Documente Academic

Documente Profesional

Documente Cultură

4000 Winch Nar

Încărcat de

JITENDRA KUMAR SHARMADescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

4000 Winch Nar

Încărcat de

JITENDRA KUMAR SHARMADrepturi de autor:

Formate disponibile

4000# NAR: 99900556: 20111213

INSTALLATION AND REPAIR MANUAL

4000 LB WINCH

CRANES USED ON:

421

425

4800 SERIES

5200 SERIES

5800 SERIES

780

880

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

TEL: 641-923-3711

MANUAL PART NUMBER 99900556

Iowa Mold Tooling Co., Inc. is an Oshkosh Corporation company.

4000# NAR:

--------

REVISIONS LIST

DATE

20021007

20030718

20031105

20070323

LOCATION

Page 6

Page 9

Page 9

COVER

DESCRIPTION OF CHANGE

Item #12 is #14

Item #20, 70056067, replaced by 70056364. (Same part)

Added gasket kit numbers.

Updated ownership statement.

4000# NAR:

20000801

INSTALLATION

GENERAL INSTALLATION

These instructions are intended for installation of a

4000 lb (1814 kg) capacity winch on the 421, 425,

4800 Series, 5200 Series, 5800 Series, 780 and 880

Cranes. The 4800, 5200 & 5800 Series Cranes, 780

& 880 are a bolt-on application and the necessary

mounting brackets are part of a standard outer boom

assembly. The 425/421 mounting is a weld-on

application and it is necessary to weld a mounting

plate to the underside of the outer boom.

CONTROLS

4800/5200/5800/780/880 - Install the control handles

and cross links using the existing crane controls as a

guide. Do not remove the plugs from the valvebank.

CAUTION

IF THE PLUGS ARE REMOVED AND THE WINCH

CONTROLS ARE ACTUATED WHILE THE PTO IS

ENGAGED AND THE ENGINE RUNNING, HIGHPRESSURE HYDRAULIC OIL WILL BE DISCHARGED

FROM THOSE PORTS.

425/421 CRANE - An appropriate valvebank and

control kit will be required - see the crane manual for

reference.

WINCH

Extend and lower the stabilizers. Position the crane

with the extension boom retracted, the inner boom

horizontal and the outer boom vertical.

1. 4800/5200/5800/780/880 - Install the winch

mounting bracket to the outer boom as shown in the

parts drawing. The 3/4" washers are used as shims

and it may not be necessary to use all of them.

Tighten the lock nut until the mounting bolt is held

securely.

CAUTION

DO NOT TIGHTEN THE NUT TO THE VALUE SHOWN IN

THE TORQUE DATA CHART IN THE CRANE MANUAL.

FAILURE TO COMPLY WITH THIS INSTRUCTION MAY

RESULT IN DAMAGE TO THE CRANE.

1a. 425/421 CRANES - It will be necessary to

remove the lugs from beneath the outer boom. Make

certain the surface is flat and does not interfere with

the winch mounting plate. Position and weld the

mounting plate to the outer boom per IMT drawing

99900070.

2. Install the studs in the winch mounting bracket

using a vise grip or channel lock pliers. Be careful

not to damage the threads. Use Loctite to secure the

studs.

3. Slide the spacers over the studs.

4. Remove the set screw securing the winch end

housing to the winch drum shaft. Slide the end

housing and drum off the shaft.

5. Slide the winch over the studs and up against the

spacers. Install the nuts and tighten to 64 ft-lbs (8.8

kg-m).

6. Slide one (1) 2-1/2" washer over the shaft and up

against the gear case.

7. Slide the drum over the shaft and then two (2)

more washers, if required.

8. Slide the end housing over the shaft and bolt it to

the winch mounting bracket with the two (2) socket

head screws. Torque to 64 ft-lbs (8.8 kg-m).

9. Tighten the set screw in the end housing.

10. Fill the winch with 2 pints of Bloom N0. 601TransWorm Gear Lube (IMTPart Number 89086059).

HYDRAULICS

1. Remove the plugs from the ports in the

valvebank section. Install the elbows in the ports.

2. Install the fittings on the winch as shown in the

installation parts list. The check valve is installed on

the side of the motor used for lifting the load.

3. Route the hydraulic hoses from the valve section

up through the mast and inner boom.

4. Connect the hoses to the valvebank ports and

the winch ports.

5. Start the engine, run the crane through all of its

motions while checking hose clearances. Once the

hose clearances have been checked and there is

sufficient clearance, install the hose clamp for the

winch hoses on the side of the outer boom.

6. Test operate the winch. Run the winch at least

five revolutions in each direction. Check for signs of

hydraulic leakage.

4000# NAR: 99900556: 19940531

ROPE AND HOOK KIT

1. If the winch was shipped without the wire rope

wrapped around the winch drum, install the wire rope

by operating the winch to wind the rope on the drum.

Notice that the wire rope goes over the top of the

drum.

CAUTION

KEEP THE WIRE ROPE AS CLEAN AS POSSIBLE WHILE

WINDING IT ONTO THE DRUM. WHILE INST ALLING

THE WIRE ROPE, HAVE SOMEONE HELP BY WIPING

DOWN THE ROPE WITH OIL AS IT IS BEING WOUND

ONTO THE DRUM.

2. Install the sheave and snatch block on the tip of

the extension boom. Notice how the dead end of the

rope is doubled back on itself and a cable clamp

installed.

CAUTION

DO NOT INSTALL THE CABLE CLAMP COMPLETELY

AROUND THE DEAD AND THE LIVE ENDS OF THE

ROPE. CLAMPING THE LIVE END OFTHE ROPE WILL

WEAKEN THE ROPE AND CAUSE PREMATURE ROPE

FAILURE.

TEST

1. Test operate the winch by lifting the maximum

rated load.

WARNING

BE SURE YOU DO NOT EXCEED THE RATED LOAD OF

THE WINCH OR CRANE AND DO NOT CAUSE

CHASSIS INSTABILITY. FAILURE TO COMPLY MAY

RESULT IN STRUCTURAL FAILURE AND CAUSE AN

INJURY.

2. Check the winch mounting bolts for tightness.

Check the winch and hydraulic hoses for leaks.

REPAIR

DISASSEMBLY

To disassemble the winch:

1. Drain the oil from the gear case.

2. Position the crane with the inner boom horizontal,

the outer boom vertical and the extension boom(s)

extended to a point where the boom(s) reach the

ground. Remove the winch from the crane.

3. Wash the exterior of the winch with warm, soapy

water and blow dry with compressed air.

4. Loosen the set screw securing the end housing

bearing to the shaft. Slide the end housing off the

shaft.

5. Pull the drum off the shaft. It may be necessary

to use either a wheel puller or a hydraulic press to

remove the drum from the shaft if corrosion or galling

has occurred.

6. Slide the washer off the drum shaft.

7. Remove the hydraulic motor and spacer.

8. Remove the bearing cup, cone and worm. It may

be necessary to use the motor to remove the bearing.

Slide the motor shaft into the end of the worm shaft.

Have another person keep the drum shaft from

turning and rotate the entire motor. This may force

the worm to turn, which will push out the bearing.

9. Remove the six screws securing the gear case

and remove the cover.

10. Use a bearing puller to remove the bearings from

the cover.

11. Slide the worm gear and shaft assembly out of

the gear case. Be careful not to damage the oil seal

unless you plan to replace the seal.

12. Pull the other set of bearings from the gear case.

13. Clean all parts in a trichloroethane solvent bath.

Blow dry with compressed air.

WARNING

USE TRICHLOROETHANE IN A WELL-VENTILATED

AREA. INCOORDINATION OR IMPAIRED JUDGEMENT

MAY OCCUR AT VAPOR EXPOSURES FROM 500-1000

PPM. DIZZINESS, DROWSINESS, LOSS OF

CONSCIOUSNESS AND EVEN DEATH CAN OCCUR

AT INCREASING LEVELS OF EXPOSURE. WHEN

INVOLVED IN A FIRE, TRICHLOROETHANE EMITS

HIGHLY TOXIC AND IRRITATING FUMES.

4000# NAR: 99900556: 19940531

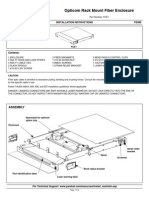

ASSEMBLY

To assemble the winch:

1. Place all bearings in a clean oil bath of SAE 30

oil.

2. If the oil seal is being replaced, press a new seal

into position.

3. If the worm gear is being replaced and has been

removed from the drum shaft, care should be taken to

press the gear onto the shaft squarely. Locate gear in

the same position as the gear that was removed. It

should be centered on keys. Tighten the set screw

securing the gear.

4. Press all of the new bearings into the gear case

and gear case cover.

5. Inspect the drum shaft for scratches, nicks or

gouges. Dress any imperfections with #400 emery

paper. Lightly lubricate the drum shaft and ID of the

oil seal with SAE 30 oil. Carefully slide the drum

shaft through the oil seal.

6. Bolt the cover to the gear case without gaskets.

Snug the screws lightly and evenly. This serves two

purposes: first, it preloads the bearings and secondly,

it permits measuring the clearance between the cover

and case to determine which gaskets are needed for

proper clearance. Measure the clearance between

the cover and case. Remove the cover and install

the necessary gaskets to obtain a thickness that is

.003" to .005" less than the measurement. There are

three thicknesses of gaskets: .002", .005" and .010".

Use in any combination to obtain the desired

thickness.

7. Inspect the worm carefully for any damage.

Dress any nicks or gouges that may have occurred

with #400 emery paper. Install the worm with

bearings and spacer.

8. Install the motor without gaskets. Snug the

screws lightly and evenly. Measure the clearance

between the motor and case. Remove the motor and

install the necessary gaskets. There are three

different thicknesses of gaskets: .002", .005" and

.010". Use in any combination to obtain a thickness

that is .003" to .005" less than the measurement

obtained above.

9. Fill the winch with 2 pints of Bloom No. 601TransWorm Gear Lube (IMT Part Number 89086059).

10. Install the winch on the crane and test operate.

MAINTENANCE

GEAR CASE OIL

Every six months, drain and refill the winch oil. Use

Bloom N0. 601 Trans-Worm Gear Lube (IMTPart

Number 89086059).

WIRE ROPE INSPECTION

Refer to the IMT Operators Crane Safety Manual for

instructions.

4000# NAR: 31705081.01: 20021007

WELD-ON WINCH KIT-425 CRANE

(31705081)

1.

2.

3.

4.

5.

60010868

60010869

60101420

71057607

72053497

6. 72532670

7. 72053611

8. 72053744

9. 72053629

10. 72060797

11. 72062004

13. 72063053

14. 72533342

SPACER (PART OF 19)

STUD 1/2-13X4-1/2 (PART OF 19)

U-TUBE (PART OF 19)

WINCH 4000LB (PART OF 19)

ADAPTER 1/2MPT 3/4MJIC

(PART OF 19)

ELBOW #8MJIC #8FJIC 45

(PART OF 19)

TEE 3/8NPT (PART OF 19)

ADAPTER #10MSTR 1/2FPT

(PART OF 19)

ADAPTER 1/2MPT 3/8MPT

(PART OF 19)

CAP SCR 1/2-13X2-1/2 SH

(PART OF 19)

NUT 1/2-13 HEX (PART OF 19)

WASHER 1/2 LOCK (PART OF 19)

FLRLS #4TUBE 1/4MPT 45

2REF

4REF

1REF

1REF

1REF

2REF

1REF

2REF

1REF

2REF

4REF

6REF

2REF

15. 72532138

16. 73054006

19. 31904001

20.

21.

22.

23.

24.

25.

26.

27.

60010383

60107648

70392861

70392863

70392868

72060048

72062103

99900070

REDUCER BUSHING 3/8-1/4NPT

(PART OF 19)

CHECK VALVE-PILOT OP

(PART OF 19)

WINCH KIT 4000# WELD-ON

(INCL:1-16)

WINCH MTG PLATE

HOSE CLAMP

DECAL-DANGER 2-BLOCKING

DECAL-DANGER HOISTING PERS

DECAL-DANGER LOADLINE

CAP SCR 3/8-16X1-1/2 HHGR5

NUT 3/8-16 LOCK

BOOM MODIFICATION DRAWING

1REF

1REF

1

1

1

2

4

1

1

1

1

NOTES

1. REMOVE LUGS FROM BO TTOM OF BOOM BEFORE

INSTALLING PLATE.

2. REFER TO DRAWING 99900070 FOR COMPLETE

DIMENSIONAL REFERENCE.

4000# NAR: 31705009.01: 19940531

BOLT-ON WINCH KIT-4800 SERIES & 780

CRANE W/MNL CONTROLS (31705009)

2. 52703575 MTG BRACKET (PART OF 31)

3. 72060199 CAP SCR 3/4-10X9 HHGR5

(PART OF 31)

4. 72062114 NUT 3/4-10 LOCK (P ART OF 31)

5. 60010869 STUD 1/2-13X4-1/2 (PART OF 31)

6. 60010868 SPACER (PART OF 31)

7. 71057607 WINCH (PART OF 31) (INCL:30)

8. 72063053 WASHER 1/2 LOCK (PART OF 31)

9. 72060797 CAP SCR 1/2-13X 2-1/2 SH

(PART OF 31)

10. 72062004 NUT 1/2-13 (PART OF 31)

11. 71039096 KNOB

12. 72066168 COTTER PIN 3/32X3/4

13. 72661169 PIN 5/16X3/4

14. 72066338 CLEVIS PIN 5/16X1

15. 72053497 ADAPTER 1/2MPT 3/4MJIC

(PART OF 31)

16. 52704745 CONTROL ROD-M

17. 52704744 CONTROL ROD-F

18. 70029451 CONTROL HANDLE

1REF

2REF

2REF

4REF

2REF

1REF

6REF

2REF

4REF

2

3

1

2

2REF

2

1

2

19.

20.

21.

23.

24.

51712717

72053760

72532700

73054006

72532670

25. 72053744

26. 72053629

27. 60101420

28. 72532138

29. 72063030

30. 72060596

31. 31904002

32. 72533342

33. 72053611

HOSE ASM 3/8X256 FF

ELBOW 9/16MSTR 9/16MJIC 90

ELBOW 9/16MSTR 9/16MJIC XLG

CHECK VALVE (PART OF 31)

ELBOW #8MJIC #8FJIC 45

(PART OF 31)

ADAPTER #10MSTR 1/2FPT

(PART OF 31)

ADAPTER 1/2MPT 3/8MPT

(PART OF 31)

TUBE (PART OF 31)

RED. BUSHING 3/8MPT 1/4FPT

(PART OF 31)

MACH BUSHING 3/4X10GA NR

(PART OF 31)

SET SCR 1/2-13X3/4 SH

(PART OF 7)

WINCH KIT BOLT-ON

(INCL:3-10,15,23-29,32-36)

FLRLS #4TUBE 1/4MPT 45

(PART OF 31)

TEE 3/8NPT (PART OF 31)

2

1

1

1REF

2REF

2REF

1REF

1REF

1REF

8REF

1REF

1

2REF

1REF

4000# NAR: 31705967.01: 19940531

BOLT-ON WINCH KIT-4800 SERIES & 780

CRANE RMT CTRLS (31705967)

2.

3.

4.

5.

6.

7.

8.

9.

10.

12. 72066168

13. 51705975

14. 72066338

15.

16.

17.

18.

19.

20.

21.

22.

23.

52702018

52702016

70141982

51704589

72532672

72531708

72532358

MTG BRACKET (PART OF 31)

CAP SCR 3/4-10X9 HH GR5

(PART OF 31)

NUT 3/4-10 LOCK (P ART OF 31)

STUD 1/2-13X4-1/2 (PART OF 31)

SPACER (PART OF 31)

WINCH (PART OF 31) (INCL:30)

WASHER 1/2 LOCK (PART OF 31)

CAP SCR 1/2-13X 2-1/2 SH

(PART OF 31)

NUT 1/2-13 (PART OF 31)

COTTER PIN 3/32X3/4

HOSE ASM 3/8X96

CLEVIS PIN 5/16X1

ADAPTER 1/2MPT 3/4MJIC

(PART OF 31)

CONTROL ROD-M

CONTROL ROD-F

CONTROL HANDLE

HOSE ASM 3/8X245

BULKHEAD UNION 3/4JIC

BULKHEAD NUT 3/4

ADAPTER 3/4MSTR 3/4MJIC

CHECK VALVE (PART OF 31)

1REF

2REF

2REF

4REF

2REF

1REF

6REF

2REF

4REF

3

2

2

2REF

1

1

1

2

2

2

2

1REF

24.

25.

26.

28.

29. 70141984

30. 72532790

31. 31904002

32.

33.

34. 94731839

35. 72063001

39. 72063030

40. 72060596

41. 70392861

42. 70392863

43. 70392868

ELBOW #8MJIC #8FJIC 45

(PART OF 31)

ADAPTER #10MSTR 1/2FPT

(PART OF 31)

ADAPTER 1/2MPT 3/8MPT

(PART OF 31)

RED. BUSHING 3/8MPT 1/4FPT

(PART OF 31)

CONTROL HANDLE-LONG

ADAPTER 9/16MJIC 3/4FJIC

WINCH KIT BOLT-ON

(INCL:2-10,15,23-28,32-33,36-39)

FLRLS #4TUBE 1/4MPT 45

(PART OF 31)

TEE 3/8NPT (PART OF 31)

LINK & PIN KIT

WASHER 1/4 WRT

MACH BUSHING 3/4X10GA NR

(PART OF 31)

SET SCR 1/2-13X3/4 SH

(PART OF 7)

DECAL-DANGER 2-BLOCKING

(PART OF 31)

DECAL-DANGER HOISTING PERS

(PART OF 31)

DECAL-DANGER LOADLINE

(PART OF 31)

2REF

2REF

1REF

1REF

1

2

1

2REF

1REF

1

4

8REF

1REF

2REF

2REF

4REF

4000# NAR: 71057607.01: 20031105

4000 LB WINCH (71057607)

1. 71014724 GEAR CASE COVER

1

2. 71014725 KWY 3/8X3/8X1-7/16

2

3. 71014726 SHAFT

1

4. 71014727 GEAR CASE

1

5. 71014728 END HOUSING

1

6. 71014729 SPACER

1

*7. 76039262 COVER GASKET .002 RED

AR

*8. 76039263 COVER GASKET .005 BLUE

AR

*9. 76039264 COVER GASKET .010 BROWN AR

(KIT # 51392353 INCLUDES 7-9. ORDER IN KITS

ONLY.)

*10. 76039265 MOTOR GASKET .002 RED

AR

*11. 76039266 MOTOR GASKET .005 BLUE

AR

*12. 76039267 MOTOR GASKET .010 BROWN AR

(KIT #51392354 INCLUDES 10-12. ORDER IN KITS

ONLY.)

9

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

76039268

70055031

70055032

70055033

70055034

70055035

70056066

70056364

72053413

72060731

72060775

72060912

72060581

72063052

72066283

73051020

72060596

70142754

OIL SEAL

BEARING CUP

BEARING CONE

BEARING CUP

BEARING CONE

BEARING

WORM GEAR

WORM SHAFT

PIPE PLUG 3/8NPT SQHD

SCR 5/16-18X3/4 SH

SCR 7/16-14X1-1/2 SH

SET SCR 5/16-24X1/4

SET SCR 3/8-16X3/4 SH

WASHER 7/16 LOCK

WOODRUFF KEY 1/4X1

MOTOR

SET SCR 1/2-13X3/4 SH

DRUM

1

3

3

1

1

1

1

1

2

6

2

2

2

2

1

1

1

1

4000# NAR: 31705637.01: 19940531

10

CABLE & HOOK KIT (31705637)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

52070705

52704143

60107592

70034204

70055024

70055025

70058033

70731716

72053508

72066145

52070151

PIN

YOKE

CABLE 3/8X65'

NYLON SHEAVE 10-1/4

BEARING

RACE

CABLE CLAMP 3/8

SWIVEL HOOK/WEDGE SOCKET

ZERK 1/8NPT

HAIR PIN

PIN

1

1

1

1

1

1

1

1

1

2

1

4000# NAR: 31711646.01: 19940531

11

BOLT-ON WINCH KIT-5200 & 5800

SERIES & 880 CRANE (31711646)

2. 52711645

3. 72060199

4.

5.

6.

7.

8.

9.

72062114

60010869

60010868

71057607

72063053

72060797

10.

11.

12.

13.

14.

15.

72062004

71039096

72066168

72661169

72066338

72053497

16.

17.

18.

19.

20.

21.

52704745

52704744

70029451

51704589

72053760

72532700

MTG BRACKET (PART OF 31)

CAP SCR 3/4-10X9 HH GR5

(PART OF 31)

NUT 3/4-10 LOCK (P ART OF 31)

STUD 1/2-13X4-1/2 (PART OF 31)

SPACER (PART OF 31)

WINCH (PART OF 31) (INCL:30)

WASHER 1/2 LOCK (PART OF 31)

CAP SCR 1/2-13X 2-1/2 SH

(PART OF 31)

NUT 1/2-13 (PART OF 31)

KNOB

COTTER PIN 3/32X3/4

PIN 5/16X3/4

CLEVIS PIN 5/16X1

ADAPTER 1/2MPT 3/4MJIC

(PART OF 31)

CONTROL ROD-M

CONTROL ROD-F

CONTROL HANDLE

HOSE ASM 3/8X245

ELBOW 9/16MSTR 9/16MJIC 90

ELBOW 9/16MSTR 9/16MJIC XLG

1REF

22. 72532722

23. 73054006

24. 72532670

2REF

2REF

4REF

2REF

1REF

6REF

25. 72053744

2REF

4REF

2

3

1

2

29. 72063030

2REF

2

1

2

2

1

1

26. 72053629

27. 60101420

28. 72532138

30. 72060596

31. 31904004

32. 72533342

33. 72053611

34. 70392861

35. 70392863

36. 70392868

ADAPTER 7/8MSTR 9/16FSTR

(PART OF VALVEBANK)

CHECK VALVE (PART OF 31)

ELBOW #8MJIC #8FJIC 45

(PART OF 31)

ADAPTER #10MSTR 1/2FPT

(PART OF 31)

ADAPTER 1/2MPT 3/8MPT

(PART OF 31)

TUBE (PART OF 31)

RED. BUSHING 3/8MPT 1/4FPT

(PART OF 31)

MACH BUSHING 3/4X10GA NR

(PART OF 31)

SET SCR 1/2-13X3/4 SH

(PART OF 7)

WINCH KIT BOLT-ON

(INCL:2-10,15,23-29,32-35)

FLRLS #4TUBE 1/4MPT 45

TEE 3/8NPT (PART OF 31)

DECAL-DANGER 2-BLOCKING

(PART OF 31)

DECAL-DANGER HOIST PERS

(PART OF 31)

DECAL-DANGER LOADLINE

(PART OF 31)

2REF

1REF

2REF

2REF

1REF

1REF

1REF

8REF

1REF

1

2REF

1REF

2REF

2REF

4REF

4000# NAR: 31904004.01: 19940531

12

BOLT-ON WINCH KIT-5200 & 5800

SERIES & 880 CRANE (31904004)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

60010868

60010869

60101420

71057607

72053497

72532670

72053611

72053744

72053629

72060797

72062004

72063030

72063053

72533342

72532138

73054006

52711645

72060199

72060596

72062114

70392861

70392863

70392868

SPACER

STUD 1/2-13X4-1/2

U-TUBE

WINCH 4000LB (INCL: 19)

ADAPTER 1/2MPT 3/4MJIC

ELBOW #8MJIC #8FJIC 45

TEE 3/8NPT

ADAPTER #10MSTR 1/2FPT

ADAPTER 1/2MPT 3/8MPT

CAP SCR 1/2-13X2-1/2 SH

NUT 1/2-13 HEX

MACH BUSHING 3/4X10GA

WASHER 1/2 LOCK

FLRLS #4TUBE 1/4MPT

REDUCER BUSHING 3/8-1/4NPT

CHECK VALVE-PILOT OP

WINCH MTG BRKT

CAP SCR 3/4-10X9 HHGR5

SET SCR 1/2-13X3/4 SH(P ART OF 4)

NUT 3/4-10 LOCK

DECAL-DANGER 2-BLOCKING

DECAL-DANGER HOISTING PERS

DECAL-DANGER LOADLINE

2

4

1

1

1

2

1

2

1

2

4

8

6

2

1

1

1

2

1REF

2

2

2

4

4000# NAR: 99900556: 19940531

13

4000# NAR:

14

IOWA MOLD TOOLING CO., INC.

BOX 189, GARNER, IA 50438-0189

TEL: 641-923-3711

TECHNICAL SUPPORT FAX: 641-923-2424

MANUAL PART NUMBER 99900556

S-ar putea să vă placă și

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Assembly and Disaassembly of PumpsDocument5 paginiAssembly and Disaassembly of Pumpsshin deiru100% (1)

- Rammer 1655 Service 2015Document52 paginiRammer 1655 Service 2015SerkanAlÎncă nu există evaluări

- Instructions: 6 Speed Transmission Super KitDocument14 paginiInstructions: 6 Speed Transmission Super KitthailanÎncă nu există evaluări

- Procedure For Removing Main Bearing of MAN B&W MC-C EngineDocument16 paginiProcedure For Removing Main Bearing of MAN B&W MC-C EngineSuhas KassaÎncă nu există evaluări

- 1CV Overhaul PDFDocument15 pagini1CV Overhaul PDFsteve@air-innovations.co.zaÎncă nu există evaluări

- Workshop Manual 500R Reversing Drum Mixers Issue 10 2016Document176 paginiWorkshop Manual 500R Reversing Drum Mixers Issue 10 2016ZimChild GAMINGÎncă nu există evaluări

- Camshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLDocument12 paginiCamshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLGabriel ChiavettoÎncă nu există evaluări

- Orbitrol Desarmado y ArmadoDocument9 paginiOrbitrol Desarmado y Armadojulio cesarÎncă nu există evaluări

- Llave de Varillas de BombeoDocument28 paginiLlave de Varillas de BombeoGianna Frola100% (1)

- Clutch ManualDocument16 paginiClutch ManualCO BDÎncă nu există evaluări

- TRW Input Shaft Seal RemovalDocument6 paginiTRW Input Shaft Seal RemovalMichael ForrestÎncă nu există evaluări

- Haynes Pump 6500 ManualDocument8 paginiHaynes Pump 6500 Manualhiram avilaÎncă nu există evaluări

- Manual Book Vibrating ScreenDocument3 paginiManual Book Vibrating Screenrizki arfi100% (2)

- Grid Coupling Installation InstructionsDocument2 paginiGrid Coupling Installation Instructionsakashwsl92Încă nu există evaluări

- A/C Compressor Servicing: Please Read This FirstDocument22 paginiA/C Compressor Servicing: Please Read This FirstbaylorguyÎncă nu există evaluări

- Remove & Install Bucket CylinderDocument8 paginiRemove & Install Bucket CylinderchanlinÎncă nu există evaluări

- Transfer CaseDocument6 paginiTransfer CaseTim SmithÎncă nu există evaluări

- Camshaft Install Qr25de InstructionsDocument3 paginiCamshaft Install Qr25de InstructionsmehralsmenschÎncă nu există evaluări

- Remove & Install Connecting Rod BearingsDocument4 paginiRemove & Install Connecting Rod BearingsRichard ChuaÎncă nu există evaluări

- Manual 1008-1010Document12 paginiManual 1008-1010Edgar Eduardo Tellez RuizÎncă nu există evaluări

- Ramsey Winch H 800 Winch Owner's ManualDocument24 paginiRamsey Winch H 800 Winch Owner's ManualMartin De BruynÎncă nu există evaluări

- Instructions On Installation Operation and Maintenance For Kirloskar PumpDocument23 paginiInstructions On Installation Operation and Maintenance For Kirloskar Pumpmonuaspire4Încă nu există evaluări

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-50-00Document40 paginiRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 72-50-00anony8103Încă nu există evaluări

- Union Giratoria 320BDocument5 paginiUnion Giratoria 320BJuan PalestinaÎncă nu există evaluări

- Transfer Case Overhaul 1988 Jeep CherokeeDocument9 paginiTransfer Case Overhaul 1988 Jeep CherokeeAhmat Juhairi AriffinÎncă nu există evaluări

- Leiten - Manual - Escarificador Masalta MC8Document11 paginiLeiten - Manual - Escarificador Masalta MC8bqbovercon2Încă nu există evaluări

- Er 96 5 14Document3 paginiEr 96 5 14DIEGO YECID MILLAN MENDOZAÎncă nu există evaluări

- Remove & Install Fuel PumpDocument4 paginiRemove & Install Fuel PumpjasleenÎncă nu există evaluări

- Rotary Tiller: Operation, Service & Parts Manual For "AS" SeriesDocument16 paginiRotary Tiller: Operation, Service & Parts Manual For "AS" SeriesSuryaSuryaÎncă nu există evaluări

- 7 - Lubrification and RepairsDocument5 pagini7 - Lubrification and RepairsGabriel vieiraÎncă nu există evaluări

- 18SP635Document8 pagini18SP635giovanni ampueroÎncă nu există evaluări

- QuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service ManualDocument10 paginiQuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service Manualcarlosar1477Încă nu există evaluări

- Service Bulletin Trucks: Unit Injectors, ReplacementDocument23 paginiService Bulletin Trucks: Unit Injectors, ReplacementbabyÎncă nu există evaluări

- PDFDocument10 paginiPDFPaul HuaraychiriÎncă nu există evaluări

- 3304-3306 Medidas de Bielas y BancadasDocument3 pagini3304-3306 Medidas de Bielas y BancadasJuan Carlos RivasÎncă nu există evaluări

- Dodge Ram A/C Compressor ClutchDocument7 paginiDodge Ram A/C Compressor ClutchKkbhuvan KkÎncă nu există evaluări

- Mitsubishi Transfer Case Recall BulletinDocument20 paginiMitsubishi Transfer Case Recall BulletinSteven LewisÎncă nu există evaluări

- DAELIM vjf125Document288 paginiDAELIM vjf125Fabricio Costa0% (1)

- Rear SealDocument9 paginiRear SealHammad Uddin JamilyÎncă nu există evaluări

- May Cap Da Voi Nhiet DienDocument14 paginiMay Cap Da Voi Nhiet Dienlinhcdt3Încă nu există evaluări

- Range Rover Manual Suspension PDFDocument14 paginiRange Rover Manual Suspension PDFsleepyninjitsuÎncă nu există evaluări

- 2100103-Tilt CylindersDocument17 pagini2100103-Tilt CylindersFrancisco DiazÎncă nu există evaluări

- m2x m5xDocument19 paginim2x m5xMohamed ElmakkyÎncă nu există evaluări

- DIY - Replacing Timing BeltsDocument3 paginiDIY - Replacing Timing Beltstron68bizz100% (2)

- Foote-Jones 8000 Series Gear Reducer ManualDocument20 paginiFoote-Jones 8000 Series Gear Reducer ManualbwelzÎncă nu există evaluări

- Medidas Cigüeñal KTA 38Document20 paginiMedidas Cigüeñal KTA 38Chardy Jarith Piragua AlvaradoÎncă nu există evaluări

- enDocument55 paginienRegistr Registr100% (4)

- Subaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceDocument88 paginiSubaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceEdgardo M. Diolola100% (1)

- Manual Taller ARN 125 CC (Idioma Ingles)Document85 paginiManual Taller ARN 125 CC (Idioma Ingles)Cordobessa50% (2)

- Sistema de TransmisionDocument239 paginiSistema de TransmisionCez Lopez BañezÎncă nu există evaluări

- Section 10 - Power Take-OffDocument19 paginiSection 10 - Power Take-OffMiller Andres ArocaÎncă nu există evaluări

- Informacion de Equipo CaterpillarDocument6 paginiInformacion de Equipo CaterpillarfelixÎncă nu există evaluări

- Poseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Document10 paginiPoseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Marlon Alejandro Arboleda TapiaÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDe la EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesEvaluare: 5 din 5 stele5/5 (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003De la EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Evaluare: 5 din 5 stele5/5 (1)

- Diesel Engine Care and Repair: A Captain's Quick GuideDe la EverandDiesel Engine Care and Repair: A Captain's Quick GuideEvaluare: 5 din 5 stele5/5 (1)

- 72 516 PDFDocument65 pagini72 516 PDFJITENDRA KUMAR SHARMAÎncă nu există evaluări

- Imt 2003i Parts ServiceDocument83 paginiImt 2003i Parts ServiceJITENDRA KUMAR SHARMAÎncă nu există evaluări

- The New 22 HM Mobile Fast-Erecting CraneDocument2 paginiThe New 22 HM Mobile Fast-Erecting CraneJITENDRA KUMAR SHARMAÎncă nu există evaluări

- CC Brochure 13HM1 en 8755-0Document2 paginiCC Brochure 13HM1 en 8755-0JITENDRA KUMAR SHARMAÎncă nu există evaluări

- ManitowocDocument44 paginiManitowocJITENDRA KUMAR SHARMAÎncă nu există evaluări

- 1326355609384-Chalak Patra Sep 2011Document17 pagini1326355609384-Chalak Patra Sep 2011JITENDRA KUMAR SHARMA0% (1)

- E 133 Thermo LyneDocument48 paginiE 133 Thermo LyneJITENDRA KUMAR SHARMAÎncă nu există evaluări

- 6HP19 Manual CompletoDocument15 pagini6HP19 Manual CompletoMaría Martz De García92% (12)

- 966K-972K M07 966K972KEHStr EN SLDDocument21 pagini966K-972K M07 966K972KEHStr EN SLDDARIOÎncă nu există evaluări

- 2 - Wan Chai 5Document3 pagini2 - Wan Chai 5Usman AÎncă nu există evaluări

- Types of BearingsDocument13 paginiTypes of Bearings6403 Rohit Gaikwad100% (1)

- Maytag Top Load - MAT12PDDocument122 paginiMaytag Top Load - MAT12PDKenneth Herretes0% (1)

- Project Report G4 (V3)Document57 paginiProject Report G4 (V3)Irfan K MÎncă nu există evaluări

- CompressorsDocument22 paginiCompressorsgoutteÎncă nu există evaluări

- Engine Overhauling AssignmentDocument11 paginiEngine Overhauling AssignmentSabeeh Safdar100% (1)

- 62 11052Document32 pagini62 11052jgokey100% (2)

- 7-3097a - Calibracion de ValvulasDocument5 pagini7-3097a - Calibracion de ValvulasJavier PalaciosÎncă nu există evaluări

- Manual MoynoDocument34 paginiManual Moynocarlangas77Încă nu există evaluări

- M Coupe 1999 2005Document417 paginiM Coupe 1999 2005Carlos CarvajalÎncă nu există evaluări

- SE Bikes - 2014 Tripel - Bike ArchivesDocument2 paginiSE Bikes - 2014 Tripel - Bike ArchivesMark ArchambeaultÎncă nu există evaluări

- 01 Flexible Jaw Bin Bush ROTEXDocument35 pagini01 Flexible Jaw Bin Bush ROTEXcamilohuratadoÎncă nu există evaluări

- Sem 680DDocument2 paginiSem 680DVinoth KumarÎncă nu există evaluări

- Electrical Supplies and MaterialsDocument15 paginiElectrical Supplies and MaterialsChris NazaretaÎncă nu există evaluări

- Valtra 8150 Tractor Service Repair ManualDocument20 paginiValtra 8150 Tractor Service Repair Manualtimothy100% (51)

- Bearings: Nizwa College of TechnologyDocument22 paginiBearings: Nizwa College of TechnologyAjay Kumar Reddy KÎncă nu există evaluări

- Ex6 Hyundai Ex6 Double Cab Cargo - Technical Specs.Document3 paginiEx6 Hyundai Ex6 Double Cab Cargo - Technical Specs.manu .mÎncă nu există evaluări

- Opticom Rack Mount Fiber Enclosure: Installation Instructions FS060Document4 paginiOpticom Rack Mount Fiber Enclosure: Installation Instructions FS060Dario Campos AlcantaraÎncă nu există evaluări

- U-Bolt 2Document1 paginăU-Bolt 2Nanang RisdiantoÎncă nu există evaluări

- Riser Diagram: Produced by An Autodesk Student VersionDocument1 paginăRiser Diagram: Produced by An Autodesk Student VersionMark Kenneth BaldoqueÎncă nu există evaluări

- Figure UG-34 Forged HeadDocument8 paginiFigure UG-34 Forged Headmiteshpatel191Încă nu există evaluări

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document10 paginiInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Jhousep steven Mesia gonzalesÎncă nu există evaluări

- Rexroth: Spare Parts ListDocument39 paginiRexroth: Spare Parts ListChester Dalitso Mwanza100% (4)

- Kubota Flat Rate ScheduleDocument133 paginiKubota Flat Rate ScheduleSteyn Visser0% (1)

- Opposed Piston Pulling Rod EngineDocument38 paginiOpposed Piston Pulling Rod Enginepaul20000Încă nu există evaluări

- Thermostat HousingDocument2 paginiThermostat HousingCrespo JorgeÎncă nu există evaluări

- PDFsam - MANUAL DE PARTES LINCOLN BIG RED 500Document2 paginiPDFsam - MANUAL DE PARTES LINCOLN BIG RED 500Luis Chan ChanÎncă nu există evaluări

- 128 Ppid 435 0-1Document3 pagini128 Ppid 435 0-1Khinmg Aye 554Încă nu există evaluări