Documente Academic

Documente Profesional

Documente Cultură

A Cost Estimation Model To Develop Mock

Încărcat de

Aditya IsnainiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Cost Estimation Model To Develop Mock

Încărcat de

Aditya IsnainiDrepturi de autor:

Formate disponibile

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

A Cost Estimation Model to Develop Mock-Up of Electric Car

a,b)

Wahyudi Sutopo, a,b)Rakhman Ardiansyah,

Dwi P.T., b,c)Muhammad Nizam

b,c)

D. Danardono

a)

Laboratory of Logistic and Business System, Department of Industrial Engineering,

Faculty of Engineering, Sebelas Maret University

b)

Team of Research & Development for Indonesia Electric Vehicle Consortium of Sebelas

Maret University

c)

Department of Mechanical Engineering, Faculty of Engineering, Sebelas Maret

University Jl. Ir. Sutami No. 36A Surakarta 57126

E-mail: wahyudisutopo@gmail.com; rakhmanne@live.com; danar1405@gmail.com;

nizamkh@gmail.com

Abstrak: Cost estimation is a calculation that used to generate total cost of a product.

Generally cost estimation is done after the product through the design phase. But now,

calculation of cost estimation was conducted when the product is in the product design

phase. Based on many research before, model of cost estimation is formulated for a product

at design phase, development phase, and mass production. Mobil Listrik Nasional (Molina)

as know Indonesia Electric Vehicle called Smart-T is a product which still in product

design phase. That product is designed by Molinas Team from Sebelas Maret University

(UNS). Before producing prototype and mass production, UNS have to build mock-up of

Molina. Cost estimation system for mock-up must be determined which is the most

applicable. Research Approaches to generate model is parametric method. Purpose of this

research is to know cost estimation model for mock-up of Molina. The approach to finalize

cost estimation of mock-up is parametric method. The final output from the research is total

cost estimation with numerical example for mock-up of electric vehicle.

Keywords: cost estimation; electric vehicle; mock-up; product design

1.

INTRODUCTION

The Government of Republic of Indonesia is aggressively pursuing research and development of national electric

vehicle called Mobil Listrik Nasional/Molina (Indonesia Electric Vehicle). Sebelas Maret University is trusted the

Republic of Indonesia establish research and development team of Molina. The research process of Molina is

professional research. That professional process is set up to make the product with high quality and ready for mass

production in the future. The project of Molina is funded by Directorate General of Higher Education (DGHE),

Ministry of Education and Cultural.

Molina is a product that are still in the design phase. At this phase is still performed many experiments and

research. The output of this phase is form of mock up. Mock up is physical form of Molina but couldnt be operated.

After the stage is passed, formed the prototype that can be operated and then ready to continue to mass-production.

According to Weustink et al. (2000), design phase have the biggest opprtunities to minimize production cost that affect

to pricing strategy.

Cost estimation is a calculation of cost which is used to find total cost of a product before actual production

process is performed (Kesavan et al., 2008). Cost estimation make decision maker have a detail calculation to evaluate

and to compare alternatives. To make an accurate pricing strategy, cost estimation is needed. The greatest potential for

cost reduction is at design and development phase (Duran et al., 2009). Since cost estimation is done at early stage of

41 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

product cycle, it is making easier for researcher to find comparison between cost and productivity estimation

(Cavalieri et al., 2004).

Generally, stage of product cycle is design, development, and mass-production. Cost estimation usually done at

every stage of product cycle. Cost estimation for a mass-production is easy to calculate because the product are already

exist (Tsuchiya & Kobayashi, 2004). But cost estimation at that stage is hard to make the greatest cost reduction

because after design phase is through so the best opportunity to minimize cost is also through (Weustink et al., 2000).

There are many benefits derived from the activity cost estimate in design stage i.e. for determining patent and royalty.

Molina that is still at design and development have a great potential to be patented. Without cost estimation at design

stage, it is really hard to calculate value of patent. Advantages from patent is maximizes profit from product that

licensed (Poddar & Sinha, 2002).

Cost estimation for mock-up of Molina should use the most appropriate kind of cost estimation systems. The

purposes of this research is to find cost estimation model for mock-up of Molina. There are some cost estimation

method that usually used at many research. Some of that method are engineering approaches, analogy-based

techniques (Cavalieri et al., 2004; Duran et al., 2008), and parametric models (Qian & Ben-Arieh, 2008; Gunduz et al.,

2011). This research use parametric method.

Parametric estimating is an estimating method developed and used by trade associations. New housing

constructions is an example of this method (Kesavan et al., 2009). This method usually used at project where still a

few people that know the (Gunduz et al., 2011). This method also gives a quick estimation without need a detailed data

from whole of production process (Chougule & Ravi, 2006). The most important stage at parametric cost estimation is

collecting data and testing. After estimator develop an estimation method, sample of data have to be collected and

generate a bell curve or normal distribution. Then after parametric data is used to estimate, should do the test for actual

work and then do the proper correction to get a better estimation (Kesavan et al., 2009).

2.

RESEARCH METHOD

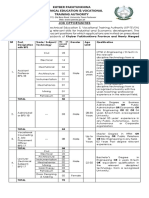

This research was conducted with approaches as follow (Figure 1). Early stage of this research is started from

design of Molina that still in a mechanical drawing. Based on mechanical drawing, material that needed to produce

Molina can be classified. Classification of material is important to calculate total material cost from price per material

and quantity of material. So, it can define total material cost that needed include overhead cost that assumed.

Next stage is analyzing attributes or factors that affect cost estimation for mock-up of Molina. Mock-up is a part

of product development stage. Mock-up is formed a car but couldnt ready to operate. Production process of mock up

is different with mass-production process. Production process of mock up still has many things that must be consider

and lastly established some cost activity like engineering activity. It called engineering cost which consists of designstyling, verification and testing, body and compartment development, chassis system and power management, and

battery charger.

42 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

Fig. 1. Research Approach

Based on materials that needed and experts that involved, then analyzed and estimated total cost for mock-up of

Molina. From the process flow can be identified component of cost. Figure 2 shows position of mock-up at product

cycle and estimation method that appropriate.

Fig. 2. Using of Cost Estimation Method

43 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

After calculated all of the cost that consist at process of mock-up then the cost estimation model for the mock-up

Molina is generated. From this initial estimation model is able to calculate all the components of the costs involved.

However, this model still must go through phases of verification before it became a model that can be used. To verify

the accuracy of the model required an analysis of the model. If the model has been verified and is considered accurate

then the cost estimation model mock-up can be used.

RESULT AND DISCUSSION

Generally cost elements of a product consist of labor cost, material cost, and overhead cost. There are some

differences to classify cost components. Figure 3 shows classification of cost element for Mock-up Molina. That

difference established because mock-up is a product that not ready to use yet. However, engineering cost appeared to

replace labor cost. Cost elements of engineering cost consist from four parts. Each part consists of experts that

separated to three types of experts. They are senior, middle, and junior of experts.

3.

Figure 3. Cost Element of Mock-up Molina

Generally phases that must be through to produce a mock-up engineering, manufacturing, tooling, quality

controlling, and testing. But for mock-up Molina, engineering cost can represent all of process that generate cost. If the

product are ready to mass production so the phases going to be more complex.

Term

TC

EC

MAC

OC

Table 1. Term of Cost Element

Description

Total cost

Engineering cost

Material cost

Other cost

From equation (1) can be identified that cost component for mock-up composed from 3 type of cost. They are

engineering cost, manufacturing cost, and other cost. Table 1 describes the equation of total cost.

(1)

44 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

Engineering cost on manufacturing mock-up have similarities with labor cost that usually calculated to find total

cost of a product. Engineering cost calculate total cost involved in the use of experts. Calculation of engineering cost

involves four components. There are Design-styling, Body and compartment development, Chassis system and power

management, and Battery charger.

Table 2. Term of Engineering Cost

Description

Design-style hour

Design-style rate

Design-style overhead

Body and compartment hour

Body and compartment rate

Body and compartment overhead

Chassis system and power management hour

Chassis system and power management rate

Chassis system and power management overhead

Battery charger hour

Battery charger rate

Battery charger overhead

i = (1, 2, 3) type of experts

Term

DSHi

DSRi

DSO

BCHi

BCRi

BCO

CSPHi

CSPRi

CSPO

BcHi

BcRi

BcO

i

Equation (2) identifies that calculation of EC involving four part of engineering. That equation multiply

engineering rate with engineering hour of each part. Then overhead costs of each part are added. Table 2 shows

description each part of equation (2).

(2)

Material cost of mock-up can be calculated based on bill of material (BOM). BOM represent material type and

amount required to produce a mock up.

Term

Q

P

MACO

Table 3. Term of Material Cost

Description

Quantity

Price of material

Material cost overhead

Equation (3) identify calculation of material cost are multiplying amount of part needed with price of material.

Then overhead cost of material cost is added. Table 3 shows description of equation (3).

(3)

Other cost is the support cost that is not related directly to the manufacturing process of mock up. Cost involved

in other cost (OC) is administrative cost and travel cost. Table 4 shows description of equation (4).

45 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

Term

Adc

TRc

Ovc

Table 4. Term of Other Cost

Description

Administrative cost

Travel cost

Overhead cost

Equation (4) identifies calculation of other cost involving administrative cost, travel cost, and overhead cost.

(4)

Numerical examples of the model are shown in the tables below. To fill in values of model parameters, we

developed an MS. Excel-Macro based application. The user can input data such as all the parameters from the

historical data and set the parameters of engineering, material, and other cost. Display data input can be seen in the

Table 5 to Table 8. Table 9 and Table 10 describe the total material cost and other cost. Total Cost Estimation of

Mock Up can be seen in Fig. 11

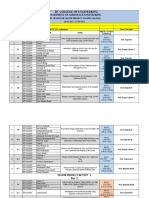

Table 5. Total Design Styling Cost

46 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

Table 6. Total Body and Compartment Cost

Table 7. Total Chassis and Power Management Cost

47 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

Table 8. Total Battery Charger Cost

Table 9. Total Material Cost

MATERIAL COST

Part

Cover Dashboard

Seat

Under Frame

Hinge and Door

Front Bulkhead

Front Baggage

Single Wiper

Car Paint

Bracket Motor and Battery

Front Windshield

Door Windshield

Frame

Total Material Cost

Overhead

Total Material Cost + Overhead

Table 10. Total Other Cost

48 | I C E A S T 2 0 1 2

Total

Rp 2,100,000

Rp 4,000,000

Rp 10,500,000

Rp 3,500,000

Rp 1,355,000

Rp 1,850,000

Rp

550,000

Rp 10,000,000

Rp 6,375,000

Rp

960,000

Rp 1,550,000

Rp 4,000,000

Rp

Rp

Rp

Rp 46,740,000

20%

Rp 56,088,000

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

Table 11. Total Cost Estimation of Mock Up

Based on numerical example, total cost estimation of Mock Up is Rp566.688.000. The overhead are also

included on that calculation. In this numerical example, assumed rate of overhead for engineering and material cost is

20%. Otherwise assumed rate of overhead for other cost is 10%.

4.

CONCLUSION

Cost estimation model for mock up that generated is simple model which generally calculate total cost of a

product. The proposed model can be used to calculate total cost of a product which is still at design phase. Calculation

total cost of product design quiet different with total cost of finished goods. Total cost of mock-up can be used to

determine value of patent. Generally cost estimation of product design calculates the knowledge, experiment, and

brain of the experts or researchers that involver.

Further research is needed to develop the application of decision support system of cost estimation which

considers an engineering bill of material model. The application of decision support system is also needed to develop

algorithms approach to speed up the time processing of selected cost estimation model.

5.

ACKNOWLEDGMENT

The authors gratefully acknowledgment the Directorate General of Higher Education (DGHE),

Ministry of Education and Cultural, the Republic of Indonesia for the financial support under Penelitian

Kerja Sama Perguruan Tinggi, Pemda, dan Industri program FY 2012.

6.

REFERENCE

[1] Camargo, M., Rabenasolo, B., Jolly-Desodt, A-M., Castelain, J-M. 2003. Application of The Parametric

Cost Estimation in The Textile Supply Chain. Journal of Textile and Apparel Technology and

Management (JTATM). 3: 1 12.

[2] Caputo, A.C., and Pelagagge, P.M. 2008. Parametric and neural methods for cost estimation of process

vessels. Int. J. Production Economics. 112: 934 954.

[3] Cavalieri, Sergio., Maccarrone, Paolo., and Pinto, Roberto. Parametric vs. neural network models for

the estimation of production costs: A case study in the automotive industry. Int. J. Production

Economics. 91: 165 177.

49 | I C E A S T 2 0 1 2

International Conference and Exhibition on

Automotive Science and Technology (ICEAST)

2012

[4] Chougule, R.G., and Ravi, B. 2006. Casting cost estimation in an integrated product and process design

environment. International Journal of Computer Integrated Manufacturing. 19: 676 688.

[5] Collopy, Paul D., and Curran, Richard. 2005. The Challenge of Modeling Cost: The Problem.

International Conference on Innovation and Integration in Aerospace Sciences (CEIAT). 85: 1 10.

[6] Duran, Orlando., Rodriguez, Nibaldo, and Consalter, L.A. Neural Networks for Cost Estimation of shell

and tube exchangers. Expert systems with Applications. 36: 7435 7440.

[7] Ehrlenspiel, Klaus., Kiewart, Alfons, and Lindemann, Udo. 2006. Cost-Efficient Design. Munich:

Springer.

[8] Ereev, S.Y., and Patel, M.K. 2012. Standardized cost estimation for new technologies (SCENT)

methodology and tool. Journal of Business Chemistry. 9: 31 49.

[9] Gunduz, Murat., Ugur, Latif Onur., and Ozturk, Erhan. 2011. Parametric cost estimation system for

light rail transit and metro trackworks. Expert Systems with Applications. 38: 2873 2877.

[10]

Kareem, Buliaminu, and Aderoba, Adeyemi A. 2008. A Cost Estimation Model of Maintenance

Jobshop Operations. AU J.T. 12: 25 33.

[11]

Kesavan, R., Elanchezhian, C., and Ramnath, B. Vijaya. 2009. Process Planning and Cost

Estimation. New Delhi: New Age International Publishers.

[12]

Koonce, David, . 2003. A hierarchical cost estimation tool. Computers in Industry. 50: 293 202.

[13]

Newnes, L.B., Mileham, A.R., Cheung, W.M., Marsh, R., Lanham, J.D., Saravi, M.E., Bradbery,

R.W. 2008. Predicting the whole-life cost of a product at the conceptual design stage. Journal of

Engineering Design. 19: 99 112.

[14]

Poddar, Sougata, dan Sinha, Uday Bhanu. 2002. The Role of Fixed Fee and Royalty in Patent

Licensing. Department of Economics Working Paper NUS. 0211: 1 16.

[15]

Qian, Li, and Ben-Arieh, David. 2008. Parametric cost estimation based on activity-based costing:

A case study for design and development of rotational parts. Int. J. Production Economics. 113: 805

818.

[16]

Tsuchiya, Haruki, and Kobayashi, Osamu. 2004. Mass production cost of PEM fuel cell by learning

curve. International Journal of Hydrogen Energy (IJHYDENE). 29: 985 990.

[17]

Wang, H.S. 2007. Application of BPN with feature-based models on cost estimation of plastic

injection products. Computers & Industrial Engineering. 53: 79 94.

[18]

Weustink, I.F., ten Brinke, E., Streppel, A.H., Kals, H.J.J. 2000. A generic framework for cost

estimation and cost control in product design. Journal of Materials Processing Technology. 103: 141

148.

50 | I C E A S T 2 0 1 2

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Carriage RequirementsDocument63 paginiCarriage RequirementsFred GrosfilerÎncă nu există evaluări

- 13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Document10 pagini13 Adsorption of Congo Red A Basic Dye by ZnFe-CO3Jorellie PetalverÎncă nu există evaluări

- Harper Independent Distributor Tri FoldDocument2 paginiHarper Independent Distributor Tri FoldYipper ShnipperÎncă nu există evaluări

- 18 June 2020 12:03: New Section 1 Page 1Document4 pagini18 June 2020 12:03: New Section 1 Page 1KarthikNayakaÎncă nu există evaluări

- Android Developer PDFDocument2 paginiAndroid Developer PDFDarshan ChakrasaliÎncă nu există evaluări

- SSGC-RSGLEG Draft Study On The Applicability of IAL To Cyber Threats Against Civil AviationDocument41 paginiSSGC-RSGLEG Draft Study On The Applicability of IAL To Cyber Threats Against Civil AviationPrachita AgrawalÎncă nu există evaluări

- CEE Annual Report 2018Document100 paginiCEE Annual Report 2018BusinessTech100% (1)

- Ricoh IM C2000 IM C2500: Full Colour Multi Function PrinterDocument4 paginiRicoh IM C2000 IM C2500: Full Colour Multi Function PrinterKothapalli ChiranjeeviÎncă nu există evaluări

- Report Card Grade 1 2Document3 paginiReport Card Grade 1 2Mely DelacruzÎncă nu există evaluări

- Movie Piracy in Ethiopian CinemaDocument22 paginiMovie Piracy in Ethiopian CinemaBehailu Shiferaw MihireteÎncă nu există evaluări

- Richardson Heidegger PDFDocument18 paginiRichardson Heidegger PDFweltfremdheitÎncă nu există evaluări

- Benevisión N15 Mindray Service ManualDocument123 paginiBenevisión N15 Mindray Service ManualSulay Avila LlanosÎncă nu există evaluări

- Snapdragon 435 Processor Product Brief PDFDocument2 paginiSnapdragon 435 Processor Product Brief PDFrichardtao89Încă nu există evaluări

- A Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDocument110 paginiA Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDeepak SinghalÎncă nu există evaluări

- Review1 ScheduleDocument3 paginiReview1 Schedulejayasuryam.ae18Încă nu există evaluări

- Talking Art As The Spirit Moves UsDocument7 paginiTalking Art As The Spirit Moves UsUCLA_SPARCÎncă nu există evaluări

- DPSD ProjectDocument30 paginiDPSD ProjectSri NidhiÎncă nu există evaluări

- 2009 2011 DS Manual - Club Car (001-061)Document61 pagini2009 2011 DS Manual - Club Car (001-061)misaÎncă nu există evaluări

- Time-Sensitive Networking - An IntroductionDocument5 paginiTime-Sensitive Networking - An Introductionsmyethdrath24Încă nu există evaluări

- Carob-Tree As CO2 Sink in The Carbon MarketDocument5 paginiCarob-Tree As CO2 Sink in The Carbon MarketFayssal KartobiÎncă nu există evaluări

- Ron Kangas - IoanDocument11 paginiRon Kangas - IoanBogdan SoptereanÎncă nu există evaluări

- Test ScienceDocument2 paginiTest Sciencejam syÎncă nu există evaluări

- DQ Vibro SifterDocument13 paginiDQ Vibro SifterDhaval Chapla67% (3)

- KP Tevta Advertisement 16-09-2019Document4 paginiKP Tevta Advertisement 16-09-2019Ishaq AminÎncă nu există evaluări

- Project ManagementDocument11 paginiProject ManagementBonaventure NzeyimanaÎncă nu există evaluări

- Recommendations For Students With High Functioning AutismDocument7 paginiRecommendations For Students With High Functioning AutismLucia SaizÎncă nu există evaluări

- Modulo EminicDocument13 paginiModulo EminicAndreaÎncă nu există evaluări

- Hdfs Default XML ParametersDocument14 paginiHdfs Default XML ParametersVinod BihalÎncă nu există evaluări

- II 2022 06 Baena-Rojas CanoDocument11 paginiII 2022 06 Baena-Rojas CanoSebastian GaonaÎncă nu există evaluări

- On Derridean Différance - UsiefDocument16 paginiOn Derridean Différance - UsiefS JEROME 2070505Încă nu există evaluări