Documente Academic

Documente Profesional

Documente Cultură

Coating Specs for Quadax Butterfly Valves

Încărcat de

jkhgvdj mnhsnjkhgDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Coating Specs for Quadax Butterfly Valves

Încărcat de

jkhgvdj mnhsnjkhgDrepturi de autor:

Formate disponibile

Coating Specifications

Quadax Series Butterfly Valves

Version July 2011

mller co-ax ag

Gottfried-Mller-Str. 1

74670 Forchtenberg

Germany

Tel.

Fax

E-Mail

Internet

+49 7947 828-0

+49 7947 828-11

info@co-ax.com

www.co-ax.com

Coating Specifications

Table of Contents

1 Scope

2 Applicable standards

3 Preparation

4 Covering

5 Coating preparation

6 Coating

7 Protection of non-coated surfaces

8 Final inspection

Version July 2011

Page 2/5

Coating Specifications

1 Scope

These specifications describe the passive corrosion protection through the external coating

of housing elements of QUADAX butterfly valves that do not come into contact with medium.

These specifications do not apply to butterfly valves made of rust-resistant materials that are

not coated in the standard configuration.

2 Applicable standards

Standards

EN ISO 8503

Preparation of steel substrates before application of

paints and related products Visual assessment of

surface cleanliness

Preparation of steel substrates before application of

paints and related products Surface roughness

characteristics of blast-cleaned steel substrates

EN ISO 12944

Paints and varnishes Corrosion protection of steel

structures by protective paint systems

EN ISO 11124

Preparation of steel substrates before application of

paints and related products

EN ISO 2808

Paints and varnishes Determination of film thickness

DIN EN 10204

EN ISO 4628

Iron ores - types of test coatings

Non-conductive coatings on non-magnetic electrically

conductive basis materials Measurement of coating

thickness Amplitude-sensitive eddy-current method

Paints and varnishes Evaluation of degradation of

coatings Designation of quantity and size of defects,

and of intensity of uniform changes in appearance

DIN EN 13463

Non-electrical devices for use in explosive areas

RAL

National Committee for Delivery Conditions Color-Coding

DIN 6164

DIN color cards, DIN color card for the 2 standard

observer

EN ISO 8501-1,2 ,4

EN ISO 2360

3 Preparation

All soil and loose particles must be removed from the surfaces to be coated.

The surfaces to be coated must be free from oil and grease.

If necessary, roughen or blast the surfaces to be coated.

Components requiring coating are painted on the fully assembled valve.

Version July 2011

Page 3/5

Coating Specifications

4 Covering

The following parts of the valve are coated:

Body (partially)

Cover plate incl. screws

gland follower incl. screws

The following need to be covered:

Flange sealing surfaces on body

Welding stubs of housing (welding version)

Shaft incl. key

Any actuators mounted to the valve are not coated.

5 Coating preparation

The parts to be coated must be at least 5 above the dew point

Relative humidity must be below 80%

The temperature of the parts to be coated must be between10C and 35C.

6 Coating

One-component silicone resin varnish (cover coating material) and conventional

atomizing spray are applied to the surface.

The varnish has a single-layer structure and a minimum dry film thickness of

30 5 m.

7 Protection of non-coated surfaces

The coverings of non-coated surfaces must be removed

Any adhesive residues must be removed

Non-coated surfaces such as flange sealing surfaces must be protected against

corrosion with suitable measures (e.g. greasing) prior to installation.

Version July 2011

Page 4/5

Coating Specifications

8 Final inspection

A final inspection of the coating of the valves is to be performed on a random-basis.

The total thickness is to be inspected in line with DIN ISO 2808

The total thickness may not be less than 80% of the specified coat thickness at any

point

The total thickness may not exceed 250% of the specified coat thickness at any point

The quality of the surface is to be inspected in line with EN ISO 4628

The color must be inspected in line with RAL or DIN 6164

Description

The coating is designed for corrosion protection for warm and

hot steel surfaces, for interior area as sole coating as well as

for outdoor weathering in rural, urban and industrial

atmospheres.

Minimum permissible

duration - temperature

-20C

Maximum permissible

duration - temperature

+500C

Maximum temporary

permissible temperature

+600C

Corrosion class

No official corrosion class

Expected duration of

corrosion protection

5 years (no liability)

Materials for coating

Ferrous materials such as steel and cast steel

Total drying film thickness

110 m

Pretreatment of surface

Primer

Primer color

See specifications

1-component silicon-phosphate primer

Red-brown (matt)

Primer dry film thickness

60 m

Topcoat

Topcoat color

1-component silicon-resin varnish

Silver ( Alu ) matt

Topcoat dry film thickness

30 m 5m

Applicable standards

EN ISO 8501-1, 2 ,4 / EN ISO 8503 / EN ISO 12944 / EN

ISO 11124 / EN ISO 2808 / DIN EN 10204 / EN ISO 2360 /

EN ISO 4628 / DIN EN 13463 / RAL / DIN 6164

Version July 2011

Page 5/5

S-ar putea să vă placă și

- TL 260 Engl 20040501 PDFDocument4 paginiTL 260 Engl 20040501 PDFAniruddha HawalÎncă nu există evaluări

- Coating Application & Inspection Procedure-Rev 0Document27 paginiCoating Application & Inspection Procedure-Rev 0tinphat100% (1)

- Astm A780Document4 paginiAstm A780Raúl Venegas Munita100% (5)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDe la EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesEvaluare: 3.5 din 5 stele3.5/5 (3)

- Painting Scheme StructureDocument10 paginiPainting Scheme StructureVeerapandianÎncă nu există evaluări

- Jotaprime Mastic 80 AGDocument8 paginiJotaprime Mastic 80 AGMuthu Sivarama Krishnan Nallaiah100% (1)

- Corus - A Corrosion Protection GuideDocument6 paginiCorus - A Corrosion Protection GuideBellana SirishÎncă nu există evaluări

- Scour Under StructuresDocument24 paginiScour Under StructuresRamkumarÎncă nu există evaluări

- Prevent Negative Volume in Foam ModelsDocument9 paginiPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusÎncă nu există evaluări

- Coating Spec 01 PDFDocument5 paginiCoating Spec 01 PDFWINÎncă nu există evaluări

- 190326quadax Valves Coating SpecificationsDocument5 pagini190326quadax Valves Coating SpecificationsS MhÎncă nu există evaluări

- 03 - Paint Spec - Added - FDC 25KDocument15 pagini03 - Paint Spec - Added - FDC 25KJIM CAMPBELLÎncă nu există evaluări

- Barrier: Technical Data Sheet Application GuideDocument8 paginiBarrier: Technical Data Sheet Application GuideNurmalinda SihombingÎncă nu există evaluări

- Barrier 77: Technical Data Sheet Application GuideDocument8 paginiBarrier 77: Technical Data Sheet Application GuideNurmalinda SihombingÎncă nu există evaluări

- Resist 78: Technical Data Sheet Application GuideDocument7 paginiResist 78: Technical Data Sheet Application GuideMohd YusriÎncă nu există evaluări

- Coating Specification: 1. ScopeDocument4 paginiCoating Specification: 1. ScopeThaiminh Vo100% (2)

- Chemflake Special AGDocument9 paginiChemflake Special AGAnantha PadmanabhanÎncă nu există evaluări

- Technical Data Sheet for Zinc-Rich Epoxy CoatingDocument8 paginiTechnical Data Sheet for Zinc-Rich Epoxy Coatingadeoye_okunoyeÎncă nu există evaluări

- Barrier: Technical Data Sheet Application GuideDocument8 paginiBarrier: Technical Data Sheet Application GuideANIBALLOPEZVEGAÎncă nu există evaluări

- RA1158-RHDHV-EG-ZZ-SC-S-9001-A1-C06 - Dock Gates Specification-Pg27-28Document2 paginiRA1158-RHDHV-EG-ZZ-SC-S-9001-A1-C06 - Dock Gates Specification-Pg27-28AnasÎncă nu există evaluări

- GTL-81-02 Rev 01 Coating and Wrapping of Buried PipingDocument17 paginiGTL-81-02 Rev 01 Coating and Wrapping of Buried Pipingjasminnee100% (2)

- Exico Paint SpecificationDocument5 paginiExico Paint SpecificationFredy Xavier DomínguezÎncă nu există evaluări

- Tankguard PlusDocument11 paginiTankguard PlusAbrar HussainÎncă nu există evaluări

- Barrier - 80 - Product - Description - Technicad HL PDFDocument8 paginiBarrier - 80 - Product - Description - Technicad HL PDFDimas BatamÎncă nu există evaluări

- Barrier ZEP: Technical Data Sheet Application GuideDocument7 paginiBarrier ZEP: Technical Data Sheet Application GuideNurmalinda SihombingÎncă nu există evaluări

- MDS Fore ChemtechDocument8 paginiMDS Fore ChemtechfouedÎncă nu există evaluări

- Jotun Resist 86 Data SheetDocument7 paginiJotun Resist 86 Data SheetKunal AjgaonkarÎncă nu există evaluări

- Technical Data Sheet and Application Guide SummaryDocument10 paginiTechnical Data Sheet and Application Guide SummaryMohanadÎncă nu există evaluări

- Technical Data Sheet Application GuideDocument8 paginiTechnical Data Sheet Application GuideAyman JadÎncă nu există evaluări

- Painting SpecDocument10 paginiPainting SpecTroy HooperÎncă nu există evaluări

- Attachment: Painting ProcedureDocument79 paginiAttachment: Painting ProcedureOmar Wardeh100% (2)

- Polyurea Hot Spray Steel Surfaces Method StatementDocument9 paginiPolyurea Hot Spray Steel Surfaces Method StatementGvsr SunnyÎncă nu există evaluări

- PDFDocument12 paginiPDFThamaraikani ManiÎncă nu există evaluări

- Resist 5 WF: Technical Data Sheet Application GuideDocument7 paginiResist 5 WF: Technical Data Sheet Application GuideEngTamerÎncă nu există evaluări

- Jotachar JF750Document17 paginiJotachar JF750samet çelikÎncă nu există evaluări

- Painting Data SheetsDocument12 paginiPainting Data SheetsRachidNakhil100% (1)

- AG 7740 Tankguard SF Euk GBDocument11 paginiAG 7740 Tankguard SF Euk GBChandran NairÎncă nu există evaluări

- 222-307-012K EMD 30 Grau TRDocument2 pagini222-307-012K EMD 30 Grau TRszafakÎncă nu există evaluări

- Tankguard 412: Technical Data Sheet Application GuideDocument9 paginiTankguard 412: Technical Data Sheet Application GuideEngTamerÎncă nu există evaluări

- Chemflake SpecialDocument10 paginiChemflake SpecialNabeel K SÎncă nu există evaluări

- Pipes FittingsDocument7 paginiPipes FittingsTushar ArekarÎncă nu există evaluări

- Barrier 65: Technical Data Sheet Application GuideDocument8 paginiBarrier 65: Technical Data Sheet Application Guidesabari ramasamyÎncă nu există evaluări

- TL245 English 2004Document8 paginiTL245 English 2004Elliott RussellÎncă nu există evaluări

- GRP General Procedure (EWS)Document16 paginiGRP General Procedure (EWS)Maged Ali Ragheb100% (1)

- EFD-Info No. 20 Corrosion Protection TestingDocument4 paginiEFD-Info No. 20 Corrosion Protection TestingNenad DeusicÎncă nu există evaluări

- Pts Ip Paint SystemDocument51 paginiPts Ip Paint SystemshiqinmkÎncă nu există evaluări

- Resist 86: Technical Data Sheet Application GuideDocument8 paginiResist 86: Technical Data Sheet Application Guidepmendonça_18Încă nu există evaluări

- AG 25780 Steelmaster 1200WF Euk GBDocument14 paginiAG 25780 Steelmaster 1200WF Euk GBOsama KheadryÎncă nu există evaluări

- Baltoflake: Technical Data Sheet Application GuideDocument11 paginiBaltoflake: Technical Data Sheet Application GuideNurmalinda SihombingÎncă nu există evaluări

- CEILCOTE 505 Coroline.Document2 paginiCEILCOTE 505 Coroline.stuart3962Încă nu există evaluări

- Painting Process Equipment and PipingDocument17 paginiPainting Process Equipment and PipingJoseph Darwin ZionÎncă nu există evaluări

- Surface Protection External Coating of Claas ProductsDocument1 paginăSurface Protection External Coating of Claas ProductsTomaszÎncă nu există evaluări

- Data Ketebalan Cat JotunDocument13 paginiData Ketebalan Cat JotunDeniÎncă nu există evaluări

- Tankguard 412 Application GuideDocument1 paginăTankguard 412 Application GuideTamerTamerÎncă nu există evaluări

- Jotamastic 80 AG NewDocument10 paginiJotamastic 80 AG NewMuthu Sivarama Krishnan NallaiahÎncă nu există evaluări

- Con-011 Instruction For Painting Work Rev.0Document11 paginiCon-011 Instruction For Painting Work Rev.0monchai_626Încă nu există evaluări

- Application Jotamastic 90 AlDocument13 paginiApplication Jotamastic 90 Aladitya kristantoÎncă nu există evaluări

- PaintingSpecifications T 8567 PDFDocument7 paginiPaintingSpecifications T 8567 PDFRaed ThakurÎncă nu există evaluări

- Tankguard Storage: Technical Data Sheet Application GuideDocument14 paginiTankguard Storage: Technical Data Sheet Application GuideEngTamerÎncă nu există evaluări

- Method Statement For Surface Preparation Prtective CoatingDocument10 paginiMethod Statement For Surface Preparation Prtective CoatingJaved MAÎncă nu există evaluări

- Barrier 77 PDFDocument8 paginiBarrier 77 PDFRizki AhmadÎncă nu există evaluări

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- API 608 Floating Ball ValvesDocument2 paginiAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgÎncă nu există evaluări

- Tolerancesspecifications & DimensionsDocument1 paginăTolerancesspecifications & DimensionswernhowÎncă nu există evaluări

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pagini12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgÎncă nu există evaluări

- API 608 Floating Ball ValvesDocument2 paginiAPI 608 Floating Ball Valvesjkhgvdj mnhsnjkhgÎncă nu există evaluări

- MSG 00018Document7 paginiMSG 00018jkhgvdj mnhsnjkhgÎncă nu există evaluări

- ISO 5211 Drilling Patterns Imperial SizesDocument1 paginăISO 5211 Drilling Patterns Imperial Sizesjkhgvdj mnhsnjkhgÎncă nu există evaluări

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDocument5 pagini12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgÎncă nu există evaluări

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pagini12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgÎncă nu există evaluări

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler PeltierDocument5 pagini12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltierjkhgvdj mnhsnjkhgÎncă nu există evaluări

- En 12201Document33 paginiEn 12201jkhgvdj mnhsnjkhgÎncă nu există evaluări

- Cantilever Retaining Wall Design PDFDocument2 paginiCantilever Retaining Wall Design PDFjkhgvdj mnhsnjkhgÎncă nu există evaluări

- Audit Checklist Master-HEMSA - June2010Document6 paginiAudit Checklist Master-HEMSA - June2010jkhgvdj mnhsnjkhgÎncă nu există evaluări

- 12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFDocument5 pagini12v 6a 92 4w Tec 12706 Thermoelectric Cooler Peltier PDFjkhgvdj mnhsnjkhgÎncă nu există evaluări

- ASTM Method D1945-96: Analysis of Natural GasDocument1 paginăASTM Method D1945-96: Analysis of Natural GasJosep JaamÎncă nu există evaluări

- Handling PigBasket GADocument1 paginăHandling PigBasket GAjkhgvdj mnhsnjkhgÎncă nu există evaluări

- Tip Sheet 9 Web Version DocumentDocument2 paginiTip Sheet 9 Web Version DocumentKarun NooneyÎncă nu există evaluări

- Collins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsDocument2 paginiCollins Torsional Mechanical Filters: Symmetrical Torsional Filter Product SpecificationsGdfsndh GfdvhjzdÎncă nu există evaluări

- LowVoltage Feb19thDocument6 paginiLowVoltage Feb19thShreyas EsheÎncă nu există evaluări

- 164200252Document92 pagini164200252jkhgvdj mnhsnjkhgÎncă nu există evaluări

- Datasheet 1mbhDocument5 paginiDatasheet 1mbhnguanjukÎncă nu există evaluări

- BZC 14Document1 paginăBZC 14jkhgvdj mnhsnjkhgÎncă nu există evaluări

- Lawctd 603Document5 paginiLawctd 603Nguyen Anh TuanÎncă nu există evaluări

- File 1361847746Document8 paginiFile 1361847746jkhgvdj mnhsnjkhgÎncă nu există evaluări

- Carmagen 6 10Document3 paginiCarmagen 6 10ikhleifÎncă nu există evaluări

- Indian Standards For Natural Gas Pipeline SystemDocument5 paginiIndian Standards For Natural Gas Pipeline SystemNapidduÎncă nu există evaluări

- Semiconductor DevicesDocument524 paginiSemiconductor Devicesapuinwork100% (1)

- 05120Document4 pagini05120jkhgvdj mnhsnjkhgÎncă nu există evaluări

- 570 Examination Sample ItemsDocument3 pagini570 Examination Sample ItemsMaria_Victoria_5742Încă nu există evaluări

- 0871Document1 pagină0871jkhgvdj mnhsnjkhgÎncă nu există evaluări

- Material GradesDocument2 paginiMaterial Gradespankaj_pawar89Încă nu există evaluări

- Structural Notes and DetailsDocument1 paginăStructural Notes and DetailsMohammad AlkahteebÎncă nu există evaluări

- Friction Stir Welding ENHANCEMENT SEMINAR Friction Stir WeldingDocument66 paginiFriction Stir Welding ENHANCEMENT SEMINAR Friction Stir Weldingrobertalha100% (1)

- Scaffold and Aerial Lift TelewebDocument63 paginiScaffold and Aerial Lift TelewebMonika GokarnÎncă nu există evaluări

- 1.11 - Fire Following Earthquake PDFDocument27 pagini1.11 - Fire Following Earthquake PDFNicolas De NadaiÎncă nu există evaluări

- T.O.S (Surface Active Structures)Document18 paginiT.O.S (Surface Active Structures)Riddhi Aggarwal100% (1)

- Load Tests Jet Grouting MacauDocument8 paginiLoad Tests Jet Grouting MacauMatteoTrigliaReatoÎncă nu există evaluări

- Parts Explosion Diagram for Whirlpool 7MWT9601WW0 WasherDocument12 paginiParts Explosion Diagram for Whirlpool 7MWT9601WW0 WasherMARTIN CABRERAÎncă nu există evaluări

- Cracking in Post-Tensioned Slabs KBondyCrackingSlabsDocument6 paginiCracking in Post-Tensioned Slabs KBondyCrackingSlabsMark RamnarineÎncă nu există evaluări

- Model of Tender SpecificationDocument15 paginiModel of Tender SpecificationRishi KathirÎncă nu există evaluări

- Maint DataDocument4 paginiMaint DataParents' Coalition of Montgomery County, MarylandÎncă nu există evaluări

- SEISMIC ISOLATORSDocument16 paginiSEISMIC ISOLATORSWillygan PmÎncă nu există evaluări

- Clean Agent Fire Suppression System SpecificationDocument14 paginiClean Agent Fire Suppression System Specificationhendrik wibowoÎncă nu există evaluări

- Construction Site Visit OverviewDocument12 paginiConstruction Site Visit OverviewCaereel LopezÎncă nu există evaluări

- Re 25715 - 2022-05Document8 paginiRe 25715 - 2022-05HeiderHuertaÎncă nu există evaluări

- Steel Column Buckling Axial and Transverse LoadingDocument31 paginiSteel Column Buckling Axial and Transverse LoadingTor GrimlundÎncă nu există evaluări

- Car Park DesignDocument71 paginiCar Park DesignAlf Horseman100% (1)

- Wall Cladding & PanelsDocument18 paginiWall Cladding & PanelsSubrata DeyÎncă nu există evaluări

- Submersible Pumpsets - SpecificationDocument16 paginiSubmersible Pumpsets - SpecificationP Ram MoorthyÎncă nu există evaluări

- 1pf2gf - Pgf-Int-Gp-Re10213Document20 pagini1pf2gf - Pgf-Int-Gp-Re10213Johnny JessingÎncă nu există evaluări

- Fire Sprinkler System Piping Support: © Fire Smarts LLC. All Rights ReservedDocument47 paginiFire Sprinkler System Piping Support: © Fire Smarts LLC. All Rights ReservedrashidÎncă nu există evaluări

- Qdoc - Tips - Flange Asme VIIIDocument41 paginiQdoc - Tips - Flange Asme VIIIHormedo RodriguezÎncă nu există evaluări

- Analytical Study On Seismic Behaviour of High Rise Building Using Different Load Resisting MethodDocument33 paginiAnalytical Study On Seismic Behaviour of High Rise Building Using Different Load Resisting MethodAbhinav VermaÎncă nu există evaluări

- Mt1 Unit 5 NotesDocument11 paginiMt1 Unit 5 NotesvelavansuÎncă nu există evaluări

- Mechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesDocument12 paginiMechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesEric S Y KwokÎncă nu există evaluări

- A Presentation On Doors & WindowsDocument45 paginiA Presentation On Doors & WindowsFarheen BanoÎncă nu există evaluări

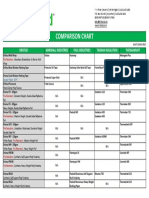

- Comparison Chart 19oct2015 7Document1 paginăComparison Chart 19oct2015 7Yury ChelominÎncă nu există evaluări

- Dishwasher Explanation TextDocument3 paginiDishwasher Explanation TextMai - Patcharee RushÎncă nu există evaluări

- 612 B Fig702 Flanged y Type Strainer UlDocument2 pagini612 B Fig702 Flanged y Type Strainer UlPradipta DwiÎncă nu există evaluări