Documente Academic

Documente Profesional

Documente Cultură

JSA For Welding Grinding

Încărcat de

BabarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

JSA For Welding Grinding

Încărcat de

BabarDrepturi de autor:

Formate disponibile

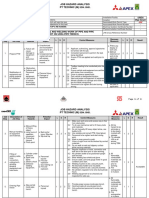

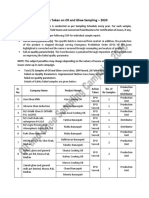

JOB SAFETY ANALYSIS

LOCATION: --------------------Task Name:

Duration:

FACILITY:---------------------

DATE: ----------

Welding, Grinding of Pipe line

Task

Steps

Controls/ Precautions

Potential Hazards

1. Applic

ation

of

Permit

to

Work.

1. Work carried out without

PTW.

2. Condu

ct TBT

1. Unawareness by team

members.

1. Apply work permits from Client prior to

work at site.

1. Tool box talk to be conducted prior to start

of work and to coordinate the work to

have a clear understanding of hazards.

3. Inspec

tion of

Tools

&

Equip

ment.

4. Perso

nal

Protec

tive

Equip

ment.

(P.P.E.

)

1. Improper or damaged

tools.

2. Bodily Injuries.

1. Proper visual inspection on tools and

equipments.

2. Damaged tools or equipments will be

removed from site.

1.

1. Bodily Injuries.

Page 1 of 7

Adequate and suitable P.P.E. Safety

helmet, safety glasses, ear plug/muff,

dust mask / respirator, safety hand gloves

and safety boot will be provided to all

workers during the course of work.

Name of

Responsible

Person

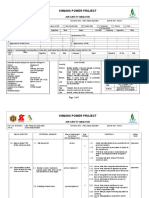

JOB SAFETY ANALYSIS

LOCATION: --------------------Task Name:

Duration:

FACILITY:---------------------

DATE: ----------

Welding, Grinding of Pipe line

Task

Steps

Potential Hazards

1. Inspection shall be done for all slings, lifting tools

Proper lift plan, check the radius, load. Crane

Inspection shall be done by HSE dept.,

Crane Safe Operating Procedure shall be followed.

2. Only qualified Crane Operator & rigger perso

gi

Carry out lifting works.

5.

Ri

1.Fall of load during off

loading, failure of crane /

slings

Controls/ Precautions

Name of

Responsible

Person

n

g

wi

th

cr

a

n

e

fo

r

pi

p

e

of

f

Page 2 of 7

JOB SAFETY ANALYSIS

LOCATION: --------------------Task Name:

Duration:

FACILITY:---------------------

DATE: ----------

Welding, Grinding of Pipe line

Task

Steps

Controls/ Precautions

Potential Hazards

lo

a

di

n

g/

Er

ec

tio

n

2.Crushing hazard or hit

by the load

3.Hit by mobile equipment

4. Hand and finger injury.

6

.G

ri

n

1. Improper Work

Permit &

Awareness.

Page 3 of 7

1. Handle the lifted load by tag line only

Walking below suspended load shall be

Prohibited. Area under lift to be barricaded.

1. Signalman shall be provided to give

Signal to the crane operator and trailer driver.

2. Use walkie-talkie for effective communication.

1. Pinch points the load shall be identified.

2. Use proper PPE,s for tool handling

(Heavy Duty gloves)

1. Get approved Hot Work Permit with

gas test certificate from FPF Control Room.

Gas test is requirement for any job near

Un- plant and ogm area to identify if there is any

Name of

Responsible

Person

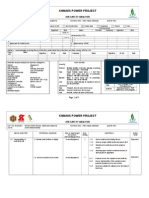

JOB SAFETY ANALYSIS

LOCATION: --------------------Task Name:

Duration:

FACILITY:---------------------

DATE: ----------

Welding, Grinding of Pipe line

Task

Steps

Potential Hazards

Controls/ Precautions

di

gas leakage which is harmful or flammable.

2. Conduct a daily toolbox talk before

start specific work.

g

W

3. Make a gas test with gas monitor

and follow permit procedure and checks

if working near OGM or FPF.

O2,CO,H2S,LEL

el

di

n

g

W

or

k

2. Poor supervision and

un-skilled person.

3. Injury due to damaged

tools

Page 4 of 7

1. Proper monitoring and supervision

required for the specific job.

2. Carry out the work only by

qualified competent personnel

Welder, Fabricator.

1.Hand tools to be inspected regularly before start

Of each day.

2. Homemade tools are not allowed at the site.

3. Use proper PPE,s for tool handling (Heavy Duty

gloves)

Name of

Responsible

Person

JOB SAFETY ANALYSIS

LOCATION: --------------------Task Name:

Duration:

FACILITY:---------------------

DATE: ----------

Welding, Grinding of Pipe line

Task

Steps

Potential Hazards

4. Electrical Shock

5. Eye / Face injury

6.Fire & Explosion

Page 5 of 7

Controls/ Precautions

1. Periodical checking and maintenance of all

power tools.

2. Power cable to be checked prior to grinding

& welding operations for no damage.

1. Safety Goggles, Face Shield, to worn by all

workers during welding cutting activity.

1. Grinding and

welding area contains

sparks by using

barriers or fire

blankets.

2. Install Fire

Extinguishers DCP /

CO2 at hot job area.

3. To monitor the hot

work area by (Fire

Watcher) during job &

after completion of

welding work to ensure

no presence of any fire

hazards.

4. Prohibit on smoking

in Plant area.

5. Clear area from any flammable material;

Remove any flammable material away from

Name of

Responsible

Person

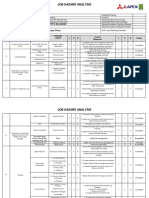

JOB SAFETY ANALYSIS

LOCATION: --------------------Task Name:

Duration:

FACILITY:---------------------

DATE: ----------

Welding, Grinding of Pipe line

Task

Steps

7Emerg

ency

Prepar

ation

at Site.

a)First

Aid

and

Medic

al

Attenti

on.

8Enviro

nment

al.

a)Ergon

omics.

Potential Hazards

Controls/ Precautions

welding, cutting and grinding operation.

1. Poor response in case of 1. All site team should be trained in

emergency.

emergency rescue procedure.

2. Always maintain or clear the access for

emergency vehicle at site.

1. Failure to rescue the

injured person.

1. One vehicle should be at site all the time

for emergency use.

2. First aid box should be at site.

1. Contamination.

2. Pollution.

3. Heat stroke, Exhaustion

and suffocation.

1. All usage of machineries/tools to be

monitored to ensure no leakage of

oil/fluids.

2. All

activities

which

produce

smoke/dust will be kept at minimal.

Water will be used to minimize dust.

3. Shed to shield workers from direct

sunlight will be provided.

1. Personnel injuries.

1. Follow the safe working procedure.

2. Implement correct manual handling

Page 6 of 7

Name of

Responsible

Person

JOB SAFETY ANALYSIS

LOCATION: --------------------Task Name:

Duration:

FACILITY:---------------------

DATE: ----------

Welding, Grinding of Pipe line

Task

Steps

09House

keepin

g.

10Demo

bilizati

on of

Equip

ment,

Tool

and

Materi

al.

Potential Hazards

1. Poor housekeeping.

1. Poor demobilization

standard or procedure.

Page 7 of 7

Controls/ Precautions

1. Housekeeping to be maintained at all

time during and after work.

2. Proper disposable of accumulated

rubbish from work area.

1. Ensure proper and safe demobilization of

machineries and material.

2. Ensure applied work permit and certificate

should be closed by Client authority at the end

of job.

Name of

Responsible

Person

S-ar putea să vă placă și

- 1installation of Steel Structures JHA 1 (06!06!2015)Document33 pagini1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Jsa For Arc WeldingDocument3 paginiJsa For Arc Weldingtnssbhaskar100% (5)

- Jsa-Jha For Using of Hand ToolsDocument2 paginiJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Scaffolding JSA (General)Document5 paginiScaffolding JSA (General)Panchdev KumarÎncă nu există evaluări

- Jsa SKDocument10 paginiJsa SKEngr Tahir UL Haq100% (2)

- Crane JSADocument5 paginiCrane JSAKritsada Tiwutanon100% (1)

- JSA WeldingDocument2 paginiJSA WeldingSigint Sides0% (3)

- JSA ElectricalDocument2 paginiJSA Electricalsubhanmusadiq100% (6)

- JSA Blasting and Coating KP 69.4Document5 paginiJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- Muscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeDocument4 paginiMuscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeCarlo FilipponeÎncă nu există evaluări

- QP Painting JSADocument6 paginiQP Painting JSAMohammed Mujahid100% (2)

- 7 - Civil WorkDocument12 pagini7 - Civil WorkPerwez21100% (1)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 paginiMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- JSA Steel Erection ManliftsDocument1 paginăJSA Steel Erection Manliftsrudygoot100% (1)

- JSA Shut Down and Tie in Work PDFDocument6 paginiJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- Hot Work: Job Hazard Analysis PT Technic (M)Document4 paginiHot Work: Job Hazard Analysis PT Technic (M)ShahrizatSmailKassim100% (1)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocument6 paginiJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Jsa For Weld and GrindingDocument6 paginiJsa For Weld and GrindingTanzeel LiaqatÎncă nu există evaluări

- How Chin Engineering: Job Safety AnalysisDocument5 paginiHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdÎncă nu există evaluări

- Hot Works JSA Example - 2Document2 paginiHot Works JSA Example - 2shaheer79% (34)

- Jsa For Lifting (Crane) 016Document6 paginiJsa For Lifting (Crane) 016aliraza572270% (27)

- JSA G20 Scaffolding (Erection, Dismantling)Document4 paginiJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- JSA Cable Pulling and Laying WorksDocument6 paginiJSA Cable Pulling and Laying Workskabir100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 paginiJsa Grinding Welding Gas CuttingRana Waseem Khan82% (79)

- JSA-Loading UnloadingDocument2 paginiJSA-Loading Unloadingsubhanmusadiq82% (55)

- Jsa Welding Cutting and Grinding at Closing AreaDocument7 paginiJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- Job Safety Analysis Sheet: FacilityDocument1 paginăJob Safety Analysis Sheet: Facilitywahyu nugrohoÎncă nu există evaluări

- Concrete Work JSADocument1 paginăConcrete Work JSAAnonymous goXrLOI33% (3)

- JSA Erection of Steel StructureDocument9 paginiJSA Erection of Steel StructureLuqman Osman77% (13)

- Aboveground Piping Installation Works 2016Document7 paginiAboveground Piping Installation Works 2016Aldrin75% (4)

- Jsa For Civil Confined Space EntryDocument11 paginiJsa For Civil Confined Space EntryKhuda BukshÎncă nu există evaluări

- 013 JSA For Earthwork at Receiving BasinDocument4 pagini013 JSA For Earthwork at Receiving BasinHilbrecht De Pedro100% (1)

- JSA To Perform Greasing of Motor BearingDocument9 paginiJSA To Perform Greasing of Motor BearingChung Trịnh100% (1)

- JSA For Working at HeightDocument1 paginăJSA For Working at HeightSafety& Security Supervisor100% (1)

- Jha Lin FillingDocument6 paginiJha Lin FillingLuqman OsmanÎncă nu există evaluări

- Civil JSA Form Block WorkDocument3 paginiCivil JSA Form Block Workdrmuhsin86% (7)

- JSA - SK-erection & DismantlingDocument1 paginăJSA - SK-erection & DismantlingEngr Tahir UL Haq100% (3)

- Jsa CraneDocument3 paginiJsa Cranenattwa201075% (24)

- JSA HandToolsDocument2 paginiJSA HandToolsCristina Rican100% (3)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 paginiHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA For Cutting, Grinding and WeldingDocument4 paginiJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 paginiJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- JSA-Working at HeightDocument2 paginiJSA-Working at Heightsubhanmusadiq84% (110)

- JSA WeldingDocument2 paginiJSA Weldingsubhanmusadiq100% (1)

- Jobs Safety Analysis (JSA)Document8 paginiJobs Safety Analysis (JSA)uttam mishra100% (1)

- 01 JSA For Earthworks at Corridor ADocument32 pagini01 JSA For Earthworks at Corridor AHilbrecht De Pedro100% (1)

- Jsa For Piping and Erection RevisedDocument1 paginăJsa For Piping and Erection RevisedAlvin Smith77% (26)

- JSA Lifting OperationsDocument4 paginiJSA Lifting OperationsCristina Rican100% (1)

- Jsa ExcavationDocument33 paginiJsa Excavationlal5012002390782% (17)

- Column Lifting & Erection JSADocument7 paginiColumn Lifting & Erection JSAAli Mohsin100% (3)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 paginiSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- JSA For False CeilingDocument4 paginiJSA For False CeilingJaved100% (3)

- JSA Welding Confined SpaceDocument2 paginiJSA Welding Confined Spacegkmlal100% (4)

- Job Safety Analysis (Jsa)Document11 paginiJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- Work Permit Compliance (Presentation)Document52 paginiWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- JSA PlumbingDocument2 paginiJSA Plumbingsubhanmusadiq71% (7)

- Postoperative Care in Thoracic Surgery A Comprehensive GuideDocument397 paginiPostoperative Care in Thoracic Surgery A Comprehensive GuideΑΘΑΝΑΣΙΟΣ ΚΟΥΤΟΥΚΤΣΗΣ100% (1)

- Safety Tips in Playing ArnisDocument2 paginiSafety Tips in Playing ArnisDensyo De MensyoÎncă nu există evaluări

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pagini0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 paginiRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariÎncă nu există evaluări

- Method Statement For Room Control UnitDocument14 paginiMethod Statement For Room Control UnitshareyhouÎncă nu există evaluări

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDocument14 paginiMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47Încă nu există evaluări

- Jsa forOperatingAForkliftDocument2 paginiJsa forOperatingAForkliftsupahing supahingÎncă nu există evaluări

- Method Statement For MV Panels and Accessories Unloading.: Project NameDocument12 paginiMethod Statement For MV Panels and Accessories Unloading.: Project NameSatish SharmaÎncă nu există evaluări

- Improving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionDocument2 paginiImproving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionPatricia AngatoÎncă nu există evaluări

- Hamraki Rag April 2010 IssueDocument20 paginiHamraki Rag April 2010 IssueHamraki RagÎncă nu există evaluări

- Scoop of Practice aOTADocument9 paginiScoop of Practice aOTAfercespedÎncă nu există evaluări

- Constipation Treatment For Infants and ChildrenDocument2 paginiConstipation Treatment For Infants and Childrenapi-559575515Încă nu există evaluări

- 13105389Document22 pagini13105389Larry RicoÎncă nu există evaluări

- Action Taken On Oil and Ghee Sampling - 2020Document2 paginiAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiÎncă nu există evaluări

- Measurement of Bioreactor K ADocument18 paginiMeasurement of Bioreactor K AAtif MehfoozÎncă nu există evaluări

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Document1 paginăUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajÎncă nu există evaluări

- Gay Costa Del Sol - 2010Document2 paginiGay Costa Del Sol - 2010gayinfospainÎncă nu există evaluări

- Cannabis Effects On Driving SkillsDocument15 paginiCannabis Effects On Driving SkillsCharles PetersÎncă nu există evaluări

- Maya Mendez ResumeDocument2 paginiMaya Mendez Resumeapi-520985654Încă nu există evaluări

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDocument10 paginiVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorÎncă nu există evaluări

- Distress Manual PDFDocument51 paginiDistress Manual PDFEIRINI ZIGKIRIADOUÎncă nu există evaluări

- Biology Q PDFDocument9 paginiBiology Q PDFsumon chowdhuryÎncă nu există evaluări

- Vaccination Schedule in Dogs and CatsDocument3 paginiVaccination Schedule in Dogs and CatsAKASH ANANDÎncă nu există evaluări

- Test On QuantifiersDocument1 paginăTest On Quantifiersvassoula35Încă nu există evaluări

- 2015 12 17 - Parenting in America - FINALDocument105 pagini2015 12 17 - Parenting in America - FINALKeaneÎncă nu există evaluări

- Form 28 Attendence RegisterDocument1 paginăForm 28 Attendence RegisterSanjeet SinghÎncă nu există evaluări

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Document4 pagini(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungÎncă nu există evaluări

- E10b MERCHANT NAVY CODE OF CONDUCTDocument1 paginăE10b MERCHANT NAVY CODE OF CONDUCTssabih75Încă nu există evaluări

- A.8. Dweck (2007) - The Secret To Raising Smart KidsDocument8 paginiA.8. Dweck (2007) - The Secret To Raising Smart KidsPina AgustinÎncă nu există evaluări

- Debunking The Evergreening Patents MythDocument3 paginiDebunking The Evergreening Patents Mythjns198Încă nu există evaluări

- Aromatic Electrophilic SubstitutionDocument71 paginiAromatic Electrophilic SubstitutionsridharancÎncă nu există evaluări

- Chapter One - FiveDocument118 paginiChapter One - FivePrecious AnthonyÎncă nu există evaluări

- CASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICADocument3 paginiCASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICAclaireÎncă nu există evaluări

- B1 Pendent SprinklerDocument2 paginiB1 Pendent SprinklerDave BrownÎncă nu există evaluări