulic Oil - CatalogTitanplyÎncă nu există evaluări

- Power Team Pump Mounted Valves - CatalogDocument1 paginăPower Team Pump Mounted Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Pump Mounted Solenoid Air Valves - CatalogDocument1 paginăPower Team Pump Mounted Solenoid Air Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Pump Mounted 3-Way/3-Position Valves - CatalogDocument1 paginăPower Team Pump Mounted 3-Way/3-Position Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Pump Mounted Solenoid Air Valves - CatalogDocument1 paginăPower Team Pump Mounted Solenoid Air Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Pump Mounted 4-Way/3-Position Valves - CatalogDocument1 paginăPower Team Pump Mounted 4-Way/3-Position Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Inline Valves - CatalogDocument1 paginăPower Team Inline Valves - CatalogTitanplyÎncă nu există evaluări

- Power Team Inline Valves Chart - CatalogDocument1 paginăPower Team Inline Valves Chart - CatalogTitanplyÎncă nu există evaluări

- Power Team PQ120/400 Series - CatalogDocument2 paginiPower Team PQ120/400 Series - CatalogTitanplyÎncă nu există evaluări

- Power Team Hoses - CatalogDocument1 paginăPower Team Hoses - CatalogTitanplyÎncă nu există evaluări

- Power Team Non-Conductive Hoses - CatalogDocument1 paginăPower Team Non-Conductive Hoses - CatalogTitanplyÎncă nu există evaluări

- Power Team PE10 Series Pumps - CatalogDocument2 paginiPower Team PE10 Series Pumps - CatalogTitanplyÎncă nu există evaluări

- Power Team Manifolds - CatalogDocument1 paginăPower Team Manifolds - CatalogTitanplyÎncă nu există evaluări

- Power Team Fittings - CatalogDocument1 paginăPower Team Fittings - CatalogTitanplyÎncă nu există evaluări

- Power Team PED Series CatalogDocument2 paginiPower Team PED Series CatalogTitanplyÎncă nu există evaluări

- Power Team PQ120 CatalogDocument2 paginiPower Team PQ120 CatalogTitanplyÎncă nu există evaluări

- Power Team PQ60 CatalogDocument2 paginiPower Team PQ60 CatalogTitanplyÎncă nu există evaluări

- Power Team Couplers - CatalogDocument1 paginăPower Team Couplers - CatalogTitanplyÎncă nu există evaluări

- Power Team PG120 Series - CatalogDocument1 paginăPower Team PG120 Series - CatalogTitanplyÎncă nu există evaluări

- Power Team PE400 CatalogDocument2 paginiPower Team PE400 CatalogTitanplyÎncă nu există evaluări

- Power Team PG30/55 Series - CatalogDocument2 paginiPower Team PG30/55 Series - CatalogTitanplyÎncă nu există evaluări

- Power Team HB44 Series - CatalogDocument1 paginăPower Team HB44 Series - CatalogTitanplyÎncă nu există evaluări

- Power Team PENUT Series - CatalogDocument1 paginăPower Team PENUT Series - CatalogTitanplyÎncă nu există evaluări

- Power Team PED Series CatalogDocument2 paginiPower Team PED Series CatalogTitanplyÎncă nu există evaluări

- Power Team PE10 Series Pumps - CatalogDocument2 paginiPower Team PE10 Series Pumps - CatalogTitanplyÎncă nu există evaluări

- ShowDocument136 paginiShowengrfvÎncă nu există evaluări

- 8719-Cummins Qsv91g Generator Set Brochure 3Document4 pagini8719-Cummins Qsv91g Generator Set Brochure 3Oscar Fernando Guerrero RomeroÎncă nu există evaluări

- CSC, OMCs Sign MoU to Facilitate LPG ServicesDocument3 paginiCSC, OMCs Sign MoU to Facilitate LPG Servicesranjan4me0% (1)

- Generator 7000 Watt Briggs and Stratton Model 040298 PDFDocument92 paginiGenerator 7000 Watt Briggs and Stratton Model 040298 PDFRob BromleyÎncă nu există evaluări

- AMSOIL 5W-40 Synthetic Motor Oil Order Online atDocument2 paginiAMSOIL 5W-40 Synthetic Motor Oil Order Online atBruce WappmanÎncă nu există evaluări

- Manual 275AX-5EO PDFDocument1.447 paginiManual 275AX-5EO PDFELMERÎncă nu există evaluări

- Mobil Cross RefDocument2 paginiMobil Cross RefpaniyaÎncă nu există evaluări

- G-Class W463 0613Document86 paginiG-Class W463 0613Tony LimÎncă nu există evaluări

- PSM 8Document5 paginiPSM 8Salvatore MirandaÎncă nu există evaluări

- Industrial Electric HeatersDocument12 paginiIndustrial Electric Heatersmayukhguha88Încă nu există evaluări

- Water and Oil Free Screw Compressor Evaluation ReportDocument4 paginiWater and Oil Free Screw Compressor Evaluation ReportdaritiÎncă nu există evaluări

- Dr.S. Sendil Velan BIODATADocument11 paginiDr.S. Sendil Velan BIODATASendilvelan SubramanianÎncă nu există evaluări

- Engine Technology InternationalDocument76 paginiEngine Technology InternationalLiviu MihonÎncă nu există evaluări

- Evidya Oisd144Document60 paginiEvidya Oisd144shahezad yemenÎncă nu există evaluări

- Msar GroupDocument20 paginiMsar GroupmchathirÎncă nu există evaluări

- Country Analysis Briefs: South China SeaDocument8 paginiCountry Analysis Briefs: South China SeaSteeljaw ScribeÎncă nu există evaluări

- 909c2c3407b0b77cf246004942ac82aaDocument4 pagini909c2c3407b0b77cf246004942ac82aaariwibowoÎncă nu există evaluări

- TK07 REPORT FINAL Rapih PDFDocument199 paginiTK07 REPORT FINAL Rapih PDFirviirviÎncă nu există evaluări

- The Second Law of ThermodynamicsDocument12 paginiThe Second Law of ThermodynamicsEdgar PeninsulaÎncă nu există evaluări

- Zimbabwe Electricity Supply Authority Grid Infrastructure CompanyDocument5 paginiZimbabwe Electricity Supply Authority Grid Infrastructure CompanyArchiford NdhlovuÎncă nu există evaluări

- Precision Airmotive's MSA Float Carburetor HandbookDocument34 paginiPrecision Airmotive's MSA Float Carburetor Handbook40Below100% (1)

- Working Ranges Specifications: SK17SR-5Document8 paginiWorking Ranges Specifications: SK17SR-5LU YOÎncă nu există evaluări

- CSWIP NotesDocument32 paginiCSWIP NotesKhaled FatnassiÎncă nu există evaluări

- 2018 Trafigura Commodities Demystified Guide Second Edition English PDFDocument84 pagini2018 Trafigura Commodities Demystified Guide Second Edition English PDFAlok SinghÎncă nu există evaluări

- CSI Bulletin CTCH -1: The CSI Bolt-On Heating SystemDocument12 paginiCSI Bulletin CTCH -1: The CSI Bolt-On Heating Systempeubrandao100% (1)

- Specification For Vertical Can Type PumpsDocument8 paginiSpecification For Vertical Can Type Pumpsnecio77Încă nu există evaluări

- Pipeline OutlooDocument60 paginiPipeline OutlooNikhil GaurÎncă nu există evaluări

- Oxygen Contamination of Hydrocarbon FeedstocksDocument6 paginiOxygen Contamination of Hydrocarbon FeedstocksChristine HendrixÎncă nu există evaluări

- Track DrillDocument28 paginiTrack DrillMarco Antonio Aquino AquinoÎncă nu există evaluări

- Fire Protection System NFPA 850 PresentationDocument15 paginiFire Protection System NFPA 850 Presentationbilly67% (3)