Documente Academic

Documente Profesional

Documente Cultură

01 HIRA Lifting & Rigging

Încărcat de

Mudhyn MIDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

01 HIRA Lifting & Rigging

Încărcat de

Mudhyn MIDrepturi de autor:

Formate disponibile

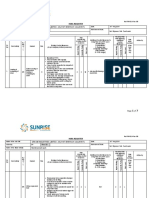

PT.

BERUSHA MAJU

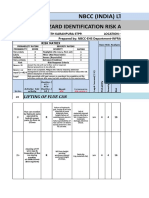

Document Title : HAZARD IDENTIFICATION & RISK ASSESSMENT OF

LIFTING AND RIGGING ACTIVITIES MAINTENANCE

CONSTRUCTION SERVICES

N

o

1

Description of work

Equipment Used

GENERAL LIFTING &

RIGGING ACTIVITIES

(Includes of .)

Potential Risk /

Hazard

Preventive Measures

General Precautionary Requirement :

Personnel Injury :

-

1. Sand Blasting & Painting

on onshore / facilities

HSE DEPARTMENT

Document No : HIRA 003

Date : Febr 22, 2015

Crane

Forklift

Trailer /

lowboy

Lifting Gear

Pinned by

Lifting Object

Struck,

stretched by

Lifting object.

Property

damage :

-

Crane colaps

Forklift Colaps

Spill

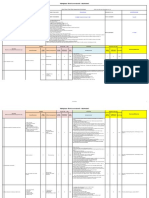

Safety working permit must have been

received & kept before starting any work (as

necessary).

A briefing / safety tool box meeting held by

foreman / supervisor & safety officer before

starting the work daily.

Make sure each worker knows well what to

do

Anomaly & near misses accident must be

reported, recorded and corrective action

implemented & reminded in toolbox meeting

Foreman & safety officer always keep a

good communication, especially for safety

work performance & Priority Safe lifting

Method / practice

Using PPE Minimum Mandatory (Safety

Helmet, Safety Glasses, Safety Shoes)

Special PPE for lifting and Rigging must be

used such as Hand Gloves, safety harness,

life jacket, Safety glasses and other support

PPE related Lifting and rigging Job.

Ensure all employees know about

emergency signal and procedure while

emergency situation

Specific Precautionary Requirement :

- Provide Lifting plan for Critical job and High

PT. BERUSHA MAJU

Document Title : HAZARD IDENTIFICATION & RISK ASSESSMENT OF

LIFTING AND RIGGING ACTIVITIES MAINTENANCE

CONSTRUCTION SERVICES

HSE DEPARTMENT

Document No : HIRA 003

Date : Febr 22, 2015

Risk

Make sure lifting object appropriate SWL of

Crane / Forklift, Radius, angle of boom &

length of boom. Compare with crane

chart/matrix before done.

Check all lifting gear in good condition.

Use lifting gear appropriate Safety Working

Load.

Use Tag line when lifting.

Lifting activities should be conducted by

competent persons.

Using pad eyes for lifting point.

Keep personnel from below lifting object,

lifting area should be clear from people.

Only one man give rigging hand signal.

Signal man should conducted by competent

person.

Secure lifting object with lacing, tied to

stabilizing lifting object when remove used

low boy / trailer.

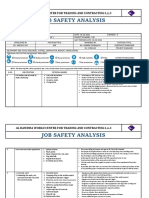

Note :

All crew who will be sent to the project site must attend the safety induction & pre work briefing in safety

meeting room Of PT. Perdana Karya at Handil base.

All crew must be attend the safety induction shall be conducted by site safety officer.

Stop the activities in emergency situation or any other emergency signal. Shut down welding machine and

Prepared

by, given by instruction given by Company/Client.

Approved by,

follow the

instruction

All crew are mandatory to join Toolbox & Weekly Safety meeting that is conducted by supervisor and

safety officer.

Kadir

Safety Officer

Nurhayati

HSE Manager

PT. BERUSHA MAJU

Document Title : HAZARD IDENTIFICATION & RISK ASSESSMENT OF

LIFTING AND RIGGING ACTIVITIES MAINTENANCE

CONSTRUCTION SERVICES

HSE DEPARTMENT

Document No : HIRA 003

Date : Febr 22, 2015

S-ar putea să vă placă și

- All HiraDocument40 paginiAll Hirarameese muhammed100% (1)

- HIRA For Civil WorkDocument11 paginiHIRA For Civil WorkYogesh Nath100% (1)

- HIRADocument57 paginiHIRAAnonymous Uc25fP83% (6)

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 paginiHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- 2.JSA-Electrical Work Installation of Fire Alarm SystemDocument5 pagini2.JSA-Electrical Work Installation of Fire Alarm SystemMuhammad Umar Gondal83% (6)

- HIRA For DPP-2 Project in I BlockDocument20 paginiHIRA For DPP-2 Project in I BlockSiddharth PÎncă nu există evaluări

- 04 HIRA For Reinforcement WorkDocument7 pagini04 HIRA For Reinforcement WorkMithlesh Singh100% (1)

- Hira For Excavation ManuallyDocument1 paginăHira For Excavation ManuallyChandru100% (1)

- Hira FormatDocument6 paginiHira FormatMOJIB33% (6)

- AFA HIRA - Electrical Control PanelDocument30 paginiAFA HIRA - Electrical Control PaneljavedÎncă nu există evaluări

- HIRA NewDocument107 paginiHIRA NewPrabhakaran Gurunathan100% (1)

- Risk Assessment - Placing of Transformer - TTSDocument6 paginiRisk Assessment - Placing of Transformer - TTSnsadnan100% (2)

- DLF PCC HiraDocument6 paginiDLF PCC HiraskfahimuddinÎncă nu există evaluări

- Grounding System Jsa 2008Document4 paginiGrounding System Jsa 2008Aldrin100% (5)

- Final HIRA - GBLDocument49 paginiFinal HIRA - GBLAbdul Rasheed MangrioÎncă nu există evaluări

- HIRA - Carpentry Work-018Document8 paginiHIRA - Carpentry Work-018Satya Naidu100% (1)

- 03-HIRA For Welding Work .Document2 pagini03-HIRA For Welding Work .archit kamat89% (9)

- (SWMS-01) Loading, Unloading and ShiftingDocument5 pagini(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- Hazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted CraneDocument1 paginăHazard Identification and Risk Assessment (Hira) Unloading of Container by Tyre Mounted Cranesaravanan .b90% (10)

- HIRA 003 Welding and Cutting.Document4 paginiHIRA 003 Welding and Cutting.srinibas mohapatraÎncă nu există evaluări

- Porta Cabins Shifting Risk AssessmentDocument8 paginiPorta Cabins Shifting Risk AssessmentAsad Raza100% (3)

- HIRA For Laying of PipelineDocument33 paginiHIRA For Laying of PipelineVineet Agrawal100% (4)

- HIRA FOR Equipment Instalation.Document8 paginiHIRA FOR Equipment Instalation.Deepak G100% (1)

- Grinding ActivityDocument1 paginăGrinding ActivityKrishna Patil100% (2)

- Area Hard Barrication JsaDocument7 paginiArea Hard Barrication JsaJanakiramanÎncă nu există evaluări

- Environment Health Safety Director in Huntsville AL Resume Ainsworth ThomasDocument2 paginiEnvironment Health Safety Director in Huntsville AL Resume Ainsworth ThomasAinsworthThomasÎncă nu există evaluări

- Hira Plastering Finishing WorkDocument2 paginiHira Plastering Finishing WorkDwitikrushna Rout0% (1)

- Concreting and ShutteringDocument3 paginiConcreting and ShutteringAnuj Kjoy0% (1)

- HIRA - Fixed Scaffold and Wall BreakingDocument6 paginiHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Risk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001Document7 paginiRisk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001123shripad100% (1)

- Risk Assessment For Back FillingDocument6 paginiRisk Assessment For Back FillingBhargav BbvsÎncă nu există evaluări

- Risk Assesment For MobilizationDocument6 paginiRisk Assesment For MobilizationAmeerHamzaWarraich100% (1)

- Mass Notification Systems UL2572Document8 paginiMass Notification Systems UL2572WillyWillyÎncă nu există evaluări

- JSA Format NEW Equipment ErectionDocument5 paginiJSA Format NEW Equipment Erectionsakthi venkatÎncă nu există evaluări

- RCC at Height HiraDocument1 paginăRCC at Height Hiraskfahimuddin100% (1)

- Working at Height Rescue Mock Drill!Document36 paginiWorking at Height Rescue Mock Drill!S RÎncă nu există evaluări

- HIRA For Stores ActivityDocument5 paginiHIRA For Stores ActivityRohit Singh100% (22)

- Tower Crane HiraDocument3 paginiTower Crane HiraVikas YamagarÎncă nu există evaluări

- Jsa Cable TerminationDocument4 paginiJsa Cable TerminationSyed Yousuf Ali100% (1)

- Job Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Document7 paginiJob Safety Analysis (Jsa) Piling Activity: Document No: Rev. 01 Date: 12.03.2021Sanjay Kumar GhadaiÎncă nu există evaluări

- V Belt Pulley MartinDocument124 paginiV Belt Pulley MartinUlul Azmi100% (2)

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 paginiJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 paginiJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANÎncă nu există evaluări

- Risk Assessment - Lifting OperationsDocument3 paginiRisk Assessment - Lifting Operationsdnmule100% (2)

- Winch MachineDocument1 paginăWinch MachineJomar Rudolph Cabesas100% (6)

- Unsafe Acts & Unsafe ConditionsDocument48 paginiUnsafe Acts & Unsafe Conditionsvan geraldÎncă nu există evaluări

- Passenger Hoist LiftDocument1 paginăPassenger Hoist LiftGyanendra Narayan Nayak100% (2)

- Scope of Work For 3.kV Switchgear and Relay Testing: Unless Stamped in RED, This Is An Uncontrolled Document'Document15 paginiScope of Work For 3.kV Switchgear and Relay Testing: Unless Stamped in RED, This Is An Uncontrolled Document'kulukundunguÎncă nu există evaluări

- Dismantling of WallDocument1 paginăDismantling of WallChandruÎncă nu există evaluări

- Welding and Gas CuttingDocument2 paginiWelding and Gas CuttingKrishna Patil100% (2)

- FREE Company Profile (Construction and Mining)Document10 paginiFREE Company Profile (Construction and Mining)Yulianti WarisÎncă nu există evaluări

- BOCWDocument162 paginiBOCWvisutsiÎncă nu există evaluări

- 04 - RISK ASSESSMENT CradleDocument5 pagini04 - RISK ASSESSMENT Cradle287100% (4)

- JSA-Vertical Load On Test Pile - REV 0Document8 paginiJSA-Vertical Load On Test Pile - REV 0Sanjay Kumar GhadaiÎncă nu există evaluări

- 022 - HSSE - Full Body Harness Inspection ChecklistDocument1 pagină022 - HSSE - Full Body Harness Inspection ChecklistShashwat PandeyÎncă nu există evaluări

- HIRA - Height WorkDocument3 paginiHIRA - Height WorkHiralal Pattanayak100% (2)

- Fire Fighting JSADocument14 paginiFire Fighting JSANikhil Manjrekar83% (6)

- SWMS - HVAC ShiftingDocument6 paginiSWMS - HVAC ShiftingParas100% (1)

- Functional Safety Certificate: ICO3S, ICO4S, ICO4D, ICO4N and SOV 1 To 6Document5 paginiFunctional Safety Certificate: ICO3S, ICO4S, ICO4D, ICO4N and SOV 1 To 6Ignacio Benito100% (1)

- MSDS Asmaco 2500 Silicon SealantDocument6 paginiMSDS Asmaco 2500 Silicon SealantblackcapperÎncă nu există evaluări

- 6.chain Pulley BlockDocument2 pagini6.chain Pulley BlockFrancis Vinoj75% (4)

- 11 - JSA (Tower Crane) 12-9-06Document11 pagini11 - JSA (Tower Crane) 12-9-06sattiÎncă nu există evaluări

- Jsa For TELESCOPING BOOM AERIAL LIFTDocument2 paginiJsa For TELESCOPING BOOM AERIAL LIFTVipul Shankar100% (1)

- Bert Joshua P. Medil Answers DRRR - Module 19Document11 paginiBert Joshua P. Medil Answers DRRR - Module 19Ron Adrianne Asedilla0% (2)

- Self-Assessment-Guide NoemiDocument7 paginiSelf-Assessment-Guide NoemiCharlton Benedict BernabeÎncă nu există evaluări

- Jsa forOperatingAForkliftDocument2 paginiJsa forOperatingAForkliftsupahing supahingÎncă nu există evaluări

- 004 Annexure D Job Safety SAnalysis JSADocument3 pagini004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- 275 MTR Chimney Work Can Lifting HIRA.Document6 pagini275 MTR Chimney Work Can Lifting HIRA.Amit kumar Gupta100% (1)

- HIRA For Concrete Pouring of Diaphragm WallDocument4 paginiHIRA For Concrete Pouring of Diaphragm WallLoc Nguyen0% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 paginiThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarÎncă nu există evaluări

- Door Drive MIDI+ / SUPRA: D823MGB1$111Document31 paginiDoor Drive MIDI+ / SUPRA: D823MGB1$111oro plataÎncă nu există evaluări

- Chapter 11 Risk Management PresentationDocument16 paginiChapter 11 Risk Management Presentationcloudmaria009Încă nu există evaluări

- Clariant SDS DODIGEN 226 USA EnglishDocument15 paginiClariant SDS DODIGEN 226 USA Englishfuenmayor.lilibethÎncă nu există evaluări

- Iso 18190 2016Document12 paginiIso 18190 2016Videos VideosÎncă nu există evaluări

- Hoja de Seguridad BioDocument1 paginăHoja de Seguridad BioAlejandro Osorio ToroÎncă nu există evaluări

- VERO-S NSE3 Operating ManualDocument68 paginiVERO-S NSE3 Operating Manualyraju88Încă nu există evaluări

- Switchgear Brochure ScreenDocument12 paginiSwitchgear Brochure ScreennetlabindiaÎncă nu există evaluări

- NSTP A1 HazardMapDocument2 paginiNSTP A1 HazardMapJessa Mae OhaoÎncă nu există evaluări

- Computer Hardware Servicing NCIIDocument81 paginiComputer Hardware Servicing NCIISan Antonio Tan100% (2)

- New Niob Examination SyllabusDocument73 paginiNew Niob Examination SyllabusBldr Hamzat IsahÎncă nu există evaluări

- Part 5c Annex 1 Price Schedule-PreliminariesDocument20 paginiPart 5c Annex 1 Price Schedule-PreliminarieskumaravajiraÎncă nu există evaluări

- Safety Assessments For Cosmetics - IntertekDocument2 paginiSafety Assessments For Cosmetics - Intertekaulia nova kusumaningtyasÎncă nu există evaluări

- Thesis Title For HousekeepingDocument7 paginiThesis Title For Housekeepingaprilwbndsouthbend100% (1)

- RAC Technician 2015Document41 paginiRAC Technician 2015Hilmy AwadÎncă nu există evaluări

- Labour Solutions Australia: Assignee Induction Handbook MN-003Document36 paginiLabour Solutions Australia: Assignee Induction Handbook MN-003Kyle WatsonÎncă nu există evaluări

- Astm C542Document6 paginiAstm C542Đường Nguyễn ThừaÎncă nu există evaluări

- Hero Honda's Mission, Vision, Environmental & Indusrtial AnalysisDocument40 paginiHero Honda's Mission, Vision, Environmental & Indusrtial Analysisashish67% (6)

- Natural Freedom Deodorant: Clear Stick: Contains Natural Ingredients, Low CostDocument2 paginiNatural Freedom Deodorant: Clear Stick: Contains Natural Ingredients, Low CostAstridz Monsteqszia SilvanaÎncă nu există evaluări

- CompaxUG6 99Document200 paginiCompaxUG6 99Cesar Augusto Perez SilvaÎncă nu există evaluări

- Organisation Study On BHEL Company by AtulDocument77 paginiOrganisation Study On BHEL Company by Atulatul_rockstar100% (4)