Documente Academic

Documente Profesional

Documente Cultură

WPS-PQR For Split Tee

Încărcat de

maheshmalaichamyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

WPS-PQR For Split Tee

Încărcat de

maheshmalaichamyDrepturi de autor:

Formate disponibile

HOT TAPPING WORKS IN QATAR PETROLEUM REFINERY

PROJECT DETAILS

Asset Owner

: Qatar Petroleum

Main Contractor

: Al Balagh Trading & Contracting Co. W.L.L.

Description

: WPS & PQR for Split Tee flange joint

Client Wo No.

: TBA

Location

: Mesaieed

Wellube Ref.

: SQR002374_WS-PI-HTS Rev-2

Country

: State of Qatar

FOR WELLUBE

Prepared By

: Rajesh R

Reviewed By

: Kurien P Thomas

Position

: Project Engineer

Position

: Sr. Project Engineer

Revision 0

: 26th November 2015

Revision 0

: 26th November 2015

CUSTOMER APPROVALS

Al Balagh Trading &

Asset Owner

: Qatar Petroleum

Main Contractor

Approved By

Approved By

: Contracting Co. W.L.L.

:

Signature

Signature

Position

Position

Date

Date

Procedure No.

Prepared By

Revision

Revision Date

:

:

:

:

SRVO01283

Rajesh R

0

26th November 2015

Reviewed By

Reviewed Date

Procedure Status

Page 1 of

:

:

:

:

Kurien P Thomas

26th November 2015

Issued for Approval

9

The information contained in this document is Technical - in - confidence. Copying of this document is strictly prohibited.

No transmission to any third party without the prior permission of UNIQUE WELLUBE FZC.

HOT TAPPING WORKS IN QATAR PETROLEUM REFINERY

TABLE OF CONTENTS

WPS ,PQR FOR OF 12X 10, 14 X 10 150# SPLIT TEE

Procedure No.

Prepared By

Revision

Revision Date

:

:

:

:

SRVO01283

Rajesh R

0

26th November 2015

Reviewed By

Reviewed Date

Procedure Status

Page 2 of

:

:

:

:

Kurien P Thomas

26th November 2015

Issued for Approval

9

The information contained in this document is Technical - in - confidence. Copying of this document is strictly prohibited.

No transmission to any third party without the prior permission of UNIQUE WELLUBE FZC.

WeldFit Energy Group

4133 Southerland Drive

Houston,Texas, 77092

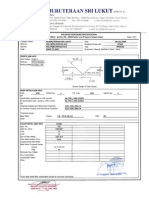

ASME Section IX QW-482 Welding Procedure Specification

Organization Name:

Weldfit Energy Group

Welding Procedure Specification No.:

Procedure Qualification Record No(s).:

Welding Process(es):

Type(s):

WF-499

PQR WF/499; WF-499(UW)

Revision:

Date:

GMAW-S, FCAW

Semi-Automatic, both

Joints (QW-402)

Joint Design:

Backing:

Backing Material:

Retainers:

Root Spacing:

Other:

Joint Details*

V-groove

none

N/A

none

0-1/8"

-

60

.67"

0 to 1/16"

1/16" - 1/8"

*Illustration is a sample only. WPS may be used for all suitable joints as called for on engineering drawings.

Base Metals (QW-403)

P-No.:

1

Grp No.:

Base Metal Qualified Thickness Range:

With Impact Requirements:

Without Impact Requirements:

Pipe Diameter:

Filler Metals

10/6/2015

1 or 2

to P-No.:

Groove:

Groove:

Groove:

Grp No.:

3/8" - .67"

3/16" - .67"

Unlimited

1 or 2

Fillet:

Fillet:

Fillet:

Unlimited

Unlimited

Unlimited

(QW-404)

SFA Specification:

AWS Classification:

F-No.:

A-No.:

Size of Filler Metal:

Max Weld Metal Deposit (t):

GMAW

FCAW

A5.18

ER70S-6

6

1

.035"

.103"

A5.20

E71T-1M

6

1

.045"

9/16"

No Single Pass >1/2"

Trade Names:

Oxford Alloys; Select Arc 727 or ESAB 7100 Ultra

Other:

Verify A1 chemistry for GMAW.

Position:

(QW-405)

Position of Groove:

1G

Weld Progression:

N/A

Other:

Gas :

Shielding

Tungsten Type and Size:

N/A

Flux/Wire Class:

Alloy Flux:

Supplemental Filler Metal:

Alloy Elements:

Flux Designation:

Flux Type:

Filler Metal Product Form:

Consum. Insert:

No Re-crushed slag used

N/A

N/A

None

None

N/A

N/A

Solid, Flux-cored

None

(QW-408)

Gas(es)

Ar - CO2

Trailing

Backing

Preheat:

(QW-405)

Preheat Temperature:

Interpass Temperature:

Preheat Maintenance:

100F

550F

N/A

Weld Layer

Process

Root

Balance

Fillet Only

GMAW

FCAW

FCAW

Filler Metal

Class

Dia.

ER70S-6

.035"

E71T-1M

.045"

E71T-1M

.045"

Post Weld Heat Treatment:

Temperature:

Time:

Cooling rate:

Percent Composition

Mixture

75/25

Flow Rate

35-45 CFH

None

(QW-407)

None

N/A

N/A

Electrical Characteristics

Travel Speed IPM

Curr / Pol

Amps

Volts

DCEP

110 - 120 16.0 - 18.0

4.5

8.0

DCEP

160 - 170 22.0 - 25.0 12.5 - 15.0

DCEP

160 - 170 22.0 - 25.0 12.5 - 15.0

Heat Input

kJ/in

28.8

20.4

20.4

Heat input listed is maximum allowed. Travel speed range is intended to correspond with appropriate amperage and voltage settings to

remain below heat input limits.

Page 1 of 2

WPS No.: WF-499

Revision:

Date:

10/6/2015

Technique (QW-410)

String or Weave Bead:

Multi-pass or Single Pass:

Single or Multiple Electrode:

Electrode Spacing:

Mode of Transfer (GMAW):

Orifice/Cup/Nozzle Size:

Stringer and weave

Mulitple

Single

N/A

1)Short circuit 2) globular

1/2" - 5/8"

Cleaning Method:

Back Gouging:

Oscillation:

Contact tube-work dist:

Peening:

Closed Chamber (GTAW):

Other:

Grinding or wire brush

Air carbon arc and grinding

None

3/8" - 3/4"

None

N/A

N/A

We certify that the statements in this record are correct and that the welds were prepared, welded and tested in accordance with the requirements of Section IX of the

ASME Boiler and Pressure Vessel Code.

Organization:

WeldFit Energy Group Inc.

Certified By:

Revision Certified By:

Revision

No.

1

2

3

4

5

6

Don Wischnewsky

Date:

4/15/2010

Jared Johnson

Date:

10/6/2015

List of Revisions

Initial release.

Update qualified T limits

Reformat; typo corrections on T limits.

Add preheat info for thicker material; add fillet-only parameters.

Author

Don Wischnewsky

Todd Sale

Jared Johnson

Jared Johnson

Date

4/15/2010

6/12/2013

5/1/2015

7/1/2015

Revise GMAW t limits; correction to FCAW class and trade name

Preheat correction; add GMAW chemistry verification; adjust max T based on

t limits.

Jared Johnson

8/31/2015

Jared Johnson

10/6/2015

Page 2 of 2

WeldFit Energy Group

4133 Southerland Drive

Houston,Texas, 77092

QW-483 Procedure Qualification Record

Organization Name:

Weldfit Energy Group

Procedure Qualification Record No.:

WF/499

Welding Procedure Specification No.(s):

WF-499. WF-1-F-004.

Revision:

Welding Process(es):

Date:

10/27/2015

GMAW, FCAW

Type(s):

Semi-Auto, both

Base Metals (QW-403)

Joints (QW-402)

Mat'l spec, type/grade:

A516 gr 70

Mat'l spec, type/grade:

A516 gr 70

P-No.:

Grp No.:

to P-No.:

Thickness of test coupon:

Groove Design of Test Coupon

30

Grp No.:

3/8"

3/8"

Size of test coupon:

Other:

1/16"

Heat #: 8494

3/16"

WF material number M21539

Filler Metals QW-404

GMAW

FCAW

Post Weld Heat Treatment

SFA Specification:

A5.18

A5.20

Temperature:

N/A

AWS Classification:

ER70S-6

E71T-1

Time:

N/A

Filler Metal F-No.:

Other:

N/A

Cooling rate:

N/A

Weld Metal A-No.:

Size of Filler Metal:

.035"

.045"

Deposited Weld Metal:

Trade Name:

3/32"

9/32"

Oxford Alloys

Select Arc 727

Tungsten Type and Size:

Other:

Gas :

N/A

(QW-408)

Shielding

GM heat#: SA04213; FC heat#: 3131B009A992

(QW-407)

Percent Composition

Gas(es)

Mixture

Flow Rate

Ar-CO2

75/25

35 CFH

Trailing

None

Backing

None

No Re-crushed slag used

Weld Layer

Process

Root

Balance

Position:

Filler Metal

Electrical Characteristics

Heat Input kJ/in

Dia.

Curr / Pol

GMAW

ER70S-6

.035"

DCEP

--

- 117

--

18.0

4.00

8.00

N/A

31.6

FCAW

E71T-1

.045"

DCEP

--

- 171

--

25.0

12.25

13.00

N/A

20.9

Technique (QW-410)

Position of Groove:

1G flat

Weld Progression:

N/A

Pre- Heat:

Volts

Wire Feed

Speed IPM

Class

(QW-405)

Amps

Travel Speed IPM

(QW-405)

String or Weave Bead:

Stringer

Multi-pass or Single Pass:

Multiple

Single or Multiple Electrode:

Single

Cleaning Method:

Grind / wire brush

Back Gouging:

air carbon arc or grind

Pre-Heat Temperature:

110F

Oscillation:

None

Interpass Temperature:

550F

Contact tube-work dist:

1/2" - 3/4"

Orifice/Cup/Nozzle Size:

1/2" - 3/4"

Transfer Mode:

GMAW - short circuit; FCAW - globular

Other:

N/A

Page 1 of 3

Procedure Qualification Record No.:

WF/499

Revision:

Date:

10/27/2015

Tensile Tests (QW-150)

Yield Strength Ultimate Tensile

KSI

Strength KSI

Specimen Number

Width

Thickness

Area

Specimen 1, Transverse

0.732

0.304

0.223

54400

Specimen 2, Transverse

0.74

0.307

0.227

52100

Elong %

RoA

Type of Failure and

Location

81000

nr

nr

Ductile, base

82900

nr

nr

Ductile, base

Guided Bend Tests (QW-160)

Figure number

Type

Results

QW 462.3(a)

Face Bend

Satisfactory

QW 462.3(a)

Root Bend

Satisfactory

QW 462.3(a)

Face Bend

Satisfactory

QW 462.3(a)

Root Bend

Satisfactory

Toughness Tests. Supplemental

Specimen 1

Specimen 2

Specimen 3

Average

Ft-Lbs

58

27

35

40

test report 285933.0

HAZ

Weld

% Shear

50

30

40

Lat Exp. Mils

Ft-Lbs

43

25

36

50

50

32

44

% Shear

Lat Exp. Mils

50

50

40

45

31

29

Temperature F

Size

-50

.394"x.320"

-50

.394"x.320"

Vickers HV10 Micro Hardness Test per NACE MR0175:

Page 2 of 3

Procedure Qualification Record No.:

WF/499

Welder's Name:

Revision:

Jose Garcia

Weld Test Conducted By:

Don Wischnewsky

Lab Tests Conducted By:

P&B Testing

Laboratory Test Report number:

Stamp No.

Date:

10/27/2015

167909.0

We certify that the statements in this record are correct and that the welds were prepared, welded and tested in accordance with the requirements of Section IX of

the ASME Boiler and Pressure Vessel Code.

Organization:

WeldFit Energy Group Inc.

Certified By:

Revision Certified By:

Revision

No.

0

1

2

3

4

Don Wischnewsky

Date:

4/8/2010

Jared Johnson

Date:

10/27/2015

List of Revisions

Initial release

reformat; correct typos on tensile data and FCAW diameter.

Add transfer modes.

Add WPS only.

Author

Don Wischnewsky

Todd Sale

Jared Johnson

Jared Johnson

Jared Johnson

Date

4/8/2010

6/13/2012

5/1/2015

8/4/2015

#########

Page 3 of 3

WeldFit Energy Group

4133 Southerland Drive

Houston,Texas, 77092

QW-483 Procedure Qualification Record

Organization Name:

Weldfit Energy Group

Procedure Qualification Record No.:

WF-499(UW)

Welding Procedure Specification No.(s):

WF-499; WF-499(UW); WF-1-F-004.

Revision:

Welding Process(es):

Date:

10/27/2015

GMAW, FCAW

Type(s):

Semi-Auto, both

Base Metals (QW-403)

Joints (QW-402)

Mat'l spec, type/grade:

A516 gr 60

Mat'l spec, type/grade:

A516 gr 70

P-No.:

Grp No.:

to P-No.:

Thickness of test coupon:

Groove Design of Test Coupon

60

Grp No.:

3/8"

3/8"

Size of test coupon:

Other:

1/16"

Heat #: 821W03180. Dual certified.

3/16"

WF material number M26900

Filler Metals QW-404

GMAW

FCAW

Post Weld Heat Treatment

SFA Specification:

A5.18

A5.20

Temperature:

N/A

AWS Classification:

ER70S-6

E71T-1

Time:

N/A

Filler Metal F-No.:

Other:

N/A

Cooling rate:

N/A

Weld Metal A-No.:

Size of Filler Metal:

.035"

.045"

Deposited Weld Metal:

Trade Name:

3/32"

9/32"

Oxford Alloys

Select Arc 727

Tungsten Type and Size:

Other:

Gas :

N/A

(QW-408)

Shielding

GM heat#: SA04213; FC heat#: 3131B009A992

(QW-407)

Percent Composition

Gas(es)

Mixture

Flow Rate

Ar-CO2

75/25

35 CFH

Trailing

None

Backing

None

No Re-crushed slag used

Weld Layer

Process

Root

Balance

Position:

Filler Metal

Electrical Characteristics

Heat Input kJ/in

Dia.

Curr / Pol

GMAW

ER70S-6

.035"

DCEP

--

- 117

--

18.0

4.00

8.00

N/A

31.6

FCAW

E71T-1

.045"

DCEP

--

- 171

--

25.0

12.25

13.00

N/A

20.9

Technique (QW-410)

Position of Groove:

1G flat

Weld Progression:

N/A

Pre- Heat:

Volts

Wire Feed

Speed IPM

Class

(QW-405)

Amps

Travel Speed IPM

(QW-405)

String or Weave Bead:

Stringer and weave

Multi-pass or Single Pass:

Multiple

Single or Multiple Electrode:

Single

Cleaning Method:

Grind / wire brush

Back Gouging:

air carbon arc or grind

Pre-Heat Temperature:

110F

Oscillation:

None

Interpass Temperature:

550F

Contact tube-work dist:

1/2" - 3/4"

Orifice/Cup/Nozzle Size:

1/2" - 3/4"

Closed Chamber (GTAW):

N/A

Transfer Mode:

1) short circuit, 2) globular

Other:

N/A

Page 1 of 2

Procedure Qualification Record No.:

WF-499(UW)

Revision:

Date:

10/27/2015

Tensile Tests (QW-150)

Specimen Number

Yield Strength Ultimate Tensile

KSI

Strength KSI

Width

Thickness

Area

Specimen 1, Transverse

0.74

0.316

0.234

47300

Specimen 2, Transverse

0.741

0.271

0.201

51100

Elong %

RoA

Type of Failure and

Location

73400

26

57

Ductile, base

75000

28

59

Ductile, base

Guided Bend Tests (QW-160)

Figure number

Type

Results

QW 462.2

Side Bend

Satisfactory

QW 462.2

Side Bend

Satisfactory

QW 462.2

Side Bend

Satisfactory

QW 462.2

Side Bend

Satisfactory

Toughness Tests

HAZ

Weld

Specimen 1

Specimen 2

Specimen 3

Average

Ft-Lbs

83

35

89

69

% Shear

100

30

100

Lat Exp. Mils

Ft-Lbs

71

33

76

73

69

54

65

% Shear

Lat Exp. Mils

80

50

40

61

58

49

Temperature F

Size

-50

10x7.5mm

-50

10x7.5mm

Brinell Surface Hardness:

Weld:

HAZ:

Base:

174 HBW

174 HBW

152 HBW

Procedure Qualification Record No.:

WF-499(UW)

Welder's Name:

Bernardo Bardenas

Weld Test Conducted By:

Scott Thompson

Lab Tests Conducted By:

P&B Testing

Laboratory Test Report number:

Revision:

Stamp No.

Date:

10/27/2015

252023.0

We certify that the statements in this record are correct and that the welds were prepared, welded and tested in accordance with the requirements of Section IX of the

ASME Boiler and Pressure Vessel Code.

Organization:

WeldFit Energy Group Inc.

Certified By:

Revision Certified By:

Revision

No.

0

1

2

Scott Thompson

Date:

10/31/2013

Jared Johnson

Date:

10/27/2015

List of Revisions

Initial release

reformat; correct typos on tensile data and FCAW diameter.

Add WPS only.

Author

Scott Thompson

Jared Johnson

Jared Johnson

Date

10/31/2013

5/1/2015

10/27/2015

Page 2 of 2

S-ar putea să vă placă și

- 12V140 Seris Engine Shop ManualDocument471 pagini12V140 Seris Engine Shop ManualRaed Mahyoub100% (4)

- Split Tee Specifications and Drawings - 20130906 - 191217Document17 paginiSplit Tee Specifications and Drawings - 20130906 - 191217Anonymous cuOIjrLIÎncă nu există evaluări

- WPS FormatDocument2 paginiWPS FormatAmit SarkarÎncă nu există evaluări

- Method Statement For Hot Tapping Rev 0Document9 paginiMethod Statement For Hot Tapping Rev 0Thomas100% (4)

- WPS PQRDocument23 paginiWPS PQRHashim Khan88% (8)

- Qa&qc-Log-04 PQR Log Sheet With CSD CommentsDocument2 paginiQa&qc-Log-04 PQR Log Sheet With CSD CommentsasiqÎncă nu există evaluări

- Hydrotest Procedure For PipelineDocument12 paginiHydrotest Procedure For Pipelineaike_577% (13)

- Inspect Hot Tap Installation: Saudi AramcoDocument53 paginiInspect Hot Tap Installation: Saudi AramcoSivaram SivaÎncă nu există evaluări

- Piping Pneumatic Test ProcedureDocument2 paginiPiping Pneumatic Test Procedureruzla67% (3)

- WPS GTAW Stainless SteelDocument4 paginiWPS GTAW Stainless SteelAnand NarayananÎncă nu există evaluări

- Hot TappingDocument21 paginiHot TappingnayakyaÎncă nu există evaluări

- Vlosi Holiday Test Report No-16Document1 paginăVlosi Holiday Test Report No-16Anonymous uJzSZ5100% (1)

- Guidelines For Hot TappingDocument13 paginiGuidelines For Hot TappingJosmag JatemÎncă nu există evaluări

- Pneumatic TestDocument10 paginiPneumatic Testchitobarba19726762100% (3)

- Hot Topping Split TeeDocument4 paginiHot Topping Split Teelili100% (1)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 paginiQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Wps p91 - BhelDocument2 paginiWps p91 - BhelAshish Gupta100% (4)

- Pipeline Hydrotest ProcedureDocument78 paginiPipeline Hydrotest Procedurealinor_tn100% (1)

- Split TeeDocument80 paginiSplit TeeJohn Peter100% (1)

- Hot TappingDocument88 paginiHot TappingAlexis Pacheco100% (1)

- Super Duplex Stainless SteelDocument1 paginăSuper Duplex Stainless SteelUma Shankar100% (2)

- Piping WpsDocument37 paginiPiping WpsZulfokar FahdawiÎncă nu există evaluări

- Pneumatic Testing Procedure For PipelinesDocument3 paginiPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinÎncă nu există evaluări

- Hot Tapping SequenceDocument4 paginiHot Tapping Sequenceasoka.pw100% (1)

- Hot TapDocument4 paginiHot TapmiteshÎncă nu există evaluări

- Welding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauDocument5 paginiWelding Procedure Specification NO. 1-7-1: National Certified Pipe Welding BureauTharakeshÎncă nu există evaluări

- Hydratight Hot Tap ProcedureDocument39 paginiHydratight Hot Tap Proceduremitesh0% (1)

- QCP Hot TapDocument9 paginiQCP Hot TaparockiyathassÎncă nu există evaluări

- MOS For Hot TappingDocument6 paginiMOS For Hot TappingLu Min HanÎncă nu există evaluări

- Welder Cirt TotalDocument78 paginiWelder Cirt TotalNguyễn ChâuÎncă nu există evaluări

- Inspection and Test Plan: On-Shore Pipeline CertificationDocument2 paginiInspection and Test Plan: On-Shore Pipeline CertificationKayra Riri Chirul100% (1)

- WPS & PQRDocument7 paginiWPS & PQRRanjan KumarÎncă nu există evaluări

- Aramco Hot Tap Welding Procedure Rev. 1Document3 paginiAramco Hot Tap Welding Procedure Rev. 1arockiyathass100% (10)

- Wps A53 Gtaw R00Document2 paginiWps A53 Gtaw R00Richard PeriyanayagamÎncă nu există evaluări

- Proposed 12' Hot Tap WPSDocument6 paginiProposed 12' Hot Tap WPSOgbonde100% (1)

- Welding Procecure SpecificationDocument9 paginiWelding Procecure SpecificationNwoha PeterÎncă nu există evaluări

- PQR FormatDocument2 paginiPQR Formatravi0009880% (5)

- Psp-Koti-19 - Hot Tapping Procedure - Rev 0Document14 paginiPsp-Koti-19 - Hot Tapping Procedure - Rev 0cheehoong82Încă nu există evaluări

- Full Hot TapDocument91 paginiFull Hot TapHaseeb Bokhari100% (1)

- Hot Tapping PDFDocument32 paginiHot Tapping PDFSreenivas Kamachi Chettiar100% (1)

- Tie in Joint Welding (Gold Weld) SpecDocument8 paginiTie in Joint Welding (Gold Weld) Specrepository1100% (2)

- QCP For Hot Tap PDFDocument30 paginiQCP For Hot Tap PDFjahaan100% (1)

- PWPS For Piping-API 1104Document6 paginiPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Hot Tapping GuideDocument3 paginiHot Tapping GuidegshdavidÎncă nu există evaluări

- Inspection & Test Plan For 16 Inch Pipeline (R0)Document13 paginiInspection & Test Plan For 16 Inch Pipeline (R0)Nilesh Kabade100% (1)

- DESBLOQUEADO Synesis Erik Hollnagel 2022Document81 paginiDESBLOQUEADO Synesis Erik Hollnagel 2022Tribu de SSOÎncă nu există evaluări

- Hot Tap ReportDocument2 paginiHot Tap ReportCak NhassÎncă nu există evaluări

- GS Ep Tec 260 enDocument61 paginiGS Ep Tec 260 enCesarÎncă nu există evaluări

- Brochure Exterior LightingDocument49 paginiBrochure Exterior Lightingmurali_227Încă nu există evaluări

- Piping Release Report (Spool For Paint)Document2 paginiPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Post Weld Head Treament Piping-ProcedureDocument12 paginiPost Weld Head Treament Piping-ProcedureAnh Võ100% (1)

- Hot Tap ProcedureDocument7 paginiHot Tap Procedurerashid zamanÎncă nu există evaluări

- WPS PQR WPQRDocument1 paginăWPS PQR WPQRFazeel Rick MohammedÎncă nu există evaluări

- KSL Wps PQR 012 DuplexDocument33 paginiKSL Wps PQR 012 DuplexJunaidi Minhat100% (6)

- Hot TappingDocument15 paginiHot Tappingghkashyap150% (2)

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusDocument18 paginiInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiÎncă nu există evaluări

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 paginiWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizÎncă nu există evaluări

- SS WPSDocument1 paginăSS WPSMOHAMEDABBASÎncă nu există evaluări

- 328.4.2 End Preparation: ASME B31.3-2012Document2 pagini328.4.2 End Preparation: ASME B31.3-2012Stephen Raj100% (1)

- Gtaw Smaw 6 Inch 6G CSDocument1 paginăGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Wps Pip Gtaw - ArabianDocument1 paginăWps Pip Gtaw - ArabianIshack MohammedÎncă nu există evaluări

- Hot TappingDocument9 paginiHot Tappingvinonagu100% (3)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarÎncă nu există evaluări

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 paginăQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Încă nu există evaluări

- IUK Routemap - GovernanceDocument27 paginiIUK Routemap - GovernanceTom RedwayÎncă nu există evaluări

- Case Analysis, Case 1Document2 paginiCase Analysis, Case 1Aakarsha MaharjanÎncă nu există evaluări

- 1.1. CHILLER 1.2. Centrifugal: 5.2.hrizontalDocument2 pagini1.1. CHILLER 1.2. Centrifugal: 5.2.hrizontalShah ArafatÎncă nu există evaluări

- Evaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellDocument6 paginiEvaluation of A Systematic Approach To Matrix Acidizing On An Oil Producing WellTrần Hoàng ChươngÎncă nu există evaluări

- Lab Session 8: To Develop and Understanding About Fatigue and To Draw S-N Curve For The Given Specimen: I. SteelDocument4 paginiLab Session 8: To Develop and Understanding About Fatigue and To Draw S-N Curve For The Given Specimen: I. SteelMehboob MeharÎncă nu există evaluări

- SIP Project ProposalDocument2 paginiSIP Project ProposalDeep SutariaÎncă nu există evaluări

- Heat ExchangerDocument5 paginiHeat Exchangersara smithÎncă nu există evaluări

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDocument3 paginiIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriÎncă nu există evaluări

- JMPGuitars 18 Watt Tremolo TMB Reverb LayoutDocument1 paginăJMPGuitars 18 Watt Tremolo TMB Reverb LayoutRenan Franzon GoettenÎncă nu există evaluări

- Product Matrix: Network Security Platform - Top Selling Models MatrixDocument6 paginiProduct Matrix: Network Security Platform - Top Selling Models MatrixWashington CárdenasÎncă nu există evaluări

- Prescriptions For Closing The Seven Service Quality GapsDocument1 paginăPrescriptions For Closing The Seven Service Quality GapsReema NegiÎncă nu există evaluări

- CS221 - Artificial Intelligence - Search - 4 Dynamic ProgrammingDocument23 paginiCS221 - Artificial Intelligence - Search - 4 Dynamic ProgrammingArdiansyah Mochamad NugrahaÎncă nu există evaluări

- Strain GaugeDocument7 paginiStrain GaugefahadarizkiÎncă nu există evaluări

- Examen Inglés de Andalucía (Ordinaria de 2019) (WWW - Examenesdepau.com)Document2 paginiExamen Inglés de Andalucía (Ordinaria de 2019) (WWW - Examenesdepau.com)FREESTYLE WORLDÎncă nu există evaluări

- Literature 101 Assignment: Step 1: Graphic OrganizerDocument2 paginiLiterature 101 Assignment: Step 1: Graphic OrganizercatarinaÎncă nu există evaluări

- Leap Motion PDFDocument18 paginiLeap Motion PDFAnkiTwilightedÎncă nu există evaluări

- Embargoed: Embargoed Until April 24, 2019 at 12:01 A.M. (Eastern Time)Document167 paginiEmbargoed: Embargoed Until April 24, 2019 at 12:01 A.M. (Eastern Time)Las Vegas Review-JournalÎncă nu există evaluări

- Mini Riset Bahasa Inggris BisnisDocument10 paginiMini Riset Bahasa Inggris BisnissyahsabilahÎncă nu există evaluări

- MoveInSync Native Android Mobile AppDocument12 paginiMoveInSync Native Android Mobile AppRismaÎncă nu există evaluări

- PSY502 OLd PapersDocument6 paginiPSY502 OLd Paperscs619finalproject.com100% (4)

- Straightforward Pre-Intermediate Progress Test 4: Language Section VocabularyDocument8 paginiStraightforward Pre-Intermediate Progress Test 4: Language Section VocabularyStrange BrawlerÎncă nu există evaluări

- Adsa Ka SyllabusDocument3 paginiAdsa Ka SyllabusHacker RanjanÎncă nu există evaluări

- Imarest 2021 Warship Development 1997Document43 paginiImarest 2021 Warship Development 1997nugrohoÎncă nu există evaluări

- Remote Sensing: Carbon Stocks, Species Diversity and Their Spatial Relationships in The Yucatán Peninsula, MexicoDocument18 paginiRemote Sensing: Carbon Stocks, Species Diversity and Their Spatial Relationships in The Yucatán Peninsula, MexicoSara EspinozaÎncă nu există evaluări

- COCapplication08rev Working SampleDocument34 paginiCOCapplication08rev Working SampleTanya HerreraÎncă nu există evaluări

- FINAL Shivani Confined Space PermitDocument1 paginăFINAL Shivani Confined Space PermitVimal SinghÎncă nu există evaluări