Documente Academic

Documente Profesional

Documente Cultură

Case-2 280mm Thick Slab - Pa2

Încărcat de

ihpeterTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Case-2 280mm Thick Slab - Pa2

Încărcat de

ihpeterDrepturi de autor:

Formate disponibile

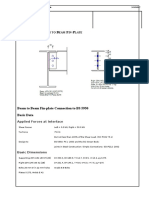

PLOT-7

CASE (II) 400MM

CANTILEVER STUB

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

11/8/2015

Specifier's comments:

1 Input data

Anchor type and diameter:

HVZ M10x75

Dynamic set or any suitable annular gap filling solution

Effective embedment depth:

hef = 75 mm, hnom = 90 mm

Material:

8.8

Evaluation Service Report:

ETA 03/0032

Issued I Valid:

6/4/2013 | 6/4/2018

Proof:

Engineering judgement SOFA - based on ETAG testing

Stand-off installation:

eb = 0 mm (no stand-off); t = 30 mm

Anchor plate:

Custom; E = 205000.00 N/mm2; fyk = 275.00 N/mm2; gMs = 1.000

lx x ly x t = 200 mm x 900 mm x 30 mm; (Recommended plate thickness: calculated)

Profile:

Pipe; (L x W x T) = 140 mm x 140 mm x 13 mm

Base material:

cracked concrete, C30/37, fc = 37.00 N/mm2; h = 180 mm, Temp. short/long: 30/40 C

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

with longitudinal edge reinforcement d >= 12 + close mesh (stirrups, hangers) s <=

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

2

11/8/2015

2 Load case/Resulting anchor forces

1

Compression

y

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Shear force x

Anchor

1

10.389

3.824

0.750

2

12.137

3.824

0.750

3

13.885

3.824

0.750

4

15.634

3.824

0.750

max. concrete compressive strain:

0.34 []

max. concrete compressive stress:

10.20 [N/mm2]

resulting tension force in (x/y)=(0/-42):

52.045 [kN]

resulting compression force in (x/y)=(94/343): 17.045 [kN]

Shear force y

3.750

3.750

3.750

3.750

x

Tension

3

3 Tension load (ETAG, Annex C, Section 5.2.2)

Load [kN]

15.634

Steel Strength*

Pullout Strength*

Concrete Breakout Strength**

Splitting failure**

* anchor having the highest loading

Capacity [kN]

23.333

Utilization bN [%]

68

Status

OK

N/A

N/A

N/A

N/A

52.045

56.782

92

OK

52.045

64.120

82

OK

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

35.000

gM,s

1.500

NRd,s [kN]

23.333

NSd [kN]

15.634

3.2 Concrete Breakout Strength

Ac,N [mm2]

202500

A0c,N [mm2]

50625

ccr,N [mm]

113

scr,N [mm]

225

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

42

yec2,N

0.749

N0Rk,c [kN]

28.446

gM,c

1.500

NRd,c [kN]

56.782

NSd [kN]

52.045

Ac,N [mm2]

202500

A0c,N [mm2]

50625

ccr,sp [mm]

113

scr,sp [mm]

225

yh,sp

1.129

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

42

yec2,N

0.749

ys,N

1.000

N0Rk,c [kN]

28.446

gM,sp

1.500

NRd,sp [kN]

64.120

NSd [kN]

52.045

ys,N

1.000

yre,N

1.000

k1

7.200

yre,N

1.000

k1

7.200

3.3 Splitting failure

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

11/8/2015

4 Shear load (ETAG, Annex C, Section 5.2.3)

Load [kN]

3.824

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Capacity [kN]

14.400

Utilization bV [%]

27

Status

OK

N/A

N/A

N/A

N/A

Pryout Strength**

15.297

151.713

11

OK

Concrete edge failure in direction x+**

15.297

143.598

11

OK

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel Strength (without lever arm)

VRk,s [kN]

18.000

gM,s

1.250

VRd,s [kN]

14.400

VSd [kN]

3.824

Ac,N [mm2]

202500

A0c,N [mm2]

50625

ccr,N [mm]

113

scr,N [mm]

225

k-factor

2.000

ec1,V [mm]

0

yec1,N

1.000

ec2,V [mm]

0

yec2,N

1.000

ys,N

1.000

N0Rk,c [kN]

28.446

gM,c,p

1.500

VRd,c1 [kN]

151.713

VSd [kN]

15.297

a

0.077

b

0.063

yec,V

1.000

4.2 Pryout Strength

yre,N

1.000

4.3 Concrete edge failure in direction x+

lf [mm]

75

dnom [mm]

12.0

k1

1.700

c1 [mm]

125

Ac,V [mm2]

202500

A0c,V [mm2]

70313

ys,V

1.000

yh,V

1.021

ya,V

2.280

ec,V [mm]

0

V0Rk,c [kN]

22.954

gM,c

1.500

VRd,c [kN]

143.598

VSd [kN]

15.297

yre,V

1.400

5 Combined tension and shear loads (ETAG, Annex C, Section 5.2.4)

bN

0.917

bV

0.266

a

1.000

Utilization bN,V [%]

99

Status

OK

(bN + bV) / 1.2 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

11.581 [kN]

dN

0.282 [mm]

VSk

2.833 [kN]

dV

0.319 [mm]

dNV

0.426 [mm]

Long term loading:

NSk

11.581 [kN]

dN

1.130 [mm]

VSk

2.833 [kN]

dV

0.490 [mm]

dNV

1.231 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

11/8/2015

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Checking the transfer of loads into the base material is required in accordance with ETAG 001, Annex C(2010)Section 7! The software

considers that the grout is installed under the anchor plate without creating air voids and before application of the loads.

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of ETAG 001, Annex C! For larger

diameters of the clearance hole see Chapter 1.1. of ETAG 001, Annex C!

The design method ETAG (filled holes) assumes that no hole clearance between the anchors and the fixture is present. This can

be

achieved by filling the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

The design method SOFA assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by filling

the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means.

The compliance with current standards (e.g. EC3) is the responsibility of the user

An SLS-check is not performed for SOFA and has to be provided by the user!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

11/8/2015

8 Installation data

Anchor plate, steel: Custom; E = 205000.00 N/mm2; fyk = 275.00 N/mm2 Anchor type and diameter: HVZ M10x75

Profile: Pipe; 140 x 140 x 13 mm

Installation torque: 0.040 kNm

Hole diameter in the fixture: df = 12 mm

Hole diameter in the base material: 12 mm

Plate thickness (input): 30 mm

Hole depth in the base material: 90 mm

Recommended plate thickness: calculated

Minimum thickness of the base material: 150 mm

Cleaning: Manual cleaning of the drilled hole according to instructions for use is required.

8.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Manual blow-out pump

Setting

HVA square drive shafts

Dynamic set

Torque wrench

100

75

100

450

250

250

75

100

100

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

0

0

0

0

y

375

125

-125

-375

c-x

125

125

125

125

c+x

125

125

125

125

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

450

250

Profis Anchor 2.5.0

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

11/8/2015

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

S-ar putea să vă placă și

- 11Document3 pagini11ihpeterÎncă nu există evaluări

- 20180923Document13 pagini20180923ihpeterÎncă nu există evaluări

- SBBDocument3 paginiSBBihpeterÎncă nu există evaluări

- Hilti Design Report PDFDocument6 paginiHilti Design Report PDFihpeterÎncă nu există evaluări

- Anchor Bolt CheckDocument1 paginăAnchor Bolt CheckihpeterÎncă nu există evaluări

- Connections UB457 191x98xconnDocument3 paginiConnections UB457 191x98xconnihpeterÎncă nu există evaluări

- Connections UB457 191x98xconnDocument3 paginiConnections UB457 191x98xconnihpeterÎncă nu există evaluări

- UB457 End PlateDocument4 paginiUB457 End PlateihpeterÎncă nu există evaluări

- Portal Output 20180718 R2Document60 paginiPortal Output 20180718 R2ihpeterÎncă nu există evaluări

- Anchor Bolt CheckDocument1 paginăAnchor Bolt CheckihpeterÎncă nu există evaluări

- Expo Favoriteroom 5Document1 paginăExpo Favoriteroom 5ihpeterÎncă nu există evaluări

- 20170303Document4 pagini20170303ihpeterÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.1Document6 pagini1 Input Data: Profis Anchor 2.6.1ihpeterÎncă nu există evaluări

- Circular Skylight Splice DetailDocument1 paginăCircular Skylight Splice DetailihpeterÎncă nu există evaluări

- Conn DetailDocument1 paginăConn DetailihpeterÎncă nu există evaluări

- SHS120 Post FixingDocument6 paginiSHS120 Post FixingihpeterÎncă nu există evaluări

- Reaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZDocument1 paginăReaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZihpeterÎncă nu există evaluări

- UB 457 152 52 B B F - P: X X EAM TO EAM IN LateDocument6 paginiUB 457 152 52 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- RRDocument6 paginiRRihpeterÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.4Document6 pagini1 Input Data: Profis Anchor 2.6.4ihpeterÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.6.4Document6 pagini1 Input Data: Profis Anchor 2.6.4ihpeterÎncă nu există evaluări

- Conn ForcesDocument2 paginiConn ForcesihpeterÎncă nu există evaluări

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocument7 paginiUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- SHS120 Post FixingDocument6 paginiSHS120 Post FixingihpeterÎncă nu există evaluări

- UB 356 171 45 B B F - P: X X EAM TO EAM IN LateDocument6 paginiUB 356 171 45 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- ADocument7 paginiAihpeterÎncă nu există evaluări

- ADocument7 paginiAihpeterÎncă nu există evaluări

- ADocument9 paginiAihpeterÎncă nu există evaluări

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDocument7 paginiUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterÎncă nu există evaluări

- ADocument2 paginiAihpeterÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Crodamide ER Z 000040 Technical Data SheetDocument2 paginiCrodamide ER Z 000040 Technical Data Sheetkarishma2Încă nu există evaluări

- Background Report AP-42 SECTION 8.6: Hydrochloric Acid ProductionDocument26 paginiBackground Report AP-42 SECTION 8.6: Hydrochloric Acid ProductionQuang ThanhÎncă nu există evaluări

- Listino Sea RecoveryDocument117 paginiListino Sea RecoveryEduardo Harold ChapuzÎncă nu există evaluări

- Cookery 9 (Clean, Sanitize and Store Kitchen Tools and Equipment)Document5 paginiCookery 9 (Clean, Sanitize and Store Kitchen Tools and Equipment)Maureen Madriaga88% (8)

- IBR Thickness CalculationDocument18 paginiIBR Thickness Calculationreach_arindomÎncă nu există evaluări

- OGA - Chemical Series - EPDM Rubber Market Outlook 2019-2025Document22 paginiOGA - Chemical Series - EPDM Rubber Market Outlook 2019-2025ambarish ramÎncă nu există evaluări

- Control of Decarburization of Steel PDFDocument5 paginiControl of Decarburization of Steel PDFBhushan VermaÎncă nu există evaluări

- Reactive Dye PrintingDocument15 paginiReactive Dye Printingsandipsoni221811Încă nu există evaluări

- ABB 2600 Series-SealsDocument40 paginiABB 2600 Series-SealsDarkhan Serikbayev100% (1)

- CIV 4001 Proposal Presentstion Group#2Document29 paginiCIV 4001 Proposal Presentstion Group#2Shan SinghÎncă nu există evaluări

- 5th International Seminar On Process Hydrometallurgy PDFDocument447 pagini5th International Seminar On Process Hydrometallurgy PDFRicardo BertolottoÎncă nu există evaluări

- CF CM HE 4206a enDocument60 paginiCF CM HE 4206a enNius Pahala NainggolanÎncă nu există evaluări

- CB MFG ProcessDocument35 paginiCB MFG ProcessChinmoy DholeÎncă nu există evaluări

- Type of Industries in SipcotDocument9 paginiType of Industries in Sipcotbalaji0% (1)

- TM9-1765B Ordnance Maintenance Bomb Truck M6 PDFDocument363 paginiTM9-1765B Ordnance Maintenance Bomb Truck M6 PDFdieudecafeÎncă nu există evaluări

- Bhushan Power and Steel Limited Chandigarh Prepared in Partial Fulfillment of Industrial TrainingDocument36 paginiBhushan Power and Steel Limited Chandigarh Prepared in Partial Fulfillment of Industrial TrainingSam BasatiÎncă nu există evaluări

- Understanding Process Vacuum Condensers: Issue 3Document4 paginiUnderstanding Process Vacuum Condensers: Issue 3pothanÎncă nu există evaluări

- Applications: Eni Spa Refining&Marketing Viale Giorgio Ribotta, 51 - 00144 Roma +39 06 5988.1 Date 25/01/2019 Code 1035 1Document2 paginiApplications: Eni Spa Refining&Marketing Viale Giorgio Ribotta, 51 - 00144 Roma +39 06 5988.1 Date 25/01/2019 Code 1035 1haripuscasÎncă nu există evaluări

- Chapter 6 - Pipeline Pigs PDFDocument25 paginiChapter 6 - Pipeline Pigs PDFObionochie Onyinye PatrickÎncă nu există evaluări

- MiG AMMO Acrylic Paint ChartDocument2 paginiMiG AMMO Acrylic Paint ChartPablo Maicá Machado50% (2)

- Falling Head Permeability Test Lab ManualDocument3 paginiFalling Head Permeability Test Lab Manualmm0% (1)

- Perform Basic BenchworkDocument46 paginiPerform Basic Benchworkray100% (1)

- 154 Top Theory of Machines MCQDocument26 pagini154 Top Theory of Machines MCQRajpalsinh JadejaÎncă nu există evaluări

- 1 BravermanDocument105 pagini1 Bravermanridho ma'rufÎncă nu există evaluări

- LT Buckling Beam Design - Simple Method - 2upDocument5 paginiLT Buckling Beam Design - Simple Method - 2upberto2008Încă nu există evaluări

- Chiller Heat RecoveryDocument6 paginiChiller Heat RecoveryWid El-Amer100% (1)

- 40W Solar Panel Specifications: Main FeaturesDocument2 pagini40W Solar Panel Specifications: Main FeaturesthoroidÎncă nu există evaluări

- Technical Data Sheet: High Performance Rail Grease With GraphiteDocument1 paginăTechnical Data Sheet: High Performance Rail Grease With GraphiteDon HowardÎncă nu există evaluări

- Hot PlateDocument2 paginiHot PlateGiniung AugieÎncă nu există evaluări

- Air Cooler: Instruction Manual Model: Air Stream-15ADocument6 paginiAir Cooler: Instruction Manual Model: Air Stream-15AJeavons MesiaÎncă nu există evaluări