Documente Academic

Documente Profesional

Documente Cultură

Automotregive Design Analysis

Încărcat de

Rajat Dalia0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări3 paginirthss

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentrthss

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

15 vizualizări3 paginiAutomotregive Design Analysis

Încărcat de

Rajat Daliarthss

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 3

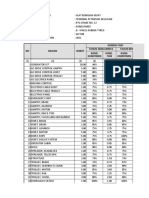

DAY- Removal of Tires, Brakes and other

parts.

3

Removal of starter, alternator,

radiator and even some sensors

and exhaust components.

Removal of tires.

Lift to raise the automobile off of

the ground.

Removal of all brake pads, drums,

shoes and lines

Removal of rotors.

DAY- Dismantling the suspension and

steering.

4

Removal of all fenders, doors, and

the roof of the car in order to take

it down to the frame.

Unbolting the steering rack.

Removal of steering columns.

Removal of tie rods from knuckles.

Dismantling the steering

mechanism.

Demonstration of rack and pinion

arrangement.

Removal of suspension points

from knuckles.

Removal of damper and spring

arrangements.

Removal of leaf springs, if any.

DAY- Dismantling the Transmission system.

Removal of external parts of

5

the transmission.

Removal of shift linkage,

mount, the top cover, and the

input bearing collar.

Orientation of shafts to a

certain position before they

can be removed.

Removal of shift forks.

Energy conversion during braking

Types

Drum brakes

Disc brakes

Calculations of Peak force

Power dissipation

Fade

Smoothness

Pedal force

Drag

Durability History and usage

Manufacturing process

Components in a tyre Construction

Types bias, belted, radial, solid

Tyre codes

Vehicle applications

SUSPENSION SYSTEM

Need of suspension and basic principle

Springs, dampers, dashpot

Camber and Caster

Scrub radius | weight transfer | sprung

mass | un sprung mass

Independent systems

Single and double wishbone

Multi-link

Mac pherson

Hydro elastic suspension

Air suspension

Leaf springs-parts in leaf spring

Suspension geometry and calculations

Current usage in different vehicles.

STEERING SYSTEM

Linkage and mechanisms

U joint-components in the system

Wheel steering geometry

Ackermann steering geometry

Caster angle/camber angle

Toe in/Toe out

Types

Rack and pinion

Recirculating ball mechanism

Power steering

Speed sensitive steering

Over steer and under steer

Common faults

Current examples.

TRANSMISION SYSTEM

Power transmission assembly

Types

Manual/automatic/semi/full/CVT

Clutch

Gear train

Transmission shaft

Differential-planetary gears

Axles

Torque converter

Designing of complex

parts using

SolidWorks.

Simulation of a piston

cylinder assembly for

static analysis.

Introduction to

Computational Fluid

Dynamics

Removal of the sliding collars.

Removal of main shaft

assembly.

Removal of gaskets, seals,

bushings, bearings/ rollers,

synchro rings, plus the various

spring clips, retaining clips,

and other small parts.

Removal of differential and its

further dismantling.

DAY- Inspection and repairing techniques.

Examine all bushings for looseness

6

with their respective parts.

Examine for nicks, cracks and

other possible damage.

Gears will be examined for uneven

tooth bearing, cracks or other

damage due to wear.

Inspection of ball bearings and its

lubrication.

Cleaning and polishing engine

parts.

Usage patterns for Cotter pins,

safety wire, all gaskets, oil seals,

lock washers, ignition cables, and

rubber hoses.

Dog clutch

DSG/DCT gearbox

2WD, 4WD and AWD

Advantages and disadvantages of

different systems

Current examples.

Turbochargers and Superchargers

Supercharger working principle

Compressors

Supercharger drives

Efficiency

Turbocharger working principle

Key components and types

Efficiency

Difference between supercharger and

turbocharger.

Common examples.

Doubts or queries.

S-ar putea să vă placă și

- Skoda QuestionaireDocument1 paginăSkoda QuestionaireRajat DaliaÎncă nu există evaluări

- SopDocument2 paginiSopRajat DaliaÎncă nu există evaluări

- CostewrthjDocument89 paginiCostewrthjRajat DaliaÎncă nu există evaluări

- Beta Geo Correction3Document22 paginiBeta Geo Correction3Rajat DaliaÎncă nu există evaluări

- This Is Shelja Guptta I Want To Download Maruti File Don't You Fuck With Me U All FucklardsDocument1 paginăThis Is Shelja Guptta I Want To Download Maruti File Don't You Fuck With Me U All FucklardsRajat DaliaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- GPI Trimec DP ManualDocument8 paginiGPI Trimec DP ManualAndres Felipe Torres PradaÎncă nu există evaluări

- 04443720AA Masterpact NW User ManualDocument1 pagină04443720AA Masterpact NW User ManualdaywalkeryÎncă nu există evaluări

- Big Red 600 Lincoln ElectricDocument6 paginiBig Red 600 Lincoln Electricamerica1591Încă nu există evaluări

- Hydraulic Puller Kit TMHC 110E: ApplicationDocument2 paginiHydraulic Puller Kit TMHC 110E: Applicationsbosch54Încă nu există evaluări

- Reovib Mfs 168: Unique Selling PointDocument8 paginiReovib Mfs 168: Unique Selling PointMarianNeaguÎncă nu există evaluări

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 paginiInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Elie Abisaad100% (1)

- DSP2 Manual PDFDocument147 paginiDSP2 Manual PDFEcaterina Irimia100% (2)

- Eei Master Storage InverterDocument4 paginiEei Master Storage Inverterpaohung linÎncă nu există evaluări

- V0lvo &scaniaDocument41 paginiV0lvo &scaniairawan budi santosaÎncă nu există evaluări

- Voltronic Axpert MKSDocument1 paginăVoltronic Axpert MKSMiguel CondoriÎncă nu există evaluări

- Content - Fisher RegulatorsDocument44 paginiContent - Fisher Regulatorsbcjal100% (1)

- ES.2.14.0035 LV Cage Induction MotorsDocument54 paginiES.2.14.0035 LV Cage Induction MotorsAhmed FayedÎncă nu există evaluări

- Econair 2Document0 paginiEconair 2Dashtseren TulgaÎncă nu există evaluări

- Impact Panel Printer For Industrial Use: CharacteristicsDocument3 paginiImpact Panel Printer For Industrial Use: CharacteristicsWALTER DANIEL GUTIERREZ VEREAUÎncă nu există evaluări

- Vision 4000 Service Manual.Document42 paginiVision 4000 Service Manual.Rko OrtonÎncă nu există evaluări

- Section 35 - Hydraulic SystemDocument74 paginiSection 35 - Hydraulic SystemCristian SterieÎncă nu există evaluări

- 21-19700-120 Reintjes Product Guide 2021 - Final - LowDocument186 pagini21-19700-120 Reintjes Product Guide 2021 - Final - LowLaodenovriÎncă nu există evaluări

- Ceckmate enDocument4 paginiCeckmate enHerlan MaulanaÎncă nu există evaluări

- Service Manual PDFDocument428 paginiService Manual PDFAprajita Kayastha100% (2)

- Unor3smbus 2.inoDocument6 paginiUnor3smbus 2.inoM. Randy AswinÎncă nu există evaluări

- TCC-80/80I Series: Port-Powered RS-232 To RS-422/485 Converters With Optional 2.5 KV IsolationDocument5 paginiTCC-80/80I Series: Port-Powered RS-232 To RS-422/485 Converters With Optional 2.5 KV IsolationSudharsan KingÎncă nu există evaluări

- Watson Marlow 3000 Series Peristaltic Pump ReportDocument2 paginiWatson Marlow 3000 Series Peristaltic Pump ReportAbilash muraliÎncă nu există evaluări

- HPR-2Document12 paginiHPR-2v2nssysy6fÎncă nu există evaluări

- Fermator Landing Door LD30 Maintenance Manual Premium - 09.18Document60 paginiFermator Landing Door LD30 Maintenance Manual Premium - 09.18alfreliaÎncă nu există evaluări

- Crossvent-3+: Operation & Service ManualDocument102 paginiCrossvent-3+: Operation & Service ManualIngenieria NemoconÎncă nu există evaluări

- 0 Kit Rfid ArduinoDocument9 pagini0 Kit Rfid ArduinoStevanus ColonneÎncă nu există evaluări

- Form Survey Kondisi Fisik & Draft Rencana BongkarDocument25 paginiForm Survey Kondisi Fisik & Draft Rencana BongkarKONSULTAN RELOKASI RTGÎncă nu există evaluări

- 1Document1 pagină1ngokhanhtÎncă nu există evaluări

- Information Systems 363 Stair Chapter 3 11th EditionDocument55 paginiInformation Systems 363 Stair Chapter 3 11th EditionVictoria NguyenÎncă nu există evaluări

- 105 DataDocument2 pagini105 DataKarim OmranÎncă nu există evaluări