Documente Academic

Documente Profesional

Documente Cultură

Flamex Fire Protection

Încărcat de

Tori SmallDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Flamex Fire Protection

Încărcat de

Tori SmallDrepturi de autor:

Formate disponibile

Flamex Fire Protection

constructive solutions

Flexible intumescent sealants

Uses

Design criteria

Flamex products can be used to maintain the continuity of

fire rated walls, floors and ceilings, confining smoke and

fire, giving extra time for people to escape from a fire

situation. They also perform as an effective building

sealants.

Joint design

Flamex can be used in joints from 5 mm up to 50 mm

wide. The depth of sealant should be half the width, with

a minimum depth of 12 mm. In trafficked joints, sealant

depth should be a minimum of 20 mm.

Advantages

Suitable for fire stopping of joints as defined by

Approved Document B of the United Kingdom Building

Regulations.

Flamex One may be used in low movement joints from 5

mm to 20 mm wide. The minimum depth of wet seal

should be 15 mm. The sealant will form a concave

surface when cured.

Fire tested in accordance with BS476 Part 20:1987.

Joint backing

Tested in overhead joints as well as in wall joints.

Hydrocell, Expandafoam and Bitucell are suitable joint

backing materials for the sealant. Please see separate

data sheets for further details.

Prevents the passage of smoke through joints under

fire conditions.

Flamex Ceramic Strip is used in conjunction with Flamex

sealants to give 4 hours insulation in soffit joints 30 mm

wide and in wall joins depending to the joint design. The

strips 150 mm wide are cut into suitable lengths, doubled

over and inserted into the joint. The strip should be

pushed as near as possible to the middle of the joint,

Expandafoam or Expacell is then used to control the depth

of the sealing slot.

Effective as normal building sealants.

Standards Compliance

Tested in accordance with BS 476 Part 20:1987, Flamex 2

meets the performance requirements of BS 4254 : 1983

for two part polysulphide.

The specification of different joint widths is given below

Description

Flamex Ceramic Strip (13 mm x 150 mm wide)

Flamex is a high performance two-part intumescent

sealant based on our proven polysulphide technology. It

is supplied as pre-measured components in one container

which, once mixed, cures to form a tough, flexible rubber

like seal with excellent movement performance.

Joint width

1 strip 150 mm doubled around a

halved strip 75 mm wide:

2 strips doubled:

2 strips doubled:

* 4 hours rating

Flamex One is an emulsion based intumescent sealant

supplied in a cartridge which sets quickly forming a flexible

rubbery seal possessing excellent adhesion to most

building materials.

30 mm*

40 mm

50 mm

Flamex is suitable for use in expansion joints in

compartment walls and soffits, where a high degree of

movement accommodation and fire rating is required. The

sealant may be used in external as well as internal joints.

Flamex Ceramic Strip is a ceramic fibre based blanket

materials which is used as a joint packing and is supplied

in strips 150 mm wide x 13 mm thick. It is noncombustible and has excellent fire insulation properties.

Flamex Ceramic Strip is made from long ceramic fibres,

ensuring good resilience and flexibility and is made

without the use of binders; thus avoiding additional smoke

hazards during a fire.

Specification clauses

Where designated on the drawing, joints are to be sealed

using Flamex intumescent building sealants manufactured

by Fosroc. The sealant should be tested in accordance

with BS 476 Part 20:1987.

Technical support

In joints where movement is anticipated, the joint sealant

should have been tested for compliance with BS

4254:1983.

Joint should be prepared and the sealant applied in

accordance with the companys current data sheet.

Fosroc offers a comprehensive range of high

performance, high quality flooring, jointing and repair

products for both new and existing floor surfaces. In

addition, Fosroc offers a technical support package to

specifiers, end-users and contractors, as well as on-site

technical assistance in locations all over the world.

Page 1

Flamex Fire Protection

Properties

Conduit wall penetration

Extensive fire testing has been carried out on Flamex

range. Testing has been carried out in accordance with

BS 476 Part. 20:1987 at the Technical Centre of the Loss

Prevention Council (LPC).

20 mm

conduit in

normal 50

mm hole

25 mm

conduit in

normal 50

mm hole

The following summary of tests results is extracted from

LPC test reports TE 7701, TE 7702, TE 7703, TE 7787

and TE 80169.

Joint width

X depth

15x20 mm

Backing

material

Expandafoam

Insulation

3.5 hrs

Integrity

12x20 mm

Expandafoam

2.5 hrs

>4 hrs

>4 hrs

Results summary

Technical data - Flamex

Flamex Two - Two part polysulphide intumescent sealant

Soffit joints

Joint width

X depth

15x12 mm

20x12 mm

25x12 mm

30x15 mm

30x15 mm

In concrete

Joint sealed

45x25 mm

50x25 mm

50x25 mm

Backing

material

Expandafoam

Flamex

Ceramic Strip

Expandafoam

Flamex

Ceramic Strip

Insulation

>4 hrs

>4 hrs

>4 hrs

3.5 hrs

Integrity

>5 hrs

>5

hours

>5 hrs

2 hrs

>5 hrs

>5 hrs

2 hrs

>5 hrs

>4 hrs

>4 hrs

>4hrs

>5 hrs

Solids content:

Density:

Skinning time:

(typical rates)

Cure time:

(typical rates)

Hardness shore

o

at A 25 C:

Movement

accommodation

factor (MAF):

25% butt joints, 50% lap joints

Technical data - Flamex One

Wall joints

Lightweight

blocks

10x12 mm

25x12 mm

Expandafoam

>5 hrs

>3 hrs

>5 hrs

3.5 hrs

Concrete

lintel to

lightweight

blocks

20x12 mm

40x20 mm

Expandafoam

>5 hrs

4 hrs

>5 hrs

4.5 hrs

Solids content:

Density:

Skinning time:

Cure time:

Flamex One - One-part intumescent sealant

Wall joints

Single seal in

lightweight

blocks

Double seal in

lightweight

blocks

Building board

to

lightweight

blocks

(single seal)

Lightweight

blocks to

hardwood

frame

Lightweight

blocks to

concrete lintel

100%

1.61 kg/litre

o

96 hours at 5 C

o

48 hours at 15 C

24 hours at 25oC

o

4 weeks at 5 C

o

2 weeks at 15 C

o

1 week at 25 C

30-38, typical 34 (7 days cure

o

25 C, 50% RH)

20x20

mm

Expandafoam

40 mins

50 mins

10x15

mm

Expandafoam

>4 hrs

>4 hrs

10x15

mm

Expandafoam

Hardness shore

at A 25oC:

Movement

accommodation

factor (MAF):

85%

1.48 kg/litre

20-40 minutes, depending on

temperature and relative humidity

As a guide a 20x15 mm joint is

o

fully cured in 28 day at 25 C, 50%

RH. Smaller joints will cure more

quickly. A fairly advanced state of

cure is reached at 7 days under

the same conditions

30-50, typical 45 (28 days cure

25oC, 50% RH)

10% butt joints

Technical data - Flamex Ceramic Strip

30 mins

70 mins

Density:

64 kg/m

Application instructions

15x15

mm

15x15

mm

Expandafoam

Expandafoam

constructive solutions

2 hrs

3.5 hrs

2 hrs

Joint preparation

The joint surfaces must be thoroughly dry, clean and frost

free. Remove all the dust and laitance by rigorous wire

brushing, grinding or grit blasting. Remove all rust, scale

and protective lacquers from metal surfaces. Remove any

oil or grease with joint cleaner.

>4 hrs

Page 2

Flamex Fire Protection

Mixing

The sealant should be supported by a polyethylene foam

backing cord or strip such as Expandafoam or Expancell,

and in expansion joints by an expansion joint filler such as

Hydrocell, Expandafoam sheet or Bitucell.

Flamex: Both the base component and curing agent are

supplied ready for mixing in a single tin. Mix thoroughly

using a slow speed drill (300-500 rpm) fitted with a Paddle

Stirrer for a full 5 minutes. Only thorough mixing will result

in proper curing. In cold weather Flamex mixes more

easily if stored overnight at room temperature.

Immediately after mixing, load the sealant in to a 'G' Gun

and apply to the joint.

Any expansion joint filler must be checked to ensure it is

tightly packed and no gaps or voids exist at the base of

the sealing slot, before positioning a bond breaker.

Note: The use of a bond breaker is not required in

expansion joints containing Hydrocell, Expancell or

Expandafoam joint fillers. For construction or contraction

joint slots and with other expansion joint fillers a bond

breaker or backup tape should be used.

o

Application life is approximately 2 hours at 25 C.

Finishing

Where Flamex Ceramic Strip is required it should be

installed before priming, by folding and inserting into the

joint using two thin metal plates to compress the strip and

push it into the joint at the same time. Expandafoam is

then placed over Flamex Ceramic Strip before joint

sealing takes place.

Flamex should be tooled to a smooth finish. A minimal

amount of surface lubricant such as dilute detergent

solution may be used to assist the process.

Flamex One is applied using a W Gun and should be

tooled off within 15 minutes of sealing using water or very

dilute detergent solution. Any masking tape should be

removed immediately after tooling. Normally Flamex

joints will be flush and unpainted.

Gunning of the sealant must be carried out with particular

care, ensuring good contact is made with the joint sides.

For very wide joints it may be necessary to apply the

sealant in two or more passes.

Where a particularly neat finish is required, mask the face

edges of the joint with masking tape before priming and

remove after tooling is complete.

If required, the sealants may be painted with conventional

decorative paint but consideration should be given to

movement subsequently taking place and causing

cracking of the paint finish.

Priming

Cleaning

Flamex (two-part sealant)

Uncured Flamex should be cleaned from equipment using

Solvent 102. Uncured Flamex One may be cleaned from

tools and neighbouring surfaces using a damp cloth and

water.

Porous surfaces: All porous surfaces such as concrete,

stone, brickwork, block work and timber, must be primed

with Primer 7.

Limitations

Apply by brush, working in well, ensuring complete

coverage. Avoid over priming resulting in an excess of

primer in the base of the joint or beyond the join faces.

The mixed Flamex should be applied when the Primer 7 is

tack free, normally within 20 minutes to 1 hour - that is

after the evaporation of the solvent but before the prime

film has completely reacted. After 3 hours the surfaces

must be re-primed before applying the sealant.

The fire rating of Flamex sealants is specific to the tests

quoted on this data sheet.

Users should satisfy

themselves that the test results are applicable to their own

installations. The chemical resistance of Flamex sealant

is limited and exposure to solvents, oils and other

chemicals should be restricted to infrequent contact.

Not suitable for contact with bitumen or asphalt.

Porous surfaces may require a second coat of primer.

This is applied once the first coat is thoroughly dry.

Flamex sealants are not designed for use in situations

where water cannot freely drain away.

Non-porous surfaces: All non-porous surfaces should be

primed with Primer 4. The sealant should be applied after

the primer is tack free but within 3 hours. Iron and steel

must be treated with a suitable anti-corrosion primer to

prevent corrosion.

Flamex One is not suitable for any joints subject to

trafficking.

Application temperature

Flamex One

Flamex:

Flamex One:

In most cases priming is not required. On excessively

porous surfaces such as some renders and aerated lightweight blocks, a primer made by diluting a small quantity

of Flamex One 1:3 by volume with water should be

applied onto the joint sides and allowed to become tack

free before sealing.

constructive solutions

Page 3

o

o

5 C to 30 C

o

5 C to 30oC

Flamex Fire Protection

Estimating

Precautions

Supply

Health and safety

Flamex: Flash point over 65oC. Harmful. The curing agent

consists of a heavy meal based oxide. Avoid skin contact.

Wear impervious rubber or PVC gloves and eye protection.

Hands should be thoroughly washed with soap and water

before eating or smoking. Cured sealant should not be

burned off due to the generation of toxic fumes. Empty

containers must be collected for careful disposal and not left

lying about.

The materials are supplied as follows:

Flamex is supplied in 2.5 litre packs with the base and

curing agent packed in the same tin. 4 packs are supplied

in each carton.

Guide to quantities

Joint size

Litres per

Metre run per 2.5

in mm

metre run

litre pack

5x12

0.06

41.66

10x12

0.12

20.83

15x12

0.18

13.88

20x12

0.24

10.40

25x12

0.30

8.30

30x15

0.45

5.50

40x20

0.80

3.12

50x25

1.25

2.00

Flamex One is supplied in 400 ml plastic cartridges packed

in cartons of 12.

Flamex One: This product is non-hazardous, however with

any material good personal hygiene practices should be

followed, i.e. keep out of eyes, do not consume, keep away

from children and pets. Wash hands thoroughly after use.

Flamex Ceramic Strip: Harmful by inhalation. May be

irritating to skin, eyes and respiratory system. Avoid contact

with skin and eyes. Do not breathe dust.

Flamex Ceramic Filler is subject to a maximum exposure

limit (MEL) for man-made fibres of 5 mg/m3 total dust. In

normal site and installation conditions these are unlikely to

be approached. Minimise airborne dust. Wear an approved

dust mask/respirator if dust levels are likely to exceed MEL.

Wear suitable loose-fitting, long sleeved clothing, gloves

and eye protection. After handling, wash exposed skin with

soap and water. Wash work clothing separately.

Guide to quantities

Joint size

Litres per

Metre run per 2.5

in mm

metre run

litre pack

10x15

0.150

2.60

15x15

0.225

1.70

20x15

0.300

1.33

Flamex Ceramic Strip is supplied as 150 mm wide strips 7.3

metres long in boxes of 8 strips.

Primer 7: Highly flammable liquid. Flash point 23oC. Store

away from heat. Do not use near a naked flame. Avoid

prolonged breathing of vapour. Avoid skin contact. Wear

eye protection and impervious rubber or PVC gloves. Wash

hands thoroughly before eating or smoking. Water will not

remove this primer. In case of eye contact seek medical

attention immediately.

Guide to primer quantities

Theoretical

Typical

2

Primer 4:

1 to 300 litre of sealant

50-60 m /lire

2

Primer 7:

1 to 30 litre of sealant

10-12 m /litre

Actual usage will depend on joint dimensions and other

factors.

Primer 4: Highly flammable liquid. Flash point 13oC. Store

away from heat. Do not use near a naked flame. Avoid

prolonged breathing of vapour. Avoid skin contact. Wear

eye protection and impervious rubber or PVC gloves. Wash

hands thoroughly before eating or smoking. Water will not

remove this primer. In case of eye contact seek medical

attention immediately.

Storage

Store sealants and primers in cool dry conditions in original

containers within the range of 5oC to 25oC.

Joint Cleaner: Flammable liquid. Flash point 43oC. Store

away from heat. Do not use near a naked flame. Use in

well ventilated surroundings.

Avoid skin contact and

inhalation of the vapour.

Storage life

Flamex / Flamex One:

Primer 4:

Primer 7:

12 months

6 months

12 months

Solvent 102: Flammable liquid. Flash point 33oC. Store

away from heat. Do not use near a naked flame. Wear

suitable protective clothing. Wash hands thoroughly before

eating or smoking. In case of eye contact seek medical

advice immediately.

Important note:

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions

for the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that

any advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct

or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Fosam Company Limited

Head Office

Post Box 11081

Jeddah 21453

Saudi Arabia

www.fosroc.com

Telephone: +966 2 637 5345

Fax: +966 2 637 5891

email: fosam@fosroc.com

Regional Offices

Jeddah Sales Office

Jeddah Showroom

Riyadh

Dammam

Khamis Mushayt

Tel: (02) 6080999

Tel: (02) 665 0787

Tel: (01) 482 9303

Tel: (03) 814 1282

Tel: (07) 250 0469

Fax: (02) 635 3330

Fax: (02) 667 4884

Fax: (01) 482 7562

Fax: (03) 814 1581

Fax: (07) 250 0469

Yanbu Tel: (04) 322 4280

Makkah Tel: (02) 542 0869

Medinah Tel: (04) 845 1767

Jubail Tel: (03) 362 3904

Fax: (04) 391 2980

Fax: (02) 542 0869

Fax: (04) 846 3195

Fax: (03) 362 3875

Registered Office: Industrial Area, Phase 4, Road No. 414, Street No. 407

Page 4

FO SA/Flamex Fire Protection /05/A

S-ar putea să vă placă și

- Duracord & Durasheet 40/100: Bond-Breaker and Closed-Cell Back-Up Material For Use With Joint SealantsDocument2 paginiDuracord & Durasheet 40/100: Bond-Breaker and Closed-Cell Back-Up Material For Use With Joint SealantspbodooÎncă nu există evaluări

- Dimensions Tolerance SpecificationDocument12 paginiDimensions Tolerance SpecificationProfessor Dr. Nabeel Al-Bayati-Consultant Engineer0% (1)

- Tie Bar and StrapsDocument2 paginiTie Bar and StrapsStaszek WoznyÎncă nu există evaluări

- Waterproofing Membrane With InsulationDocument3 paginiWaterproofing Membrane With InsulationAljon Angeles TanÎncă nu există evaluări

- MasonDocument7 paginiMasonMichael Jherome NuqueÎncă nu există evaluări

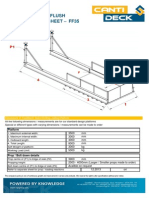

- FF35 CantiDeck Data SheetDocument1 paginăFF35 CantiDeck Data SheetAndreas AntonopoulosÎncă nu există evaluări

- Roofing Solutions IsomatDocument36 paginiRoofing Solutions IsomatBragarin DanÎncă nu există evaluări

- The Cue Dependency Theory of Forgetting by Tulving Essay QuestionDocument2 paginiThe Cue Dependency Theory of Forgetting by Tulving Essay QuestionJustin DavenportÎncă nu există evaluări

- Wall Ties and Restraint FixingsDocument9 paginiWall Ties and Restraint FixingsaahtagoÎncă nu există evaluări

- Scaffolding: Bhagwan Mahavir Collage of ArchitectureDocument33 paginiScaffolding: Bhagwan Mahavir Collage of ArchitectureVala Vraj M.Încă nu există evaluări

- St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1Document1 paginăSt-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1MØhãmmed ØwięsÎncă nu există evaluări

- MS005 Block WorkDocument5 paginiMS005 Block WorkMhando Ignas100% (1)

- Is 9918 1981Document18 paginiIs 9918 1981VenkataraoNalamothuÎncă nu există evaluări

- Analyzing A Propped Cantilever Beam Using FEMAP10 and ABAQUS6.11-2Document16 paginiAnalyzing A Propped Cantilever Beam Using FEMAP10 and ABAQUS6.11-2Lakshman ReddyÎncă nu există evaluări

- Specifications Concrete Products Aug 08Document9 paginiSpecifications Concrete Products Aug 08vijvel100% (1)

- Shoring and Purlins Layout PDFDocument1 paginăShoring and Purlins Layout PDFDexter Lex F. SatanaÎncă nu există evaluări

- Post Tension Grouts and Grouting Equipment - tcm45-340366Document3 paginiPost Tension Grouts and Grouting Equipment - tcm45-340366MosstafaÎncă nu există evaluări

- Method Statement For Construction - Method Statement - Non Suspended SlabDocument3 paginiMethod Statement For Construction - Method Statement - Non Suspended SlabKellyÎncă nu există evaluări

- AAC Block MasonaryDocument7 paginiAAC Block MasonaryDipak ThakerÎncă nu există evaluări

- Formwork Design For Settling TankDocument6 paginiFormwork Design For Settling TankPartha GorainÎncă nu există evaluări

- 2020 Dockzilla Loading Dock Buyers GuideDocument11 pagini2020 Dockzilla Loading Dock Buyers GuideNadeem RazaÎncă nu există evaluări

- Advances in Waterproofing Materials & Technology PDFDocument20 paginiAdvances in Waterproofing Materials & Technology PDFVic Charls Orbon IIIÎncă nu există evaluări

- Penetron - Ceo - Sonasea - Waterproofing Details and SpecsDocument7 paginiPenetron - Ceo - Sonasea - Waterproofing Details and SpecsNguyễn ThanhÎncă nu există evaluări

- Structured Method Statement For Concrete Repair - 2Document10 paginiStructured Method Statement For Concrete Repair - 2m.umarÎncă nu există evaluări

- Tension RodDocument4 paginiTension RodMarkÎncă nu există evaluări

- Overhead Protection SystemsDocument8 paginiOverhead Protection SystemsmangatamritÎncă nu există evaluări

- Assembly and Operating Instructions: Rack and Pinion HoistDocument54 paginiAssembly and Operating Instructions: Rack and Pinion HoistDahanTowerCraneÎncă nu există evaluări

- Structure Damage Robustness Stability PDFDocument20 paginiStructure Damage Robustness Stability PDFDodi CastelloÎncă nu există evaluări

- Design of Simple WeldDocument1 paginăDesign of Simple Weldshantanu chowdhuryÎncă nu există evaluări

- MS - CHRYSO Tapelastic Premia (Kalpitiya)Document3 paginiMS - CHRYSO Tapelastic Premia (Kalpitiya)Kasun HewagamaÎncă nu există evaluări

- Workmanship On Building SitesDocument28 paginiWorkmanship On Building SitesSa Reddi100% (1)

- Bocker Giant Construction HoistDocument8 paginiBocker Giant Construction HoistRajanbabuÎncă nu există evaluări

- False Form WKDocument12 paginiFalse Form WKRonald Cario SeguinÎncă nu există evaluări

- DR - Fixit Roofseal UltraDocument3 paginiDR - Fixit Roofseal Ultrareshmitapalla100% (1)

- Recommended Practice For Grouting of Post-Tensioned Prestressed ConcreteDocument8 paginiRecommended Practice For Grouting of Post-Tensioned Prestressed Concretevenkateswara rao PothinaÎncă nu există evaluări

- 5.backfilling and CompactionDocument4 pagini5.backfilling and CompactionZeeshan Abbasi100% (1)

- Epoxy LiteratureDocument11 paginiEpoxy Literaturepratap naiduÎncă nu există evaluări

- User Manual For FlexStep Platform - UKDocument2 paginiUser Manual For FlexStep Platform - UKCreaciones VilberÎncă nu există evaluări

- MS Outside Scaffolding - Orkide RV00Document10 paginiMS Outside Scaffolding - Orkide RV00Thành CôngÎncă nu există evaluări

- Procedure For Slab To SlabDocument5 paginiProcedure For Slab To SlabKarthik Chalageri 7100% (1)

- Structured Method Statement For Concrete Repair - 1Document15 paginiStructured Method Statement For Concrete Repair - 1m.umar100% (1)

- Scaffolding: Putlog ScaffoldsDocument10 paginiScaffolding: Putlog ScaffoldsMageshwarÎncă nu există evaluări

- TDS - Standard Method of Curing CubesDocument4 paginiTDS - Standard Method of Curing CubesVenkata RaoÎncă nu există evaluări

- Waterproof Planiseal 288Document3 paginiWaterproof Planiseal 288Chezy629Încă nu există evaluări

- 09 - PEX20 Screed & Concrete FloorDocument4 pagini09 - PEX20 Screed & Concrete FloorIbrahim SahinÎncă nu există evaluări

- General Guidelines InsulationDocument56 paginiGeneral Guidelines InsulationPadmanaban SoundirarajanÎncă nu există evaluări

- Autoclaved Aerated Concrete Blocks (Acc Blocks)Document3 paginiAutoclaved Aerated Concrete Blocks (Acc Blocks)Omar DaghistaniÎncă nu există evaluări

- Master Emaco S5400Document2 paginiMaster Emaco S5400WahyudiBlueghostÎncă nu există evaluări

- Roofing ChannelDocument16 paginiRoofing ChannelarchayuÎncă nu există evaluări

- Flooring ReportDocument4 paginiFlooring Reportn.k.indiaÎncă nu există evaluări

- Welded Connection DesignDocument10 paginiWelded Connection DesignManuelDarioFranciscoÎncă nu există evaluări

- Wall Ties and Restraint FixingsDocument32 paginiWall Ties and Restraint FixingsErnest JuniorÎncă nu există evaluări

- 07a BoQDocument15 pagini07a BoQDean KoortzenÎncă nu există evaluări

- A Guide To Commissioning Scaffold Design: 1 of 6 June 2020Document6 paginiA Guide To Commissioning Scaffold Design: 1 of 6 June 2020Matthew PowellÎncă nu există evaluări

- What Is Bearing Pressure - Independent Design House LTDDocument6 paginiWhat Is Bearing Pressure - Independent Design House LTDCE Passaj100% (1)

- Flamex One: Flexible Intumescent SealantDocument3 paginiFlamex One: Flexible Intumescent SealantBalasubramanian AnanthÎncă nu există evaluări

- Flamex Fire Protection: Flexible Intumescent SealantsDocument4 paginiFlamex Fire Protection: Flexible Intumescent SealantsOMAZÎncă nu există evaluări

- Proofex Torchseal Method of StatementDocument3 paginiProofex Torchseal Method of StatementKaren Mirad0% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- Course Book 6Document19 paginiCourse Book 6Tori SmallÎncă nu există evaluări

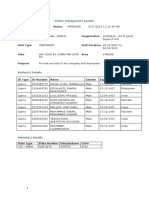

- S.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsDocument2 paginiS.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsTori SmallÎncă nu există evaluări

- I Site Progress Civil Works: A 380 KV GIS BuildingDocument3 paginiI Site Progress Civil Works: A 380 KV GIS BuildingTori SmallÎncă nu există evaluări

- Project: JUAYMAH380/230KV BSP: SL No ADocument4 paginiProject: JUAYMAH380/230KV BSP: SL No ATori SmallÎncă nu există evaluări

- Assets List Against File # 23352: Alfanar ConstructionDocument1 paginăAssets List Against File # 23352: Alfanar ConstructionTori SmallÎncă nu există evaluări

- Assets List Against File # 17920: Alfanar ConstructionDocument1 paginăAssets List Against File # 17920: Alfanar ConstructionTori SmallÎncă nu există evaluări

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Document4 pagini7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallÎncă nu există evaluări

- Details of Company Car Expenses (01.12.15)Document266 paginiDetails of Company Car Expenses (01.12.15)Tori SmallÎncă nu există evaluări

- Prism Online QuestionnaireDocument2 paginiPrism Online QuestionnaireTori SmallÎncă nu există evaluări

- Request# Status: Visitor Management SystemDocument1 paginăRequest# Status: Visitor Management SystemTori SmallÎncă nu există evaluări

- Shahrour FreedomDocument14 paginiShahrour FreedomTori SmallÎncă nu există evaluări

- 230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Document10 pagini230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Tori SmallÎncă nu există evaluări

- Acomplishment Chart 380kVDocument8 paginiAcomplishment Chart 380kVTori Small100% (1)

- Main Lab: FT-A-21226 29Y Female SelfDocument1 paginăMain Lab: FT-A-21226 29Y Female SelfTori SmallÎncă nu există evaluări

- Expense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterDocument4 paginiExpense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterTori SmallÎncă nu există evaluări

- CRC ChecklistDocument1 paginăCRC ChecklistTori SmallÎncă nu există evaluări

- Imam Hussain Sermon at MinaDocument15 paginiImam Hussain Sermon at MinaTori SmallÎncă nu există evaluări

- 5th Kannada EvsDocument256 pagini5th Kannada EvsnalinagcÎncă nu există evaluări

- Rotork: Product TrainingDocument4 paginiRotork: Product TraininghieuÎncă nu există evaluări

- Pd-Coated Wire Bonding Technology - Chip Design, Process Optimization, Production Qualification and Reliability Test For HIgh Reliability Semiconductor DevicesDocument8 paginiPd-Coated Wire Bonding Technology - Chip Design, Process Optimization, Production Qualification and Reliability Test For HIgh Reliability Semiconductor Devicescrazyclown333100% (1)

- XLPE-AL 33 KV Single Core Cable - Hoja de Datos - NKT CablesDocument2 paginiXLPE-AL 33 KV Single Core Cable - Hoja de Datos - NKT CableskjkljkljlkjljlkÎncă nu există evaluări

- Colebrook EquationDocument3 paginiColebrook EquationMuhammad Ghufran KhanÎncă nu există evaluări

- University of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementDocument15 paginiUniversity of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementPrasanga WdzÎncă nu există evaluări

- Decline Curve AnalysisDocument37 paginiDecline Curve AnalysisAshwin VelÎncă nu există evaluări

- Solid Desiccant DehydrationDocument5 paginiSolid Desiccant Dehydrationca_minoÎncă nu există evaluări

- Data0305 KX18DCDocument3 paginiData0305 KX18DCAbdelhamid SammoudiÎncă nu există evaluări

- Fax 283Document3 paginiFax 283gary476Încă nu există evaluări

- Procedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0Document13 paginiProcedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0José Angel TorrealbaÎncă nu există evaluări

- Manual Instructions For Using Biometric DevicesDocument6 paginiManual Instructions For Using Biometric DevicesramunagatiÎncă nu există evaluări

- The Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4Document2 paginiThe Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4ammarhashmi198633% (12)

- Oracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0Document12 paginiOracle® Auto Service Request: Exadata Database Machine Quick Installation Guide Release 5.0ManifoldÎncă nu există evaluări

- A318/A319/A320/A321: Service BulletinDocument22 paginiA318/A319/A320/A321: Service BulletinPradeep K sÎncă nu există evaluări

- BS 4485-4-1996 PDFDocument34 paginiBS 4485-4-1996 PDFtienÎncă nu există evaluări

- An 4160Document8 paginiAn 4160aurumstar2000Încă nu există evaluări

- Ultrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookDocument84 paginiUltrasonic Levndsgjalshfgkdjakel Endress Hauser Fmu 40 Manual BookrancidÎncă nu există evaluări

- Eseu EnglezaDocument1 paginăEseu EnglezaAndreea IoanaÎncă nu există evaluări

- Digital Design Course FileDocument191 paginiDigital Design Course FileCharan NethaÎncă nu există evaluări

- Internal Strength PositionDocument11 paginiInternal Strength PositionkulsoomalamÎncă nu există evaluări

- Guidelines For Hall IC SubassemblyDocument9 paginiGuidelines For Hall IC SubassemblyvkmsÎncă nu există evaluări

- How To Import PRN Files in IdeaDocument7 paginiHow To Import PRN Files in Ideainformation technology auditÎncă nu există evaluări

- Volvo InstructionsDocument4 paginiVolvo InstructionsRonaldo Adriano WojcikiÎncă nu există evaluări

- Niner RIP9 RDODocument5 paginiNiner RIP9 RDOSwitchback BikesÎncă nu există evaluări

- BibliografieDocument2 paginiBibliografieMadalin AlexandruÎncă nu există evaluări

- New Centum VP Dcs With Network Io WhitepaperDocument4 paginiNew Centum VP Dcs With Network Io WhitepaperFarrukh MajeedÎncă nu există evaluări

- Answers For SummariesDocument6 paginiAnswers For SummariesDaphneÎncă nu există evaluări

- Real Time Blood Type Determination by Gel Test Method On An Embedded SystemDocument4 paginiReal Time Blood Type Determination by Gel Test Method On An Embedded Systemngocbienk56Încă nu există evaluări

- Methodology: Procedure For Checking of VerticalityDocument6 paginiMethodology: Procedure For Checking of VerticalityDinesh Kumar PatelÎncă nu există evaluări