Documente Academic

Documente Profesional

Documente Cultură

Carburetor and Fuel Injection ME 359

Încărcat de

Shaharukh KhanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Carburetor and Fuel Injection ME 359

Încărcat de

Shaharukh KhanDrepturi de autor:

Formate disponibile

10/1/2015

IIT Kanpur

Kanpur, India (208016)

Carburetion and fuel injection

Introduction

ThewordcarburetorcamefromtheFrenchcarburemeaning"carbide".Carburemeanstocombine

withcarbon.

ThecarburetorwaspatentedbyKarlBenzin1886.

FuelinjectionsystemisavitalcomponentofbothCI&SIengines.

Ottocycleenginesarefedwithfuel(normalgasoline,,methylorethylalcoholetc.),whichissufficiently

volatileandhasignitionpropertieswhichallowittobepremixedwiththecombustionairbeforethe

combustionisinitiatedbythesparkplug.

inDieselcycleengines,thefuelislessvolatileandairisonlymixedinsidethecombustionchamber,

wherethepressureandtemperatureconditionsaresuchtoinducenaturalignition.sothepower

deliveryofdieselenginesmaybeadjustedbyfueldeliveryalone,withouttheneedtocontrolthe

airflow.

InSIengine,theliquidfuelandtheair(whichcontainsnecessaryoxygen)aremixedpriortoarrivalin

thecombustionchamber.

InOttocycleengines,whenthefuelispremixedwiththeair,itisnecessarytocontroltheairflowand

therefore,indirectlytheairfuelmixture.

10/1/2015

Gasoline engines cannot run on liquid gasoline. It must be vaporized and mixed with air in the

proper proportions for varying conditions.

the process of producing a mixture of air and fuel in the correct proportion for engine

combustion Is called carburation

A carburetor is a device that blends air and fuel for an internal combustion engine.

Induction system

Induction system is responsible for preparing correct air-fuel mixture and directing this mixture

to each of the cylinder.

Carburetor is main part of induction system.

Liquid fuel supplied to carburetor from the fuel system.

Air is drawn into carburetor form atmosphere by the action of the engine piston on intake

stroke. most of the automobile engine induct air directly into carburetor through air cleaner.

Through Intake manifold fuel and air mixture travels from carburetor to the cylinder.

The throttle located in the carburetor regulates the quantity of mixture entering the cylinder.

10/1/2015

During the suction stroke vacuum created in the cylinder causes air to flow through carburetor

and fuel to sprayed from the fuel jets.

most of the fuel vaporizes and forms a combustible fuel-air mixture because of volatility of fuel.

how ever some of the larger droplets may reach the cylinder in liquid form which should be

vaporized and mixed with air during compression stroke before ignition.

Important factor affecting the process of carburation

1. Time available for preparation of mixture.

2. Temperature of the incoming air of the mixture.

3. Quality of fuel supplied.

4. Design of the induction system and combustion chamber.

Chemically correct air/fuel ratio

A chemical equation for combustion hydrocarbon can be written as follows:

C8H18 + 12.5 O2 = 8 CO2 + 9 H2O

From this we can calculate for complete combustion, there must be 15.12 k.g. of air required

for every k.g. of C8H18 fuel.

The air/fuel ration (A/F) in this case is 15.12 : 1, that is 0.0661.

The quantity of fuel calculated by this method is an ideal amount necessary to react completely

with all the oxygen. So this A/F ratio is known as chemically correct or stoichiometric A/F ratio

for this type of fuel.

The chemically correct A/F mixture is not mandatory condition for engine operation.

However, with in a limited range of A/F ratios Si engine combustion will occur. Outside this

range ,the ratio is too rich or too lean to sustain flame propagation.

10/1/2015

Theoretical carburetor considerations

Carburetor must fulfill following functions

1. Meter the liquid fuel in correct quantities to produce A/F ratio required to meet engine

operating conditions.

2. Atomize the fuel, and mix it homogeneously with the air.

Carburetor must be designed to provide as nearly as possible A/F ratio which the

engine requires.

The mixture corresponding to the

maximum point on bhp curve is

called best power mixture.

The mixture corresponding to the

minimum point on the bsfc curve is

called the best economy mixture.

The above figure is based on full throttle position operation.

It is important to note that, the best power mixture is richer than the chemically correct

mixture, and the best economy mixture is leaner than the chemically correct.

The A/F ratios for best power and best economy at part throttle are not strictly the same as full

load.

Carburetor could be set for the best power mixture when maximum performance desired and

for best economy mixture when fuel economy is primary consideration.

There are three general ranges of throttle operation. in each of these, engine has different

requirement.

The carburetor must modify the A/F ratio to satisfy these demands

The three ranges are

1. Idling (mixture must be enriched)

2. Crushing (mixture must be leaned)

3. High power (mixture must be enriched)

10/1/2015

Mixture requirements for maximum power

Maximum power is obtained at about

12.5: 1.

Maximum energy is released when

mixture is slightly rich so all the

oxygen present in the cylinder is

utilized.

(For full throttle and constant speed operation)

This is undesirable as combustion of large excess of fuel with same amount of oxygen

results in smaller energy release due to partial combustion hence carbon monoxide is

formed

Mixture requirement for minimum specific fuel consumption

Maximum efficiency occurs at A/F ratio of

about 17:1 (0.06 :1 F/A ratio)

Maximum efficiency occurs at a point

slightly leaner than chemically correct A/F

ratio because mixing is not perfect, excess

air requires for complete combustion of

fuel.

(For various throttle position)

10

10/1/2015

Engine A/F mixture requirement

1. IDLE MIXTURE

an idle engine is one operating at no load condition and the throttle position is nearly closed.

Engine produces power only to overcome friction between parts, and a rich mixture is to be fed

to the engine to sustain combustion.

The engine requires a rich mixture. This is because existing pressure conditions within the

combustion chamber and intake manifold, which causes exhaust gas dilution of the fresh

charge.

When intake valve opens, the pressure differential

between combustion chamber and the intake manifold

results in backward initial flow of exhaust gases into

intake manifold.

As the piston moves down on the intake stroke, these

exhaust gases are drawn back into the cylinder along

with fresh charge. so the final mixture of fuel and air is

diluted by exhaust gas.

11

This exhaust gas obstruct the contact between fuel and air particles. As a result less power

obtained.

Hence it is required to provide more fuel particle by enriching the air and fuel mixture which

increases the probability of contact between fuel and air particles, thus improves combustion.

As the throttle is gradually opened the pressure differential becomes smaller and exhaust gas

dilution of the fresh charge diminishes

Idling system

The idling system consists of an idling fuel

passage and idling port.

When the throttle is partially closed, a

depression past the throttle allows the fuel

to go into the intake through the idle tube.

The depression also draws air through the

idle air bleed and mixes with fuel .

12

10/1/2015

2. CRUSHING RANGE

normal power or crushing operation have lower fuel consumption for maximum economy.

The arrangement used is the auxiliary port

carburetor where opening of butterfly valve

allows additional air to be admitted and at the

same time depression at the venturi throat gets

reduced, there by decreasing the fuel flow rate

13

3. POWER RANGE

Richer mixture required for following reason

a) Provide best power as high power is desired so it is required to transfer the cruising range to

the mixture which will produce the greatest power or near the vicinity of best power mixture.

b) Prevent overheating of exhaust valve area enriching the mixture reduce the flame temperature

and cylinder temperature. So it reduces the cooling problem and lessening the tendency to

damage exhaust valve at high power.

c) Inhibit detonation in air craft engines enriching the mixture beyond chemically correct

reduces the flame temperature so it reduces detonation.

In automobile engine detonation are produced in the form of audible knock or ping. Also these

automobile engine operate well below full power and enriching fuel air mixture will not be

economical for this purpose.

For aircraft engine installations, richening the mixture is justified and necessary to increase

permissible take off power.

14

10/1/2015

POWER ENRICHMENT SYSTEM

For rich mixture, additional fuel supplied by a power

enrichment system

It consist of a meter rod economizer that provides a larger

orifice opening to the main jet as the throttle is opened

beyond a certain point.

ACCELERATING PUMP SYSTEM

During sudden acceleration of an engine an extra

amount of fuel is momentarily required to supply a rich

mixture.

This is obtained by accelerating pump system consists of

a spring-loaded plunger and necessary linkage

mechanism

15

Transient mixture requirements

Carburetor has to provide suitable mixture for transient conditions where speed, load ,

temperature ,pressure changes rapidly.

The principle transition conditions of operations are

1. starting

2. Warming up

3. Acceleration

4. Deceleration

The difference between steady state and transient state are

1. Incomplete evaporation

2. Fluctuation in quantity of liquid fuel in inlet manifold (increasing or decreasing)

3. Distribution of fuel to various cylinder

16

10/1/2015

1. Starting and warm up

while starting from cold

the speed as well as

engine temperature are low, hence fuel supplied

by carburetor does not vaporize and remain in

liquid form.

Also the vaporized fuel may recondence on

coming in contact with cold cylinder walls and

piston head.

Therefore even when air-fuel ratio at carburetor is

well enough but the ratio of evaporated fuel to air

in the cylinder may be too lean to ignite. Hence

during start up 5 to 10 times the normal amount

(During start-up the components are cold

so fuel evaporation is very slow, as a result

additional fuel is added through a second

injecting valve)

fuel must be supplied for proper combustion.

As engine warms up the amount of evaporated fuel increases and hence the mixture ratio

should made leaner to avoid rich evaporated fuel-air ratio. Too high or too low volatility, both

create difficulties in operation.

17

2. Acceleration and deceleration

Acceleration means increase in engine speed resulting from

opening the throttle.

Fuel evaporated in intake manifold moves faster than the

liquid film formed on the induction system walls.

When throttle is suddenly open, the liquid fuel lags behind

and temporarily the engine cylinder receives a lean mixture

whilst rich mixture is needed to produce instantaneous

power for acceleration.

To compensate for temporary leaning of mixture and to

provide rich mixture needed for acceleration period,

additional fuel must be supplied by suitable mechanism.

18

10/1/2015

Simple carburettor

The simple carburetor mainly

consists of

1.

float chamber,

2.

fuel discharge nozzle

3.

a metering orifice

4.

venturi

5.

throttle valve

6.

choke.

19

FLOAT CHAMBER

1. The float and a needle valve system maintain a constant level of gasoline in the float chamber

2. Float chamber is vented either to the atmosphere or to the upstream side of the venturi

VENTURI

1. A tube of decreasing cross-section with a minimum area at the throat, and is so shaped that it

offers minimum resistance to the air flow.

2. As the air passes through the venturi the velocity increases

reaching a maximum at the venturi throat.

Correspondingly, the pressure decreases reaching a

minimum.

3. From the float chamber, the fuel is fed to a discharge jet,

the tip of which is located in the throat of the venturi

4. Because of the differential pressure between the float

chamber and the throat of the venturi, known as

carburetor depression, fuel is discharged into the air

stream

20

10

10/1/2015

CHOKE VALVE

1. A choke valve to control air supply in order to provide rich or lean mixture.

2. When the choke is partly closed, large pressure drop occurs at the venturi which inducts large

amount of fuel from the main nozzle and provides a very rich mixture.

THROTTLE VALVE

1. A throttle valve to supply varying quantity of the mixture at different load conditions.

FUEL NOZZLE

1. It is used to atomize and produce a spray of fuel

OPERATION

1. The fuel supply to the float chamber is controlled by the action of the float and the attached

fuel supply valve. during the intake stroke of the engine, the piston moves from TDC to BDC ,

and creates a vacuum in suction manifold.

2. due to fall in the pressure, the atmospheric air rushes into carburetor. Near the venturi, the

velocity increases, pressure decreases and the fuel comes out in the form of a jet. the fuel gets

mixed with air and goes into the cylinder

21

Because of the narrow passage at the venturi throat, the air velocity increases but its pressure

falls. this is known as carburetor depression at venturi throat.

This causes fuel to come out as jet in the form of a spray . This fuel spray vaporizes and mixes

with the incoming air, and the mixture goes into the cylinder through the throttle valve.

22

11

10/1/2015

BETWEEN THROTTLE VALVE AND ENGINE IS A PARTIAL VACUUM

CAUSED BY SUCTION

FROM ENGINE

AND FLOW RESTRICTION THROUGH THROTTLE VALVE

CARB.

AIR

FILTER

FUEL AND AIR ISVENTURI

MIXED

DUE TO LOWERED AIR

PRESSURE

INLET

MANIFOLD

CONTROLS

THROTTLE

MIXTURE FLOW

TO

VALVE

ENGINE

EXHAUST

MANIFOLD

ENGINE

ENGINE PULLS AIR

IN DURING

INDUCTION STROKE

SIMPLIFIED PISTON ENGINE FUEL SYSTEM

Drawback of simple carburetor

At a very low speed, the mixture supplied by a simple carburetor is so weak that it will not

ignite properly and for its enrichment, some arrangement in the carburetor is required to be

made.

The working of simple carburetor is affected by changes of atmospheric pressure.

If the setting is done in winter season, it will be found to give too rich mixture in the summer.

This is happened due to less density of air with the rise of temperature to a grater extent than

the density of fuel.

It gives the proper mixture at only one engine speed and load, therefore, suitable only for

engines running at constant speed.

increase or decrease ,the quantity of fuel issuing out will change and not match the velocity of

air flowing through the venturi and proper mixture is not take place.

In simple carburetor, the mixture is weakened when the throttle is suddenly opened because of

Inertia effect of the fuel which prevents the proper quantity of fuel from flowing immediately.

24

12

10/1/2015

Compensating Devices

An automobile on road has to run on different loads and speeds.

the tendency of a simple carburetor is to progressively richen the mixture as the throttle starts

opening. The main metering system alone will not be sufficient to take care of the needs of the

engine.

Therefore, certain compensating devices are usually added in the carburetor along with the

main metering system so as to supply a mixture with the required air/fuel ratio.

A number of compensating devices are in use. The important ones are

1. Air-bleed jet

2. Compensating jet

3. Emulsion tube

4. Back suction control mechanism

5. Auxiliary air valve

6. Auxiliary air port

25

Air bleed jet

it contains an air-bleed into the main nozzle.

An orifice restricts the flow of air through this bleed and therefore it is called restricted air-bleed

jet .

When the engine is not operating the main jet and the air bleed jet will be filled with fuel. When

the engine starts, initially the fuel starts coming through the main as well as the air bleed jet.

As the engine picks up, only air

starts coming through the air

bleed and mixes with fuel at

making a air fuel emulsion.

it is possible to maintain a fairly

uniform mixture ratio for the

entire power range of the

operation of an engine

26

13

10/1/2015

Compensating Jet

The principle of compensating jet device is to make the mixture leaner as the throttle opens

progressively.

In this method, in addition to the main jet, a compensating jet is incorporated.

The compensating jet is connected to the compensation well and it is vented to atmosphere

like the main float chamber.

The compensating well is supplied with fuel

from the main float chamber through a

restricting orifice. With the increase in airflow

rate, there is decrease of fuel level in the

compensating well, with the result that fuel

supply through the compensating jet decreases.

The compensating jet thus progressively makes

the mixture leaner as the main jet progressively

makes the mixture richer

27

Emulsion Tube

The mixture correction is attempted by air bleeding in modern carburetor. In one such

arrangement, the main metering jet is kept at a level of about 25 mm below the fuel level in the

float chamber. Therefore, it is also called submerged jet which is located at the bottom of a

well. The sides of the well have holes which communication with the atmosphere.

In the beginning the level of petrol in the float chamber

and the well is same. When the throttle is opened the

pressure at the venturi throat decreases and petrol is

drawn into the air stream. This results in progressively

uncovering the holes in the central tube leading to

increasing air-fuel ratios or decreasing richness of

mixture.

The air is drawn through these holes in the well, and the

fuel is emulsified and the pressure differential across

the column of fuel is not as high as that in simple

carburetor.

28

14

10/1/2015

Types of carburetors

There are 3 general types of carburetors depending on the direction

of flow of air.

Updraught, Downdraught, Cross- draught

a) Updraught

Air enters at the bottom and leaves at the top hence the direction

of the flow is upward.

The disadvantage is that it must lift the sprayed fuel droplet by air

friction.

b) Downdraught

To overcome the drawback of downdraught carburetor it is used.

It is placed at a level higher than the inlet manifold and air and

mixture generally follow a downward course. Here fuel does not

have to lifted by air friction but move into the cylinder by gravity

even if the air velocity is low.

29

c) Cross-draught

It consists of a horizontal mixing tube with a float

chamber on one side of it.it reduce the resistance to

flow by eliminating the right angle turn in the inlet

passage

Constant choke carburetor

1. The air and fuel passage areas are always maintained constant, but the pressure difference

which causes the flow of fuel and air vary as per demand.

2. Example are Solex and zenith carburetor.

Constant vacuum carburetor

1. Air and fuel areas are varied as per demand on the engine, while the vacuum is maintained to

be always same.

2. Example are S.U. and carter carburetors

30

15

10/1/2015

Multiple venturi carburetor

1. It has double or triple venturi.

2. Boost venturi is located concentrically with in the main venturi and discharge edge of the

boost venturi is located at the throat of the main venturi.

3. Only a fraction of the total air flows through it also pressure at the boost venturi exit equals the

pressure at the main venturi throat.

4. Better control over the fuel flow as high depression is created in the region of the fuel nozzle.

5. Excellent low speed full throttle operation is possible

6. More efficient mixing of the air fuel mixture

7. An annular blanket of air is formed .

8. The advantage of this carburetor are

Reducing condensation of the fuel

High speed system

31

Distribution

Problem of distribution comes in multi

cylinder engine, as the carburetor must

supply air-fuel mixture to each of several

cylinders.

It is impossible to obtain complete

atomization and vaporization of fuel by

carburetor.

Mixture passing through intake manifold generally contains a certain amount of liquid in

droplet form. these droplet has higher inertia than gaseous mixture. So whenever the direction

changed ,the droplets tend to continue in their original direction of movement.

In addition to fuel droplets, there exist a thin film of liquid fuel adhering to the inner walls of

intake manifold which causes uneven distribution.

A partial solution is to heat the mixture in intake manifold.

Another solution is to enrich the overall air fuel mixture so that leanest cylinder receives the

required A/F ratio. This causes, some of cylinder receive a richer A/F ratio than necessary

32

16

10/1/2015

Mixture preparation

The air/fuel mixture can be prepared by either a carburetor or a fuel injection system. In both

cases fuel will be present in the inlet manifold as, vapour, liquid droplets and a liquid film.

Although emissions legislation is now reducing the scope for using carburetor still their use is

still widespread. There are two main types of carburetor

1. Fixed jet (or fixed venturi)

2. variable jet (or variable venturi)

There are also two types of fuel injection system used on spark ignition engine

multi-point injection and single-point injection

The multi-point injection system employs Injectors usually mounted close to the inlet port(s)

of each

cylinder.

The single-point injection system look very much like a carburetor, and the throttle plate and

inlet manifold play an important part in mixture preparation.

Even with multipoint fuel injection systems, a liquid fuel film will develop on the walls of the

inlet manifold.

33

The carburetor (or fuel injection system) and manifold have to perform satisfactorily in both

steady-state and transient conditions.

When an engine is started, extra fuel floods into the inlet manifold. So the engine starts on a

very rich mixture and often there small ribs are provided to control the flow of liquid fuel.

In a simple branched manifold with a single-point injection system, the intersections will

often have sharp corners. The reason is the sharp corners help to break up the liquid film

flowing on the manifold walls.

With the use of multiple carburetor installations, the aerodynamic performance of the inlet

manifold improves.

34

17

10/1/2015

The engine should normally receive a lean mixture and at full throttle a rich mixture. If a lean

mixture were used at full throttle, this would reduce the power output and possible overheat

the exhaust valve because of the slower combustion.

When the engine is idling or operating at low load the low pressure in the inlet manifold

increases the exhaust, gas residuals in the cylinder, and consequently the carburetor has to

provide rich mixture.

The below picture shows the optimum air/fuel ratio changes for maximum power and

maximum economy with varying power output for particular engine at constant speed

35

When the throttle is opened, extra fuel is needed for several reasons .

1. The air flow into the engine increases, more rapidly than the fuel flow, since some fuel is in the

form of droplets and some is present as a film on the manifold walls.

2. for maximum power a rich mixture is needed.

3. when the throttle is opened the vaporized fuel will tend to condense

When the throttle opens the pressure in the manifold increases also the partial pressure of the

fuel vapour will increase. If the partial pressure of the fuel rises above its saturation pressure

then fuel will condense and extra fuel is injected to compensate.

When the throttle is suddenly closed, the reduced manifold pressure causes the fuel film to

evaporate . This can provide an over-rich mixture, and so lead to emissions of unburnt

hydrocarbons. This problem is over come by a spring-loaded over-run valve on the throttle

value plate that by-passes air into the manifold .

36

18

10/1/2015

Some times heated manifolds are used to reduce the liquid film and droplets. The manifold

can be heated by the engine coolant, or by conduction from the exhaust manifold. The

disadvantage of a heated inlet manifold is the ensuing reduction in volumetric efficiency

However, supplementary electrical heaters can be used during warm-up.

these heaters often use PTC (positive temperature coefficient) materials. so as to give

automatic temperature control. The heaters employ extended surfaces (usually spines), and arc

located in the manifold under the carburetor or a single-point fuel injector.

Despite the careful attention paid to manifold design, it is quite usual for carburetor to give 5

percent variation in mixture strength between cylinders, even for steady-state operation

37

Variable jet carburetor

The fuel is supplied to the jet from an integral float

chamber. This has a float-operated valve that

maintains a fuel level just below the level of the jet

If the throttle is opened, the air flow through the

venturi increases. This decreases the pressure

downstream of the venturi and causes the piston to

rise.

The piston will rise until the

pressure on the piston is balanced by its weight and

the force from the light spring .

The position of the tapered needle in the Jet or orifice

varies with piston position, thus controlling the

air/fuel mixture.

38

19

10/1/2015

The damper in the oil stop the piston oscillating when there is a change in load. A valve in the

damper causes a stronger damping action when the piston rises than when it falls.

When the throttle is opened the piston movement is delayed by the damper and this causes

fuel enrichment of the mixture .

For an incompressible fluid the flow through an orifice or venturi is proportional to the square

root of the pressure drop. As air is compressible its pressure drop will be greater than that

predicted by incompressible flow and this will cause extra fuel to flow.

For starting - extra fuel is provided by a lever that lowers the jet. A linkage and cam also

operate the throttle valve to raise the idling speed.

This simple type of carburetor is found on some small engines (such as motorcycles and

outboard motors) and does not have facilities like enrichment for acceleration.

39

Fixed jet carburetor

It resembles the simpler variable-jet

type carburetor

The components are

1. Air intake

2. Idling jet holder

3. Idling mixture tube

4. Needle valve

5. Float fulcrum povot

6. Float

7. Carburetor bowl

8. Idling jet

9. Main jet

10. Throttle butterfly

11. Choke tube

12. Emulsioning tube

13. Air bleed screw

40

20

10/1/2015

Fixed jet carburettor

This carburettor can only sense air flow rate without distinguishing between fully open throttle at a

slow engine speed or partially closed throttle at a higher engine speed. The fuel outlet is at the

smallest cross-sectional area so that the maximum velocity promotes break-up of the liquid jet and

mixing with the air; the minimum pressure also promotes fuel evaporation.

No fuel will flow until the pressure drop in the venturi overcomes the surface tension at the fuel outlet

and the head difference from the float chamber.

As the air flow increases to its maximum the velocity than at the venturi throat the velocity is

supersonic.

Fuel can be treated as incompressible,

and for flow through an orifice

41

air is compressible. Air mass flow rate for flow through the venturi

r is always less than unity, so the square bracket term in equation will always he less than unity.

This term accounts for the compressible nature of the flow. Thus, for a given mass now rate the

pressure drop will he greater than that predicted.

the pressure drop is larger than that predicted, then the fuel flow will also be larger than

expected and the air/fuel ratio will be richer as well.

21

10/1/2015

As the velocity increases in the venturi the pressure drops and density also reduces . The reduction in

density dictates a greater flow velocity than that predicted by incompressible theory , thus causing a

greater drop in pressure.

This effect becomes more pronounced as flow rates increase, until the speed in the throat is at the

speed of sound (Mach No. I) and the venturi is said to be choked.

To make allowance for the mixture becoming richer at larger flow rates a secondary flow of fuel added

where the flow of fuel reduces with increase air flow rate.

One of the method is using the compensating jet and emulsion tube

43

Emulsion tube

The emulsion tube has a series of holes along its length, and air bleed to the center. At low flow rates

the emulsion tube will be full of fuel. As the flow rate increases the fuel level will fall in the emulsion

tube, since air is drawn in through the bleed in addition to the fuel through the compensating jet.

The fuel level will be lower inside the emulsion tube than outside it ,

owing to the pressure drop associated with the air flowing through the

emulsion tube holes. As air emerges from the emulsion tube it will

evaporate the fuel and form a two-phase flow or emulsion. The

secondary flow will assist the break up of the main now.

44

22

10/1/2015

A rich mixture for full throttle operation can he provided by a variety of means, by either

sensing throttle position or manifold pressure. The mixture can he enriched by an extra jet (the

power jet) or the air supply to the emulsion system can he reduced .

Alternatively an air bleed controlled by manifold pressure can he used to dilute a normally rich

mixture.

45

Fuel injection

purpose of fuel injection is to obtain the maximum power output from all engine.

The pressure drop in a carburetor impairs the volumetric efficiency of all engine and reduces its

power output.

there are two types of fuel injection system

1.

Single point injector

2. Multipoint injector

46

23

10/1/2015

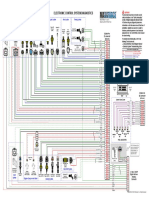

(Overview of Electronic Fuel Injection System)

47

Single point injection

The single-point fuel injection system is a

cheaper alternative to multi-point fuel

injection .

it can lead to 10 percent lower power output

than multipoint injection system.

the injector sprays fuel into a region at

atmospheric pressure, so a constant gauge

pressure is maintained by the fuel pressure

regulator.

Single-point injection uses a single injector at the throttle body (the same location as was

used by carburetors).

48

24

10/1/2015

Multipoint fuel injection

Multipoint (or port) fuel injection means there is a separate fuel injector for each cylinder that

shoots fuel into the intake port. it has the potential for a higher power output, since the

manifold can be design for optimum air flow.

In multi-point injection systems, the fuel pressure regulator has an inlet connection from the

fuel rail, and an outlet that lets fuel return to the tank. The fuelling level is controlled by the

fuel supply pressure and the duration of the injection pulses

control diaphragm and pressure spring

determines the exposed opening of the outlet, and

the amount of fuel that can return..

The pulse duration is in the range of 2-8 ms.

The ratio of maximum to minimum fuel flow rate

in S.I engine can be 50 or so.

At maximum power. the injectors will be open

almost continuously.

49

while at light load , then the injector duration will be an order of magnitude less (about 2 ms).

At part load operation, if injection occurs, when inlet valve is closed leads to lower emission of

Nox and unburnt hydrocarbons.

Advantages

1. Absence of Venturi No Restriction in Air Flow/Higher Vol. Eff./Torque/Power

2. Hot Spots for Preheating cold air eliminated/Denser air enters

3. Manifold Branch Pipes Not concerned with Mixture Preparation (MPI)

4. Better Acceleration Response (MPI)

5. Fuel Atomization Generally Improved.

6. Use of Greater Valve Overlap

7. Use of Sensors to Monitor Operating Parameters/Gives Accurate Matching of Air/fuel

Requirements: Improves Power, Reduces fuel consumption and Emissions

8. Precise in Metering Fuel in Ports

25

10/1/2015

Electronic control of engines

There are two approaches to electronic control of engines or engine management. The first is

to use a memory for storing the optimum values of variables. such as ignition timing and

mixture strength, for a set of discrete engine-operating conditions.

The second approach is to use an adaptive or self-tuning control system to continuously

optimize the engine at each operating point.

The advantages of an electronic engine management system are the greater control on

variables like ignition timing and mixture strength. this manifest reductions in both fuel

consumption and emissions.

51

Electronic unit injectors are mechanically pressurized and electronically controlled. This

means injection timing, duration, and metering are controlled by the ECM or electronic

governor. Electronic ignition and fuel injections is a logical step since the additional

computing power is very cheap.

injection systems unit functions

1. Time fuel delivery

2.

Pressurize the fuel for combustion

3. Atomize and distribute fuel in the combustion chamber

52

26

10/1/2015

When an engine is tested, the power output,

emissions, manifold depression, optimum

ignition timing and air/fuel mixture will all

be recorded for each throttle setting and

speed.

This information is then used by the engine

management system to control the ignition

timing, the exhaust gas recirculation valve,

and the fuel injection equipment.

The results are plotted against engine speed and bmep In a microprocessor controlled system.

the optimum operating conditions will be stored in ROM (Read Only Memory) for each

operating point.

In engine management system, some of the parameters can be measured like specific fuel

consumption , pressure drop across throttle ,wide open throttle etc.

53

Since the engine calibrated to operate with a particular schedule of air/fuel ratio, it is very

important to know the air flow rate.

This leads to two types of electronic fuel injection control, the major difference between the

two is the method used to determine the air flow rate. The first one is speed - density systems.

Different component of speeddensity MPFI system are

1. ECU

2. Fuel pressure regulator

3. Injection valve

4. Pressure senor

5. Temperature sensor

6. Start valve

7. Electronic fuel pump

8. Fuel filter

9. Throttle valve switch

53

27

10/1/2015

The speed-density systems measure the manifold pressure and air temperature, and then from

the engine speed/manifold pressure relationship (stored in memory), the engine management

system can deduce the air flow rate. This approach is less direct and less accurate .

Two common flow measuring techniques are

1. The use of a pivoted vane connected to a variable resistor, that is deflected by the air flow

2. The use of a hot wire anemometer

Here the appropriate coil excitation pulse duration or width is set by the electronic control unit

(ECU). In the speed-density system, the primary inputs to the ECU are the outputs from the

manifold pressure sensor, the engine speed sensor and the temperature sensors installed in the

intake manifold to monitor air temperature and engine block to monitor the water-jacket

temperature.

L-Jetronic (which uses an air-flow meter to measure air flow directly)

Advantage of direct flow measurement are

1. Dependence of volumetric efficiency on speed

and exhaust back pressure is automatically

accounted for.

2. Improved idling stability

3. Lack of sensitivity of the system to EGR since

the fresh air flow is measured

4. Less acceleration enrichment is required

K-jetronic

The K-Jetronic mechanical injection system

injects fuel continuously in front of the intake

valves with the spray directed toward the valves.

54

28

10/1/2015

Lambda censor

the sensor is used to decide whether the mixture is rich or weak.

The principle of operation is One electrode (platinum) is exposed to air. and the other electrode

is exposed to the exhaust gas. The difference in the partial pressures of oxygen leads to a flow of

electrons related to the difference in partial pressure.

55

IIT Kanpur

Kanpur, India (208016)

Diesel Fuel Injection

29

10/1/2015

Diesel Fuel Injection System

The fuel injection system injects fuel into the combustion chamber at high pressure, at the

right time and in the right quantity.

The main components of the fuel injection system are the injection pump that generates high

injection pressure and the injection nozzles that are linked to the injection pump via high

pressure delivery lines except with the unit injector system.

Injection Pump

High Pressure fuel

line

Injection nozzle

In most systems, the nozzle opens when the fuel pressure reaches a specific opening pressure

and closes when it drops below this pressure.

The nozzle is only controlled externally by an electronic controller in the common rail system.

Fuel Injection Processes

Requirements of fuel injection

Must provide accurate metering of fuel

Must provide accurate metering of fuel

Must provide accurate timing of injection

Must atomize the fuel into fine droplets

Must provide sufficient penetration into the cylinder

Must initiate mixing of fuel with air

Must accomplish complete injection within some milliseconds (depending

on engine speed)

Must be repeatable and durable

The injection systems are manufactured with great accuracy, especially the

parts that actually meter and inject the fuel. Some of the tolerances

between the moving parts are very small of the order of 1 micron. Such

closely fitting parts require special attention during manufacture and

hence the injection systems are costly.

30

10/1/2015

Requirements of a diesel injection system

1) The fuel should be introduced into the combustion chamber within a precisely defined period

of the cycle.

2) The amount of fuel injected per cycle should be metered very accurately. The clearances

between the working parts of a fuel pump as well as the size of the orifice are very small.

3) The rate of injection should be such that it results in the desired heat release pattern.

4) The quantities of the fuel metered should vary to meet changing speed and load requirements.

5) The injected fuel must be broken into very fine droplets, i.e., good atomization should be

obtained.

6) The spray pattern must be such that it results in rapid mixing of fuel and air.

7) The beginning and the end of injection should be sharp, i.e., there should not be any dribbling

or after injection.

8) The injection timing, if desired, should change to suit the engine speed and load requirements.

9) In the case of multi-cylinder engines, the distribution of the metered fuel among various

cylinders should be uniform.

10) The weight and the size of the fuel injection system must be minimum. It should not be costly

to manufacture and expensive to attend to, adjust or repair.

Functional Elements required in a fuel injection system

1. Pumping Elements : Its function is to move the fuel from the fuel tank to cylinder (plus

piping, etc.).

2. Metering Elements : The function of the Metering elements is to measure and supply the

fuel according to the requirement 0f speed and load.

3. Metering Controls : Its function is to adjust the rate of the metering elements for changes in

load and speed of the engine.

4. Distributing elements : Its function is to divide the metered fuel equally among the

cylinders.

5. Timing Controls : Its function is to adjust the start and the stop injection.

6. Mixing Elements : Its function is to atomize and distribute the fuel within the combustion

chamber.

31

10/1/2015

Fuel Injection Processes

General methods of fuel injection

Air Injection - compressed air is used to blast fuel into the cylinder.

Used by early diesel engines; not currently used

Traditional (jerk) pump systems positive displacement

Distributor-type fuel pumps (smaller engines)

Unit injectors pump/nozzle in same assembly

High-pressure, common rail uses separate high pressure pump to

supply common rail; mechanisms to open nozzles to control timing and

delivery

Many other types and variations of the above

Types of injection Systems

Direct injection systems can be divided into two types :

1) Air injection

2) Solid injection

Air Injection : The fuel is metered and pumped to the fuel valve by a camshaft driven fuel

pump. The fuel valve is opened by means of a mechanical linkage operated by the camshaft

which controls the timing of injection. The fuel valve is also connected to a high pressure air

line fed by a multi stage compressor, which supplies air at a pressure of about 60-70 bar. When

the fuel valve is opened the blast air sweeps the fuel along with it and a well atomised fuel

spray is sent to the combustion chamber.

Fig shows: Schematic

diagram of Air Injection

System.

7

32

10/1/2015

Advantages and Disadvantages of Air injection

The main advantage of the air injection system is the good atomisation obtained. A high mep

can be attained as rapid combustion results due to good mixing of fuel and air.

Heavy and viscous fuels, which are cheaper, can also be injected.

The fuel pump is required to develop only a small pressure.

Disadvantages :

It requires a high pressure multi stage compressor. The large number of parts, the inter-cooler,

etc., make the system complicated and expensive.

A separate mechanical linkage is required to time the operation of the fuel valve.

Due to the compressor and the linkage the bulk of the engine increases. This also results in

reduced bhp due to power loss in operating the compressor and the linkage.

The fuel in the combustion chamber burns very near to the injection nozzle which many times

leads to overheating and burning of the valve and its seat.

The fuel valve sealing requires considerable skill.

In case of sticking of the fuel valve, the system becomes quite dangerous due to the presence of

high pressure air.

Solid Injection

Injection of fuel directly into the combustion chamber without primary atomisation is

termed as solid injection. This is also called airless mechanical injection.

Every solid injection system must have :

A pressurising unit (the pump).

An atomising unit (the injector).

The different types of solid injection systems vary only in the manner of operation and control

of these two basic elements . The main types of modern fuel injection system are :

1. Individual pump and injector or jerk pump system.

2. Distributor system

3. Common rail system

4. Unit Injector and Unit Pump Systems

33

10/1/2015

Air/Fuel Ratio Curve

Rich areas are responsible

for sooty combustion. In

order to prevent the

formation of too many rich

areas, diesel engines run

with an overall excess air.

Lambda level at full load

may vary from 1.15 to 2.0

Around the outer zone of a

single liquid droplet (vapor

envelop), there are localized

lambda levels of .3 to 1.5,

known as combustible zone.

Progress of combustion in a direct-injection test engine

with a multi-hole nozzle.

34

10/1/2015

Development of Reacting Jet in Diesel Engine

Rapid Compression Machine

Optical CI Engine

Diesel Combustion Optimization

General Rules

Center fuel injector in bowl, and if possible, center bowl in piston

Trade off fuel injection pressure versus air motion to provide

required mixing while not over-mixing at light load

Supply sufficient air to meet peak torque smoke limits, and trade off

timing and compression ratio for best fuel economy

Optimize for optimum fuel economy within emission constraints

35

10/1/2015

Injection system pump distributor with Mechanical control

1. Fuel Tank

2. Fuel Filter

3. Distributor pump

4. injector

5. Return fuel

6. Rod glow plug (GSK)

7. Battery

8. Ignition switch

9. Preheat timer (GZS)

Bosch Fuel Injection pump (Construction)

L is the plunger which is driven by a cam and tappet mechanism at the bottom.

B is the barrel in which the plunger reciprocate .

There is a rectangular vertical groove in the

plunger which extends from top to another helical groove .

V is the delivery valve which lifts off its seat under the

liquid fuel pressure and the spring force.

The fuel pump is connected to the fuel atomiser

through the passage P.

SP and Y are the spill and supply ports respectively.

16

36

10/1/2015

Method of operation of plunger-and-barrel assembly

(stroke phase sequence)

Fuel-delivery control

37

10/1/2015

Working of Bosch Fuel Injection Pump (Working)

When the plunger is at its bottom stroke the ports SP and Y are uncovered .

Oil from low pressure pump after being filtered is forced into the barrel.

When the plunger moves up due to cam and tappet mechanism, a stage reaches when both the

ports SP and Y are closed and with the further upward movement of the plunger the fuel gets

compressed.

The high pressure thus developed lifts the delivery valve off its seats and fuel flows to atomiser

through the passage P.

With the furthur rise of the plunger, at a certain moment, the port SP is connected to the fuel

in the upper part of the plunger through the rectangular vertical groove by the helical groove ,

as a result of which a sudden drop in pressure occurs and the delivery valve falls back and

occupies its seat against the spring force.

The plunger is rotated by the rack R which is moved in or out by the governor. By changing the

angular position of the helical groove of the plunger relative to the supply port , the length of

the stroke during which the oil is delivered can be varied and thereby the quantity of fuel

delivered to the engine is also varied accordingly.

17

Distributor system

In this system, the fuel is metered at a central point , a pump pressurises, meters the fuel and

times the injection. From here the fuel is distributed to cylinders in correct firing order by cam

operated poppet valves which open to admit fuel to the nozzles.

Fig shows: The

Distributor System

10

38

10/1/2015

Distributor injection pump

It has only one pump unit that serves all the cylinders.

A vane pump forces the fuel into the high pressure chamber.

High pressure is generated by an axial piston or several radial pistons.

11

Common rail fuel system

12

39

10/1/2015

Common Rail System

The function of pressure generation and fuel injection are separated.

High pressure fuel pump delivers fuel to an accumulator, whose pressure is kept constant with

the help of a pressure regulating valve.

The supply pressure of the fuel is independent of the speed and hence it is not affected by the

fuel pump.

The main disadvantage is that in case of injection needle sticking in an open position an excess

amount of the fuel may be injected into cylinders.

13

Unit pump System

The nozzle and holder assembly is separated from the fuel injection pump and linked by a

short pressure line.

This separation of high pressure generation and nozzle and nozzle holder assembly allows for a

simpler attachment to the engine.

14

40

10/1/2015

Unit Injector system (UIS)

The fuel injector, pump and injection nozzle form a single unit.

It is designed to operate at higher injection pressure and the maximum injection pressure is

about 2200 bar.

15

Different types of fuel injection system

Throttle body or Single point injection : This is the simplest and the foremost fuel

injection system which was employed in cars as a replacement for carburetors. This employs

one or two fuel injectors in the throttle body which delivers the apt ratio of fuel air mixture to

every fuel intake manifold in the engine.

The drawback of this system is that the cylinders closest to the fuel injectors would get a

better mixture than the ones away from them.

The reason why Throttle body Injectors (TBI) replaced carburetors was because they would

easily adjust according to air density and altitude and were independent of the vacuum

manifold.

18

41

10/1/2015

Multi point fuel injection or Port injection

As the name suggests the multi point fuel injector denotes one fuel injector for every

cylinder-the fuel is misted at the intake manifold.

If an engine has six cylinders then it will have six fuel injectors- one for each cylinder located at

the intake port of the manifold.

Since the fuel is misted so closed to the intake manifold, it ensures complete amount is used

for combustion making it more efficient than the TBI, hence aiding in enhanced fuel economy

as well.

Multi port fuel injectors fire fuel all at the same time, with the fuel sitting at the intake

manifold till the time its needed. This happens for a split second, even during engine idling.

MPFI allows for more even fuel distribution.

19

Sequential fuel injection

Sequential fuel injection is a type of MPFI. While in an MPFI all the injectors are fired at the

same time, in SFI they are fired according to the intake timing of the respective cylinder i.e.

just before the intake valve of that particular cylinder opens.

This timing is matched according to the camshaft and though it may seem as a minor change it

helped improve efficiency and emissions.

DIRECT FUEL INJECTION :

Direct fuel injection is one of the most advanced fuel injection systems.

More commonly seen on diesel engines, this technology is now making way in petrol engines.

In a direct injection system, the fuel is injected directly in the combustion chamber i.e. the

cylinder .

The advantage of this type of system is that there is no wastage of fuel or any carbon deposit on

the intake valve.

The sensor monitor the exact amount of fuel needed by the vehicle and supply the same to the

chamber. In direct injection fuel metering is more precise than any other system.

20

42

10/1/2015

Types of Nozzles

Single hole nozzle

Multi-hole nozzle

Pintle nozzle

Pintaux nozzle

SINGLE HOLE NOZZLE : They are used in open combustion chambers. The size of the hole is

usually larger than 0.2 mm. The hole may be drilled centrally or at an angle to the centre line of

the nozzle.

Fig shows : Single hole

nozzle

21

The main disadvantages of the single hole nozzle are :

1) Since whole of the fuel passes through a single hole and also because the relative fuel velocity

required is high, very high injection pressure is needed.

2) Single hole nozzle has a tendency to dribble which reduces the pressure drop available across

the orifice resulting in a weak injection at the start of injection and dribbling at the end of

injection.

3) The spray angle is very narrow (usually about 15 degree). This doe not facilitate good mixing

unless higher air velocities are provided.

MULTI HOLE NOZZLE

These are needed in order to mix the fuel properly with the slow air movement available with

many open combustion chambers.

The number of holes varies from 4 to 18

and the size from 1.5 mm to 0.35 mm.

Usually the holes are drilled symmetrically but many times

they are non- symmetrical to meet certain specific

requirements of the combustion chamber.

22

43

10/1/2015

Pintle Nozzle (Design and Method of operation)

Inside the nozzle body is the nozzle needle. It is pressed downwards by the force (Ff ) exerted

by the spring and the pressure pin in the nozzle holder so that it seals off the nozzle from the

combustion chamber. As the pressure of the fuel in the pressure chamber increases, it acts on

the pressure shoulder and forces the nozzle needle upwards (force FD ) . The pintle lifts away

from the injector orifice and opens the way for the fuel to pass through into the combustion

chamber.

23

Pintle Nozzle continued...

The nozzle opens, opening pressure is 110..170 bar. When the pressure drops the nozzle closes

again. Opening and closing of the nozzle is thus controlled by the pressure inside the nozzle.

Pintle nozzles are used on Indirect injection engines i.e., engines that have pre-chambers or

whirl chambers.

Pintle nozzles are not suitable for the direct injection engines as the peak pressures inside the

combustion chamber would open the nozzle.

The following types of pintle nozzle are available :

Standard pintle nozzle.

Throttling pintle nozzles.

Flatted pintle nozzles.

24

44

10/1/2015

Pintaux Nozzle

This type of nozzle is used to improve cold starting performance without any detrimental effect

on efficiency.

The is a development of the pintle nozzle and has an auxiliary hole drilled in the nozzle body

which allows for a small amount of fuel injection in the upstream direction (Pilot injection) at

a time slightly in advance of the main downstream injection.

The main disadvantage of the pintaux nozzle is the tendency for the side hole to choke. The

injection characterisitcs of the nozzle is even poorer than multi-hole nozzle.

Fig shows :

Pintaux nozzle

25

Injection rate characteristics of different nozzles

In order to avoid knocking in the engine it is always desirable to supply less quantity of fuel .

The characteristics of multi hole, pintle and pintaux nozzles are shown respectively :

It is obvious from the figure the pintle nozzle gives desired characteristics as (dmf/d) which is

smaller at the beginning compared with multi hole nozzles.

The characterisitcs of pintaux nozzle is totally different because of fuel supply through

auxiliary and main orifices.

Fig shows : Injection rate characteristics of different nozzles

26

45

10/1/2015

Overview of Diesel Fuel Injection Systems

Objectives of the Injection System:

The injection system of the compression ignition engine should fulfill the

following objectives consistently and precisely:

o

Meter the appropriate quantity of fuel, as demanded by the speed of, and

the load on, the engine at the given time.

Distribute the metered fuel equally among cylinders in a multi-cylinder

engine.

Inject the fuel at the correct time (with respect to crank angle) in the

cycle.

Inject the fuel at the correct rate (per unit time or crank angle degree).

Inject the fuel with the correct spray pattern and sufficient atomization as

demanded by the design of the combustion chamber, to provide proper

penetration also.

Begin and end injection sharply without dribbling or after injection.

46

10/1/2015

Diesel Fuel Injection System

The fuel injection system injects fuel into the combustion chamber at

high pressure, at the right time, & in the right quantity.

The main components of the fuel injection system are the injection pump

that generates high pressure, & the injection nozzles that are linked to

the injection pump via high pressure delivery lines- except with the Unit

Injector System.

In most systems, the nozzle opens when the fuel pressure reaches a

specific opening pressure, & closes when it drops below this pressure.

The nozzle is only controlled externally by an electronic controller in the

common rail system.

Fuel Injection Systems Classification

o

There are two main classifications for fuel-injection systems,

namely

1. Air Injection which had become obsolete but now some

interest has been shown by researchers (however very high

pressure is required for air) and

2. Solid (or airless) Injection systems.

47

10/1/2015

The airless, mechanical, or solid injection systems consist

of three types

Individual pump system: This consists of a separate metering and

compression pump for each cylinder

Distribution system: This consists of a single pump for compressing the

fuel (which may also meter), plus a delivery device for distributing the

fuel to the cylinders (which may also meter).

Common rail system: A single pump for compressing the fuel, plus a

metering element for each cylinder

In-line Fuel Injection Pumps

In-line fuel injection pumps

have a separate pump element

consisting of a barrel & plunger

for each engine cylinder.

When the helix of the plunger

clears the inlet port, fuel can

escape & pressure is lost. The

nozzle closes & fuel injection

ceases.

The piston travel between

opening & closing the inlet

opening is the effective stroke.

The pump plunger is turned by

a control rack to control the

injected fuel quantity as a

factor of engine speed & load.

This changes the position of the

helix relative to the inlet

opening, & thus the effective

stroke.

48

10/1/2015

Inline Fuel Pump

Examples of in-line fuel injection pumps

49

10/1/2015

Distributor Injection Pump

Distributor injection pumps have only one pump unit that

cylinders.

serves all

A vane pump forces the fuel into the high pressure chamber.

High pressure is generated by an axial piston or several radial pistons.

Distributor Pump

50

10/1/2015

Distributor Pump

Radial Distributor Pump

Axial-piston distributor pump

Unit Injector System

The fuel injector, pump &

injection nozzle form a single unit.

The UIS can therefore be designed

to operate at higher injection

pressures.

The maximum injection pressure

is about 2200 bar.

51

10/1/2015

Diesel Engine Piezo unit injectors

Unit Pump System

The nozzle & holder assembly

is separated from the fuel

injection pump & linked by a

short high pressure line.

This

separation

of

high

pressure generation & nozzle &

nozzle holder assembly allows

for a simpler attachment to the

engine.

52

10/1/2015

Common Rail System

The

function

of

pressure

generation & fuel injection are

separated.

This takes place by means of an

accumulator volume composed of

the CR & the injectors.

Injection pressure is independent

of engine speed or injected fuel

quantity.

Presently, pressures range up to

1800 bar.

Common rail fuel system

53

10/1/2015

Evolution: Diesel Engine Patented in 1893

Four stroke Compression Ignition engine

Rudolph Diesels Patent

First Diesel Engine

Rudolf Diesel

Rudolf Diesel (1853-1913),

born in Paris, decided at 14 that

he wanted to become an

engineer.

Diesel developed his engine

initially on paper, based on

Carnots models

He completed his theoretical

studies in 1890 & in Feb 1892

applied for a patent on New

rational thermal engines.

In Feb 1893, he received

patent document DRP 67207

entitled Operating Process &

Type

of

Construction

for

combustion engines.

54

10/1/2015

First Design of Diesel Engine

New engine initially only existed on paper.

The required compression pressures of 250

bar were beyond technical feasibility

In 1893, MAN began to build the first uncooled test engine by an agreement with Diesel,

reducing max. pressure from 250 to 90 bar &

then later to 30 bar

In 1897, in cooperation with MAN, Diesel

built the first working prototype of a

combustion engine to be run on heavy fuel oil

with a high level efficiency of 26.2%

Bosch Diesel Fuel Injection

In 1886, Robert Bosch opened a workshop

for light & electrical engineering in

Stuttgart.

In 1922, Robert Bosch turned his attention

to

the

diesel

engine

&

started

manufacturing fuel-injection pumps &

nozzles.

The required injection pressures were at

that time already over 100 bar &

guaranteed over 2,000 operating hours.

55

10/1/2015

Series Production By Bosch

In 1925, Bosch concluded

contracts with Acro AG to

utilize the Acro patents on a

diesel engine system with

air

chamber

&

the

associated injection pump &

nozzle.

The first specimens of the

Bosch fuel injection pump

really suitable for volume

production

were

manufactured

in

April 1927.

Diesel Engine Facts

The diesel engine is a type of internal combustion engine (more

specifically, a compression ignition engine) in which the fuel is

ignited by suddenly being exposed to the high temperature and

pressure compressed gas containing oxygen (usually

atmospheric air), [rather than a separate source of ignition

energy (such as a spark plug), as is the case in the petrol

engine].

Initial CI engines were large and slow.

Heavy distillate petroleum was forced into the cylinder using

compressed air.

Robert Bosch began producing injection systems in 1927.

In very cold weather, diesel fuel thickens and increases in

viscosity and forms wax crystals or a gel. This can make it

difficult for the fuel injector to get fuel into the cylinder in an

effective manner, making cold weather starts difficult at times,

though recent advances in diesel fuel technology have made

these difficulties rare.

56

10/1/2015

Diesel Engine Facts

A common method to electrically heat the fuel filter and fuel lines.

Other engines utilize small electric heaters called glow plugs inside

the cylinder to warm the cylinders prior to starting. A small number

use resistive grid heaters in the intake manifold to warm the inlet

air until the engine reaches operating temperature.

A vital component of any diesel engine system is the governor, which

limits the speed of the engine by controlling the rate of fuel delivery.

Older governors were driven by a gear system from the engine (and

thus supplied fuel only linearly with engine speed.)

Modern electronically-controlled engines achieve this through the

electronic control module (ECM) or electronic control unit (ECU).

Diesel Engine Facts

The addition of a turbocharger or supercharger (boost

pressures can be higher on diesels) to the engine greatly

assists in increasing fuel economy and power output.

The higher compression ratio allows a diesel engine to be

more efficient than a comparable spark ignition engine,

although the calorific value of the fuel is slightly lower at

45.3 MJ/kg to gasoline at 43.8 MJ/kg.

57

10/1/2015

Diesel Engines - Applications

High-Speed (approximately 1200 rpm and greater) engines are

used to power lorries (trucks), buses, tractors, cars, yachts,

compressors, pumps and small generators.

Large electrical generators are driven by medium speed engines,

(approx. 300 to 1200 rpm) optimized to run at a set speed and

provide a rapid response to load changes.

The largest diesel engines are used to power ships. These

engines have power outputs over 80,000 kW, turn at about 60 to

100 rpm, and are up to 15 m tall. They often run on cheap lowgrade fuel, which require extra heat treatment in the ship for

tanking and before injection due to their low volatility.

LargeMarineEngines

58

10/1/2015

LargeMarineEngines

SULZER RTA96

Turbocharged two-stroke inline diesel engine

6 through 14 cylinder versions

38" bore and the 98 stroke

Displacement volume 1820 liters

7780 horsepower per cylinder

Some facts about the 14 cylinder version:

Total engine weight: 2300 tons

Length: 28 m, Height: 14 m

Maximum power: 108,920 HP at 102 rpm

Thermal efficiency: more than 50%

SULZERRTA96

59

10/1/2015

SULZERRTA96

SULZERRTA96

60

10/1/2015

SULZERRTA96

Basic Principles of Diesel Engine

Stroke 1:

Stroke 2:

Stroke 3:

Air is introduced into cylinder through intake valve

Air is compressed

Combustion (roughly constant pressure) occurs and

product gases expand doing work

Product gases pushed out of the cylinder through the

exhaust valve

Stroke 4:

A

Fuel Injector

I

R

Air

Intake

Stroke

Compression

Stroke

Combustion

Products

Power

Stroke

Exhaust

Stroke

61

10/1/2015

Diesel Cycle

Isentropic

Compression(1-2)

Isochoric heat

propagation(2-3)

Isobaric heat

propagation(3-3)

Isentropic Expansion(34)

Isochoric heat

dissipation(4-1)

Real Process

To determine the work done in the real process, the pressure curve in

the cylinder is measured & presented in the p-v chart.

The area of upper curve corresponds to the work present at the piston.

For turbocharged engine the gas exchange area (Wg) has to be added to

this since the compressed air delivered by the turbocharger, also helps to

press the piston downwards on the induction stroke.

62

10/1/2015

Method of Operation

Piston performs up & down

movements & hence the name

reciprocating piston engine

The connecting rod converts

the linear reciprocating action

of the piston into rotational

movement of the crankshaft.

A flywheel connected to the end

of the crankshaft helps to

maintain

continuous

crankshaft rotation & reduce

unevenness of rotation caused

by the periodic nature of fuel

combustion in the individual

cylinders.

63

10/1/2015

Temperature Rise During Compression

In the process of compression

the air heats up to temperatures

as high as 900C.

When the compression stroke is

almost complete, the fuel

injection system injects fuel at

high pressure (as much as 2000

bar in modern engines) into the

hot compressed air.

When the piston reaches TDC,

the cylinder capacity is at its

smallest (compression volume, Vc)

Four-Stroke CI Engine

Cylinder

volume

Fuel mass

flow rate

Cylinder

pressure

SOI start of injection

EOI end of injection

SOC start of combustion

EOC end of combustion

Fuel mass

burn rate

64

10/1/2015

Valve Timing

Inlet valve is open before

TDC

so that valve is fully open

when piston reaches TDC

Inlet valve is closed few

degrees after BDC to get the

ramming effect

Exhaust valve is opened

before BDC during expansion

stroke to flush the hot exhaust

gases sue to pressure difference

Exhaust valve is closed some

degrees after TDC, this causes

valve overlap, helps to flush out

the remaining exhaust & cool

the cylinders.

Torque & power Output

Torque increases with engine

speed until maximum torque is

reached.

As the engine speed is

increases beyond certain point

the torque begins to fall again

The power generated by the

engine depends upon torque &

engine speed

P=2..n.M

Engine

power

output

increases with engine speed

until it reaches its maximum

level, or rated power Prated at the

engines rated speed, nrated.

65

10/1/2015

Starting The Engine

Starting an engine involves: cranking, ignition & running up to self

sustained operation.

The minimum ignition temperature required for diesel fuel is

approx. 250C.

This temperature must also be reached in poor conditions.

Low engine speeds, low outside temperatures, & a cold engine lead

to relatively low final compression temperatures.

Starting The Engine

The lower the engine speed, the

lower the ultimate pressure at the

end of compression stroke

&

accordingly

the

ultimate

temperature because of leakage

losses through the piston ring gaps.

Due to heat loss during

compression, maximum compression

temperature is reached a few

degrees bTDC .

Another means of assisted

starting is to inject an excess

amount of fuel for starting to

compensate for condensation &

leakage losses in the cold engine, &

to increase engine torque in the

running up phase.

66

10/1/2015

Temperature Progression of Glow Plugs

To raise the temperature during starting fuel heating or glow

plugs may be used.

Glow plugs of the latest generation require a preheating

time of only a few seconds, thus allowing a rapid start.

The lower post -glow temperature also permits longer postglow times.

This reduces not only harmful pollutant emissions but also

noise levels during the engine's warm-up period.

Operating Statuses

Starting: Includes cranking, ignition, & running up.

No Load: All speed ranges without torque.

Idle: Lowest no load speed

Full Load: Wide open throttle (WOT); accelerator pedal is fully depressed.

Part Load: No load to full load (zero to maximum possible torque)

Over Run: External force is acting through the drive train.

Steady-state operation: Torque delivered by the engine equals torque required by

the accelerator pedal position.

Non-steady-state operation: Engines torque output does not equals the required

output.

67

10/1/2015

Operating Conditions

The fuel-injection system must assume the functions of metering

the fuel & distributing it evenly over the entire charge. For any

combination of engine operating parameters fuel injection system

must deliver:

The correct amount of fuel

At the correct time.

At the correct pressure.

At the correct position.

Operating Conditions

Metering the fuel quantity also requires taking account of

operating limits such as:

Smoke limit.

Combustion pressure limits.

Exhaust-gas temperature limits.

Engine speed limits.

Altitude limits.

Turbocharger/supercharger pressure limits.

68

10/1/2015

27

69

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Ans. V (0.0774, 0, 0)Document3 paginiAns. V (0.0774, 0, 0)Shaharukh KhanÎncă nu există evaluări

- HW 1 2018Document2 paginiHW 1 2018Shaharukh KhanÎncă nu există evaluări

- List of Students in CourseDocument1 paginăList of Students in CourseShaharukh KhanÎncă nu există evaluări

- 2 - Conduction - Thermal ConductivityDocument16 pagini2 - Conduction - Thermal ConductivityShaharukh KhanÎncă nu există evaluări

- State of The Economy: An OverviewDocument30 paginiState of The Economy: An OverviewsujoyludÎncă nu există evaluări

- External Sector: Lobal Conomic NvironmentDocument25 paginiExternal Sector: Lobal Conomic NvironmentShaharukh KhanÎncă nu există evaluări

- Ae641 Problems Set 1 2016Document1 paginăAe641 Problems Set 1 2016Shaharukh KhanÎncă nu există evaluări

- Virtual Work (Energy Principles)Document16 paginiVirtual Work (Energy Principles)Shaharukh KhanÎncă nu există evaluări

- Pressure DistributionDocument3 paginiPressure DistributionShaharukh KhanÎncă nu există evaluări

- Research ProposalDocument1 paginăResearch ProposalShaharukh KhanÎncă nu există evaluări

- 6 - Air Breathing Engines - TurbojetDocument10 pagini6 - Air Breathing Engines - TurbojetShaharukh KhanÎncă nu există evaluări

- Stresses Due To Bending ShearDocument25 paginiStresses Due To Bending ShearShaharukh KhanÎncă nu există evaluări

- Sectional Properties1Document18 paginiSectional Properties1Shaharukh KhanÎncă nu există evaluări

- tableGasDynamics 2Document616 paginitableGasDynamics 2rockon605Încă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)