Documente Academic

Documente Profesional

Documente Cultură

Toolbox Meeting Outlines To Help Organize Your Meeting

Încărcat de

sjmpakTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Toolbox Meeting Outlines To Help Organize Your Meeting

Încărcat de

sjmpakDrepturi de autor:

Formate disponibile

Toolbox Meeting Topics

#1 - PINCH POINTS

On a construction site, we always have to be conscious of objects that could jam a part or parts of your

body against another object. We call these situations a Pinch Point.

For Example:

!When pouring concrete from a concrete bucket, we always have to be aware of the bucket's swing and

our proximity to an object that it could jam us against, i.e.- form work, rebar, concrete truck, etc. One

moment of inattention on our part and we may get jammed against an object.

!When working around cranes, we always have to be aware of the area around the counterweight. When

the crane is swinging a load, be alert to our surroundings especially if working behind the crane. If we are

too close to the crane, we may be struck by the counterweight or jammed against another object.

!When rigging a load for hoisting, always wait for the load to be airborne before trying to guide it. If the

load shifts during the period when the crane is beginning its lift, the material may jam your hand(s). Also,

never guide the load by using the slings. If the load were to shift or the slings were to tighten further or

slide, your hand(s) would be jammed between the load and the sling.

REMEMBER!!!

On every construction site there are numerous pinch points that could result in injury.

Always be aware of objects, tools, machinery or situations that could cause a part

or parts of our body to become jammed.

Page 1

Toolbox Meeting Topics

#2 - VEHICLE OPERATIONS

!Check your vehicle before getting into the cab. If the air pressure, brakes, oil, coolant or hydraulic fluid is

low or not functioning properly, stop and report it immediately to your supervisor.

!Prior to starting the vehicle, ensure that any objects that could act as a projectile if the vehicle came to a

sudden stop are removed or securely stowed away. i.e. pop cans, books, tools, construction materials,

etc.

!Always fasten your seatbelt prior to moving a vehicle. Always look before reversing. then, when all is

clear, sound your horn and look again before moving. If you are being guided by a spotter, take your

signals from him, and before moving the vehicle, make sure that he is clearly in view and out of your path.

If he disappears from view, stop immediately!!

!Obey the rules of the road. This includes local or project regulations as well.

!Keep your windshield and side-view mirrors clean for good vision. See that your wipers are operational.

!When workers are in areas where heavy equipment is operating, use extreme care.

!Always have a hard hat with you. You may not be required to wear it while you are in the cab, but you

will need it when you step out of the cab.

!Remember! Sound your horn before backing up.

Can your group remember any recent occasions when someone was endangered by a truck working

near him?

Page 2

Toolbox Meeting Topics

#3 - 3-POINT CONTACT

There are many things a person does each day without thinking. This is usually because the actions

become automatic. On construction sites, one common example is getting on and off equipment that can

range from a boom truck to a 150-ton crane. Strains, sprains, abrasions and fractures occur regularly to

equipment operators mounting or dismounting - and it all happens so quickly.

Three-point contact can prevent most of these injuries.

Three-point contact means that while mounting or dismounting equipment either two feet and one hand or

two hands and one foot are always in firm contact with the equipment.

!If the equipment you are working with is not equipped with proper foot and hand holds, it is not difficult to

add them. Let your supervisor know of any equipment lacking proper steps and rails. Arrangements can

be made for our mechanic to retrofit that equipment so that three-point contact is possible.

!However, all hand and foot holds in the world will not help if they are not kept free of mud, ice and diesel

fuel. Keep the holds clean and make sure you use three-point contact every time you get on or off your

equipment.

!Note: Handgrips could be taped with a distinctive color to make them readily visible.

Page 3

Toolbox Meeting Topics

#4 - CRANE OPERATIONS

The actions of a crane are almost human - except that they have no brain of their own to direct their

actions. The "brain" is really the operator. the operator thinks for the machine - the machine does what

the operator wants it to do. It doesn't matter if the operator doesn't know his stuff.

!Be aware of the "Cowboy" operator - smartass operating may look flashy to sidewalk superintendents,

but it's hard on the machine and hazardous to people working around the crane.

!Be conscientious of your working area around a crane. Always be alert to areas or situations that could

cause you to become jammed between the load or counterweight and any other object. Always have

escape routes planned in the event something goes wrong.

Some safety practices we must adhere to when working around cranes are:

!Don't store gasoline in the cap - why create an explosive situation when you already have enough to

think about?

!Never swing the boom over the ground crew - how would you feel if you dropped the load on your buddy

or anyone else?

!Keep the boom well away from overhead wires - if the boom does come in contact with power lines, stay

on the machine until the boom is cleared, or the power is shut off. Don't let anyone on the ground touch

or come near your machine. If you have to leave the crane for any reason (with the boom still

touching the power lines) JUMP! -- do NOT step off. Then hop away from the machine with both

feet together.

REMEMBER!!!

Think before you act!!! You may prevent an accident.

Page 4

Toolbox Meeting Topics

#5 - WHAT IS SAFETY?

Safety is a word often used, but seldom understood. The dictionary defines safety as "the condition of

being safe; freedom from danger or causing hurt, injury or loss."

!Regardless of how much equipment we use, whether we are clad from head to toe in a suit of armor, we

are still in danger of being injured.

!Until each of us performs his work in a manner that does not endanger himself or his fellow workers,

there will be no such thing as a safe job.

!Don't depend on someone else for your safety. It is up to you to avoid injury and help eliminate hazards.

!When doing a job, do not take shortcuts or chances that may put you or your fellow worker in danger.

!Safety means security. Safety practices are not important just because we put a priority on human

safety. they also are important because they are good business. The better a company's safety record,

the more it saves on property loss, time and production losses, compensation losses, and so on. Every

incident or accident - even if there is no serious damage or injury - costs the company money because to

some extent it interrupts the smooth flow of productivity. The more serious it is, of course, the more it

costs in terms of labor time lost, if nothing else. the better the safety record, therefore, the healthier the

company is, and the more competitive the company can be. That translates into more work and better

security for all employees.

REMEMBER!!!

When you have a close call, thank your lucky stars it was not an injury and learn a

lesson from it, because next time your luck may run out.

Page 5

Toolbox Meeting Topics

#6 - COMMON SENSE

Everyone in construction can agree that for the most part safety at the worksite is based on common

sense. However, sometimes we let our common sense be overruled by doing or job in a way we know to

be unsafe.

Before you act - think!!!

!Use your imagination. What would you do if the load or boom suddenly dropped when you were under a

crane?

!What if a piece of metal or concrete lodged in your eye because you did not wear your eye protection?

!Your boots are muddy, but you climb you vehicle anyway.

!Most times the injury might be slight, but is it worth taking the risk and trying it anyway?

!Management does not want you to take shortcuts if it means working unsafely. You really do not help

yourself or the company by working this way.

!If you are to do a job and unsure of the proper job procedure, ask your supervisor. They will provide you

with the proper instruction on how to do the job properly.

!Workers who act without thinking are often sorry for their actions. Serious and permanent injuries have

occurred because workers acted too quickly and thought too slowly.

Be a pro, work safely and build a healthy future by thinking before you act.

Page 6

Toolbox Meeting Topics

#7 - WHAT CAUSES ACCIDENTS

Accident are caused - they don't happen by chance.

A safe job requires planning on the part of supervision and active participation on the part of every

worker.

A few accident causing situations might be:

!The 2"x2" plant used as a ramp.

!A scaffold erected improperly.

!Scrap thrown from an upper level.

!Trash piled at the bottom of a poorly lit stairwell.

!Spikes left in scrap lumber.

!Fueling a gasoline engine while it's still running or hot.

All of these conditions and many more can cause an accident. One important fact often overlooked is

that each of these conditions was caused by someone on the job.

Most injuries occur because someone did not care enough to do his very best. Supervision cares about

accident prevention, so do most of the workers. But the help and interest of everyone on the project is

needed if we are to prevent accidents.

So take pride in your work and remember the safe way is more rewarding in the long run.

Page 7

Toolbox Meeting Topics

#8 - ACCIDENTS & INCIDENTS

What's the difference between accidents and incidents? Usually when someone is injured or there is

property damage of some type we call it an accident. On the other hand, an incident usually describes a

close call or a near miss where someone or something could have been hurt or damaged.

Accidents usually attract more attention than incidents. Some action is usually taken after an accident

occurs. Unfortunately for us, most incidents are never reported. Why is it unfortunate for us? Simply

because there are usually many close calls and near misses before we even have an accident. If all of us

were to report near misses or close calls, something could be done to correct the situation before it

causes an accident.

We should never consider near misses or close calls unimportant. They should be re- ported to

supervision immediately and action taken to improve the situation so that a similar incident will not occur

again.

We can all learn from one another. Now is a good time to talk about any close calls or near misses we

know about.

Page 8

Toolbox Meeting Topics

#9 - ACCIDENT SITUATIONS

Have we ever heard someone say after an accident "I figured that would happen sooner or later"?

Obviously the person had seen or heard something that warned him of a dangerous situation.

For example:

!Suppose you are going up a ramp, your foot slips but you are fast on your feet and regain your balance no harm done.

!Someone comes along ten minutes later. His reactions are a little slower than yours, but he grabs the

guardrail and hangs on - again, no harm done.

!Then comes the third man carrying a load. He's fast on his feet, but the load resists his movement and

down he goes fracturing his ankle.

We ignored two warnings. Consequently, someone was hurt. Now we look for the loose cleat or mud or

ice and rectify the situation.

At least two people had a warning, but failed to take action.

If we had to refer to studies done on accident ratios in the construction industry, the following findings

were recorded:

!For every 600 incidents with no visible damage or injury, there are 30 property damage accidents. For

every 30 property damage accidents, there are 10 minor injuries. For every 10 minor injuries, there is

one serious or major injury.

REMEMBER!!!

Close calls and near misses are indications that SOMETHING IS WRONG!

Don't ignore these warnings. Report them to supervision

so that action can be taken to pre-vent an accident.

Page 9

Toolbox Meeting Topics

#10 - FIRST AID

Occasionally, we get the odd scrape or cut, and sometimes a serious injury may occur on our worksites.

All these injuries will require some type of first aid. In order to care for these injuries, the appropriate First

Aid Kits and Certified Aiders must be on site.

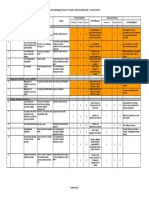

Type of First Aid Kit

on Worksite

Level of Training Required

for First Aiders

Nova Scotia #1(minimum)

Emergency First Aid Cert.

Up to 19

Nova Scotia #2(minimum)

Emergency First Aid Cert.

Up to 49

Nova Scotia #3(minimum)

Standard First Aid Cert.

Up to 100

Nova Scotia #3 and an increase in

supply that is appropriate to the

number of employees in excess of 49.

Standard First Aid Cert.

100 or more but not an office

First Aid Room or an approved facility

Advanced First Aid Cert.

# of Employees

A record must be kept regarding the treatment provided and the supplies used. This record will include

the following information, Nature of Injury, Treatment, Type of Accident(lost time medical and/or first aid

only), foreman's signature, first aiders initials and patients name or signature.

This record is important as it may be the only evidence to establish a W.C.B. claim if the injury becomes

more serious in the future. The First aider can also see that supplies in the kit are replenished and

updated.

There is also a requirement that the first aider on site post the certificate near the first aid box.

First aid is something we take for granted, but there is more to it than we ma have thought.

Page 10

Toolbox Meeting Topics

#11 - WHY TAKE A CHANCE?

Trapeze artists, race-car drivers, sword swallowers and high divers are all paid to take chances. But as a

construction worker, you are not paid to take chances. You were hired because you were qualified to do

a job. If by taking a chance you are injured and can no longer do your job, you become a burden to

yourself, your family and your employer.

We sometimes hear it said "Why worry? Compensation will look after me." Just remember that

compensation does not pay your full wages, nor can it compensate for the pain you endure.

Construction is hazardous enough. So why take a chance that you might be injured? You may get away

with it once or twice, but in the long run you won't gain a single thing.

Safety is simply the most efficient way of doing a job - any job!

REMEMBER!!!

Play it safe - don't take chances.

Page 11

Toolbox Meeting Topics

#12 - IS SOMETHING WRONG?

Most accidents can be prevented. To protect yourself and those around you, use your senses of seeing,

hearing, smelling and touching.

SEEING:

Keep you eyes open for hazardous conditions. Watch where you step. Wear eye

protection to preserve your sight.

HEARING:Listen for warnings - shouts, horns, backup alarms, the sounds of defective or improperly

adjusted equipment.

SMELLING:

Your nose can detect most gas or chemical leaks, overheated bearings, burning brakes

or arcing electricity.

TOUCHING:

Your hands can warn you of such things as excessive vibration, overheating, broken

fittings, and wear and tear.

Accidents are usually attributed to people neglecting not only common sense but their natural senses as

well. Be aware of what is going on in the world around you-keep your eyes and ears open and your

senses sharpened.

REMEMBER!!!

Don't forget the most important sense you possess - COMMON SENSE.

Use it with your other senses, and PLAY IT SAFE!!!

Page 12

Toolbox Meeting Topics

#13 - THE CHANCE TAKER

Have you had any close calls lately? Think back over the past few weeks. Ho many scrapes and bruises

have you suffered? Most of them are probably minor, but any one of them could have been serious.

The odds are about 30 to 1 that when you take a chance you will get away with it and not be injured.

You are not placing odds with a bookie when you gamble with your job. You might win sometimes, but

the bookie wins all the time! Why bet your life on a mistake and get no return for the risk? Even though

they are in your favor, don't depend on the odds to reach 30 to 1 before you become a casualty - the odds

may be 2 to 1.

In accidents, luck merely determines whether an injury will be minor, serious or fatal. For example, a

concrete block could fall as you are walking by a scaffold. The block could a) miss you by only 2 inches,

b) hit you on the shoulder and cause a painful injury, or c) hit you on the head and be fatal, if you aren't

wearing the proper head protection.

Construction an be safe if everyone decided that taking a chance is not worth the risk. Then close calls

will be reduced. If close calls are reduced, so will injuries and fatalities.

REMEMBER!!!

Protect yourself - think and act safely

DON'T GAMBLE WITH YOUR LIFE!!!

Page 13

Toolbox Meeting Topics

#14 - "THE OTHER GUY" IN YOU!!

Have you noticed how accidents always seem to happen to "the other guy"? When you stop to think

about it, to everyone else on the job "the other guy" is YOU.

It is so easy to become involved in an accident - too easy. Anyone can do it. One good reason for taking

time out to talk on safety is to remind you that accident prevention is everybody's business.

Give this a little thought. Your employer , your foreman, your union and your Construction Safety

Association are all concerned about safety on the job. But they are powerless to do anything for you if

you aren't prepared to do something for yourself. You can do most to prevent an accident because you

can do most to control you actions.

Every accident has the potential to cause injury or death. Every one of us has the instinct to counteract

the accident potential. But do we?

Think about it - and give is a try.

REMEMBER!!!

Accident don't always happen to "the other guy".

Sooner or later "the other guy" is you!!

Page 14

Toolbox Meeting Topics

#15 - DO'S ARE BETTER THAN DON'TS

When some construction workers think of safety, they look at a lot of "don'ts".

"

"

"

"

DON'T go on the project without your hard hat.

DON'T horseplay on the job.

DON'T climb on moving equipment.

DON'T do this! DON'T do that!

Wouldn't it be more positive if we came to the job with "do's" instead of "don'ts"?

For instance:

" DO learn to recognize whether your task is hazardous and take steps to minimize any danger.

" DO your part to keep the job orderly by cleaning up the mess you made.

" DO make suggestions to your foreman about ways to improve conditions on the job.

" DO think before you act.

Accident prevention is much more than having an inspector in to run a check. A truly safe job is where

every worker on the project takes an interest and becomes a "doer". Sitting back and letting the other guy

do it just doesn't work.

How may do's have you done lately?

Page 15

Toolbox Meeting Topics

#16 - HO -- HUM

Here we go again with another safety talk. Well, let's make the best of it. Al least it is a chance for

another break.

Could this be what we are thinking? Safety this, safety that, safety rules, safety equipment, safety

inspector? Maybe we think it is a waste of time, but let's make these talks more than just another break.

Let's remember either our own experience or what we have learned about constructions sites 10 to 15

years ago, when safety left a lot to be desired. Many workers were killed or maimed for life because of

lack of interest in accident prevention.

Today, when it sometimes seems that too much emphasis is placed on safety, remember that the people

who benefit most are us.

Government, unions and management are concerned about our health and safety at work. But what it all

boils down to, is that safety depends on the attitude each of us has toward making out sites a safer place

to work.

Let's show more interest in these talks and contribute useful comments that can help all of us on this site.

Page 16

Toolbox Meeting Topics

#17 - ELIMINATING HAZARDS

There is a story about an old Bruce County farmer who used to go over his fields the day before plowing

to kill every rattlesnake he could find.

One day, a curious passerby asked if this wasn't a dangerous practice. The wise old farmer replied, "I

reckon it could be, but it seems to me if I don't kill them all today when I'm looking, they might kill me

tomorrow when I'm not looking."

The farmer knew what he was doing. He removed the hazard before it could harm him at the most

vulnerable moment - when he wasn't looking. We sometimes get so tied up in our job that we don't spot

hazards that can be harmful to us.

It might be a good idea to take a look ahead before we start the job. Use our past experience and the

knowledge of others to identify, remove or guard against known hazards.

Regardless of how small the hazard seems at the time, it could cause serious harm for us or one of our

buddies later on.

REMEMBER!!!

Let's not ignore hazards. Let's remove them before they remove us.

Page 17

Toolbox Meeting Topics

#18 - DON'T KID YOURSELF

Have you ever spoken to a guy who tells you how good his chances are? He's never had an accident,

but when you watch him work and see the chances he takes, you know that it's only a matter of time

before his number comes up.

This type of person is only kidding himself when he:

" Climbs a step ladder without locking it.

" Uses a fastening tool, a cutting torch or grinds and chips without eye protection.

" Indulges in an off-site "liquid lunch".

" Removes guardrails and never replaces them.

"

Only wears a hard hat when their supervisor is around.

The person who knows better, but continually takes chances or shortcuts is not going to kid himself

forever. Eventually he is going to pick up a reminder that might remain with him for the rest of his life.

Leave kidding to kids.

REMEMBER!!!

Practice self-defense and enjoy a long health life in construction.

Page 18

Toolbox Meeting Topics

#19 - ALERTNESS

Because things are constantly changing on most construction sites, we must be alert to changes. Being

aware of conditions where we walk, stand, sit, crouch or climb is a priority in self-survival. If we are like

the man who stepped back to admire his work and fell off the scaffolding, we won't last long in

construction. It's good to be able to admire our work, but it's necessary to look before stepping in any

direction and that applies at ground level as well as heights. You could be stepping into an excavation,

into an open stairwell or into the path of an oncoming vehicle or descending load if you are not alert to

what's going on.

Because things change rapidly on most sites, it is difficult to put up signs and barriers at hazardous points

as soon as they occur. We, therefore, need to be aware and alert at all times.

Some of the ever changing construction hazards can be common to most sites; other hazards are

peculiar to certain trades and types of construction. The old hands know most of the conditions to watch

for in their job, but their experience should be passed on to the new man.

Some of these conditions to look for on this job are:

1.

2.

3.

4.

5.

Page 19

Toolbox Meeting Topics

#20 - WEATHER CONDITIONS

Few jobs are more affected by the weather than construction. Heavy rain on outside jobs usually means a

shutdown. A big snowfall can bring work to a stop. So can extremes of cold. All these conditions cause

us to lose work

days.

With rain comes mud and with cold weather comes snow and ice. These can turn a safe worksite into a

hazardous place. Snow, ice and mud are fairly easy to spot, but rubbish underneath is not. That's why

housekeeping as we go is a smart way of working. Clean up while you can still see the garbage.

There is, however, another element of the weather that can be bad for construction projects and workers.

This wrecker of projects and killer of workers is WIND. Usually there is not much warning before gale or

tornado force winds whip into a project. Sometimes the hazard is increased when the winds are

accompanied by lightning. Every year construction workers are killed by being blown off structures or

struck by flying objects driven by wind.

Some points to consider:

" Keep an eye out for storm clouds. High wind often signals a storm. This can serve as your early

warning. Listen to weather forecasts and alerts as you drive to work.

" Secure any materials that are likely to be picked up by high winds. This is very important at

heights where wind speed is usually greater than on ground level.

" Construct proper bracing for unsupported masonry walls, storage tanks, vessels, etc.

" When working at heights in windy conditions, wear your safety belts and tie off to a solid part of

the structure.

" Tie down tarps and other materials. High winds can occur without warning or after you have left

the project.

Page 20

Toolbox Meeting Topics

#21 - FRACTIONS

No, this is not a lesson in mathematics. What we are talking about today is the fraction of a minute or

fraction of an inch that makes the difference between a close call and an injury.

Here are some construction examples that illustrate what I mean:

" The ladder that starts to slip because of poor footing or not being tied off, but stops a fraction of

an inch before it falls over.

" The brick that's knocked off a scaffold with no toe board and falls 20 feet towards a worker below,

but just misses him by a fraction of an inch.

" The driver that backs up without proper signaling and almost hits the workers behind him before

they jump clear by a fraction of a minute.

" The load that has been improperly rigged and breaks up while being hoisted over a work area,

but misses workers by a fraction of an inch.

In all these cases, luck was with the workers. Don't depend on luck to prevent injuries. Taking the time to

do the job right can eliminate close calls. Let's make our margin of safety more than a fraction of an inch

or a fraction of a second.

Page 21

Toolbox Meeting Topics

#22 - FIRE EXTINGUISHERS

If a fire started on the job today, would you know where to locate a fire extinguisher? If you did locate

one, would you know how to use it?

Foreman: List fire extinguish locations here and inform the crew of their locations.

Dry chemical extinguishers are effective against liquids and electrical fires. They can also be used on

small wood and paper fires.

The extinguisher is only as effect as the worker using it. To extinguish a fire quickly, direct the nozzle at

the leading edge and work the spray back and forth across the fire in a rapid motion, pushing the flame

back and eventually extinguishing it.

Don't break or tamper with the seal on any extinguisher unless you are going to use it.

Once a unit has been used, have it recharged immediately, even though the gauge shows only partial

discharge.

Check extinguishers frequently to see that they are fully charged and ready to work when you need them.

It is good practice to call the local fire department before attempting to extinguish any fire. Do you know

the phone number to call?

Page 22

Toolbox Meeting Topics

#23 - SAFETY FOOTWEAR

How many times have you dropped something on your toes?

Have you ever stepped on a nail?

Do you know somebody who has?

The chances are that you will answer "yes" to one or more of these questions. It is surprising that far too

many construction workers still have to answer "yes" to all.

Common sense tells us that wearing safety footwear is a "must" if we are to avoid injuries which can put

us off the job or at least make us limp around nursing an injured foot!

Ask yourself - is it really worth taking the chance?

At all times - on the job, you must wear CSA certified Grade 1 footwear or CSA certified footwear with

heavy duty toe and sole protection.

Workers purchasing new wordbooks should obtain CSA certified Grade 1 footwear. The boots bear a

green triangular patch stamped with registered trademark of the Canadian Standards Association on the

outside and a rectangular green label on the inside.

Select good leather that you can treat with waterproofing to give you maximum protection in wet weather.

A high-cut boot, properly laced, protects you ankles from injury.

Your feet need more protection than any other part of your body. They are worth the best protection that

money can buy.

REMEMBER!!!

Wear your safety boots, or you might foot the bill.

Page 23

Toolbox Meeting Topics

#24 - EYE PROTECTION -- COMPLAINTS

Some of the reasons we hear for not wearing safety glasses include:

"

"

"

"

"

They blur my vision.

They cause headaches.

They slide down my nose or hurt my ears.

They fog up.

They get dirty.

Distortion, blurring of vision and headaches are sometimes related to the need for prescription glasses.

For this reason, we should have a regular eye examination.

Complaints about glasses, which slide down the nose, pinch the nose, hurt the ears , etc.

are usually because of improper fit. Bridge size, eye size and temple length are unique for each

individual. For best results, the glasses should be fitted by a trained person.

Fogging can be reduced with anti-fog solutions, anti-fog sticks and anti-fog treated lenses.

Glasses which get dusty and dirty are a problem associated with the wearing of eye protection. A

practical way to deal with this is to rinse glasses off at a water cooler or lens cleaning station. A supply of

tissues can also be carried in your pocket.

" The alternative to wearing eye protection can be a serious eye injury and possible loss of sight.

All the reasons in the world will never return our sight. So let's look at ways of overcoming the

objections to wearing eye protection.

Page 24

Toolbox Meeting Topics

#25 - MATCHING EYE PROTECTION TO THE HAZARD

Forms of eye protection such as safety spectacles, goggles, welding helmets, face shields and hoods are

each designed for specific types of hazards.

For example: grinding, chipping and drilling operations, which produce flying metal or dust particles

require protection other than basic safety spectacles do not provide all round eye protection. The extra

protection for the eyes and face provided by goggles and face shields is therefore required.

Other operations, such as hot asphalt paving, spot welding and blasting, also require specialized

protection - full face shields for hot asphalt, welding goggles for spot welding and air-supplied hoods for

sandblasting.

When matching eye protection to the hazard, it is important to protect the face as well as the eyes. This

is especially important where there is danger from flying metal particles as in grinding or splash from

chemicals.

Your safety glasses are designed to protect you from accidental injury. They will not withstand repeated

impact or abuse, however. Inspect them regularly for scratches, cracks or other wear and replace them if

they are scratched, bent or uncomfortable. Scratches not only interfere with your ability to see what you

are doing - a hazard in itself, they can also weaken the structure of the lens and its resistance to impact.

REMEMBER!!!

Taking care of your glasses and using them will help you

"LOOK' your best on the job.

Page 25

Toolbox Meeting Topics

#26 - EYE PROTECTION

You never appreciate what you have until you loose it.

Many construction workers don't seem to care whether they keep their eyesight for a lifetime or not; at

least it appears that way when you see them gambling with blindness.

Masonry workers and others engaged in chipping, grinding, cutting, drilling must wear goggles. Eye

protection must be provided and used with masonry saws.

Workers using a cutting torch should protect themselves from hot slag, particularly their face. Use

goggles or face shield designed for the job, which will also prevent flash burn.

Where powder or powder-actuated tools are being used, particularly in mechanical trades, there is

constant danger from flying material. Each tool is supplies with goggles that won't do any good if left in

the box. Do not use any powder actuated tools unless the muzzle guard is in place and in good shape.

Misting or fogging of glasses can be corrected by applying an anti-fog and cleaning compound at the

start of the working day. Some cleaners also reduce static electricity on plastic goggles and glasses.

Scores of men with impaired vision would like a second chance to use eye protection, but it is too later for

them. You have the chance to keep you full eyesight. Do it now before it is too late!!

REMEMBER!!!

Whenever you are doing a job that endangers your eyesight,

it is up to YOU to wear eye protection!!!

Page 26

Toolbox Meeting Topics

#27 - EVERYDAY HAZARDS

Most of us have worked at our jobs long enough to know many of the everyday hazards.

The electrician follows proper switching, tagging and grounding procedure to protect himself against

accidental contacts with live equipment. The heavy equipment operator wears hearing protection when

operating his machine. The ironworker, carpenter, window washer, etc. wears or uses the proper Fall

Protection methods when working more than 3 meters from the nearest safe surface.

But all of us must occasionally do a job we have never done before. When using different tools,

equipment and materials, we must be on the lookout for hazards that we are not familiar with.

In such situations, take the following precautions:

-

For new equipment, read the manufacturer's instructions.

Check the label on unfamiliar substances.

Look at the procedure manual for proper work or handling methods.

Ask your supervisor, foreman or an experienced person for instructions.

Consult with the supplier to develop or obtain proper handling or operation procedures.

It can be dangerous to do a job without instruction. Since no one is expected to know everything, don't be

afraid to ask. This applies to everyone, whether young or old. The experienced worker should always

alert the new man to unknown hazards and the new man should not be ashamed to ask for help.

Unfamiliar hazards on this job include:

1.

2.

3.

4.

Page 27

Toolbox Meeting Topics

#28 - PERSONAL PROTECTIVE CLOTHING

The Occupational Health and Safety Act requires that every worker shall "wear or use personal protective

clothing, equipment or device as is necessary for the protection from the particular hazards to which he is

exposed."

Personal protective clothing reduces the possibility of injury to ourselves and using the proper protective

equipment or device can prevent injury to others.

The O.H.&S. Act requires that on all construction sites a hard hat and safety boots must always be worn.

This is a rule to which there is no exception. Additionally, some companies require that safety glasses be

worn at all times outside the office and lunch room areas. When grinding, chipping, welding, drilling or

using hazardous substances, additional eye and face protection should be used to suit the hazard.

Cuffs on overalls are not only a nuisance, but a hazard as they may get caught in objects and cause a

tripping hazard or they may trap molten metal or sparks. Tank tops and shorts are prohibited. Full length

pants and a T-shirt are the minimum work clothes to be worn. Long sleeve shirts are recommended as

they protect your arms from sunburn and scratches.

Gloves should be worn by all construction workers except those working around machinery. Rings, watch

chains, key chains and similar items should not be worn on the job since they can be caught in moving

machinery.

In winter, watch out for parka strings. At all times, avoid wearing loose, torn or ragged garments. Take

care of your protective clothing if you expect it to take care of you.

Page 28

Toolbox Meeting Topics

#29 - FALL ARREST EQUIPMENT

Note to supervisor - Have a harness available for demonstration during this talk.

The Occupational Health and Safety Act requires that a full body harness shall be worn when there is a

danger of a person falling three(3) meters or more from any height into a hazardous area. Common

sense should tell us to protect our lives without being required by law to do so.

But fatalities and serious injuries still occur because equipment is not worn where falling is a hazard.

When using fall arrest equipment, take these precautions:

" Inspect your equipment prior to use to ensure there are no cuts, broken strands, knots, heat

burns, abrasions or signs of excessive wear.

" Always position the D-ring centered between the shoulder blades.

" Wear the safety harness with all hardware and straps intact, snug fitting and properly fastened.

" Make sure that lanyards comply with CSA standards, are made of nylon rope (minimum 16mm

diameter), or nylon webbing.

" Secure the lanyard or harness to a rigid support or lifeline so that in case of a fall you will drop no

more than 1.22 meters without shock absorbing lanyard or when using a shock absorbing lanyard

you will stop your fall above the hazard.

REMEMBER!!!

It does not always take a fall from a great height to cause injury or death.

A safety belt or harness can save your life; use and wear it properly.

Page 29

Toolbox Meeting Topics

#30 - HARD HATS & THINKING CAPS

Your head is the most vulnerable part of your body. A severe blow to the head can cause permanent

injury or instant death.

New hard hats are stronger, lighter and less expensive than the old styles. Be sure your hard hat bears

the CSA label. Only a CSA certified Class "B" or Class "E" hard hat is acceptable on construction sites.

In the summer, your hard hat serves a dual purpose. It protects your head from injuries and from

exposure to the sun.

If your hard hat is to protect you, then you must protect it. Clean and inspect it regularly. Look for hairline

cracks, dents and abrasions; replace it when damaged. Wash the suspension in warm soap and water

to remove oils, grease and acids that destroy its elasticity.

Don't drill holes in hard hats or paint them. You are only reducing their effectiveness. Don't leave your

hard hat in the rear window of your car. It may shoot forward if you brake suddenly. Or the magnified

heat of the sun in a closed car may reduce its impact resistance.

REMEMBER!!!

Wear your hard hat and don't take chances.

Page 30

Toolbox Meeting Topics

#31 - ELECTRICITY ON THE CONSTRUCTION SITE

Electricity is a great aid, but like fire, water and other natural power, it can be your worst enemy, if you

don't respect the rules.

Temporary wiring should be installed and adjusted only by qualified electricians.

For your protection, all portable power tools must be effectively grounded or double insulated.

Remember - double insulated tools are subject to the same breakdowns as grounded tools and should be

checked by a competent person on a regular basis. The ground terminal on a tool is of no value unless

your extension cord is also properly grounded.

Make sure all your power tools are inspected by a qualified electrician.

Treat all power lines as though they are alive, until proven otherwise by an electrician.

Avoid handling any electrician apparatus in wet locations. This is a dangerous practice and a potential

"widow maker".

REMEMBER!!

Unlit areas are a menace and constant source of accidents.

Temporary systems are installed for your protection.

Don't be a bulb snatcher -- you may be forever in the dark!!

Page 31

Toolbox Meeting Topics

#32 - ELECTRICAL HAZARDS

Each year construction workers continue to ignore the warnings about respecting electricity. Some don't

live to regret it...but their families do!

Causes of construction electrocutions include:

" Placing ladders against, around, or near electrical lines.

" Operating hoisting or excavating equipment too close to overhead lines.

" Failing to properly ground electrical tools that require grounding.

" Bypassing or tampering with switches, fuses or special protective devices.

The chances of being killed by high voltage are great, but there are cases where 70 volts have been fatal.

Even the voltage developed by arc welders can be lethal if the conditions are right.

REMEMBER!!!

Always slow electricity the respect it deserves.

Page 32

Toolbox Meeting Topics

#33 - STEP UP TO SAFETY

Single or extension ladders are not work platforms. They are designed primarily as a means of access

from one level to another. When you must work from a ladder, you are required to use a work positioning

system that will enable you to maintain 3-point contact with the ladder at all times. Most falls from ladders

occur when a worker removes one or both hands to perform a task.

Under certain conditions, most ladders can conduct electricity to some extent. Aluminum and other metal

ladders are especially hazardous in this regard. When using metal ladders, always watch out for

overhead wires and energized electrical equipment.

An extension ladder should be secured at the top to prevent it from slipping or being blown over. Make

sure that the footing is reasonably level and solid. An unsecured ladder should be held in place by one or

more workers while anyone is using it.

Only tradesmen qualified in wood or metal work should repair ladders. Damaged rungs or other parts

should be replaced with material of the same quality and design. Aluminum ladders are light and

convenient to use, but bruise easily if mishandled. Beware of bent or dented side rails on an aluminum

ladder. Such conditions can impair the ladder's strength.

Single and extension ladders must be set up at the proper angle. Depending on the length of the ladder,

a good rule of thumb is one foot out for every three or four feet up. When leading to a floor or landing, the

ladder should extend a minimum of one meter above the floor or landing and secured to prevent tipping

or sliding.

REMEMBER!!!

Always use the type of ladder best suited for the job.

Page 33

Toolbox Meeting Topics

#34 - SLIPS & FALLS

Every year too many construction workers are injured by slips and falls.

Slipping on the floor is bad enough, but falling from a height can be disastrous.

How can falls be prevented?

KEEP YOUR EYES OPEN!!!

When working at heights , proper guardrails must be used and where necessary, a fall arrest system be

used that is anchored to the structure.

Scaffolding must rest on firm footing with all the bracing installed. When using multilevel staging, the

scaffolding must be secured to the structure at every 4.6 meters vertically and 6.4 meters horizontally or

where no anchor point is available, guy wires, out rigging stabilizers or an equivalent means must equip a

scaffold to achieve a three to one principal. The height can never be greater than three times the base.

Orderliness plays a big part in preventing slips and falls. Debris lying around on floors and working areas

is an open invitation to accidents. Weather increases hazards, particularly in winter when debris becomes

snow covered and cannot be seen. Ice conditions create additional dangers. Sand and/or calcium

should be applied to icy areas.

Wet weather causes muddy boots which contribute in turn to slips and falls. Wipe your boots before

climbing steps or entering a work area.

When climbing a ladder, hold on with both hands. When walking down stairs, use the guardrail.

Page 34

Toolbox Meeting Topics

#35 - WELDING ON THE CONSTRUCTION SITE

On most construction jobs some welding is in progress. All workers on the site should be alert to the

hazards of welding.

A welding flash can seriously damage the eyes of persons working nearby. The welder should use a

shield around his work to protect the eyes of workers within 75 feet of him.

The welder's assistant must wear eye protection. No one should watch the arc with the naked eye - this

can cause temporary or even permanent blindness.

It may not be generally known, but you are just as susceptible to welding flash out of doors in bright

sunlight. The intensity of the arc is not diminished by working in sunlight, so wear your eye protection at

all times -- indoors and out.

For oxyacetylene welding, the cylinders must be used in an upright position. This applies to the storage

of oxygen and acetylene cylinders whether they are empty or full.

If a cylinder is found to be leaking, remove it away from possible ignition.

Never leave cylinders in the sun or store them near direct heat.

Treat cylinders with care. They are very useful, but can be extremely dangerous if mishandled.

Fire fighting equipment should always be available where welding is in progress.

Page 35

Toolbox Meeting Topics

#36 - JOBSITE HOUSEKEEPING

Have you noticed that on a clean project, where materials are piled properly and debris is removed daily,

the job seems to go much better?

Poor housekeeping around the job is double trouble; it breeds inefficiency and accidents.

The PRIMARY responsibility for good housekeeping rest with the superintendent, but

everyone has an obligation to keep his work area clean.

As you are doing your job, don't let debris pile up underfoot; remove it at regular intervals. It will speed up

your production and lessen your exposure to injury. Moreover, you are required to do so by law.

Subcontractors have a bit part to play in job orderliness. Time is never wasted by stopping to clean up. It

has to be done sometime, so why not do it when it will benefit you most? It is much easier to work in a

clean area than one cluttered with material and scrap.

One part of job orderliness is to remove nails from lumber as you go. By removing or flattening nails at

the time, you won't have to handle the material again and you can prevent a foot injury as well.

When setting up machinery or stacking materials, do not use an isle, passageway or entrance that will

prevent other people from doing their work.

REMEMBER!!!

A clean job is a safe job!!!

Page 36

Toolbox Meeting Topics

#37 - CONGESTED WORK AREAS

Some jobs require a lot of workers in a small area. This is evident on many large projects where various

trades are working closely in one area. The more congested our working area becomes, the more

caution we must take.

Often there are men working on various levels. Ensure that materials, tools and debris are placed so that

they will not fall from one level to another. A welding rod falling 10 meters could pierce a man's body.

When carrying long loads, such as rebar and pipe, keep them below shoulder level if possible. This could

prevent someone from walking into your load and receiving a face or head injury.

Congested areas may require the use of special protective equipment. Eye protection is especially

important for all persons working in these areas.

Housekeeping is of major importance when we have a lot of people in a congested area. Remove scrap

before it becomes a problem.

With cooperation and proper pre-job planning, all trades can work safely and productively in congested

areas, especially if we give a little care and thought to the other guy.

Some of the area of this job we should be aware of are:

1.

2.

3.

4.

Page 37

Toolbox Meeting Topics

#38 - WORKING IN CONFINED SPACES

A confined space as any working area in which an oxygen deficient atmosphere may occur or explosive

or toxic fumes can collect. This can included vessels, manholes, silos, tanks and even trenches.

In confined spaces, three life hazards are extremely dangerous because they cannot be seen, smelled or

felt:

HAZARD #1 - LACK OF OXYGEN

Entry into an oxygen deficient atmosphere can cause immediate loss of consciousness and quick death.

HAZARD #2 - PRESENCE OF TOXIC FUMES

Certain fumes can cause severe dizziness and unconsciousness. In higher concentrations, they can

cause immediate death.

HAZARD #3 - ACCUMULATION OF EXPLOSIVE FUSES OR DUST

One spark could cause the work area to explode with terrible consequences.

In some situations, all three hazards can exist.

Before workers enter a confined space, it must be tested by a competent person for:

" Adequate oxygen content (21%).

" Possible explosive mixtures.

" Toxic gas.

Continuous forced ventilation with fresh air can reduce the hazards to an acceptable level or eliminate

them completely. Monitoring equipment should be used before and during work in the confined space.

Never enter a confined space before it has been tested.

Where confined space cannot be adequately purged and ventilated, workers must wear suitable

breathing apparatus and safety harness attached to a line. The line must be fastened to a solid point

outside the confined space and be held by a person keeping watch and equipped for an alarm.

Page 38

Toolbox Meeting Topics

#39 - SHOP PROCEDURES

When working in a shop environment, we are exposed to many different hazards. In order to reduce or

eliminate these hazards, we could use several different methods. Here are some methods for improving

this situation:

" VENTILATION: Before starting engines or welding, turn on the vent fans. Carbon monoxide and

welding fumes contribute to accidents by slowing a person's reflexes and sometimes are severe

enough to make workers ill.

" ORDERLINESS: A clean shop is an efficient shop. Don't leave discarded parts or tools lying

around on the floor. When bringing equipment or machinery into the shop, place it so that it will

not interfere with the work of other personnel.

" SPILLS: Oil, water and mud make for poor footing. Spills should be cleaned up immediately.

Drip pans are useful in preventing spills. Before bringing in equipment, clean off the mud and

snow outside.

" TOOLS & EQUIPMENT: Tools must be kept in good condition. Use the proper tool for the job;

don't use makeshift equipment. Portable electric tools should be properly grounded or double

insulated. Replace each tool in its storage area when you have finished using it.

" PROTECTIVE EQUIPMENT: Before drilling, chipping, grinding or welding, additional eye

protection other than your safety glasses may be required. If in doubt, check with your

supervisor. If you used a fire extinguisher, be sure it is recharged immediately.

REMEMBER!!!

These methods will only work with your cooperation

to reduce or eliminate hazards in the workplace.

Page 39

Toolbox Meeting Topics

#40 - HORSEPLAY

In construction, there is no such thing as a practical joke. Playing tricks on your fellow workers is no joke

at all. In fact, it can cause serious injury or death.

Construction is dangerous enough without jokers. Horseplay is for children or for adults in their own living

room - but not on a construction site.

DON'T distract a man while he is doing his job.

DON'T startle your fellow worker.

DON'T play tricks on the young or new worker. He may become confused to the point where he injures

himself or someone else.

DON'T wrestle. Wrestling matches can be held after working hours, not on the jobsite.

DON'T show off with feats of strength. You may drop something on yourself or someone else.

REMEMBER!!!

Be a smart worker, not a smartass.

Keep horseplay off the job.

Page 40

Toolbox Meeting Topics

#41 - WATCH FOR MOVING EQUIPMENT

The operator of heavy equipment or machinery on the construction site cannot read your mind. He cannot

anticipate your next move and sometimes is not aware that you are even there.

It is your responsibility to let the operator know that you are there and everyone's responsibility to warn

other workers if they are in the path or are in proximity of moving equipment.

Under NO circumstances are any workers permitted to operate any equipment unless you are qualified

and have been authorized by your foreman to do so.

When working around materials, equipment or machinery that is being loaded or unloaded form trucks or

floats, always stay clear unless you are involved in the unloading/forklift truck or front-end loader.

REMEMBER!!!

The operator does not have eyes in the back of his head.

He might not be able to see you.

Protect yourself and avoid danger - get out of the way

of moving machinery and equipment.

LOOK LIVELY AND LIVE.

Page 41

Toolbox Meeting Topics

#42 - CABLES/SLINGS & CHOKERS

Whenever possible, it is best to use wire rope instead of chairs or nylon slings. Small cracks or flaws in

chains are almost invisible to the eye and nylon slings can be cut by the load or may become frayed due

to abrasion by the load.

These faults/damages may cause the chain or nylon sling to break without warning. Trade people who

are not professional riggers must nonetheless rig loads at times on the job.

All wire ropes, slings, lines, chokers and cables should be checked frequently. Chains need to be

inspected for elongated or stretched links; bent, twisted or cracked links; links that are gouged, chipped or

scored; and that are worn. Nylon slings need to be checked for overexposure to sunlight(chalky

appearance), frayed exterior (causes are shock loading or abraded), oil contamination, stitching breaks or

tears (sling must be destroyed in these situations), and the capacity of the slings when new. Wire rope

slings need to be checked for broken wires (replace rope if there are: 6 or more broken wires in one lay. 3

or more broken wires in one strand in one lay, 3 or more broken wires in one lay in standing ropes). If the

wire rope sling is kinked, bird caged, has crushed strands, bulges in the rope or gaps between the

strands, the sling needs to be replaced and destroyed.

When using wire rope clips always check for proper installation, minimum three clips with the u-bolts of

all clips on the dead end of the rope and tightness before each lift. Remember wire ropes stretch when

loaded which may cause clips to loosen. Consideration should also be given to the use of thimbles.

Thimbles will prevent excessive wear and strain on the wire rope.

REMEMBER!!!

There is only one way to rig.

Follow the proper method and use reliable equipment.

Page 42

Toolbox Meeting Topics

#43 - RECOGNIZE A HAZARD WHEN YOU SEE IT!

Certain words are important to your safety. Take the word "Hazard" for example. You hear it every day,

but do you know what it means?

The dictionary says it is "a source of danger". Good enough! Let's learn to recognize a hazard as a

source of danger:

"

"

"

"

To ourselves.

To our workmates.

To our equipment.

To our company.

We should make it our business to recognize a hazard when we see one. But don't stop there - report it

to the foreman so that something can be done about it! Any-thing that isn't in good working order is a

hazard. Check any equipment that is:

Bent

Blunt

Broken

Cracked

Collapsible

Crooked

Dirty

Decomposed

Electrical

Explosive

Faulty

Flammable

Frayed

Insecure

Jagged

Kinked

Leaking

Loose

Missing

Mutilated

Noisy

Overloaded

Poisonous

Protruding

Ragged

Rough

Sharp

Slippery

Splintered

Torn

Twisted

Unsafe

Uneven

Vibrating

Warped

Worn

REMEMBER!!!

You can avoid accidents if you learn to recognize a hazard when you see one.

Page 43

Toolbox Meeting Topics

#44 - LOOKING AHEAD

Scouting for hazards goes a long way back into history. Pioneers on wagon trains moving west were

aided by scouts on horseback, probing for danger ahead and report-back on safe routes.

Today the same principal can be applied. Look for hazards and report them so that we can enjoy a safe

healthy future.

Check your work area and discover what is hazardous and must be cleaned up.

A foreman should always check the next move to be made by his men. They must understand what they

are to do and how to do it safely.

Are tools and equipment in proper condition? List any items your crew feel should be examined, repaired

or replaced.

Section 17 of The Occupational Health and Safety Act requires workers to report to supervisor any safety

conditions encountered in the course of work.

If you have any ideas about improving your firm's safety record, have a word with your foreman. Pass

your ideas onto him, so that both of you can do something about safety. Two heads are better than one.

Page 44

Toolbox Meeting Topics

#45 - AVOIDING INJURIES

Remember we talked about everyone using common sense and thinking before acting?

Workers who can and do, use common sense are the most likely to make a full and rewarding life for

themselves in construction.

There is only one way to do a job. THE RIGHT WAY IS THE SAFE WAY!!

If you are in doubt about how to perform the task - ASK SOMEONE WHO KNOWS!!

Keep your mind on the job at hand - DON'T BE A DAYDREAMER!!

Watch for unsafe conditions around the jobsite. When you spot a hazard, report it to your foreman so that

action can be taken to prevent an injury. You could be doing yourself a favor.

Necessity may be the mother of invention, but don't experiment with makeshift measures on your job.

Makeshift means unsafe!

Remember the new man on the job. A few words of advise from you could help him avoid injury. Don't

let him learn the hard way.

Be a pro! Be a safe worker! Watch out for the other guy whose actions might endanger you - and don't

take chances.

REMEMBER!!!

Accident prevention is doing the work right the first time.

So it won't be the last time.

Page 45

Toolbox Meeting Topics

#46 - METAL DRUMS

Metal drums are often used around job sites and lunch areas as garbage bins for small scrap items.

They are provided by supervision for purposes of housekeeping only. The drums serve the purpose well

- but only after the top is properly removed.

Occasionally there are not enough drums for the purpose and someone takes it upon himself to remove

the tops from the closed drums lying around. The quick method is to use a cutting torch. This is a

highly dangerous practice and should never be used.

Unless a drum is completely purged with steam and/or chemicals, there is a high risk of explosion

occurring as heat from the torch vaporizes the contents of the drum. When vaporized, even everyday

substances such as forming oil can be explosively lethal. Al it takes is the right air-to-fuel ratio and the

flame from the cutting torch will set off a powerful bomb. Even without ignition, pressure can build up

inside the drum from the heat of the torch and cause an explosion.

Drum tops can be removed safely by no sparking mechanical devices which are specifically designed for

the purpose.

Metal drums for good housekeeping, YES - but not at the risk of an explosion!

Page 46

Toolbox Meeting Topics

#47 - SLAVE OR MASTER

I weigh in at 80kg when full

I am pressurized at 15.00 kPa

I stand 140cm tall

I am 20cm in diameter

I wear many colors, depending on my task

When I am left unsecured or without my cap, I can:

" Smash my way through brick walls.

" Fly through the air and reach distances on 1 km or more.

" Spin, ricochet, crash and slash through anything in my path.

" Overcome any efforts of human flesh, bone and muscle to restrain me.

You can be my master by handling me correctly; then with proper loses, gauges and valves I can

transform:

" Pieces of steel into might structures.

" Stacks of pipe into useful carriers.

" Sheets of metal into productive vessels.

When used properly I can help you, but I am ruthless in the hands of careless or uninformed workers.

Keep me in a secure rack or tied off and make sure that my cap is snug whether I am full or empty.

I am a compressed gas cylinder and I can be either your master or your slave.

Page 47

Toolbox Meeting Topics

#48 - FLAMMABLE LIQUIDS

Every year, scores of construction workers are seriously burned by improper handling of flammable

liquids. The most common hazard is gasoline.

Vapors from flammable liquids are dangerous, particularly during hot weather when the liquids are

warmer than usual. Under these conditions an explosion can result.

Flammable liquids stored outdoors must be protected from the direct rays of the sun. Always store these

liquids properly; never use glass, plastic or any other makeshift container.

If a flammable liquid is to stored indoors, ensure the liquid is stored in a safe container that is well marked

as to contents. The indoor storage area is to be well ventilated and located away from entrances and

exits.

Never use any flammable liquid for other than the purpose it was intended. For example, gasoline must

never be used to ignite a fire either indoors or outdoors.

Never smoke, weld, or use temporary heaters near inflammable liquids.

Never use gasoline as a cleaning solvent.

REMEMBER!!!

Flammable liquid can be easily ignited.

Always take the proper precautions as detailed on their Material Safety Data Sheets

when handling these liquids.

Page 48

Toolbox Meeting Topics

#49 - MATERIALS HANDLING

Every year a high percentage of accidents occur because workers handle material improperly. The injury

usually affects the hands, feet or back.

We know that safety boots help protect your feet and a good pair of gloves can protect your hands. Are

you wearing both?

Only you can protect you back. You can't get back protection any other way.

Here are some tips on handling materials:

" Avoid pinched fingers by keeping your hands from under or between moving loads.

" Handling heavy equipment and material is a job for experienced people with the proper

mechanical aids. Don't strain yourself manhandling loads that a machine can do more efficiently.

Let the machine do the work!

" Don't handle wire cable with your bare hands - this is asking for trouble.

" If a load is too heavy for you, ask for help to lift it. It is not a sign of weakness to ask for help - it is

a sign of common sense. Don't try to show your buddies how strong you are. Throwing your

weight around might throw your back out.

" REMEMBER when lifting, don't try to imitate a derrick; let your legs do the work, not your back.

Face the load, plant both feet squarely on each side of the load, squat down and get a good

handhold. Test the weight of the load. Now, keeping the back straight, lift with your legs pushing

you up.

" Simply reverse the procedure to put the load down, keeping your back straight all the time.

Page 49

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Environemental Management System - Risk Register - Aspect and Impacts RegisterDocument6 paginiEnvironemental Management System - Risk Register - Aspect and Impacts Registersjmpak100% (8)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Requirements For Azure Information Protection - AIP - Microsoft DocsDocument5 paginiRequirements For Azure Information Protection - AIP - Microsoft DocssjmpakÎncă nu există evaluări

- Requirements For Azure Information Protection - AIP - Microsoft DocsDocument5 paginiRequirements For Azure Information Protection - AIP - Microsoft DocssjmpakÎncă nu există evaluări

- C32 Electronic Unit Injector - Adjust PDFDocument4 paginiC32 Electronic Unit Injector - Adjust PDFmanu luvunga100% (2)

- Requirements For Azure Information Protection - AIP - Microsoft DocsDocument2 paginiRequirements For Azure Information Protection - AIP - Microsoft DocssjmpakÎncă nu există evaluări

- Diamond PDFDocument61 paginiDiamond PDFsjmpakÎncă nu există evaluări

- Diamond Threat ModelingDocument21 paginiDiamond Threat ModelingsjmpakÎncă nu există evaluări

- BRKCRS 3146Document89 paginiBRKCRS 3146sjmpakÎncă nu există evaluări

- SBM - Screening Form (14412)Document2 paginiSBM - Screening Form (14412)sjmpakÎncă nu există evaluări

- Safety GramDocument4 paginiSafety GramsjmpakÎncă nu există evaluări

- Silkroad Ultimate Guide To PerformanceDocument12 paginiSilkroad Ultimate Guide To PerformancesjmpakÎncă nu există evaluări

- Business Plan Template: Executive SummaryDocument2 paginiBusiness Plan Template: Executive SummarysjmpakÎncă nu există evaluări

- PGS-WI-MC-02 Cranes Load Test ProcedureDocument6 paginiPGS-WI-MC-02 Cranes Load Test ProceduresjmpakÎncă nu există evaluări

- PGS-FM-MC-01 Measuring Tape Verification RecordDocument1 paginăPGS-FM-MC-01 Measuring Tape Verification RecordsjmpakÎncă nu există evaluări

- Articulo de TQM e ISODocument14 paginiArticulo de TQM e ISONelson GonzalezÎncă nu există evaluări

- Guidance For OrganisationsDocument24 paginiGuidance For OrganisationssjmpakÎncă nu există evaluări

- Guidance For StakeholdersDocument25 paginiGuidance For StakeholderssjmpakÎncă nu există evaluări

- Using DNP3 & IEC 60870-5 Communication Protocols in The Oil & Gas IndustryDocument4 paginiUsing DNP3 & IEC 60870-5 Communication Protocols in The Oil & Gas IndustryzdnÎncă nu există evaluări

- Risk Based Thinking in ISO 9001 2015 PaperDocument5 paginiRisk Based Thinking in ISO 9001 2015 PapersjmpakÎncă nu există evaluări

- AY 2015-16cvbbnjDocument245 paginiAY 2015-16cvbbnjSyed Abdul AzizÎncă nu există evaluări

- Hayward Super II Pump Model SP3005X7 ManualDocument14 paginiHayward Super II Pump Model SP3005X7 ManualhsmerkelÎncă nu există evaluări

- Environmental Engineering Jobs in Bangladesh - Careerjet - Com.bdDocument4 paginiEnvironmental Engineering Jobs in Bangladesh - Careerjet - Com.bdamrin jannatÎncă nu există evaluări

- Surface Condenser Eng2Document5 paginiSurface Condenser Eng2MuhammadFikriÎncă nu există evaluări

- Nickel-Titanium Alloys: A Systematic Review: Original ArticleDocument12 paginiNickel-Titanium Alloys: A Systematic Review: Original ArticleMudavath BaburamÎncă nu există evaluări

- Aerospace MaterialsDocument68 paginiAerospace MaterialsAykut Üçtepe100% (1)

- IA SeriesDocument20 paginiIA Seriessina20795Încă nu există evaluări

- No35-Inclined Roof SystemDocument24 paginiNo35-Inclined Roof SystemKitanovic NenadÎncă nu există evaluări

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDocument4 paginiInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDÎncă nu există evaluări

- Electromagnetic CompatibilityDocument12 paginiElectromagnetic Compatibilityoadipphone7031Încă nu există evaluări

- Customizing The ADFS Sign-In PagesDocument4 paginiCustomizing The ADFS Sign-In Pagesmicu0% (1)

- Lube-Tech: Lubricants For Wind TurbinesDocument6 paginiLube-Tech: Lubricants For Wind TurbinesMC AÎncă nu există evaluări

- 02 MF Anchors PDFDocument13 pagini02 MF Anchors PDFThaksenÎncă nu există evaluări

- nRF24LU1 - NordicDocument187 pagininRF24LU1 - NordicEdward SURIELÎncă nu există evaluări

- Manual Deus II UkDocument52 paginiManual Deus II UkMariusÎncă nu există evaluări

- Manual PSW 2600Document18 paginiManual PSW 2600Jc C. GomezÎncă nu există evaluări

- Nitrogen Purge Manifold For C2H2Document3 paginiNitrogen Purge Manifold For C2H2Abdullah FazilÎncă nu există evaluări

- Fracture in Concrete and Reinforced ConcreteDocument23 paginiFracture in Concrete and Reinforced ConcreteNilay GandhiÎncă nu există evaluări

- D-Link DI-524 ManualDocument92 paginiD-Link DI-524 ManualhadzicinetÎncă nu există evaluări

- E-Line DLDocument21 paginiE-Line DLiulian17dÎncă nu există evaluări

- Presented By:: Rafi Sheikh Sheeraz Malik Syed Ahmed Ali Umair Ali Waqar AmeenDocument34 paginiPresented By:: Rafi Sheikh Sheeraz Malik Syed Ahmed Ali Umair Ali Waqar AmeenSyed Ahmed AliÎncă nu există evaluări

- Parts Catalog: F Y 8 - 3 1 F X - 0 0 0Document86 paginiParts Catalog: F Y 8 - 3 1 F X - 0 0 0julian gonzalezÎncă nu există evaluări

- Citrix Xenserver ® 6.0.2 Emergency Network Reset: Published Wednesday, 29 February 2012 1.0 EditionDocument6 paginiCitrix Xenserver ® 6.0.2 Emergency Network Reset: Published Wednesday, 29 February 2012 1.0 EditionJuan CarlosÎncă nu există evaluări

- Project Title: Hotel Management Software Project: PurposeDocument3 paginiProject Title: Hotel Management Software Project: PurposesuryaÎncă nu există evaluări

- Computer Netwroks 15CS52: Venugopala Rao A S Assistant Professor (Senior) Dept of CSE, SMVITM BantakalDocument12 paginiComputer Netwroks 15CS52: Venugopala Rao A S Assistant Professor (Senior) Dept of CSE, SMVITM BantakalVenugopal RaoÎncă nu există evaluări

- Engineering Department ProcedureDocument29 paginiEngineering Department ProcedureOmar Ahmed Elkhalil100% (1)

- Cable TrenchDocument57 paginiCable TrenchHari Krishna AaryanÎncă nu există evaluări

- Introduccion To PhysicsDocument475 paginiIntroduccion To PhysicsLyvsÎncă nu există evaluări

- While Start Drive Test Learning, You Must Know The Basic Things! These All Conotents Are at Introductory LevelDocument15 paginiWhile Start Drive Test Learning, You Must Know The Basic Things! These All Conotents Are at Introductory LevelRakesh SolankiÎncă nu există evaluări