Documente Academic

Documente Profesional

Documente Cultură

Analysis and Design of Cascade Aerator Construction For Mettur Water Treatment Plant

Încărcat de

mailmaverick8167Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Analysis and Design of Cascade Aerator Construction For Mettur Water Treatment Plant

Încărcat de

mailmaverick8167Drepturi de autor:

Formate disponibile

National Conference on Research Advances in Communication, Computation, Electrical Science and

Structures (NCRACCESS-2015)

Analysis and Design of Cascade Aerator Construction for Mettur

Water Treatment Plant

Kokila.K1, R.Divya2

Assistant Professor, Civil Engineering

Bharathiyar Institute of Engineering for Women

Abstract: Generally water can be treated in

treatment plants for removing harmful substances

present in it. The treatment process includes pretreatment, aeration, coagulation, flocculation,

sedimentation,

filtration,

fluoridation,

conditioning and disinfection. In our project we

concentrate on aeration process using cascade

aerators. The cascade aerators are efficient in

raising dissolved oxygen content of water, CO2

removal and a large contribution occurs to the

self-purification of water due to increase in DO,

which accelerates the process of decomposition of

organic matter. The working stress method

approach of design has been used and

recommendations of IS 456-2000, IS 875(Part III),

IS 1893 (Part I):2002 and SP-16 have been

adhered too. Here we analysis and design a

Cascade Aerator for Mettur water treatment

plant having a height of 21.6m using Staad Pro v8i

and Auto Cad 2010 respectively. The elements of

the aerator such as top and bottom ring beams,

slab, column, plinth beams, footing & foundation

are to be designed.M25 and Fe415 have been used

to design all the components of the aerator. The

typical analysis of a cascade aerator has been

performed on the basis of quantity of water

intake.

I. INTRODUCTION:

The main objective of treating water

intended for public water supplies is to produce

a supply of water that is chemically and

bacteriologically safe for human Consumption.

The treatment process includes pre-treatment,

aeration,

coagulation,

flocculation,

sedimentation,

filtration,

fluoridation,

conditioning and disinfection. In our project we

undergo aeration process using cascade aerators.

Aeration brings water and air in close contact in

order to remove dissolved gases (such as carbon

dioxide).

It oxidizes dissolved metals such as iron,

hydrogen sulfide, and volatile organic chemicals

(VOCs).

ISSN: 2348 8352

Aeration is often the first major process at the t

reatment plant. During aeration,

constituents are removed or modified before

they can interfere with the treatment processes.

All aerators are designed to create a greater

amount of contact between air and water to

enhance the transfer of gases and increase

oxidation. This makes the impure source of

water in greater rate of purity approximately 60

to 70% .The aeration processes is carried out

through various types of aerators.

II. TYPES OF AERATORS:

Aerators

Gravity

Mechanical

Aerators

Fountain

Aerators

Injection or

Diffused

Aerators

Chemicals removed or oxidized by aeration

Constituents commonly affected by

aeration are:

Volatile organic chemicals, such as

benzene

(found

in

gasoline),

or

trichloroethylene,

dichloroethylene,

and

perchloroethylene (used in dry-cleaning or

industrial processes).

Ammonia

Chlorine

Carbon dioxide

Hydrogen sulfide

Methane

Iron and Manganese

www.internationaljournalssrg.org

Page 42

National Conference on Research Advances in Communication, Computation, Electrical Science and

Structures (NCRACCESS-2015)

Design criteria

1 Number of steps

2 Space

requirement

3 Head required

Typical value

3

to

6

normally

(maximum

could be More than 10,

in fact more the number,

higher the efficiency)

0.015 - 0.045 m/m.h

0.50 - 3.0 m

4 Tread of step

20 - 40 cm

5 Rise of step

20 - 40 cm

6 Velocity of water 0.6 m/s - 0.9 m/s

in

theCollecting

channel

7 CO2

removal 20 - 45%

efficiency

8 H2S

removal 35%.

efficiency

Cascade Aeration

In this method, the water is made to fall

through certain height (1 to 3m) over a series of

steps (3 to 10) with a fall of about 0.15 to 0.3 m

in each step. The structure so formed is known

as a free fall Aerator. The simplest type of a free

fall aerator is known as a Cascade Aerator. Such

aerators are widely used as water features. They

will take large quantities of water in a

comparatively small area at low head, are simple

to be kept clean and can be made of robust and

durable materials with a long life.

The plates can be made of cast iron, or

of RCC, or timber, or even of glass. The aerator

should preferably be installed in open air.

However, for protection against air pollution,

freezing and algal growth, it can be installed in a

small house having plenty of louvered air inlets.

The cascade aerators are efficient in raising

dissolved oxygen content of water, but not for

CO2 removal, which is removed only in the

range of 60 to 70%.

Weirs and waterfalls of any kind are, of

course, cascade aerator. Where a stream passes

over an artificial or naturally occurring obstacle,

a large contribution occurs to the selfpurification of the river water, due to increase in

DO, which accelerates the process of

decomposition of organic matter. In a cascade

ISSN: 2348 8352

aerator, usually, the rate of flow may vary

between 20 to 100 m/h per m length of weir. To

allow entrained air to mix in the water, each

receiving basin should have a pool of water of

depth 0.3 to 0.5 m.

Weirs with serrated edges perform

better, as they help to break water flow into

separate jets. If the water is allowed to cling to

the steps, especially at low discharge rates, the

efficiency is reduced. The space requirement is

typically of the order of 0.5 m per 1m/h water

treated. The oxygen transfer efficiency should be

as 2.5 kg O2 / kWh.

Operating considerations:

Aeration raises the dissolved oxygen

content of the water. If too much oxygen is

injected into the water, the water becomes

supersaturated. Aerators fall into two categories.

They either introduce air to water, or water to

air. The water-in-air method is designed to

produce small drops of water that fall through

the air. The air-in-water method creates small

bubbles of air that are injected into the water

stream. All aerators are designed to create a

greater amount of contact between air and water

to enhance the transfer of gases and increase

oxidation.

Figure 1 Process of Cascade aerator

www.internationaljournalssrg.org

Page 43

National Conference on Research Advances in Communication, Computation, Electrical Science and

Structures (NCRACCESS-2015)

Figure 2 Cascade aerator plan layout

Cascade aerator typical design criteria:

(ratio between module 0f elasticity of concrete

and steel) can be used to determine the stresses

in steel and concrete. It used a factor of about

three times with respect to cube strength for

concrete and a factor of safety of about 1.8(with

respect to yield strength) for steel.

Even though the structures designed by

this method have been performing their

functions satisfactorily for many years, it has

three major defects.

1.

2.

Figure 3 Cascade aerator in Mettur water

treatment plant

Objective of project

The main objective is to produce a

supply water that is chemically and

bacteriological safe for human consumption.

In this project, the construction of

cascade aerator for effective treatment of water

has been done.

Scope of project

The scope of the study covers the design

of cascade aerator for water treatment plant,

Mettur using a new logic of increasing the

number of steps for effective splitting of Water

molecules and by reducing the usage of Alum in

Water treatment.

III. SPECIFICATIONS

Working stress method

This method of design was evolved

around in 1990 and was theoretical method

accepted by National Codes of practice for

design concrete sections. It assumes that both

concrete and steel acts together and are perfectly

elastic at all stages so that the modular ratio

ISSN: 2348 8352

Method deals only with the elastic

behavior of the member; it neither

shows its real strength nor gives the

true factor of safety of the structure

against failure.

The modular ratio itself is an

imaginary quantity. Because of

creep and nonlinear stress- strain

relationship, concrete does not have

a definite modulus of elasticity as in

steel.

The design moment and shear in the

structure are calculated by elastic analysis with

the characteristic loads. The stress in concrete

and steel in the sections are calculated on the

basis of elastic behavior of composite section.

I.S 456 recommended a modulus of elasticity of

concrete which varies with the strength of

concrete. But this method forms the part of limit

state design for a serviceability condition.

General design requirements according to the

Indian standards, code of practice (IS: 3370Part-II, 1965)

Plain concrete structures

Plain concrete members of reinforced

concrete liquid structures may be designed

against structural failure by allowing tension in

plain concrete as per the permissible limits for

tension in bending specified in IS456-2000. This

will automatically take care of failure due to

cracking. However nominal shear reinforcement

in accordance with the requirements of IS: 456

shall be provided for plain cement concrete

structural members.

www.internationaljournalssrg.org

Page 44

National Conference on Research Advances in Communication, Computation, Electrical Science and

Structures (NCRACCESS-2015)

Permissible stress in concrete for strength

calculation

Reinforceme

nt

Permissible tensile stress in the

reinforcement

and concrete and the corresponding allowable

stress in concrete.

Stresses in the reinforcement

The following working stresses are

adopted

Near water

face

Away from

water face

Mild steel

100 N/mm

125 N/mm

A steel reinforcement not less than 0.3 percent

of the cross section shall be provided in each

principle direction.

Fe 415

170 N/mm

200 N/mm

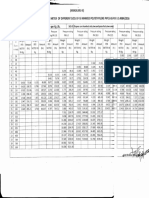

IV. RESULTANT COMPARISON

Fe 500

205 N/mm

245 N/mm

S.

N

O

PARAMETE

R

Type of

Aerator

No. of Trays

Speed of

water

Head

Water

treatment

capacity

Purity rate

In strength calculation the usual

permissible stresses, in accordance with

IS456:2000 is used. Where the calculated shear

stresses in concrete above exceeds the

permissible values , reinforcement acting in

conjunction with diagonal compression in

concrete shall be provided to take the whole of

the shear.

2

3

4

5

Stresses due to dry shrinkage or temperature

change

6

Stresses due to drying shrinkage or

temperature change may be ignored provided

that adequate precautions are taken to avoid

cracking of concrete during the construction

period and until the reservoir is put into use.

The recommendations as regards the

provisions of joints and for the suitable sliding

layer are complied with, or the reservoir is to be

used only for the storage of water or aqueous

liquids at or near ambient temperature and the

circumstances are such that the concrete will

never dry out.

METTUR

WATER

TREATMEN

T PLANT

Cascade

FROM

THIS

PROJEC

T

Cascade

4 Nos.

1450 rpm

9 Nos.

1450 rpm

60 m

348 m/hr.

60 m

783 m/hr.

60%

75%

IV. STRESS DIAGRAMS

Permissible stress in steel reinforcement for

resistance to cracking

When the steel and concrete are

assumed to act together for checking the tensile

stresses in concrete for avoidance of cracking

the tensile stresses in steel is limited by the

requirement that the permissible tensile stress in

concrete is not to exceed so that tensile stress in

steel is equal to product of modular ratio of steel

ISSN: 2348 8352

Figure 4 Stress contour for Mx

www.internationaljournalssrg.org

Page 45

National Conference on Research Advances in Communication, Computation, Electrical Science and

Structures (NCRACCESS-2015)

Figure 5 Stress contour for

My

of increasing the steps or trays in cascade aerator

for decreasing the usage of alum in treatment

process. At present in Mettur water treatment

plant, the water treatment capacity is 348 m/hr&

the purity rate is about 60%. From our project it

is expected to obtain the water treatment

capacity on 783 m/hr& the purity rate in about

75%. Here we analyzed and designed a Cascade

Aerator for Mettur water treatment plant having

a height of 21.6m using Staad Pro v8i and Auto

Cad 2010 respectively. The elements of the

aerator such as top and bottom ring beams, slab,

column, plinth beams, footing &foundation are

designed.M25 and Fe415 have been used to

design all the components of the aerator.

REFERENCES

The Staad 3D model is shown below and

1.

analyzed

2.

3.

4.

5.

6.

7.

Baruth EE (Ed.) Mc Graw Hill, AWWA ASCE

Water Treatment Plant Design, 4t Edition.

J. K. Edzwald, editor. New York: McGraw-Hill,

AWWA (2010b). Water Quality & Treatment: A

Handbook on Drinking Water, 6th Edition.

We collected some details from Mettur Water

Treatment Plant regarding our project.

Dr B.C.Punmia, AshokKumar Jain, Arun Kumar

Jain, IS 456-2000 & IS 456-1978 Design aids for

Reinforced

concreteR.C.C.

Designs

(Reinforcedconcrete structures),

N.Krishnaraju, Design of Reinforced concrete

structures.

S.K.Garg on Types of Aerators-Water supply

Engineering.

Dr.FahidRabah-Environment Engineering, Water

Treatement.

General design requirements according to the Indian

standards, code of practice

1. IS 875 (Part -I, Part-II, Part-III)-Wind & Seismic

Loads

2. IS 1893 (Part 1) : 2002-Earthquake Resistant

Structures

3. I.S 496:2000, Plain and Reinforced

4. SP-16,Design aids for RC to IS 456-2000

5. I.S 3373 (Part II, Part-III and Part IV-1967)

Figure 6 Deflection diagram

V. CONCLUSION

The Design of Cascade Aerator for

Mettur water treatment plant has been done

successfully. The calculations we have done

using working stress method are within safe

limits. In our project we introducing a new logic

ISSN: 2348 8352

www.internationaljournalssrg.org

Page 46

S-ar putea să vă placă și

- Pipeline Design for Water EngineersDe la EverandPipeline Design for Water EngineersEvaluare: 5 din 5 stele5/5 (1)

- Grit ChamberDocument29 paginiGrit Chamberazcomp100% (1)

- Bar Screen DesignDocument3 paginiBar Screen DesignJagannath SethiÎncă nu există evaluări

- Rapid Sand Filter DesignDocument3 paginiRapid Sand Filter DesignCivilian Venkadesh100% (1)

- Design of Sewage Treatment PlantDocument7 paginiDesign of Sewage Treatment PlantBill Harley VinsmokeÎncă nu există evaluări

- Sewage Design Report OptimizationDocument6 paginiSewage Design Report OptimizationMehroz Imtiaz100% (3)

- Design of Secondary ClarifierDocument7 paginiDesign of Secondary Clarifierusmansherdin100% (1)

- WTP Hydraulics 1Document6 paginiWTP Hydraulics 1Hemant Sonawadekar100% (3)

- Cascade Aerator PDFDocument8 paginiCascade Aerator PDFPANKAJ TAMBAKHEÎncă nu există evaluări

- Mini Project ReportDocument5 paginiMini Project ReportSaj BhaiÎncă nu există evaluări

- Waste-Water PE Calculation ExplainedDocument1 paginăWaste-Water PE Calculation ExplainedAlishiyaEliasÎncă nu există evaluări

- Efficiency Comparison of Sewage Treatment Plants in BangaloreDocument36 paginiEfficiency Comparison of Sewage Treatment Plants in BangalorePRETTY MARY100% (1)

- Design of Rapid Gravity Filter Using AUTOCAD and CDocument44 paginiDesign of Rapid Gravity Filter Using AUTOCAD and CBinyam Kebede100% (4)

- Sand Filter Design PDFDocument14 paginiSand Filter Design PDFWONG TS63% (8)

- Grit RemovalDocument42 paginiGrit RemovalChanelÎncă nu există evaluări

- Clariflocculator TypesDocument7 paginiClariflocculator TypesdexterÎncă nu există evaluări

- Sweage Treatment Plant (STP)Document57 paginiSweage Treatment Plant (STP)pra311288Încă nu există evaluări

- Water Treatment Plant DesignDocument36 paginiWater Treatment Plant Designnopime100% (2)

- WATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9b - FlocculationDocument37 paginiWATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 9b - Flocculationmamat88100% (2)

- Oxidation Ditch Design Criteria A DBDocument2 paginiOxidation Ditch Design Criteria A DBngocdungmtÎncă nu există evaluări

- Design Basis Report - STP 90 KLDDocument11 paginiDesign Basis Report - STP 90 KLDvishu talapeÎncă nu există evaluări

- 1000 LPH RO Plant in FRPDocument7 pagini1000 LPH RO Plant in FRPKetan VadorÎncă nu există evaluări

- Advances in Textile Waste Water TreatmentDocument17 paginiAdvances in Textile Waste Water TreatmentYamitakaiÎncă nu există evaluări

- Clariflocculator CalculationsDocument4 paginiClariflocculator Calculationssanu80% (5)

- Sewerage Collection System For A KURI ROAD Islamabad ......... LAB REPORT.......Document11 paginiSewerage Collection System For A KURI ROAD Islamabad ......... LAB REPORT.......sania50% (2)

- Clariflocculator DesignDocument8 paginiClariflocculator DesignsubratapapiyaÎncă nu există evaluări

- Grit ChambersDocument28 paginiGrit ChambersmkkÎncă nu există evaluări

- Treatment Plant Hydraulics ProfileDocument11 paginiTreatment Plant Hydraulics ProfileMadhavan DurairajÎncă nu există evaluări

- WTP Hydraulic CalculationDocument4 paginiWTP Hydraulic Calculationabhishek581050% (2)

- Process Calculations 1 MLD SBRDocument168 paginiProcess Calculations 1 MLD SBRAngelo EndozoÎncă nu există evaluări

- 35 MLD WTP EstimateDocument78 pagini35 MLD WTP EstimateaneeshmeloottuÎncă nu există evaluări

- SBR - 6 MLDDocument38 paginiSBR - 6 MLDsharan kommi100% (1)

- Presentation On STP (SBR)Document8 paginiPresentation On STP (SBR)Leo VictorÎncă nu există evaluări

- Tube SettlerDocument4 paginiTube SettlerSIVAPATHASEKARAN100% (4)

- SBR DesignDocument25 paginiSBR DesignConya Smathel100% (1)

- Oil and Grease TrapDocument2 paginiOil and Grease TrapArjay Hosmillo100% (2)

- Design Criteria SBRDocument8 paginiDesign Criteria SBRranbeer41100% (1)

- Excel Spreadsheets for Secondary Clarifier DesignDocument3 paginiExcel Spreadsheets for Secondary Clarifier DesignNiong DavidÎncă nu există evaluări

- Bar Screen PDFDocument61 paginiBar Screen PDFAhmedSalemÎncă nu există evaluări

- Design of Grit Chamber - Environment Civ105 - 15Document9 paginiDesign of Grit Chamber - Environment Civ105 - 15Atish Kumar90% (10)

- Equipment Design: Aeration Tank TitleDocument6 paginiEquipment Design: Aeration Tank TitleKENGERALDÎncă nu există evaluări

- Design of Slow Sand Filter FinalDocument11 paginiDesign of Slow Sand Filter FinalHemant SonawadekarÎncă nu există evaluări

- Primary Sedimentation Tank DesignDocument42 paginiPrimary Sedimentation Tank DesignRohab100% (1)

- Tube SettlersDocument3 paginiTube Settlersmsajidfcc100% (1)

- Activated Sludge Waste Water Treatment SI Unit CalculationsDocument2 paginiActivated Sludge Waste Water Treatment SI Unit CalculationsAshraf El-AttarÎncă nu există evaluări

- Design and Control of Equalization TanksDocument482 paginiDesign and Control of Equalization TanksDauren Gabbasov100% (2)

- Water and Waste Water EngDocument79 paginiWater and Waste Water Engbundhooz6087100% (5)

- Biological Wastewater Treatment Process Design Calculations: Harlan H. Bengtson, Pe, PHDDocument116 paginiBiological Wastewater Treatment Process Design Calculations: Harlan H. Bengtson, Pe, PHDEnder Gökmen100% (2)

- DNIT Vol 2 Part 1Document196 paginiDNIT Vol 2 Part 1JitendraHatwarÎncă nu există evaluări

- Grit Chamber CalculationDocument2 paginiGrit Chamber Calculationindikuma100% (2)

- UASB-Process Design For Various Types of WastewatersDocument21 paginiUASB-Process Design For Various Types of WastewatersapitbhuÎncă nu există evaluări

- Buxar STPDocument333 paginiBuxar STPPradeep SharmaÎncă nu există evaluări

- Sewagetreatmentplant Designcalculation 130528150104 Phpapp01Document8 paginiSewagetreatmentplant Designcalculation 130528150104 Phpapp01Muhammad IdrisÎncă nu există evaluări

- Water Treatment Plant Performance Evaluations and OperationsDe la EverandWater Treatment Plant Performance Evaluations and OperationsÎncă nu există evaluări

- An Applied Guide to Water and Effluent Treatment Plant DesignDe la EverandAn Applied Guide to Water and Effluent Treatment Plant DesignEvaluare: 5 din 5 stele5/5 (4)

- Monther,+5621 Article+Text 17153 1 6 20200312Document27 paginiMonther,+5621 Article+Text 17153 1 6 20200312Vigor ModemÎncă nu există evaluări

- Hdpe Rates Pe80Document1 paginăHdpe Rates Pe80mailmaverick8167Încă nu există evaluări

- Hydraulic Design of Storm Sewers With Excel CourseDocument41 paginiHydraulic Design of Storm Sewers With Excel CourseRonal Salvatierra100% (1)

- Hdpe Rates Pe100Document1 paginăHdpe Rates Pe100mailmaverick8167Încă nu există evaluări

- Centrifugal Pump SelectionDocument25 paginiCentrifugal Pump SelectionAbhay Sisodia100% (1)

- Joint Efficiency Factors For Seam-Welded Factory-Made Pipeline BendsDocument18 paginiJoint Efficiency Factors For Seam-Welded Factory-Made Pipeline Bendsmailmaverick8167Încă nu există evaluări

- Surge Analysis and The Wave Plan MethodDocument126 paginiSurge Analysis and The Wave Plan Methodmailmaverick8167Încă nu există evaluări

- Properly Sizing Pumps and Pipes for Variable Viscosity Non-Newtonian FluidsDocument3 paginiProperly Sizing Pumps and Pipes for Variable Viscosity Non-Newtonian Fluidsmailmaverick8167Încă nu există evaluări

- Modeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsDocument22 paginiModeling A Pump Start-Up Transient Event in HAMMER - OpenFlowsmailmaverick8167Încă nu există evaluări

- Effect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration SystemDocument11 paginiEffect of Hydraulic and Geometrical Properties On Stepped Cascade Aeration Systemmailmaverick8167Încă nu există evaluări

- Air Valve Orifice SizeDocument1 paginăAir Valve Orifice Sizemailmaverick8167Încă nu există evaluări

- By Dr. A Jon Kimerling, Professor Emeritus, Oregon State UniversityDocument3 paginiBy Dr. A Jon Kimerling, Professor Emeritus, Oregon State Universitymailmaverick8167Încă nu există evaluări

- Enhancement of Efficiency of Biogas Dige PDFDocument6 paginiEnhancement of Efficiency of Biogas Dige PDFmailmaverick8167Încă nu există evaluări

- The Secrets of Breakpoint ChlorinationDocument26 paginiThe Secrets of Breakpoint Chlorinationmailmaverick8167Încă nu există evaluări

- Modeling pump startup and shutdown transients in the same simulationDocument5 paginiModeling pump startup and shutdown transients in the same simulationmailmaverick8167Încă nu există evaluări

- HDPE Pipe InformationDocument24 paginiHDPE Pipe InformationTylerÎncă nu există evaluări

- Flow Control ValvesDocument24 paginiFlow Control Valvesmk_chandru100% (1)

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 paginiDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167Încă nu există evaluări

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 paginiDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167Încă nu există evaluări

- 5822Document16 pagini5822rambinodÎncă nu există evaluări

- Design of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA AlgorithmDocument8 paginiDesign of Surge Tank For Water Supply Systems Using The Impulse Response Method With The GA Algorithmmailmaverick8167Încă nu există evaluări

- Flow Control ValvesDocument6 paginiFlow Control Valvesmailmaverick8167100% (1)

- CHP Old Projects Pump DimensionsDocument2 paginiCHP Old Projects Pump Dimensionsmailmaverick8167Încă nu există evaluări

- Flow Control ValvesDocument6 paginiFlow Control Valvesmailmaverick8167100% (1)

- Siewtanyimboh Warm 2012 Epanet PDXDocument23 paginiSiewtanyimboh Warm 2012 Epanet PDXmailmaverick8167Încă nu există evaluări

- Computation of Afflux With Particular Reference To Widening of Bridges On A RoadwayDocument8 paginiComputation of Afflux With Particular Reference To Widening of Bridges On A Roadwaymailmaverick8167Încă nu există evaluări

- Is 9523 Ductile Iron FittingsDocument32 paginiIs 9523 Ductile Iron FittingsKathiravan Manimegalai100% (2)

- Surge Tank Design Considerations ForDocument14 paginiSurge Tank Design Considerations ForPatricio Muñoz Proboste100% (1)

- 12 Shibly RahmanDocument34 pagini12 Shibly Rahmanmailmaverick8167Încă nu există evaluări

- PG 67 IS 456Document1 paginăPG 67 IS 456mailmaverick8167Încă nu există evaluări

- PSV Sizing (Steam)Document2 paginiPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Eng MaterialsDocument6 paginiEng MaterialsMyca MiraÎncă nu există evaluări

- EWAD-C - Technical Data - PDFDocument56 paginiEWAD-C - Technical Data - PDFAbooaliÎncă nu există evaluări

- Láser ND YVO4..Document5 paginiLáser ND YVO4..María PérezÎncă nu există evaluări

- List of Physical Quantities - Wikipedia, The Free Encyclopedia PDFDocument6 paginiList of Physical Quantities - Wikipedia, The Free Encyclopedia PDFadithyaÎncă nu există evaluări

- Daikin AG 31-002 Centrifugal Chiller Fundamentals Guide Vers 2.2Document33 paginiDaikin AG 31-002 Centrifugal Chiller Fundamentals Guide Vers 2.2usmanafzal246Încă nu există evaluări

- Ficha GP3477 Epoxy Water EmulsionDocument2 paginiFicha GP3477 Epoxy Water EmulsionMarina AvÎncă nu există evaluări

- Analysis of Moisture Transfer During The Drying of Clay Tiles With Particular Reference To An Estimation of The Time Dependent Effective DiffusivityDocument13 paginiAnalysis of Moisture Transfer During The Drying of Clay Tiles With Particular Reference To An Estimation of The Time Dependent Effective DiffusivityMilos VasicÎncă nu există evaluări

- BraggDocument6 paginiBraggsaji kumarÎncă nu există evaluări

- Plates # 3Document9 paginiPlates # 3Joshua Perez AlbayÎncă nu există evaluări

- Astm D-6439-2005Document29 paginiAstm D-6439-2005MasÎncă nu există evaluări

- Atomic Structure & The Periodic Table 2 MS.Document13 paginiAtomic Structure & The Periodic Table 2 MS.Zaina AbedrabboÎncă nu există evaluări

- E 457 - 08 (2015)Document6 paginiE 457 - 08 (2015)ruben carcamoÎncă nu există evaluări

- Case Study AMPCOLOY® NozcapDocument4 paginiCase Study AMPCOLOY® NozcapAshwani DusadhÎncă nu există evaluări

- SCI 104 Lecture 3 ThermochemistryDocument50 paginiSCI 104 Lecture 3 ThermochemistryYana100% (1)

- CE8302 Fluid Mechanics Question BankDocument10 paginiCE8302 Fluid Mechanics Question BankPung Kang QinÎncă nu există evaluări

- Dr. Eng. Khalid Mohamed Hafez ProfileDocument6 paginiDr. Eng. Khalid Mohamed Hafez ProfileKhalid M. HafezÎncă nu există evaluări

- Zadaci Fizika - EngDocument13 paginiZadaci Fizika - EngAljoša GraovacÎncă nu există evaluări

- C1314 18Document9 paginiC1314 18NİLAY SABAHOĞLU100% (2)

- Seasonal Energy Efficien..Document6 paginiSeasonal Energy Efficien..Karthikeyan SankarrajanÎncă nu există evaluări

- Reflection Refraction WorksheetDocument2 paginiReflection Refraction WorksheetJfoxx Samuel71% (7)

- Bonding MCEDocument6 paginiBonding MCETrung NguyenÎncă nu există evaluări

- Pipe Flow Software: Submerged Coils - Heat Transfer CoefficientsDocument6 paginiPipe Flow Software: Submerged Coils - Heat Transfer CoefficientspaldopalÎncă nu există evaluări

- Mil C 14550BDocument4 paginiMil C 14550BKris PathinatherÎncă nu există evaluări

- CourseNotes Chapter7 Soil MechanicsDocument13 paginiCourseNotes Chapter7 Soil MechanicsjessicaÎncă nu există evaluări

- Ultramid: Product Information ®Document2 paginiUltramid: Product Information ®muthuÎncă nu există evaluări

- Tension Test Analysis and Material ComparisonDocument8 paginiTension Test Analysis and Material ComparisonUsman ishaqÎncă nu există evaluări

- Wireless Power TransmissionDocument19 paginiWireless Power TransmissionAarizMalikÎncă nu există evaluări

- 21 SOP For Vacuum PumpDocument6 pagini21 SOP For Vacuum PumpAmit Biswas100% (1)

- Thin-Walled Structures: Son Tung Vy, Mahen Mahendran, Thananjayan SivaprakasamDocument18 paginiThin-Walled Structures: Son Tung Vy, Mahen Mahendran, Thananjayan SivaprakasamLidya DewiÎncă nu există evaluări