Documente Academic

Documente Profesional

Documente Cultură

Sugar CaneMill V5.1

Încărcat de

uksrajDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sugar CaneMill V5.1

Încărcat de

uksrajDrepturi de autor:

Formate disponibile

Allied-Tek CANE MILL

Allied-Tek Cane Mill_V 5.1

27.07.2012

Allied-Tek Cane Mill

Cane Roller Mill

A roller mill for extracting juice from cane sugar with 4 or 6 rolls of which three are crushing rolls, one is

underfeed roll and the other two at the same time feeding and pre-crushing rolls.

For 4 roller mill, there comprises of three crushing rolls sitting on cheeks in triangular form. The top roll is

placed on top position where pressure is applied on, one at the position of cane feeding so called feed roll

and there is the delivery roll placed at cane outlet. Underfeed roll is the forth roll being placed in the front of

feed roll.

For 6 roller mill, there comprises of 3 crushing rolls, two in front of top and feed rolls being for feeding so

called pressure feed (PF) rolls and the underfeed roll is placed in the front. PF rolls installed with separated

drives from crushing rolls are so called heavy duty pressure feed and light duty pressure feed where they are

driven through chain by top and feed roll.

6-Roller Mill

4- Roller Mill

Design

The latest development at Allied-Tek was in 2010 that an included angle of the 3-crushing rolls has been

reduced to 73 degree in order to reduce the length of turner plate as well as the length of pressure feed

chute, aiming at better juice extraction as well as lower power consumption.

Mill cheeks are modified for higher strength by increasing throat depth as well as placing of stiffeners at the

right positions. Corrosion resistant steel, 3Cr12 is clad on inside cheeks' surface at juice contact area.

Top caps are redesigned in order to suit for contunous operation up to 220 bars hydraulics pressure being for

higher juice extraction as well as lower bagasse moisture. Experiences show that first mill extraction is > 75%

while bagasse moisture is in between 47 50%.

Construction

Mill cheek comprises of two pieces high strength steel plate quality EN S355JR, each is cut from a single

piece plate. Fabrication is by low heat input welding process, MAG with mixed shielding gas 82/18 Ar/CO 2.

The latest welding technology of arc dynamics or forced spray arc which is designed for application root

welidng is under practiced for the fabrication of mill cheeks.

In combination with proper weld sequencing and furnace stress relieving the produced mill cheek is

minimized in distortion and residual stress. Pressure feed cheek is manufactured in the same procedure.

Stiffeners are additional placed at sensitive failure areas like top cap and throat of the headstock assuring its

strength as well as rigidity.

Cane Mill 37.41.45.47.49.53

Page 5/6

Allied-Tek Cane Mill

Single piece cut steel plate

for fabrication

of mill cheeks

MAG Welding

under proper sequencing

Mill Rollers and Journal Bearings

Crushing rolls and pressure feed rolls are flangeless type, grey cast iron shell shrink fitted with solid forged

steel shaft. Underfeed roll is hollow cast iron shell with end discs and key fitted with steel shaft.

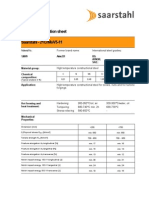

Material for shaft is either forged 28Mn6 or AISI 1030/1035.

Top roll is vertically movable by hydraulics at top cap with two

accumulators and automatic pressure control. Gauges showing

floating of top roll can be either mechanical or electronic

means.

Perforated or Lotus Top Roll is widely used.

Side rolls are fixed in positions by side caps and

removable pins.

Arcing or roll surface roughening

by arc welding with carbide alloy

helps in wear resistant and

better gripping of cane or

bagasse during feeding.

Rings bolted onto the end of rolls are for passage of juice to

juice tray as well as deflecting juice away from roll journal.

Side wear plates bolted on inside surface of mill cheek are for

guiding cane or bagasse to pass through crushing rolls,

fighting against abrasion.

Side wear plates are manufactured by weld surfacing of carbide

alloys.

Journal bearing is of bronze material, LBC-3 with independent

lubrication grooves and water cooling system.

Bearing for top roll is square half at top position and shell at bottom

position. Side roll bearings are in the opposite way.

Cane Mill 37.41.45.47.49.53

Page 5/6

Allied-Tek Cane Mill

Trash Beam and Turner Plate

Trash beam and turner plate are of cast steel, machined and

rigidly tightened in position by high tensile steel bolts.

The beam is vertically and horizontally adjustable by shims.

Setting of turner plate is by dead eye bearings, linkages and

adjusting arms.

There developed a technology at Allied-Tek that turner plate

hardfaced with martensitic and complex carbide alloys at

tooth side as well as top faces and the whole top surface of

turner plate.

Setting or adjusting of trash beam and plate is

conveniently one by loosening and tightening of bolts

Scraper Plates and Scraper Blades

There are, at top and delivery rolls Scraper

Plates being for removing off bagasse

compacting in grooves of roll.

Teeth of craper plate are hardfaced with

Cr-martensitic alloy.

Scraper blades are provided at the

delivery roll.

Cane Mill 37.41.45.47.49.53

Page 5/6

Allied-Tek Cane Mill

Top Cap Cylinder & Piston

Experience in Thai sugar mills there happens often leakage during operation. Good results from maintenance

service by Allied-Tek, the technology has been applied on the manufacture of new cane mill.

Top cap cylinder is shrink fitted with a hard chrome sleeve.

The piston is by copper bronze alloy

welded on frictional area in order to reduce

wear due to vertical movements during

operation. Additionally, there are two sly rings

placed on piston to avoid leaks.

Lubrication and Cooling System

Mill and PF roll journals are grease lubricated by an automatic injection system.

Bearings are cooling by water where nipples are provided ready for connection.

Lubrication, a central supply system comprises of

air pump, motor and grease drum. Lube tubes shall

copper or stainless steel.

Cane Mill 37.41.45.47.49.53

Page 5/6

Allied-Tek Cane Mill

Mill Drives

Today, electric motor is a preferable installation for the reasons of mill crushing flexibility.power saving,

working environment as well as maintenance.

AC squirrel cage induction motors as well as AC Drives are among other technologies are of most interest.

Cane Mill 37.41.45.47.49.53

Page 5/6

Allied-Tek Cane Mill

Standard Models

Allied-Tek Cane Mill :

CM 3771

CM 4179

CM 4587

CM 4790

CM 4995

CM 5313

Mill Roller, D x L,mm

CRS, mm

950 x 1.800

2,680

1,050 x 2.000

2,940

1.150 x 2.200

3,220

1,200 x 2,300

3,340

1.250 x 2.400

3,480

1.350 x 2.600

.. 3,760

TCD min-max + HF (6-Roller Mill)

TCD min-max

(4-Roller Mill)

3.500 7.000

2.500 - 5.000

4.500 9.000

3.500 7.000

6.000 12.000

5.000 - 9.000

8.000 16.000

7.500 12.000

10.000 20.000

9.000 14.000

12,000 24,000

12,000 18,000

Mill Shaft Dia x L, mm

Journal Size, DxL mm

Bearing Lubrication Points

530 x 4,540

460 x 560

3

570 x 4,950

500 x 620

3

640 x 5,440

560 x 680

4

680 x 5,680

580 x 700

4

700 x 5,880

620 x 740

5

780 x 6,350

680 x 800

5

Top Cap Cylinder Dia, mm

380 (15)

Top Cap Pressure, bars

160 240

Top Roll Vertical Movement, mm

30

406 16)

160 240

30

431 (17)

160 240

30

431 ( 17)

160 240

30

457 (18)

160 240

30

482 (19)

160 240

30

Square End x Length, mm

Pinion Bore, DxL mm

390 x 390 x 300

505 x 520

420 x 420 x 320

545 x 560

460 x 460 x 360

585 x 600

480 x 480 x 380

600 x 625

500 x 500 x 400

625 x 650

550 x 550 x 440

715 x 720

Mill Speed, 1/min

Rated Operating Power, kW

Single Drive at Top Roll / PF Roll

4 rollers Mill

6 rollers Mill, Mill Roll / PF Roll

UF Roll Driven by Chain

1.0 7.5

1.0 7.5

1.0 7.0

1.0 7.0

1.0 6.8

1.0 6.8

800

800 + 315

ATE 1245

1,000

1,000 + 400

ATE 635

1,200

1,200 + 500

ATE 635

1.500

1.500 + 600

ATE 1620-A

1,650

1.650 + 630

ATE 1620-A

1,800

1,800 + 750

ATE 6042

650

315 315

250 250

ATE 635

800

355 355

315 315

ATE 1620-A

900

400 400

355 355

ATE 1620-A

1,000

600 - 600

400 400

ATE 6042

Individual Drive at Top, Feed, Delivery Roll

PF Top and Bottom Roll

Top Roll, kW

400

500

Feed Delivery Roll, kW

200 - 200

250 250

PF Top Bottom Roll, kW

160 160

200 - 200

UF Roll Drivenby Chain

ATE 1245

ATE 635

** The above installed Power is general recommendation only,

actual Power to be installed shall be consulted.

Cane Mill 37.41.45.47.49.53

Page 6

S-ar putea să vă placă și

- Donnelly Chute BrochureDocument8 paginiDonnelly Chute BrochureTung Bui ThanhÎncă nu există evaluări

- GFCP P&F 1.4.2 Submittal CH 02 - Flanges & Stub EndsDocument12 paginiGFCP P&F 1.4.2 Submittal CH 02 - Flanges & Stub EndsJose BustosÎncă nu există evaluări

- Comparision Between Longitudinal Circular StockpileDocument2 paginiComparision Between Longitudinal Circular Stockpileayaskant751001Încă nu există evaluări

- Selection of Bucket Elevator Style and Design Based On Conveyed Material Chapter Lead: Jeff GerhartDocument7 paginiSelection of Bucket Elevator Style and Design Based On Conveyed Material Chapter Lead: Jeff GerhartEduardo D. MenteÎncă nu există evaluări

- Minutes Bucket Elevator Teleconference October 5 2012Document4 paginiMinutes Bucket Elevator Teleconference October 5 2012MohsenÎncă nu există evaluări

- Chapt 06 PDFDocument3 paginiChapt 06 PDFindocodeÎncă nu există evaluări

- Symetro Gear UnitDocument8 paginiSymetro Gear UnitYaser AsmaniÎncă nu există evaluări

- Mollier Hs Diagram Full Scale A3 FreeDocument1 paginăMollier Hs Diagram Full Scale A3 FreeResa WaskitaÎncă nu există evaluări

- 2007 Dias, Efficient Cooling of Fermentation Vats in Ethanol Production - Part 1Document8 pagini2007 Dias, Efficient Cooling of Fermentation Vats in Ethanol Production - Part 1roger_shÎncă nu există evaluări

- Sulzer TB Seal: Installation, Operation and Maintenance InstructionsDocument6 paginiSulzer TB Seal: Installation, Operation and Maintenance InstructionsHazem HasanÎncă nu există evaluări

- Cane ShredderDocument5 paginiCane Shredderamarnath jagirdarÎncă nu există evaluări

- FEECO Handbook Section4Document62 paginiFEECO Handbook Section4hashem62100% (2)

- Martin Sprocket CalculationDocument3 paginiMartin Sprocket CalculationKiran Kumar K T100% (1)

- Gardner Denver Nash CL Serien BroschyrDocument8 paginiGardner Denver Nash CL Serien BroschyrjorgekichiÎncă nu există evaluări

- Mill HousingDocument10 paginiMill HousingOmar Ahmed Elkhalil100% (1)

- Inquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteDocument5 paginiInquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteCik MinnÎncă nu există evaluări

- Java Method Mill SettingsDocument1 paginăJava Method Mill SettingsZahid MirzaÎncă nu există evaluări

- NUTDocument1 paginăNUTAnonymous 8CHsfYRÎncă nu există evaluări

- Movitec B (50Hz) PDFDocument62 paginiMovitec B (50Hz) PDFTurbo Snail RÎncă nu există evaluări

- Analysis of LimeDocument5 paginiAnalysis of LimeToni VilayÎncă nu există evaluări

- Moor 1994 Cane ShreddingDocument4 paginiMoor 1994 Cane Shreddingamarnath jagirdar100% (1)

- Steam Trap TesterDocument4 paginiSteam Trap TesterISMAEL RAMIREZÎncă nu există evaluări

- EC 2017 Bulk Conveyor Safety Committee Agenda SetDocument51 paginiEC 2017 Bulk Conveyor Safety Committee Agenda Setmbakhshi2Încă nu există evaluări

- 1964 - Van Hengel - Suggestions For The SettingsDocument4 pagini1964 - Van Hengel - Suggestions For The SettingsCecilio Valderrama100% (1)

- Bucket ConveyorsDocument9 paginiBucket ConveyorsAirom Lee PenuliarÎncă nu există evaluări

- 1986 Anand A Self-Setting Mill - A Simple But Cost Effective InnovationDocument9 pagini1986 Anand A Self-Setting Mill - A Simple But Cost Effective Innovationamarnath jagirdarÎncă nu există evaluări

- Vacuum System ParametersDocument7 paginiVacuum System ParametersOmar Ahmed ElkhalilÎncă nu există evaluări

- Catalogo de Bombas de Caudal VariableDocument29 paginiCatalogo de Bombas de Caudal VariableRaul Rivera100% (1)

- SCC Screw Lift 289B LDocument12 paginiSCC Screw Lift 289B LJuan Carlos RÎncă nu există evaluări

- M.tech. Sugar TechnologyDocument25 paginiM.tech. Sugar TechnologyrrameshsmitÎncă nu există evaluări

- Ribbon BlenderDocument2 paginiRibbon Blenderkinley dorjeeÎncă nu există evaluări

- Properties and Operating Experience With Bagasse As A Boiler FuelDocument6 paginiProperties and Operating Experience With Bagasse As A Boiler FuelAmulya KumarÎncă nu există evaluări

- Pulp and PaperDocument8 paginiPulp and PaperDevanshGoenkaÎncă nu există evaluări

- Gauge Accessories - Syphons TypeDocument2 paginiGauge Accessories - Syphons Typecasio662Încă nu există evaluări

- Powder Cooler - BrochureDocument4 paginiPowder Cooler - BrochureAnonymous Cxriyx9HIX100% (1)

- Impeller Design For Mixing of SuspensionsDocument16 paginiImpeller Design For Mixing of SuspensionsFaycel OuerdienÎncă nu există evaluări

- Gear Coupling SelectionDocument3 paginiGear Coupling SelectionPriyam NandwanaÎncă nu există evaluări

- BIWDocument62 paginiBIWingpochoÎncă nu există evaluări

- Vessel Enquiry Form: Company: Date: Contact: Dotmar Quote No: Address Date: Project: Fax: Phone: EmailDocument1 paginăVessel Enquiry Form: Company: Date: Contact: Dotmar Quote No: Address Date: Project: Fax: Phone: EmailTan Chee MingÎncă nu există evaluări

- Falling Film Evaporator Performance Results From Two Reunion Island Factories - ZI - 2009 PDFDocument5 paginiFalling Film Evaporator Performance Results From Two Reunion Island Factories - ZI - 2009 PDFFajar KurniawanÎncă nu există evaluări

- Optimisation of Fibriser Hub ProfileDocument4 paginiOptimisation of Fibriser Hub Profileamarnath jagirdarÎncă nu există evaluări

- SKF BRGDocument316 paginiSKF BRGMaheshÎncă nu există evaluări

- (1918) Louden Hay Unloading Tools (Catalogue)Document52 pagini(1918) Louden Hay Unloading Tools (Catalogue)Herbert Hillary Booker 2nd100% (1)

- Renold Conveyor Section4 0508Document41 paginiRenold Conveyor Section4 0508deep200Încă nu există evaluări

- Altronic Iii: Ignition System For Industrial EnginesDocument4 paginiAltronic Iii: Ignition System For Industrial EnginesClever NegreteÎncă nu există evaluări

- Design Calculations of Pitch Blade TurbineDocument6 paginiDesign Calculations of Pitch Blade TurbineAyaz_HasanjiÎncă nu există evaluări

- AGMA Fatores de ServiçoDocument4 paginiAGMA Fatores de Serviçochu42Încă nu există evaluări

- Centrifuge Design For Raw SugarDocument6 paginiCentrifuge Design For Raw SugarAira DiolataÎncă nu există evaluări

- A Technical Reference Manual For Plate Heat Exchangers in Refrigeration & Air Conditioning ApplicationsDocument176 paginiA Technical Reference Manual For Plate Heat Exchangers in Refrigeration & Air Conditioning Applicationsmdalt9180Încă nu există evaluări

- Linear Screen SizingDocument4 paginiLinear Screen SizingHARIPRASADÎncă nu există evaluări

- Rovalve PDFDocument4 paginiRovalve PDFWilliam ValenciaÎncă nu există evaluări

- Gear Reference PDFDocument15 paginiGear Reference PDFXuan Phuong HuynhÎncă nu există evaluări

- M&E SPC 4 PS-RDocument12 paginiM&E SPC 4 PS-Ramirul8686Încă nu există evaluări

- Innomag TBmag Sales GuideDocument65 paginiInnomag TBmag Sales Guideganesan 0011Încă nu există evaluări

- Bombas Gorman RuppDocument12 paginiBombas Gorman RuppRafael Hernández RcrewÎncă nu există evaluări

- XL2000 Technical SpecificationDocument3 paginiXL2000 Technical SpecificationLeonardo SilvaÎncă nu există evaluări

- Ariel JGK and JGT CompressorsDocument5 paginiAriel JGK and JGT CompressorsPablo GutierrezÎncă nu există evaluări

- KSB Centrifugal PumpsDocument12 paginiKSB Centrifugal Pumpswoodywheel100% (1)

- Basic Engine: Systems OperationDocument3 paginiBasic Engine: Systems OperationTri WahyuningsihÎncă nu există evaluări

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDe la EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceÎncă nu există evaluări

- CableDocument1 paginăCableuksrajÎncă nu există evaluări

- 3Document1 pagină3uksrajÎncă nu există evaluări

- CableDocument1 paginăCableuksrajÎncă nu există evaluări

- Detailed SoP - Birsa Sinchai Koop SanvardhanDocument62 paginiDetailed SoP - Birsa Sinchai Koop Sanvardhanuksraj0% (1)

- Control CableDocument1 paginăControl CableuksrajÎncă nu există evaluări

- CH 11Document5 paginiCH 11anil.gelra5140Încă nu există evaluări

- Drip Irrigation Pipe: Profile No.: 33 NIC Code: 24311Document8 paginiDrip Irrigation Pipe: Profile No.: 33 NIC Code: 24311uksrajÎncă nu există evaluări

- ASCI - Agriculture Skill Council of India QPDocument6 paginiASCI - Agriculture Skill Council of India QPuksrajÎncă nu există evaluări

- Control CableDocument1 paginăControl CableuksrajÎncă nu există evaluări

- 2018the World This YearDocument16 pagini2018the World This YearuksrajÎncă nu există evaluări

- Advance Tax CalculatorDocument5 paginiAdvance Tax CalculatoruksrajÎncă nu există evaluări

- The Sugar Mill Roller: BV R. I,. Geokge MDocument9 paginiThe Sugar Mill Roller: BV R. I,. Geokge MuksrajÎncă nu există evaluări

- Solved 2017 SSC CGL 17 Aug Shift-1 Paper With SolutionsDocument40 paginiSolved 2017 SSC CGL 17 Aug Shift-1 Paper With SolutionsuksrajÎncă nu există evaluări

- MUDRA - Loan ApplicationDocument5 paginiMUDRA - Loan ApplicationuksrajÎncă nu există evaluări

- 1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionDocument3 pagini1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionuksrajÎncă nu există evaluări

- 5001 Yarn OpenerDocument19 pagini5001 Yarn OpeneruksrajÎncă nu există evaluări

- 5201 Designer SketcherDocument20 pagini5201 Designer SketcheruksrajÎncă nu există evaluări

- Busan To Kolkata: Vessel Name VOY Doc C/Time Cgo C/TimeDocument1 paginăBusan To Kolkata: Vessel Name VOY Doc C/Time Cgo C/TimeuksrajÎncă nu există evaluări

- Burner Block SuppDocument1 paginăBurner Block SuppuksrajÎncă nu există evaluări

- Forging Members DirectoryDocument11 paginiForging Members Directoryuksraj33% (3)

- Item Mat GRP Quantity Unit Last PO / Rate Vendor Consumption (Last 6 Months) Current StockDocument6 paginiItem Mat GRP Quantity Unit Last PO / Rate Vendor Consumption (Last 6 Months) Current StockuksrajÎncă nu există evaluări

- 21 CR Mo V511Document1 pagină21 CR Mo V511uksrajÎncă nu există evaluări

- 1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionDocument3 pagini1.2311 40crmnnimo8-6-4 MCM: Chemical CompositionuksrajÎncă nu există evaluări

- Convergence & Common NormsDocument12 paginiConvergence & Common NormsuksrajÎncă nu există evaluări

- AtoZ Alloys Pvt. LTDDocument1 paginăAtoZ Alloys Pvt. LTDuksrajÎncă nu există evaluări

- Confined SpaceDocument17 paginiConfined SpaceuksrajÎncă nu există evaluări

- Air Calculation TheroreticalDocument6 paginiAir Calculation TheroreticaluksrajÎncă nu există evaluări

- Welcome To India in BusinessDocument6 paginiWelcome To India in BusinessuksrajÎncă nu există evaluări

- A2FO710 CatalogueDocument28 paginiA2FO710 CatalogueuksrajÎncă nu există evaluări

- Data Network Unit 6 - UCDocument15 paginiData Network Unit 6 - UCANISHA DONDEÎncă nu există evaluări

- IQAc 04-05Document10 paginiIQAc 04-05ymcacollegewebsiteÎncă nu există evaluări

- Low Speed Aerators PDFDocument13 paginiLow Speed Aerators PDFDgk RajuÎncă nu există evaluări

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDocument36 paginiPrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manualoutlying.pedantry.85yc100% (28)

- Lesson 1: Composition: Parts of An EggDocument22 paginiLesson 1: Composition: Parts of An Eggjohn michael pagalaÎncă nu există evaluări

- Computer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Document19 paginiComputer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Carl John GomezÎncă nu există evaluări

- Introduction To Password Cracking Part 1Document8 paginiIntroduction To Password Cracking Part 1Tibyan MuhammedÎncă nu există evaluări

- Sanskrit Subhashit CollectionDocument110 paginiSanskrit Subhashit Collectionavinash312590% (72)

- Play ClawDocument2 paginiPlay ClawFrenda SeivelunÎncă nu există evaluări

- Sales Forecast Template DownloadDocument9 paginiSales Forecast Template DownloadAshokÎncă nu există evaluări

- Stonehell Dungeon 1 Down Night Haunted Halls (LL)Document138 paginiStonehell Dungeon 1 Down Night Haunted Halls (LL)some dude100% (9)

- DAA UNIT 1 - FinalDocument38 paginiDAA UNIT 1 - FinalkarthickamsecÎncă nu există evaluări

- Guided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaDocument9 paginiGuided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaAlexander DeckerÎncă nu există evaluări

- CRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEADocument21 paginiCRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEAcristian colceriu100% (2)

- Spare Part PhilosophyDocument27 paginiSpare Part Philosophyavaisharma50% (2)

- Positive Psychology in The WorkplaceDocument12 paginiPositive Psychology in The Workplacemlenita264Încă nu există evaluări

- ET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsDocument5 paginiET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsMichael LeungÎncă nu există evaluări

- Backwards Design - Jessica W Maddison CDocument20 paginiBackwards Design - Jessica W Maddison Capi-451306299100% (1)

- Outline Calculus3Document20 paginiOutline Calculus3Joel CurtisÎncă nu există evaluări

- Pedagogy MCQS 03Document54 paginiPedagogy MCQS 03Nawab Ali MalikÎncă nu există evaluări

- Amritsar Police StationDocument5 paginiAmritsar Police StationRashmi KbÎncă nu există evaluări

- Bench-Scale Decomposition of Aluminum Chloride Hexahydrate To Produce Poly (Aluminum Chloride)Document5 paginiBench-Scale Decomposition of Aluminum Chloride Hexahydrate To Produce Poly (Aluminum Chloride)varadjoshi41Încă nu există evaluări

- Mathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XDocument32 paginiMathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XHarish HandÎncă nu există evaluări

- Jpedal ManualDocument20 paginiJpedal ManualDamián DávilaÎncă nu există evaluări

- Bgrim 1q2022Document56 paginiBgrim 1q2022Dianne SabadoÎncă nu există evaluări

- Benefits and Limitations of BEPDocument2 paginiBenefits and Limitations of BEPAnishaAppuÎncă nu există evaluări

- EQ JOURNAL 2 - AsioDocument3 paginiEQ JOURNAL 2 - AsioemanÎncă nu există evaluări

- SAFE RC Design ForDocument425 paginiSAFE RC Design ForMarlon Braggian Burgos FloresÎncă nu există evaluări

- 1.co - Deb4113 - Industrial ManagementDocument10 pagini1.co - Deb4113 - Industrial ManagementrohaizadÎncă nu există evaluări

- Stucor Qp-Ec8095Document16 paginiStucor Qp-Ec8095JohnsondassÎncă nu există evaluări