Documente Academic

Documente Profesional

Documente Cultură

Bhm1123-Mechanics of Materials 11415

Încărcat de

MysteryDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Bhm1123-Mechanics of Materials 11415

Încărcat de

MysteryDrepturi de autor:

Formate disponibile

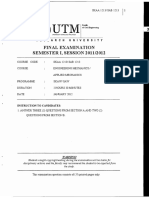

ILTjIMalaysia

Universiti

PAHANG

Engineering Technoogy 'Cratity

FACULTY OF MANUFACTURING ENGINEERING

FINAL EXAMINATION

COURSE

MECHANICS OF MATERIALS

COURSE CODE

BFF1133/BHM1 123

LECTURER

DR. AKM ASIF IQBAL

DATE

5 JANUARY 2015

DURATION

3 HOURS

SESSION/SEMESTER :

SESSION 2014/2015 SEMESTER I

PROGRAMME CODE :

BFF/BFM/BHM

INSTRUCTIONS TO CANDIDATE:

a)

b)

c)

d)

This question paper consists of FIVE (5) questions. Answer any Four (4) questions.

All answers to a new question should start on a new page.

All calculations and assumptions must be clearly stated.

Candidates are not allowed to bring any material other than those allowed by the

invigilator into the examination room.

EXAMINATION REQUIREMENTS:

1. Appendix A Average Mechanical Properties of Materials

DO NOT TURN THIS PAGE UNTIL YOU ARE TOLD TO DO SO

This examination paper consists of SEVEN (7) printed pages including front page.

BFF/BHMI1415I/BFF1133/BHM1 123

CONFIDENTIAL

QUESTION 1 [25 MARKS]

a) The truss is made from three pin-connected members having the cross-sectional areas

shown in the Figure la. Determine the average normal stress developed in each member

when the truss is subjected to the load P = 2.5 kN shown in the figure. State whether the

(12 Marks)

stress is tensile or compressive.

kN

B

L2rn

t

Figure la

b) A square hollow bar is shown in Figure lb. Determine the permanent elongation of the

bar when the axial force P = 360 kN is applied on it and released. The bar is made of a

metal alloy having a stress-strain diagram which can be approximated as shown in the

figure.

(13 Marks)

u (M.P.a)

500

.)5Ornrn

250

mm

0O0125

4105

(mm/mm)

50 mmrn

Figure lb

2

CONFIDENTIAL

BFF/BHM/141511BFF1133/BHM1 123

QUESTION 2 [25 MARKS]

a) If the gap between C and the rigid wall at D is initially 0.15 mm as shown in Figure 2a,

determine the support reactions at A and D when the force P = 200 kN is applied. The

(10 Marks)

assembly is made of A-36 steel. (Esteei = 200GPa).

Figure 2a

b) The assembly consists of three titanium (Ti-6A1-4V) rods and a rigid bar AC. The crosssectional area of each rod is given in the Figure 2b. If a force of 30 kN is applied to the

ring F, determine the horizontal displacement of point F.

(15 Marks)

L2m

r'A=6Oumrn2

I0)m

A=90:rnrn

L8 M.

Figure 2b

F

_________ kN

I1O3 m, A jr 1200 mrn

I 1

BFFIBHMI1415IJBFF1 1331BHM1123

CONFIDENTIAL

QUESTION 3 [25 MARKS]

a) The A-36 steel shaft has a diameter of 50 mm and is fixed at its ends A and B. If it is

subjected to the torque shown in Figure 3a, determine the maximum shear stress in

regions AC and CB of the shaft.

(12 Marks)

30ONm

,03 rn

Figure 3a

b) The motor, shown in Figure 3b, delivers 32 kW to the 304 stainless steel solid shaft while

it rotates at 20 Hz. The shaft has a diameter of 37.5 mm and is supported on smooth

bearings at A and B, which allow free rotation of the shaft. The gears C and D fixed to the

shaft remove 20 kW and 12 kW, respectively. Determine the absolute maximum stress in

(13 Marks)

the shaft and the angle of twist of gear C with respect to gear D.

Figure 3b

CONFIDENTIAL

BFF/BIIMJ1415IIBFF1 133IBHM1 123

QUESTION 4 [25 MARKS]

a) Draw the shear and moment diagrams for the beam shown in Figure 4a.

(13 Marks)

kN/rn

45 kNm

B

LSrn

13m

'

i.Sm,

Figure 4a

b) The steel beam has the cross-sectional area as shown in Figure 4b. If w = 75 kN/m,

(12 Marks)

determine the absolute maximum bending stress in the beam.

2Dm

8

M

8 rnmjj[z5o mm

c.

Figure 4b

CONFIDENTIAL

BFF/BHM/1415IIBFF1133IBHM1 123

QUESTION 5 [25 MARKS]

a) If the wide-flange beam as shown in Figure 5a is subjected to a shear of V 30 kN,

(10 Marks)

determine the maximum shear stress in the beam.

200 mm

30 mm

-25mm

V

250 mm

mm

Figure 5a

b) Determine the maximum and minimum normal stress on the bracket at section a-a shown

(15 Marks)

in Figure Sb when 100 kN load is applied at x = 0.

00 k

1

15 mm

lSnirn

200

a

.

.

1-

Figure 5b

END OF EXAMINATION PAPER

Average Mechanical Properties of Typical Engineering Materials'

(SI Units)

Cl)

Dens5ty

Matc,a1s

(M8/n13)

Uim2cStrength (MP)

Thid Sngth(Mn)

Nlodww of

E]nsboty, E R.gidity G

(G'a)

(OPa)

AN104ww.at

oftbezm.

pnnso a

Cc.e

% E

ption w

oLsson s

Tens.

Comp.b

Sheaz

Tens.

Compi'

Shet

SO mm spcaxncn

Ratio v

?vtfli

Cl)

2.79

13.1

27

414

414

172

49

4-69

290

10

0.35

23

2.71

6.9

26

t5

235

131

290

90

186

12

0.33

24

7.9

670

27

-.

179

669

12

728

68

276

72

06

S

0.28

172

028

12

i CS3400

CppedEaan

8,74

101

37

38

655

241

655

0,35

103

00

345

35

8.83

70J0

345

241

Alloys L. Bronzc C861 00

20

0.34

17

1.83

447

18

152

15

276

276

152

0.30

-, -26.-

7.85

200

193

75

75

250

207

250

2.07

..

40

517

400

517

30

40

0.32

0.27

12

17

&16

200

7$

703

703

800

SCO

-.

032

12

'443

120

44

924

924

1000

1,000

2.38

2.1

-'

12

38

1.45

131

145

72.4

90

0.4

3.60

13.1

965

-.

2.1c

Alurniuum.. r.b014T6

WrughA11oys L

)6t-t6

Cnst Iron r GayATM 20

Alloys

AZoy

197

(ini1O04.T61) --

SUUMnal A36

St41 r

Alloys St i1s 304

Tool L-2

11t

Allpy

t6AI.4V

Concrete1-Low Strenlz

Ptas

-clar49

Rtnforced L.30%Gl555

Vood

Douglasx

Select trtuxal L..VihxSpruCc

Grade

'

;.

2,5

th

26d

36

16

036

94

- '

*

0,15

0.1$

11

U

0.34 -

0.31'

20.3

-

2.8

-

6,2d

61d

- -

S-ar putea să vă placă și

- Conlit Firestop Systems Installation Method StatementDocument2 paginiConlit Firestop Systems Installation Method StatementramtsanÎncă nu există evaluări

- BAA 3223 Steel & Timber Design Final Exam PaperDocument11 paginiBAA 3223 Steel & Timber Design Final Exam PaperAzil14100% (4)

- Solid MechanicDocument7 paginiSolid MechaniczinilÎncă nu există evaluări

- Sab 3233Document13 paginiSab 3233xperia30Încă nu există evaluări

- Mec 323 FinalDocument7 paginiMec 323 FinalJihadHejaziÎncă nu există evaluări

- CE199 2L 1Q1819 DC 1st TakeDocument10 paginiCE199 2L 1Q1819 DC 1st TakeJohn Michael Ramos100% (1)

- Memb243 Mom Final Semi 15-16Document7 paginiMemb243 Mom Final Semi 15-16Malik Ismail100% (1)

- Advanced Design of Steel StructuresDocument3 paginiAdvanced Design of Steel StructuresManish Shashikant DharekÎncă nu există evaluări

- BAA 2113 - Theory of Structure Final Exam PaperDocument7 paginiBAA 2113 - Theory of Structure Final Exam PaperAzil14100% (1)

- IES Civil Engineering Conventional Paper 2014Document27 paginiIES Civil Engineering Conventional Paper 2014mantuiitÎncă nu există evaluări

- Engineering Mechanic Sem 1 Session 1112Document9 paginiEngineering Mechanic Sem 1 Session 1112Amirul AizatÎncă nu există evaluări

- Mechanics Ii Time Allowed: 2 HoursDocument8 paginiMechanics Ii Time Allowed: 2 HourssubipuruÎncă nu există evaluări

- 19 08 2021 NL - Nl.enDocument4 pagini19 08 2021 NL - Nl.enboujemaa boukrichaÎncă nu există evaluări

- Baa3223 - Steel & Timber DesignDocument6 paginiBaa3223 - Steel & Timber DesignTing Wee KietÎncă nu există evaluări

- UTM Final Exam - Mechanics Sab 2223 Sem 1 2012-13Document10 paginiUTM Final Exam - Mechanics Sab 2223 Sem 1 2012-13Nurhafizah AhmadÎncă nu există evaluări

- Theory of Structure 1Document10 paginiTheory of Structure 1Anil Thapa100% (1)

- Mechanics Ii Time Allowed: 2 HoursDocument9 paginiMechanics Ii Time Allowed: 2 HourssubipuruÎncă nu există evaluări

- CVEN3302 - Final Examination 2008Document5 paginiCVEN3302 - Final Examination 2008fflegendsÎncă nu există evaluări

- Machine Design Autumn 2012Document7 paginiMachine Design Autumn 2012stansilawÎncă nu există evaluări

- Mec111 October 2012Document6 paginiMec111 October 2012hahahaÎncă nu există evaluări

- Mechanics Ii Time Allowed: 2 HoursDocument8 paginiMechanics Ii Time Allowed: 2 HourssubipuruÎncă nu există evaluări

- MEMB123 Final Examination Paper Sem 2-09-10 FinalDocument6 paginiMEMB123 Final Examination Paper Sem 2-09-10 FinalMei QiiÎncă nu există evaluări

- Dynamics of Machinery r10 May-2016Document20 paginiDynamics of Machinery r10 May-2016Srimanthula SrikanthÎncă nu există evaluări

- Soalan Final Analisis Struktur UTHMDocument13 paginiSoalan Final Analisis Struktur UTHMliyana2030Încă nu există evaluări

- Mechanics Ii Time Allowed: 2 HoursDocument9 paginiMechanics Ii Time Allowed: 2 HourssubipuruÎncă nu există evaluări

- Sab 4333 Set ADocument8 paginiSab 4333 Set AUsama EL AlaouiÎncă nu există evaluări

- Gujarat Technological University: InstructionsDocument3 paginiGujarat Technological University: InstructionsBhavesh PipaliyaÎncă nu există evaluări

- DbmsDocument96 paginiDbmsSai RamÎncă nu există evaluări

- Raft DesignDocument8 paginiRaft Designramesh_madkatte1082Încă nu există evaluări

- Engineering Mechanic Sem 1 Session 1011 (Nov)Document10 paginiEngineering Mechanic Sem 1 Session 1011 (Nov)Amirul AizatÎncă nu există evaluări

- Mace 60035Document7 paginiMace 60035eng_ayman_H_MÎncă nu există evaluări

- Strength and Eco QuestionsDocument7 paginiStrength and Eco QuestionsJames TorresÎncă nu există evaluări

- Mechanics Ii Time Allowed: 2 HoursDocument10 paginiMechanics Ii Time Allowed: 2 HourssubipuruÎncă nu există evaluări

- MachineDocument8 paginiMachineshivasapkotasÎncă nu există evaluări

- Final ExamSOMFinal 2016 FinalDocument11 paginiFinal ExamSOMFinal 2016 Finalkhalil alhatabÎncă nu există evaluări

- Board Diploma Examination, (C-09) APRIL/MAY-2015 Deee-Fourth Semester Examination General Mechanical EngineeringDocument2 paginiBoard Diploma Examination, (C-09) APRIL/MAY-2015 Deee-Fourth Semester Examination General Mechanical Engineeringmass1984Încă nu există evaluări

- ENGM031Document5 paginiENGM031YHTRTRÎncă nu există evaluări

- BFC 20903Document10 paginiBFC 20903Priyaah KarunakaranÎncă nu există evaluări

- Final Exam MCT3214 Nov09Document6 paginiFinal Exam MCT3214 Nov09Deerah Aziz100% (1)

- Mechanics Ii Time Allowed: 2 HoursDocument9 paginiMechanics Ii Time Allowed: 2 HourssubipuruÎncă nu există evaluări

- Gate Mechanical SM by NodiaDocument159 paginiGate Mechanical SM by NodiaAndrew Marsh100% (6)

- College of Engineering Putrajaya Campus Final Examination SEMESTER 2 2010 / 2011Document5 paginiCollege of Engineering Putrajaya Campus Final Examination SEMESTER 2 2010 / 2011Mei QiiÎncă nu există evaluări

- Previous Exam QuestionsDocument8 paginiPrevious Exam QuestionssallyreffatÎncă nu există evaluări

- Engr 2900 Mech of Materials Exam 2 KeysDocument8 paginiEngr 2900 Mech of Materials Exam 2 KeysAshleyHeldÎncă nu există evaluări

- CVEN3302 Final Exam S2 2012Document5 paginiCVEN3302 Final Exam S2 2012Avinash SinghÎncă nu există evaluări

- Mechanics Ii Time Allowed: 2 HoursDocument6 paginiMechanics Ii Time Allowed: 2 HourssubipuruÎncă nu există evaluări

- Last Year Papaer 20112012Document14 paginiLast Year Papaer 20112012Farah Hani TEÎncă nu există evaluări

- 2018-2019 CEE2219 TM1 TermEndTest - 2018-19 PDFDocument3 pagini2018-2019 CEE2219 TM1 TermEndTest - 2018-19 PDFCyrus ChartehÎncă nu există evaluări

- BTCE - 501 Roll No. - B.Tech. (Civil) End Semesterexamination-V Sem DEC-JAN2015 Structure Analysis IiDocument4 paginiBTCE - 501 Roll No. - B.Tech. (Civil) End Semesterexamination-V Sem DEC-JAN2015 Structure Analysis IisdfghÎncă nu există evaluări

- Design 1qsy1718 QuestionsDocument9 paginiDesign 1qsy1718 QuestionsRachel Delos ReyesÎncă nu există evaluări

- 9-Plastic Centroid-Nscp2015Document15 pagini9-Plastic Centroid-Nscp2015Sheenah TelanÎncă nu există evaluări

- 4 ME Som Model Examination 2013Document3 pagini4 ME Som Model Examination 2013BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDe la EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsÎncă nu există evaluări

- The Fracture of Brittle Materials: Testing and AnalysisDe la EverandThe Fracture of Brittle Materials: Testing and AnalysisÎncă nu există evaluări

- Dynamic Damage and FragmentationDe la EverandDynamic Damage and FragmentationDavid Edward LambertÎncă nu există evaluări

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- IEEE Outline FormatDocument3 paginiIEEE Outline FormatAlex HerrmannÎncă nu există evaluări

- Bfm2313 - Digital ElectronicsDocument7 paginiBfm2313 - Digital ElectronicsMysteryÎncă nu există evaluări

- January 30, 2008: - Barometers, Pressure, Pressure Conversions - Boyle's LawDocument7 paginiJanuary 30, 2008: - Barometers, Pressure, Pressure Conversions - Boyle's LawMysteryÎncă nu există evaluări

- Bfm2313-Digital Electronics 11314Document6 paginiBfm2313-Digital Electronics 11314MysteryÎncă nu există evaluări

- Bfm2313-Digital Electronics 11213Document4 paginiBfm2313-Digital Electronics 11213MysteryÎncă nu există evaluări

- Bfm2313 - Digital ElectronicsDocument7 paginiBfm2313 - Digital ElectronicsMysteryÎncă nu există evaluări

- Bhm1123-Mechanics of MaterialsDocument6 paginiBhm1123-Mechanics of MaterialsMysteryÎncă nu există evaluări

- Bfm2313 - Digital Electronics 21112Document8 paginiBfm2313 - Digital Electronics 21112MysteryÎncă nu există evaluări

- Bff3203 Heat TransferDocument15 paginiBff3203 Heat TransferMysteryÎncă nu există evaluări

- Bff3203-Heat Transfer 21213Document10 paginiBff3203-Heat Transfer 21213MysteryÎncă nu există evaluări

- Rubrics For Each Milestone Updated (FYP)Document16 paginiRubrics For Each Milestone Updated (FYP)MysteryÎncă nu există evaluări

- Bff3203-Heat Transfer 21213Document10 paginiBff3203-Heat Transfer 21213MysteryÎncă nu există evaluări

- Bff3203-Heat Transfer 11213Document11 paginiBff3203-Heat Transfer 11213MysteryÎncă nu există evaluări

- Rectifier ChopperDocument39 paginiRectifier ChopperMysteryÎncă nu există evaluări

- Bff3203-Heat Transfer 21314Document20 paginiBff3203-Heat Transfer 21314MysteryÎncă nu există evaluări

- Gantt Chart FYPDocument13 paginiGantt Chart FYPMysteryÎncă nu există evaluări

- Sudoko Tips in MalayDocument18 paginiSudoko Tips in MalayHelmi Murad Abdul HamidÎncă nu există evaluări

- SolutDocument31 paginiSolutlolÎncă nu există evaluări

- The PearlDocument4 paginiThe PearlMysteryÎncă nu există evaluări

- Sudoko Tips in MalayDocument18 paginiSudoko Tips in MalayHelmi Murad Abdul HamidÎncă nu există evaluări

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDocument3 pagini100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalÎncă nu există evaluări

- Flowserve Durco CatalogDocument36 paginiFlowserve Durco CatalogbryandownÎncă nu există evaluări

- List of Activity For HIRA Prep As Per ISO45001Document6 paginiList of Activity For HIRA Prep As Per ISO45001Mohammad ArifÎncă nu există evaluări

- BomDocument2 paginiBomkdfdfybÎncă nu există evaluări

- Bulletin 446 - 1/06 - Alumina Loading Problems - Western AustraliaDocument2 paginiBulletin 446 - 1/06 - Alumina Loading Problems - Western Australialevent364Încă nu există evaluări

- Epoxy CuringDocument8 paginiEpoxy CuringUrban Renewal Development100% (1)

- Bemco BrochureDocument19 paginiBemco BrochurelightsonsÎncă nu există evaluări

- Aqua Mats 2005 SDFspecsheet R6Document1 paginăAqua Mats 2005 SDFspecsheet R6indomie11Încă nu există evaluări

- Cathelco ICCP Hull Protection SystemsDocument8 paginiCathelco ICCP Hull Protection SystemsdalianbouriÎncă nu există evaluări

- Rtlo-16918a SsDocument44 paginiRtlo-16918a SsLuis FigueroaÎncă nu există evaluări

- Brass - WikipediaDocument18 paginiBrass - WikipediaTahafanMaggedonÎncă nu există evaluări

- 09 Counter CellDocument3 pagini09 Counter CellTana AzeezÎncă nu există evaluări

- Polymer Processing Design Week 1Document53 paginiPolymer Processing Design Week 1Abdul RahmanÎncă nu există evaluări

- C-23 Life Cycle of Process Plants PDFDocument9 paginiC-23 Life Cycle of Process Plants PDFnike_y2k100% (1)

- AcryGuard TDS 2020Document3 paginiAcryGuard TDS 2020sarah magdyÎncă nu există evaluări

- Method Statement For Insulation of Ducting SystemDocument11 paginiMethod Statement For Insulation of Ducting SystemSaijon chandyÎncă nu există evaluări

- T-4.896.425 - C01 - MS ITP For Hot Cold Insulation WorksDocument20 paginiT-4.896.425 - C01 - MS ITP For Hot Cold Insulation Worksshahid imamÎncă nu există evaluări

- Base Panther 6x6 Stinger SpecificationDocument61 paginiBase Panther 6x6 Stinger Specificationфранки штэинÎncă nu există evaluări

- MEG (Monoethylene Glycol)Document3 paginiMEG (Monoethylene Glycol)Lakshman NaikÎncă nu există evaluări

- Ana Aerodur 3001 Hs Base Coat g30424 Pms214c Red enDocument14 paginiAna Aerodur 3001 Hs Base Coat g30424 Pms214c Red enSreejith SÎncă nu există evaluări

- Argus General Brochure V8Document20 paginiArgus General Brochure V8danieldayettddÎncă nu există evaluări

- Mechanical Design Calculation of Pipe Rack Under Pass 1Document7 paginiMechanical Design Calculation of Pipe Rack Under Pass 1tobeeprassÎncă nu există evaluări

- Long Life Bearing Series: CAT - NO.199EDocument5 paginiLong Life Bearing Series: CAT - NO.199EJhefferson FreitasÎncă nu există evaluări

- Crouse Hinds Rs RSM Rss Junction Boxes Catalog PageDocument1 paginăCrouse Hinds Rs RSM Rss Junction Boxes Catalog Pagejose luisÎncă nu există evaluări

- Technical Specifications For 132 KV LineDocument214 paginiTechnical Specifications For 132 KV LineHemant Kumar Sharma80% (10)

- Batteries ANL ESD 10-7Document45 paginiBatteries ANL ESD 10-7Ngọc Minh NguyễnÎncă nu există evaluări

- Comparitive of Waterproofing WorkDocument12 paginiComparitive of Waterproofing WorkReshik KannanÎncă nu există evaluări

- Biomedical Waste Rule 2016 ReviewDocument5 paginiBiomedical Waste Rule 2016 ReviewRakesh VermaÎncă nu există evaluări

- Advanced Polymer Panel TDS PDFDocument2 paginiAdvanced Polymer Panel TDS PDFsaint222Încă nu există evaluări