Documente Academic

Documente Profesional

Documente Cultură

Unión de Losa A Muros

Încărcat de

ericpardo59Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Unión de Losa A Muros

Încărcat de

ericpardo59Drepturi de autor:

Formate disponibile

E-HLD

Shear Load

Connectors

For the connection of new slabs to

diaphragm walls or secant pile walls in

basement construction

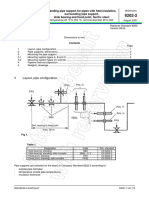

Ancon E-HLD Shear Load Connector

The Ancon E-HLD joins new concrete slabs to existing concrete

walls. It is designed to transfer shear load where new slabs are

connected to diaphragm walls or secant pile walls in basement

construction*.

The E-HLD comprises a stainless steel dowel and a high

strength, stainless steel sleeve. It is available in seven standard

sizes and can be used in a slab thickness from 160mm and

joints up to 60mm wide. Ancon two-part resin is required to

install the dowel component. The quantity of resin cartridges

required will depend on dowel diameter and number being fixed.

Sleeve

component

End cap

Dowel

diameter

Height

Dowel length

Sleeve length

12 Width 12

Dimensions

Product

Reference

Dowel Component

Diameter

Length

E-HLD 18

E-HLD 22

E-HLD 24

E-HLD 30

E-HLD 35

E-HLD 42

E-HLD 52

18

22

24

30

35

42

52

Sleeve Component

Length

Height

Width

270

300

330

350

400

470

570

155

165

175

190

215

245

295

75

95

110

140

160

180

220

70

90

100

115

132

175

210

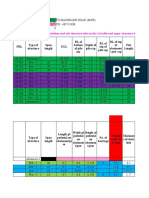

Performance

Minimum

Slab (mm)

Product

Thickness B Reference

Dowel

component

160

180

200

240

300

350

400

Longitudinal

movement

Installation

First phase - The dowel component is resin-fixed in the wall

E-HLD 18

E-HLD 22

E-HLD 24

E-HLD 30

E-HLD 35

E-HLD 42

E-HLD 52

10

41.8

69.6

83.1

120.2

165.7

200.8

302.3

FRd Design Capacities (kN) for Various

Joint Widths (mm) using C25/30 Concrete

20

30

40

50

60

36.8

59.2

71.7

106.2

148.6

182.5

280.0

30.1

50.5

62.2

94.2

133.8

166.4

260.1

25.0

42.6

53.6

83.3

120.4

151.6

242.2

21.4

36.8

46.5

73.2

107.3

136.9

225.9

18.7

32.4

41.1

65.2

96.3

123.8

210.8

Edge Distance and Spacing - Second Phase

The minimum edge distance is determined by the depth of the

adjoining slab.

min. 0.75 B

min. 1.50 B

Local Reinforcement - Second Phase

A hole should be drilled no more than 5mm wider than the

dowel, to the depth shown in the table. Ancons two-part resin is

injected into the hole and the dowel is inserted.

Dowel Diameter (mm)

18

22

24

30

35

42

52

Depth A (mm)

Approx. No. Dowels per Cartridge

130

16

155

10

170

9

180

6

205

4

240

3

290

2

Product

Reference

E-HLD 18

E-HLD 22

E-HLD 24

E-HLD 30

E-HLD 35

E-HLD 42

E-HLD 52

Options for Main Reinforcement (No. of U-bars each side)

H8

H10

H12

H14

H16

H20

3

-

2

3

-

2

3

3

4

-

2

2

3

4

4

-

2

3

3

4

5

2

3

3

Second phase - The sleeve component is installed.

Product

Options for Longitudinal Reinforcement (No. of bars top and bottom)

Reference

H8

H10

H12

H14

H16

H20

E-HLD 18

E-HLD 22

E-HLD 24

E-HLD 30

E-HLD 35

E-HLD 42

E-HLD 52

2

3

-

2

2

2

-

2

2

3

3

-

2

2

2

2

3

2

2

2

2

2

2

Note: The longitudinal reinforcement assumes that the E-HLDs are positioned at one

metre centres.

Once the resin reaches full strength, the sleeve component is

pushed over the exposed end of the dowel. The required local

reinforcement is located around the sleeve, ensuring that the

correct cover is maintained. The concrete is cast to complete the

installation.

* In applications where movement needs to be accommodated,

please contact Ancon.

Ancon Building Products

President Way, President Park, Sheffield S4 7UR, United Kingdom,

Tel: +44 (0) 114 275 5224, Fax: +44 (0) 114 276 8543

Email: info@ancon.co.uk Visit: www.ancon.co.uk

S-ar putea să vă placă și

- Ancon E-HLD Shear Load ConnectorDocument2 paginiAncon E-HLD Shear Load ConnectorJose Luis Soto PetralandaÎncă nu există evaluări

- City Multi Branch JointDocument1 paginăCity Multi Branch JointDaniel Lucas DjasibaniÎncă nu există evaluări

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142De la EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Încă nu există evaluări

- Terrain Below Ground Drainage Dimensional DataDocument16 paginiTerrain Below Ground Drainage Dimensional DatamealysrÎncă nu există evaluări

- Catalogue Ipsi EpDocument70 paginiCatalogue Ipsi EprachedscribÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- 02 Gunnebo EN 2012Document14 pagini02 Gunnebo EN 2012Edin KanticÎncă nu există evaluări

- PexFlex - LogstorDocument10 paginiPexFlex - LogstorZeljko RisticÎncă nu există evaluări

- Jet DiffuserDocument6 paginiJet DiffuserjafarkhansfÎncă nu există evaluări

- Dependent Parking For Permanent User Only! : Function Width DimensionsDocument2 paginiDependent Parking For Permanent User Only! : Function Width DimensionsEduardo PujolÎncă nu există evaluări

- VARGUS - Gear Milling Catalog - MetricDocument12 paginiVARGUS - Gear Milling Catalog - MetricGilberto ManhattanÎncă nu există evaluări

- Components Overview - Brochures V11 I400003GBDocument80 paginiComponents Overview - Brochures V11 I400003GBKirsten HernandezÎncă nu există evaluări

- CQ2 New Series PDFDocument210 paginiCQ2 New Series PDFsumit_waghmareÎncă nu există evaluări

- A202-4100 SeriesDocument1 paginăA202-4100 SeriesHeymonth ChandraÎncă nu există evaluări

- M50 enDocument338 paginiM50 entomwilkinsÎncă nu există evaluări

- Bellofram T2000 IP Transducer ImDocument6 paginiBellofram T2000 IP Transducer ImelyuyaÎncă nu există evaluări

- NBS-E60-100E (Cofraplus 60)Document13 paginiNBS-E60-100E (Cofraplus 60)wasyzsozso13Încă nu există evaluări

- KHD G120 Brochure (12-10)Document6 paginiKHD G120 Brochure (12-10)Rigoberto HerreraÎncă nu există evaluări

- LS 545-15 Anchor supports for horizontal pipingDocument7 paginiLS 545-15 Anchor supports for horizontal pipingtejasp8388Încă nu există evaluări

- Eaton's New EC230-40 Two Wire Braid Hose Offers High Flow Demand!Document4 paginiEaton's New EC230-40 Two Wire Braid Hose Offers High Flow Demand!gazwang478Încă nu există evaluări

- Garnituri Flanse SAEDocument85 paginiGarnituri Flanse SAEcudalbgeoÎncă nu există evaluări

- Geberit HDPE Installation GuideDocument78 paginiGeberit HDPE Installation GuideSong ThomsonÎncă nu există evaluări

- No.8 DTS Components 02 UK PDFDocument19 paginiNo.8 DTS Components 02 UK PDFhepcomotionÎncă nu există evaluări

- Metal Seated Gate ValvesDocument3 paginiMetal Seated Gate ValvesKamran AbidÎncă nu există evaluări

- HWD0194Document2 paginiHWD0194Ever Nina LauraÎncă nu există evaluări

- British standard soil and waste technical specifications guideDocument9 paginiBritish standard soil and waste technical specifications guideSagubar SathikaliÎncă nu există evaluări

- Astm d3567Document8 paginiAstm d3567anastasio53Încă nu există evaluări

- Rothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enDocument6 paginiRothoblaas - Alumidi Bracket With Holes - Technical Data Sheets - enAndrei GheorghicaÎncă nu există evaluări

- 2040 2e6Document6 pagini2040 2e6Jaikishan KumaraswamyÎncă nu există evaluări

- Nefit Threaded FittingsDocument10 paginiNefit Threaded Fittingsraypower2004Încă nu există evaluări

- KAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enDocument3 paginiKAT A 2410 PA ZETA Pneumatic Edition7!31!01 2013 enGabriela AxinteÎncă nu există evaluări

- CM Bu9000 Eng Bushings 3Document36 paginiCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- Conexiones MPS PDFDocument6 paginiConexiones MPS PDFMaxiaires RefrigeracionÎncă nu există evaluări

- Delvalcataloguemay 3006Document4 paginiDelvalcataloguemay 3006Balu VedhachalamÎncă nu există evaluări

- F - Ceiling DiffusersDocument25 paginiF - Ceiling Diffuserssiva_nagesh_2Încă nu există evaluări

- GesamtkatalogDocument36 paginiGesamtkatalogEduard RiemschneiderÎncă nu există evaluări

- Diaphragm Valve, Metal: ConstructionDocument6 paginiDiaphragm Valve, Metal: ConstructionDenial BasanovicÎncă nu există evaluări

- Stainless Machine FeetDocument134 paginiStainless Machine FeetVirginia Venus Visuette MarínÎncă nu există evaluări

- Volute Casing Pump Technical Data SheetDocument11 paginiVolute Casing Pump Technical Data SheetAndresÎncă nu există evaluări

- Milton ValveDocument4 paginiMilton ValvemcdermottrickÎncă nu există evaluări

- DB 698 GBDocument8 paginiDB 698 GBDenial BasanovicÎncă nu există evaluări

- En Tool Clamping Systems 2012Document72 paginiEn Tool Clamping Systems 2012Goran MiodragovicÎncă nu există evaluări

- E7M Data SheetDocument4 paginiE7M Data SheetCristian CarlettoÎncă nu există evaluări

- Modular Dual Line SystemDocument6 paginiModular Dual Line Systemangela_draguÎncă nu există evaluări

- 8202 2Document10 pagini8202 2Yang WuÎncă nu există evaluări

- Bayer: Pipes With Low-Temperature Insulation, SuspendedDocument5 paginiBayer: Pipes With Low-Temperature Insulation, SuspendedYang WuÎncă nu există evaluări

- 125HBL-8-4 Parker Brass Hose BarbDocument14 pagini125HBL-8-4 Parker Brass Hose BarbMROstop.comÎncă nu există evaluări

- XOMOXLinedPlugValvesEMEA TechnicalDataDocument20 paginiXOMOXLinedPlugValvesEMEA TechnicalDataperoooÎncă nu există evaluări

- MB 219-229 PDFDocument11 paginiMB 219-229 PDFAmitava DattaÎncă nu există evaluări

- Hose Ends - Field AttachableDocument64 paginiHose Ends - Field AttachableSasan AbbasiÎncă nu există evaluări

- Double Block Bleed TOSVDocument8 paginiDouble Block Bleed TOSVplanet123Încă nu există evaluări

- Lindapter Hollo-Bolt 807Document8 paginiLindapter Hollo-Bolt 807Amro Ahmad AliÎncă nu există evaluări

- HRC STD 6100 004 M 01 PDFDocument6 paginiHRC STD 6100 004 M 01 PDFEmir MujićÎncă nu există evaluări

- DCV Spirax PDFDocument2 paginiDCV Spirax PDFVaitheeswaran PalaniÎncă nu există evaluări

- VARGUS - Gear Milling Catalog - InchDocument12 paginiVARGUS - Gear Milling Catalog - InchGilberto ManhattanÎncă nu există evaluări

- Toyo Butterfly Valve PDFDocument20 paginiToyo Butterfly Valve PDFJimmy Adi100% (2)

- Fisher Cryogenic ValveDocument12 paginiFisher Cryogenic ValvePratik PatelÎncă nu există evaluări

- Nist GCR 14-917-31 PDFDocument42 paginiNist GCR 14-917-31 PDFsansarepÎncă nu există evaluări

- Fema - 2020 Nehrp Provisions - Part 3Document279 paginiFema - 2020 Nehrp Provisions - Part 3Gabriele BanciÎncă nu există evaluări

- 1506 Cpi Acpa UsDocument3 pagini1506 Cpi Acpa Usericpardo59Încă nu există evaluări

- OCPA DesignManualDocument145 paginiOCPA DesignManualVojin LepojevicÎncă nu există evaluări

- Astm D3034-00 PDFDocument10 paginiAstm D3034-00 PDFericpardo59100% (4)

- Sewage PipesDocument6 paginiSewage PipesMaheen MahmoodÎncă nu există evaluări

- Oldcastle Precast Catch Basins SpecificationDocument20 paginiOldcastle Precast Catch Basins Specificationericpardo59Încă nu există evaluări

- CP Info ASTM C76 Reinforcement Design Changes and Related Research PDFDocument8 paginiCP Info ASTM C76 Reinforcement Design Changes and Related Research PDFericpardo59Încă nu există evaluări

- MSPCP Final 2009 Rev 6-6-12 With Revp-150Document63 paginiMSPCP Final 2009 Rev 6-6-12 With Revp-150ericpardo59Încă nu există evaluări

- 1506 Cpi Acpa UsDocument3 pagini1506 Cpi Acpa Usericpardo59Încă nu există evaluări

- DD20 CircularPrecastConcreteManholesDocument5 paginiDD20 CircularPrecastConcreteManholesericpardo59Încă nu există evaluări

- Pipe Catalog ManholesDocument30 paginiPipe Catalog Manholesericpardo59100% (1)

- Manual de Aguas de Tormenta (Lluvia)Document487 paginiManual de Aguas de Tormenta (Lluvia)ericpardo59Încă nu există evaluări

- Fema 454 - A Manual For ArchitectsDocument394 paginiFema 454 - A Manual For ArchitectsJorge Cherres100% (1)

- TN242 Crack Mitigation Example 15Document7 paginiTN242 Crack Mitigation Example 15ericpardo59Încă nu există evaluări

- Adapt-Pt 2012 User ManualDocument169 paginiAdapt-Pt 2012 User ManualEddie AvilaÎncă nu există evaluări

- Tech1final Edificio La Jolla CaliforniaDocument33 paginiTech1final Edificio La Jolla Californiaericpardo59Încă nu există evaluări

- Manual de Aguas de Tormenta (Lluvia)Document487 paginiManual de Aguas de Tormenta (Lluvia)ericpardo59Încă nu există evaluări

- Ufgs 32 12 10Document17 paginiUfgs 32 12 10ericpardo59Încă nu există evaluări

- Ficha Tecnica Hidrante MuellerDocument6 paginiFicha Tecnica Hidrante Muellerericpardo59Încă nu există evaluări

- Femap 1024Document359 paginiFemap 1024ericpardo59Încă nu există evaluări

- Marshall Method Asphalt Mix Design GuideDocument16 paginiMarshall Method Asphalt Mix Design GuidefitrianiÎncă nu există evaluări

- Shanghai Tower 12-22-2010Document15 paginiShanghai Tower 12-22-2010Cristiano Cardoso SilvaÎncă nu există evaluări

- Super Pave IlustratedDocument80 paginiSuper Pave Ilustratedericpardo59Încă nu există evaluări

- 2010 CJ-Series Standard SpecifictionDocument30 pagini2010 CJ-Series Standard SpecifictionVrangalov PeroÎncă nu există evaluări

- Hybrid Design Reduces CostsDocument5 paginiHybrid Design Reduces Costsericpardo59Încă nu există evaluări

- Qty Estimate - ROB - Lc-34B - Structure - With RCC StairDocument22 paginiQty Estimate - ROB - Lc-34B - Structure - With RCC StairSabir AliÎncă nu există evaluări

- Cut and Cover TunnelsDocument5 paginiCut and Cover Tunnelsfethi42Încă nu există evaluări

- Static Pile Load Testing and Pile Dynamic Analysis: 8-1 IntroductionDocument8 paginiStatic Pile Load Testing and Pile Dynamic Analysis: 8-1 IntroductionBassam ElsayedÎncă nu există evaluări

- Chapter7 Substructure Design PDFDocument132 paginiChapter7 Substructure Design PDFvsballaÎncă nu există evaluări

- Franki Pile PDFDocument16 paginiFranki Pile PDFAntusias ChristopherÎncă nu există evaluări

- AISC Intro Steel Bridge Design r1 Handout 2perDocument67 paginiAISC Intro Steel Bridge Design r1 Handout 2perDarline Cano CardonaÎncă nu există evaluări

- Unit-I - Limit State Method Concept and Design of Beams: 1. MaterialsDocument7 paginiUnit-I - Limit State Method Concept and Design of Beams: 1. MaterialsYAZHINIÎncă nu există evaluări

- 02 Bid Docs Caticlan Jetty Port Final W pcg-2 PDFDocument20 pagini02 Bid Docs Caticlan Jetty Port Final W pcg-2 PDFKim GabaynoÎncă nu există evaluări

- Jet Grouting PDFDocument8 paginiJet Grouting PDFMaha KaryaÎncă nu există evaluări

- Prasarana ImaDocument97 paginiPrasarana Imamyvi317Încă nu există evaluări

- Rfsu Vs OnshoreDocument11 paginiRfsu Vs OnshoreGolfkung PairojÎncă nu există evaluări

- Sub Contractor BoQ (Boundary Walls)Document6 paginiSub Contractor BoQ (Boundary Walls)ThabisoÎncă nu există evaluări

- CADS Bearing PileDocument42 paginiCADS Bearing PileDavidÎncă nu există evaluări

- Codal Provisions For Foundation Design On Soils and Rocks: A ReviewDocument12 paginiCodal Provisions For Foundation Design On Soils and Rocks: A ReviewpareshÎncă nu există evaluări

- Exams CT3330 2004-2010Document165 paginiExams CT3330 2004-2010Ruben Rodriguez PargaÎncă nu există evaluări

- Assessing SPT-based methods for predicting pile bearing capacityDocument8 paginiAssessing SPT-based methods for predicting pile bearing capacityphamducquangÎncă nu există evaluări

- Construction Materials For Coastal StructuresDocument434 paginiConstruction Materials For Coastal Structuresleungwc2000100% (1)

- Plastic Foam in Road Meddelelse 61 Veglab PDFDocument63 paginiPlastic Foam in Road Meddelelse 61 Veglab PDFCarlos Alfredo Llanos RamirezÎncă nu există evaluări

- KLIA New A380 Hangar PDFDocument5 paginiKLIA New A380 Hangar PDFnak_osÎncă nu există evaluări

- Soil Nailing For Slope Stabilization: An Overview: December 2016Document7 paginiSoil Nailing For Slope Stabilization: An Overview: December 2016Dhareppa malageÎncă nu există evaluări

- Meever India Brochure FinalDocument44 paginiMeever India Brochure FinalSrinu NaikÎncă nu există evaluări

- General Design and Construction RequirementsDocument30 paginiGeneral Design and Construction RequirementsLester BaculiÎncă nu există evaluări

- Calcul Fundatii Micropiloti Metalici ElicoidaliDocument10 paginiCalcul Fundatii Micropiloti Metalici ElicoidaliNistor FlorinÎncă nu există evaluări

- A Case Study of Foundation Failure in The Existing Residential BuildingDocument13 paginiA Case Study of Foundation Failure in The Existing Residential BuildingBAVIRISHETTY JAYKUMARÎncă nu există evaluări

- Inspection Notification Master LogDocument732 paginiInspection Notification Master LogMark Darrel AranasÎncă nu există evaluări

- IECC Pragati Maidan project planningDocument78 paginiIECC Pragati Maidan project planningRaymon PrakashÎncă nu există evaluări

- Structural CAD Draftsman With 10 + Year ExperienceDocument3 paginiStructural CAD Draftsman With 10 + Year ExperienceVikasÎncă nu există evaluări

- Structural SystemsDocument46 paginiStructural SystemsbbÎncă nu există evaluări

- 350R 89Document55 pagini350R 89DIDIER ANGEL LOPEZ RINCONÎncă nu există evaluări

- University of Chicago Press Fall 2009 CatalogueDe la EverandUniversity of Chicago Press Fall 2009 CatalogueEvaluare: 5 din 5 stele5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDe la EverandUniversity of Chicago Press Fall 2009 Distributed TitlesEvaluare: 1 din 5 stele1/5 (1)