Documente Academic

Documente Profesional

Documente Cultură

2

Încărcat de

Saleh BreakerboyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2

Încărcat de

Saleh BreakerboyDrepturi de autor:

Formate disponibile

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

DETERMINATION OF CALCIUM AND MAGNESIUM IN CLINKER, CEMENT & FLY

ASH BASED CEMENT BY EDTA WITHOUT USING MASKING REAGENTS

Birendra Singh Rajwar*

Prof. (Dr.) I.K. Pandey**

Abstract: This method for determination of calcium and magnesium in clinker, ordinary

Portland cement and fly ash based Portland pozzolana cement, is unique among the other

available methods (such as gravimetric method, titrimetric method by using KMnO4/ EDTA

method as per IS:4032- [1].It is very quick method as compared to above. The uniqueness of

this method is that it gives accurate results in short interval of time and also avoids use of

high temperature muffle furnace.Calcium and magnesium are determined in filtrate after

separation of combined ferric oxide and alumina from the sample solution.

Key words: CaO, MgO, Cement, Clinker & EDTA.

*Research Scholar, Mewar University, Rajasthan, India

**Director International College of Engineering, Ghaziabad (M.Tech, Ph.D. from IIT Delhi,

India)

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

IJAREAS | 7

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

INTRODUCTION:

Cement including Ordinary Portland cement, Portland Pozzolana cement are used as binding

materials of concrete in civil construction industries. There is huge requirement of cement

in construction work all over the world. The main ingredient of concrete structure as binder

of concrete is cement. The quality of cement as per standard specification is very important

for the cement manufacturing industries as well as for the civil construction industries for

making solid and long life structure. Cement consists of mainly following constituents.

CHEMICAL COMPOSITION OF ORDINARY PORTLAND CEMENT, (OPC)[2]:

TABLE-1

Sr. No.

1

2

3

4

5

6

7

Constituents

Silica (as SiO2)

Calcium (as CaO)

Alumina (as Al2O3)

Iron (as Fe2O3)

Magnesia (as MgO)

Oxides of alkalis (Na2O & K2O)

Sulphuric Anhydride (as SO3)

Range

17-25 %

60-67%

3-8 %

0.5-6%

0.5-4.0 %

0.3-1.2 %

2.0 -3.5 %

Above range of constituents exists in complex compound form.

Abbreviated Formula

Sr. Formal

No. Name

of Formula #

Compound

1

Tri Calcium C3S

(3CaO. SiO2)

Silicate

Brogues Equation for calculating

%age of compound

(2CaO.SiO2)

2.87*SiO2-0.75*C3S

(3CaO. Al2O3)

2.65*Al2O3-1.69*Fe2O3

(4CaO.

Al2O3.Fe2O3)

3.04*Fe2O3

3

4

Di Calcium C2S

Silicate

Tri Calcium C3A

Aluminate

Tetra

C4AF

Calcium

Aluminate

Ferrite

4.07*CaO-7.60*SiO2-6.72*Al2O31.43*Fe2O3-2.85*SO3

#The above symbols are used in cement manufacturing industries.

The main constituent of the cement and clinker is calcium oxide (CaO) which is the major

factor for cement quality. It is determined by several analytical techniques. One of the

analytical technique to determine calcium oxide is complexometric titration with EDTA. It is

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

IJAREAS | 8

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

also used to find the total calcium and magnesium content of milk, sea water and various

solid materials. It can also be used to determine the total hardness of fresh water provided

the solutions used are diluted. The combined concentration of calcium and magnesium ions

is thetotal hardness of water.

The method uses a very large molecule called EDTA which forms a complex with calcium and

magnesium ions. A blue dye called Eriochrome Black T (EBT) is used as the indicator. This

blue dye also forms a complex with the calcium and magnesium ions, changing colour from

blue to pink in the process. The dyemetal ion complex is less stable than the EDTAmetal

ion complex. For the titration, the sample solution containing the calcium and magnesium

ion reacts with an excess of EDTA. The indicator is added and colour changes to blue as all

the Ca2+ and Mg2+ ions present are complexed with the EDTA.

The main reaction is:

Ca2++ EDTA4 [Ca-EDTA]2

In complexometric titration with EDTA, interferences are mainly caused from cations of iron,

aluminium and manganese. Apart from reacting with EDTA, these metals also react

irreversevely with indicators. These cations also give rise to colour change in the indicator,

making difficult to detect the end point. However, there are standard test methods available

to determine calcium oxide and magnesium oxide by EDTA method. But the present study

has been carried out to develop a method quicker, accurate and less expensive method.

GLASS APPARATUS REQUIRED:

Pipette (25 ml,10ml & 50ml capacity),burette(10 ml, 25 ml capacity), Volumetric flask

(100ml, 250ml, 500ml & 1000ml capacity), Conical flask-100 ml capacity.

CHEMICAL & REAGENTS REQUIRED:

STANDARD EDTA SOLUTION:0.01 M:[3]

Dissolve 1.8612 gm of disodium ethylenediamine tetra acetate dihydrate in 200 ml hot

water and make up the volume to 500 ml in calibrated volumetric flask.

BUFFER SOLUTION-pH 10: [4]

Dissolve 70 g of ammonium chloride in 570 ml of ammonium hydroxide (sp gr. 0.90) and

make up volume to 1000 ml with distilled water in a calibrated volumetric flask.

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

IJAREAS | 9

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

STANDARD ZINC SOLUTION:0.01M: [5]

Dissolve accurately weighed 0.6537gm of granulated zinc in minimum quantity of dilute

hydrochloric acid (1:1). Make up to mark with distilled water in a calibrated volumetric flask

of capacity 1000 ml.

ERICHROME BLACK T- INDICATOR: [6]

Grind 100 mg of indicator with 10 gm of sodium chloride till homogeneous mixture is

obtained and store in an airtight container.

PATTON-REEDERS INDICATOR /(P & R) INDICATOR :[7]

[2-hydroxy-1-(2-hydroxy-4 - Sulpho -1-Napthylazo)-3-Napthoic Acid], (C21H14N2O7S)

Grind 100 mg of indicator with 10 gm of sodium or potassium sulphate till homogeneous

mixture is obtained and store in airtight bottle.

METHYLTHYMOLBLUE INDICATOR-MIXTURE:

0.1 gm Methylthymolblue mixed with 10 gm of KNO3.

STANDARDIZATION OF EDTA- SOLUTION USING STANDARD ZINC SOLUTION:

Take 10 ml of standard zinc solution in conical flask. Add 20 ml buffer solution of pH-10 and

warm at 50 to 60O C. Add 50 mg Erichrome Black T indicator and titrate with 0.01M EDTA

till the color changes from red wine to clear pink blue. Note the volume of EDTA used and

calculate the molarity of EDTA by using formula, M1xV1 = M2xV2

Note: Use burette of least count 0.05 ml for accurate results.

TABLE-2

Sr.

No.

Molarity of

zinc

Solution

(M1)

0.01

Volume of

Zinc

Solution

(V1-ml)

10

Molarity of

Volume of

EDTA

EDTA

Solution

Solution

(M2)

(V2-ml)

1

To

be 9.85

determined

2

0.01

10

To

be 9.90

determined

3

0.01

10

To

be 9.85

determined

Average Molarity of EDTA Solution using standard zinc solution:

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

M1 x V1 = M2 x V2

M2 = (M1 x V1) /

V2

0.01015

0.01010

0.01015

0.01013

IJAREAS | 10

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

STANDARDIZATION OF EDTA- SOLUTION USING CERTIFIED REFERENCE MATERIAL CaCO3:

Weigh known quantity (W-gm) of the standard CaCO3 traceable to NIST into a 100 ml

capacity conical flask and dissolve in 25 ml- distilled water andadd 10 ml of 10 % KOH

solution and shake well to adjust pH to highly alkaline range of 12 or slightly more. Add

approximately 50 ml of distilled water and 50 mg of solid P & R indicator. Titrate against

0.01 M EDTA solution to a sharp change in colour from wine red to clear blue.

TABLE-3

Purity of CaCO3 [8]

Equivalent weight of CaCO3

Molecular weight of CaCO3

Purity Fraction

A

B

C

D

=

=

=

=

99.98 %

50.03

100.09

Purity/100

TABLE-4

Sr.

No.

Weight

of Purity

Volume of Molecular

CaCO3

fraction

of EDTA

weight of

Taken

(W- CaCO3

Consumed

CaCO3

gm)

(D)

(V-ml)

(C)

I

0.01232

0.9998

12.1

100.09

II

0.01626

0.9998

15.9

100.09

III

0.01142

0.9998

11.2

100.09

Average

Molarity of EDTA Solution using standard Calcium

Carbonate

Final Average Molarity used for Calculation M-EDTA

Average of (molarity standardized against Zinc and molarity

standardized against Std. Calcium Carbonate) = (0.01013+ 0.01019)/2

Molarity of EDTA

Solution

(W*D*1000)/(V*C)

0.01017

0.01021

0.01018

0.01019

0.01016

PREPARATION OF SOLUTION OF CEMENT/CLINKER SAMPLE:

Take approximately0.5 gm of the sample in an evaporating clean dish / clean beaker;

moisten with 10 ml of water at room temperature. Care should be taken to avoid any lump

formation. Add 5 to 10 ml of HCl and agitate with the help of policeman (glass rod fitted

with rubber / glass rod soften at the agitating end by melting), till completely dissolves.

Evaporate the solution till complete dryness on a steam bath or hot plate, temperature of

the steam bath or hot plate should be adjusted in such a way to avoid any spurting of the

sample from dish or beaker. Without heating the residue, further treat it 1:1 HCl and water

(20-ml) and digest on the water bath or hot plate. Dilute the volume with equal volume of

hot water. Filter through ash less filter paper (Whatman No 40 or its equivalent), wash the

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

IJAREAS | 11

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

separated silica thoroughly with hot water and reserve the residue.Re evaporate the filtrate

to dryness; bake the residue in an oven for one hour at 105 to 110 deg. C. Treat the residue

with 20-ml of HCl (1:1) and heat the solution on water bath or on hot plate. Dilute the

solution with an equal volume of hot water and catch the silica into the filter paper. Make

up the filtrate up to 250 ml in a calibrated volumetric flask. Reserve the filtrate and

washings for separation of combinedaluminium and Iron oxide.

SEPARATION OF COMBINED FERRIC OXIDE AND ALUMINA FROM SAMPLE SOLUTION:

From the filtrate reserved above in 250ml volumetric flask, take 50 ml aliquot into a conical

flask, add few drops (1-ml of H2O2 + 1-ml of HNO3) and heat to boiling in order to oxidize any

ferrous iron to the ferric condition. Treat the boiled solution with (1:1) NH4OH drop- wise till

colour of the solution becomes distinctly yellow and subsequently treat this solution with

0.5 gm of NH4S2O8 and pour excess four five drops NH4OH until the indicator turns yellow.

Boil the solution for further one minute and allow the precipitate to settle for five minutes

and filter through Whatman No. 41filter paper and wash with 2 % hot NH4NO3.

Transfer precipitate&filter paper to original beaker and dissolve the precipitatewith hot

dilute HCL (1:3) and dilute to 100 ml.Re-precipitate the hydroxides and filter the

solution.Wash the precipitate with two to 10 ml portion of the hot NH4NO3 solution.

Combine the filtrate and washings and make up to 250-ml in a calibrated volumetric flask.

Reserve the filtrate for determination of CaO and MgO.

(Final Solution:0.5 gm into 250 ml volumetric flask, Aliquot 50 ml and volume make up 250

ml)

DETERMINATION OF CALCIUM BY EDTA-METHOD:

Take 50-ml aliquot of the solution (reserved for determination of CaO & MgO) into a conical

flask and add 1 gm of NH4NO3+ 20 ml of 10 % KOH and shake well to adjust pH to highly

alkaline range of 12 or slightly more. Add approximately 50 ml of distilled water and 50 mg

of P&R indicator. Titrate against 0.01 M EDTA solution to a sharp change in colour from wine

red to clear blue. Record the volume of EDTA consumed (V-ml).

Calculations: Calculate the percentage of CaO

% CaO= (V-EDTA x 56.08 x M-EDTA x100) / (1000 x Weight of samplein aliquot taken)

Where,

V-ml=

Vol. 3 | No. 4 | April 2014

Volume of EDTA solution consumed-ml,

www.garph.co.uk

IJAREAS | 12

International Journal of Advanced Research in

Engineering and Applied Sciences

M-EDTA

ISSN: 2278-6252

Molarity of EDTA

DETERMINATION OF MAGNESIUM BY EDTA-METHOD:

Take 50- ml of the solution (reserved for determination of CaO and MgO) add 1-gm of

NH4NO3 + 20 ml. of buffer solution of pH 10 and 20 ml of NH4OH. Add 50 mg of

methylthymolblue indicator and titrate against 0.01-M EDTA to change colour from light

blue to colourless greyor50-mg of EBT indicator and titrate it against standard 0.01-M EDTA

solution until the colour changes from pink to light green. This titration gives the sum of the

calcium and magnesium oxide present in the sample solution. Titre value of magnesium is

obtained by subtracting the titre value of calcium oxide (V-ml) from the total titre valueof

(calcium + magnesium oxide), (V1ml).

Calculations:

Calculate the percentage of MgO

Magnesium Oxide (MgO) percent =(V1-V) x 40.32 x M-EDTA x 100 / (1000 x W)

Where,

V1

Titre value used for total (calcium + magnesium)

Titre value used for Calcium

Weight of the sample in aliquot.

VALIDATION OF METHOD USING REFERENCE MATERIAL OF KNOWN CHEMICAL

COMPOSITION FOR CaO AND MgO:

NAME OF REFERENCE MATERIAL FOR ORDINARY PORTLAND CEMENT(OPC):

Reference Material CRM-1012K-Ordinary Portland Cement Standard [9]

TABLE-5

CHEMICAL COMPOSITION OF CRM-1012K

Sr. No.

Chemical Constituents

% By Mass

1

2

3

4

5

6

7

8

9

Loss On Ignition

Silica (as SiO2)

Iron (as Fe2O3)

Alumina (as Al2O3)

Calcium (as CaO)

Magnesium (as MgO)

Sulphuric Anhydride (SO3)

Sodium (as Na2O)

Potassium (as K2O)

3.56

21.27

4.14

4.51

61.42

1.21

2.06

0.22

0.46

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

Expanded Uncertainty

(Coverage Factor k=2)

0.02

0.06

0.02

0.05

0.14

0.04

0.03

0.003

0.006

IJAREAS | 13

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

NAME OF REFERENCE MATERIAL FOR PORTLAND POZZOLANA CEMENT:

Reference Material CRM-1016C- Portland Pozzolana Cement Standard [10]

TABLE-6

CHEMICAL COMPOSITION OF CRM-1016C

Sr. No.

Chemical Constituents

% By Mass

1

2

3

4

5

6

7

8

9

Loss On Ignition

4.58

Silica (as SiO2)

31.24

Iron (as Fe2O3)

3.78

Alumina (as Al2O3)

9.99

Calcium (as CaO)

44.89

Magnesium (as MgO)

1.13

Sulphuric Anhydride (SO3)

2.18

Sodium (as Na2O)

0.27

Potassium (as K2O)

0.60

EXPERIMENT CARRIED OUT:

Expanded Uncertainty

(Coverage Factor k=2)

0.02

0.11

0.03

0.05

0.12

0.04

0.03

0.01

0.01

EDTAUsed forMgO

Titration(V1-ml)

% CaO = (V*M*56.08*100)/

(wt. of aliquot*1000)

22.3

61.40 1.22

0.5031 250 50

250

50

0.020124 21.7

22.3

61.44 1.22

0.5012 250 50

250

50

0.020048 21.6

22.2

61.39 1.23

% MgO = (V1-V)*M*40.32*

100) /(wt. of aliquot*1000)

Final

weightof

aliquot(samplein aliquot)(gm)

0.020136 21.7

EDTAUsed forCaO

Titration(V-ml)

Aliquottakenfor testing of CaO

& MgO(ml)

50

Aliquot takenfor R2O3

Separation(ml)

250

Volume make Up (ml)

0.5034 250 50

Weight of sampletaken (gm)

ORDINARY PORTLAND Sample Name

CEMENT

Sr. No.

Volume make from the filtrate

of R2O3 (ml)

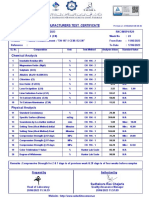

TABLE-7

Average analytical results of Calcium Oxide (CaO) and Magnesium 61.41 1.22

Oxide (MgO) %

1

0.5018 250 50

250

50

0.020072 15.8

16.4

44.85 1.22

PORTLAND

POZZOLANA

2

3

0.5042 250 50

0.5024 250 50

250

250

50

50

0.020168 15.9

0.020096 15.8

16.4

16.4

44.92 1.02

44.80 1.22

Average analytical results of Calcium Oxide (CaO) and Magnesium 44.86 1.15

Oxide (MgO) %

(PRIMARY DATA ON ACTUAL ANALYSIS BASIS) [11]

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

IJAREAS | 14

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

TABLE-8

COMPARISON OF ANALYTICAL VALUES WITH KNOWN VALUES OFCRM

Analyte

Calcium

(as CaO)

CRM-1012K

(Ordinary Portland Cement)

CRM-1016C

(Portland Pozzolana Cement)

Analytical CRM Remarks

Results by Value

experiment

Analytical

Results by

experiment

I 61.40

Average

44.85

analytical value

of CaO is within 44.92

the

specified

limit of CRM.

44.80

II 61.44

III 61.39

Average Value 61.41

61.42

0.14

Magnesium I 1.22

(as MgO)

II 1.22

44.86

1.21

0.04

1.15

Remarks

Average

analytical value

of CaO is within

the

specified

limit of CRM.

44.89

0.12

Average

1.22

analytical value

of MgO is within 1.02

the

specified

limit of CRM.

1.22

III 1.23

Average Value 1.22

CRM

Value

Average

analytical value

of MgO is within

the

specified

limit of CRM.

1.13

0.04

CONCLUSION:

The above test procedure for determination of Calcium Oxide (CaO) and Magnesium Oxide

(MgO) has been used for determination of known values of two Certified Reference

Materials (CRM). The analytical results by experiments have been found within the specified

tolerance of the known values.

REFERENCE:

1. IS 4032-1985

2. Safari Books Online (Chemical Composition of Portland Cement)

3. Clause 4.1.15 of IS 4032-1985

4. Clause 4.1.13 of IS 4032-1985

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

IJAREAS | 15

International Journal of Advanced Research in

Engineering and Applied Sciences

ISSN: 2278-6252

5. Clause 4.1.14 of IS 4032-1985

6. Clause 4.1.16 of IS 4032-1985

7. Clause 4.1.18 of IS 4032-1985

8. Certified Reference Material (CRM) traceable to NIST of CaCO3

9. Certificate of Analysis for Ordinary Portland Cement (OPC) Standard (CRM-1012 K)

10. Certificate of Analysis for Portland Pozzolana Cement (PPC) Standard (CRM-1016 C)

11. Primary Analytical Data for OPC and PPC.

Vol. 3 | No. 4 | April 2014

www.garph.co.uk

IJAREAS | 16

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- StealthDocument7 paginiStealthSaleh BreakerboyÎncă nu există evaluări

- IMWA2005 081 SarmientoDocument5 paginiIMWA2005 081 SarmientoSaleh BreakerboyÎncă nu există evaluări

- 016610024Document8 pagini016610024Saleh BreakerboyÎncă nu există evaluări

- Orgsynth KeysDocument27 paginiOrgsynth KeysDebalina DassÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Preparation and Characterization of Basic Ceramics From Moroccan MagnesiteDocument9 paginiPreparation and Characterization of Basic Ceramics From Moroccan MagnesitefonsÎncă nu există evaluări

- Use of Granular Blast Furnace Slag in Embankment ConstructionDocument5 paginiUse of Granular Blast Furnace Slag in Embankment ConstructionGRD JournalsÎncă nu există evaluări

- DemonstrationsDocument42 paginiDemonstrationsJosé YalibatÎncă nu există evaluări

- Straw As ReinforcementDocument4 paginiStraw As ReinforcementANKIT KUMARÎncă nu există evaluări

- 7 Most Common Problem in Pyro Processing For Kiln and CoolerDocument10 pagini7 Most Common Problem in Pyro Processing For Kiln and CoolerVipan Kumar DograÎncă nu există evaluări

- Composition of Cement: Ingredient Percentage in CementDocument3 paginiComposition of Cement: Ingredient Percentage in CementDevinder Chawla100% (1)

- Lecture #4&5 Time Setting and Soundness of Portland CementDocument28 paginiLecture #4&5 Time Setting and Soundness of Portland CementRome Lauren JavierÎncă nu există evaluări

- To The Student:: Box 42191, Lubbock, TX 79409 (806) 742-7200 FAX (806) 742-7222 WWW - Ode.ttu - EduDocument7 paginiTo The Student:: Box 42191, Lubbock, TX 79409 (806) 742-7200 FAX (806) 742-7222 WWW - Ode.ttu - EduDaynaLawsonGilmoreÎncă nu există evaluări

- General Science Ability NotesDocument25 paginiGeneral Science Ability NotesZulfiqar Ali TunioÎncă nu există evaluări

- MgO Carbon FootprintDocument17 paginiMgO Carbon FootprintOscar JoltÎncă nu există evaluări

- Data Sheet Sair Set PDFDocument2 paginiData Sheet Sair Set PDFSaragadam DilsriÎncă nu există evaluări

- ASTM Grades For Insulating Fire BrickDocument2 paginiASTM Grades For Insulating Fire BrickrajachemÎncă nu există evaluări

- Manufacturers Test Certificate: Printed On 21/06/2023 08:08:36Document1 paginăManufacturers Test Certificate: Printed On 21/06/2023 08:08:36BariÎncă nu există evaluări

- RHI Refractory-3Document24 paginiRHI Refractory-3Mashiur RahmanÎncă nu există evaluări

- Minnesota Clay Co. USA Technical Info - Glossary: SearchDocument5 paginiMinnesota Clay Co. USA Technical Info - Glossary: SearchHelenÎncă nu există evaluări

- Foundry Technology: Reference BooksDocument34 paginiFoundry Technology: Reference BooksGowtham VishvakarmaÎncă nu există evaluări

- Slags in Ferroalloys ProductionDocument10 paginiSlags in Ferroalloys ProductionQuinton Dean ChingokaÎncă nu există evaluări

- Recent Developments in The Chloride Processing of Nickel Laterites PDFDocument14 paginiRecent Developments in The Chloride Processing of Nickel Laterites PDFmtanaydinÎncă nu există evaluări

- CH 13Document30 paginiCH 13Laurertan TavaresÎncă nu există evaluări

- Rohini 56951549584Document10 paginiRohini 56951549584Oumar CoulibalyÎncă nu există evaluări

- FLT-1 Paper-1 Question+SolutionDocument58 paginiFLT-1 Paper-1 Question+SolutionSHIVAM KUMARÎncă nu există evaluări

- ScP019 Chemical Equations 1Document2 paginiScP019 Chemical Equations 1ORBeducationÎncă nu există evaluări

- DJDocument8 paginiDJDiego JaquesÎncă nu există evaluări

- Steel CleanlinessDocument22 paginiSteel CleanlinessfondershellÎncă nu există evaluări

- Stirring and Non-Stirring Methods Used To Make Synthetic Dolomite-Based Epsom SaltDocument8 paginiStirring and Non-Stirring Methods Used To Make Synthetic Dolomite-Based Epsom SaltcintaÎncă nu există evaluări

- Report On Industrial Training at UCILDocument25 paginiReport On Industrial Training at UCILChirag SharmaÎncă nu există evaluări

- Aderibigbe Et Al. (2019)Document22 paginiAderibigbe Et Al. (2019)Alhassan I MohammedÎncă nu există evaluări

- Astm - d3682 - 01 (Reapp 2006) (Major and Minor Element in Combustion Residues)Document7 paginiAstm - d3682 - 01 (Reapp 2006) (Major and Minor Element in Combustion Residues)Dandy RizkanÎncă nu există evaluări

- Calorimetry Lab 2Document5 paginiCalorimetry Lab 2wevsfirsttryÎncă nu există evaluări

- Std12 Chemistry EM 1 WWW - Tntextbooks.inDocument296 paginiStd12 Chemistry EM 1 WWW - Tntextbooks.inSeetha Lakshmi PalaniswamyÎncă nu există evaluări