Documente Academic

Documente Profesional

Documente Cultură

Technical Comparison of Cahors Vs Conventional Trfo - Final

Încărcat de

k_arindam1Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Comparison of Cahors Vs Conventional Trfo - Final

Încărcat de

k_arindam1Drepturi de autor:

Formate disponibile

Release no.

001 / Rev 0

Technical Comparison Document

(Conventional Oil filled Transformer Vs. CAHORS Hermetic TYPE Oil filled Transformer)

Medium Voltage Division

TRANSFIX INDIA Pvt Ltd

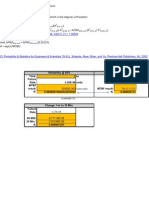

Sr.No

CLASSIFI

CATION

PARAMETER

CONVENTIONAL OIL FILLED

TRANSFORMERS

CAHORS - HERMETIC

TECHNOLOGY MAINTENANCE

FREE OIL FILLED TRANSFORMER

Conventional

Hermetic Technology with non- gas

cushion

With Breathers & Conservators

Without Breathers & Conservator

Compact

Technology

2

BENEFITS / REMARKS

Possiblilty of Oil

Contamination with Air

YES. High Exposure to Oxydation

phenomenon due to Breathing

Technology

NO. Totally Airtight

Oil BDV get maintained @ required value & all

oil properties remains unchanged for entire

life of Transformer. Hence No maintenance.

Oil filtration during precommissioning & charging

Required

Not Required

Saving of MAN-HOURS, Cost & free from any

contamination. Ready to charge product.

Oil Filtration & Oil TOP up

for preventive maintenance

Not Required

Since no preventive maintenance required,

hence no need of any shut down, DG

operation. Hence cost saving & interruption

free operation of transformer.

Radiators

Corrugated Fins

Compact. No need of any accessories fitting at

site i.e. conservator & detachable radiator

fitting. Further no need of Oil top up from

Spare oil of 10% which is suppplied in case of

conventional design.

In Radiator, oil flow for cooling through

inlet & outlet nozzle only

Corrugated fins are attached directly to

main tank where cooling is faster &

better

Provides higher surface area for cooling with

effective faster cooling. i.e. Better Heat

dissipation. This enhances the efficiency of

Transformer.

Oil need to undergo flow process for

achieving the cooling

Oil undergo emerge process for

achieving the cooling

Superior

Chemical Ageing

Yes. Faster

Extremely Slow

No adverse effect of external environment.

Hence Transformer gets Healthy working

operational condition.

10

Noise Level

High. Approx. > 60 dB as a operational

noise. (As per NEMA standard, its max

value is 65 dB)

Low. Approx.between 45 dB to 57 dB as

a operational noise. (As per NEMA

standard, its max value is 65 dB)

Low Noise & hence no disturbances by

transformer to external faculties.

11

Spare Requirement of oil

Required for Preventive maintenance

Not Required

Space saving of storage of Oil barrels & saving

on cost of spare oil.

12

OIL BDV level with ageing

effect

Reduces faster

Reduces very slow

Enhance the life of transformer from 20 years

to 30 years without any maintenance

TECHNOLOGY

Required

Cooling

PRODUCT

14

16

Gasket

Rubber Cork

Nitrile Gaskets i.e.NBR

It donot get cracks on high temprature &

hence survive with even continuous high temp

as well. It has longer life of 30 years compare

to Rubber cork gasket of 1 or 2 years.

Oil Leakage Possibility

YES, due to conventional design of

Detachable radiators, welded Tank &

gasketing structure.

Thanks to hermetically Sealed design, No

possibility of Oi leakage

Hence no need of spare oil, no need of any

shut down for atttending the oil leakage

complaint & saving of man, material & money.

Partial discharge free

Losses maintains to the actual designed values

for the complete life, unlike to increase the

losses after few years of service. This will give

Error free & maintenance free operation as

well.

Insulating Material

13

15

Craft Paper

It donot allow to produce any sluges in OIL &

Epoxy Diamond dotted paper for winding donot give any agening effect. Hence provide

& Polymide material for coils.

better & reliable insulation to inter turn

winding.

Partial Dischare

17

Losses

18

it is not partial discharge free

On lower side for standard Design &

available with STAR 3 rating, certified by

BEE

Losses get increased with its operational Losses remain steady with its operational

life

life

On higher side (conventional losses &

conventional designed)

Reduces Electricity bill values & provides

higher efficiency to the product.

Uniform operation throughtoout the life.

19

Size

Bulky due to conservator & Radiator

Compact by almost 30% as compared to

others thanks to corrugated Fins

Saving of space at site.

20

Product expected Life

15-20 Yrs

25-30 yrs

Enhances the life of product

CONFIDENTIAL COPY

Technical Comparison Document

(Conventional Oil filled Transformer Vs. CAHORS Hermetic TYPE Oil filled Transformer)

Medium Voltage Division

TRANSFIX INDIA Pvt Ltd

Sr.No

CLASSIFI

CATION

22

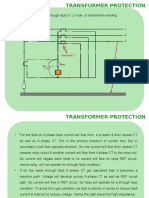

PROTECTION

21

PARAMETER

CONVENTIONAL OIL FILLED

TRANSFORMERS

Accessories for protection

Separate mounting Arrangement

required for OTI, PRV, Bukhlolz, etc for

protection.

Safety

CAHORS - HERMETIC

TECHNOLOGY MAINTENANCE

FREE OIL FILLED TRANSFORMER

BENEFITS / REMARKS

Limit the no. of cut out to Tank & provides

Integrated in single instrument i.e. DGPT

smoother function though one device instead

2 -Protection device

of group of device.

100% safety as no contact of oil with

external wheather conditions & No

Lack of safety due to oil leakages &

leakages. Also available with high flash

further chances of fire explosion due to

point of 135 Deg C. We can also supply

low fire point

oil with higher flash point upto 370 Deg

C instead of standard oil at an extra cost.

Provides Safe & Reliable operation

23

Short Circuit Withstand

Capacity

Low due to circular coil shape

High. Thanks to Oblong shape of

Winding to have better axial & radial

forces sustainability

24

DESIGN Compliance

IS 2026

IS 2026

Not easily accessible for theft of Oil & copper

in case of small ratings of transformer upto

400 KVA

Provides Rigid design to withstand different

abnormal supply & load conditions.

25

Theft Possibility

Theft of Oil, copper & core is possible

Not easily possible due to Hermetic

Technology where, many safety

interlocks are available in our

technology, which can be shown during

factory visit

26

Maintenance

Every 3 years Maintenance + Oil

Replacement for entire life

Maintenance free for entire life

Saving of Man, Material & Money

27

Failure Rate

failure rate < 5.6 % as per utility

High reliability ( failure rate < 0.1 % )

Highly reliable & trusted by our customers

Adds cost on MSEB bills due to high

losses

Saves over other transformers

Adds cost on Frequent Maintenance

Saves 100% on this parameter

30

Adds Oil Replacement & oil filtration

Cost

Saves 100% on this parameter

31

Adds Overhead Cost

28

29

33

GENERAL

32

Economical Benefit

Aesthetic Look

Handling & Installation

34

Return on investment (ROI)

35

Product Photo

Saves 100% on this parameter

Modern, compact & aesthetically sound,

Conventional look with a Bulky size with

Paint with mini 1000hrs SaltSpray

poor Paint finish likely to rust

resistance

Saving of Man, Material & Money

Long lasting paint shade which servives 30

years of rust proof services.

Difficult since detachable radiators, Oil

Barrel & their assembly at site which

lead to time & money involvement

Easy, as its a ready to charge product

without any detachable parts & loose oil

Ready to charge product without any site

activities i.e. Fitting, Oil top up etc. Hence

reduction of installation cost as well.

NIL

High. The cost of transformer gets

recovered thanks to all above mentioned

economical benefits (savings).

Competitive intial cost & negligible running

cost. Hence completely economical & ROI

product.

Note: This document is mainly for general comparison and knowledge sharing purpose

only . To know more about any point can be shared in details separately.

Astethically Sound to deliver modernization &

technology upgradation.

CONFIDENTIAL COPY

S-ar putea să vă placă și

- RailwayDocument10 paginiRailwayanitha indhuÎncă nu există evaluări

- Gmrc2509 Iss 1Document69 paginiGmrc2509 Iss 1Sanjay N ShivaniÎncă nu există evaluări

- Train Detection by Track CircuitDocument8 paginiTrain Detection by Track CircuitJavierÎncă nu există evaluări

- Introduction and Evaluation of ReliabilityDocument15 paginiIntroduction and Evaluation of ReliabilityRebbyno Deendri Andika100% (1)

- Failure Data - ENIDocument35 paginiFailure Data - ENIaleÎncă nu există evaluări

- 1zsc000562-Aar en Rev 1Document40 pagini1zsc000562-Aar en Rev 1Asif KhanÎncă nu există evaluări

- Chemical ResistanceDocument12 paginiChemical ResistancegusunÎncă nu există evaluări

- Occupational SafetyDocument73 paginiOccupational SafetyklaribabesÎncă nu există evaluări

- APTA Peer Review ReportDocument26 paginiAPTA Peer Review ReportHonolulu Star-Advertiser100% (1)

- Chemical Resistance TableDocument15 paginiChemical Resistance TableBen RahierÎncă nu există evaluări

- Chemical resistance of Polyester to common products like acids and oilsDocument5 paginiChemical resistance of Polyester to common products like acids and oilsGuz UchihaÎncă nu există evaluări

- Theta Reliability and Factor Scaling: A Better ApproachDocument35 paginiTheta Reliability and Factor Scaling: A Better ApproachsmmlsuÎncă nu există evaluări

- Chemical Resistance GuideDocument16 paginiChemical Resistance GuidePette MingÎncă nu există evaluări

- Reliability Data for Safety SystemsDocument47 paginiReliability Data for Safety SystemsSara ZaedÎncă nu există evaluări

- Apta PR M RP 003 98Document23 paginiApta PR M RP 003 98d bhnajaÎncă nu există evaluări

- Fault Tree Analysis (FTA) : Kiki Dwi Wulandari, ST., MTDocument29 paginiFault Tree Analysis (FTA) : Kiki Dwi Wulandari, ST., MTfatih muhammadÎncă nu există evaluări

- Tools For Failure Data Analysis - Section1Document19 paginiTools For Failure Data Analysis - Section1Jose GanozaÎncă nu există evaluări

- En 50126 - RAM ContentsDocument3 paginiEn 50126 - RAM ContentsGoyal SanjaiÎncă nu există evaluări

- Manual For The Development of System Safety Program Plans For Commuter RailroadsDocument0 paginiManual For The Development of System Safety Program Plans For Commuter Railroadsmkashkooli_scribdÎncă nu există evaluări

- Detailed Failure Analysis (DFA)Document11 paginiDetailed Failure Analysis (DFA)Hari Hara SuthanÎncă nu există evaluări

- Optimum Life Expectancy of The Undercarriage Parts of Amphibious Excavators Using Fatigue Failure AnalysisDocument10 paginiOptimum Life Expectancy of The Undercarriage Parts of Amphibious Excavators Using Fatigue Failure Analysisjohn bert onrubiaÎncă nu există evaluări

- Chemical Resistance ChartDocument2 paginiChemical Resistance ChartThiha Myat LwinÎncă nu există evaluări

- Astm A519 4130 Seamless Pipe & FittingsDocument4 paginiAstm A519 4130 Seamless Pipe & FittingsRahul MehtaÎncă nu există evaluări

- Euro StandardDocument21 paginiEuro Standardllauro2010Încă nu există evaluări

- Reliability BookDocument125 paginiReliability BookCHINEDU CHIEJINEÎncă nu există evaluări

- Service Pack R15.0.7 UpdateDocument44 paginiService Pack R15.0.7 UpdateKrozeÎncă nu există evaluări

- FMECA of PUMP Pumping Water From Coalescer To Second Stage Recycler and DegasserDocument12 paginiFMECA of PUMP Pumping Water From Coalescer To Second Stage Recycler and DegasserM Ahmad TauqeerÎncă nu există evaluări

- GKRT0207 Design RequirementsDocument23 paginiGKRT0207 Design RequirementshgomescoÎncă nu există evaluări

- COM Chemical Resistance ChartDocument16 paginiCOM Chemical Resistance ChartPramote.SuÎncă nu există evaluări

- Confidence Levels - Failure Rates - Confidence IntervalsDocument25 paginiConfidence Levels - Failure Rates - Confidence Intervalsgoldpanr8222Încă nu există evaluări

- Reliability Data of Omron ComponentsDocument1 paginăReliability Data of Omron Componentsastojadin1873Încă nu există evaluări

- Parts Failure AnalysisDocument3 paginiParts Failure Analysisswapneel_kulkarniÎncă nu există evaluări

- Alstom France 2001Document157 paginiAlstom France 2001Indra WidiartoÎncă nu există evaluări

- Mil STD 781dDocument47 paginiMil STD 781dHéctor Enrique Jaramillo SuárezÎncă nu există evaluări

- Excel SC 1018-1020Document5 paginiExcel SC 1018-1020Nabil MaksudÎncă nu există evaluări

- rr1114 PDFDocument54 paginirr1114 PDFrushdiÎncă nu există evaluări

- Common Cause Failure Analysis of EUROMAC SLITTING MachineDocument10 paginiCommon Cause Failure Analysis of EUROMAC SLITTING MachineKhuzaima AbidÎncă nu există evaluări

- JCSS Probabilistic Model Code Part - I PDFDocument65 paginiJCSS Probabilistic Model Code Part - I PDFLukusa BadimuenaÎncă nu există evaluări

- Reliability L D Arya PDFDocument169 paginiReliability L D Arya PDFHusnain nawaz siddiquiÎncă nu există evaluări

- Chemical Resistance PlasticsDocument2 paginiChemical Resistance PlasticsVishal V BhagwatÎncă nu există evaluări

- Kim2017 PDFDocument4 paginiKim2017 PDFkishoreÎncă nu există evaluări

- RCM GuideDocument97 paginiRCM Guidedesire1167% (3)

- Forcing The FarmDocument40 paginiForcing The Farmdiego_griffonÎncă nu există evaluări

- Mil HDBK 217f Notice 2Document80 paginiMil HDBK 217f Notice 2phanikrishna84Încă nu există evaluări

- Summary Report On Helicopter Ditching and Crashworthiness ResearchDocument193 paginiSummary Report On Helicopter Ditching and Crashworthiness ResearchmegustalazorraÎncă nu există evaluări

- Mil HDBK 217FDocument205 paginiMil HDBK 217FfrankimarceloÎncă nu există evaluări

- Iaea Tecdoc 478Document298 paginiIaea Tecdoc 478daymonÎncă nu există evaluări

- Reliability engineering fundamentalsDocument25 paginiReliability engineering fundamentalspankaj kulkarniÎncă nu există evaluări

- Risk Assessment Techniques (Part 1) - FMEADocument2 paginiRisk Assessment Techniques (Part 1) - FMEAMng LeongÎncă nu există evaluări

- Preview - ANSI AGMA 2015-1-A01 (R2014)Document7 paginiPreview - ANSI AGMA 2015-1-A01 (R2014)genaroÎncă nu există evaluări

- Oil-Free Screw Compressors: Water-Injected TechnologyDocument12 paginiOil-Free Screw Compressors: Water-Injected TechnologyCsaba SándorÎncă nu există evaluări

- Tooth Compressor ZR - ZT15 - 45Document12 paginiTooth Compressor ZR - ZT15 - 45Efe HazretleriÎncă nu există evaluări

- Comnpresor Compair L30Document8 paginiComnpresor Compair L30Roxana NegoitaÎncă nu există evaluări

- Compair 2 PDFDocument8 paginiCompair 2 PDFAveenÎncă nu există evaluări

- TG Filter Company Presentation - EN - 2015Document36 paginiTG Filter Company Presentation - EN - 2015igor_sandulenkoÎncă nu există evaluări

- DH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsDocument16 paginiDH Series: 15 kW-110 KW Oil-Less Rotary Screw CompressorsVijay KumarÎncă nu există evaluări

- Atlas Copco ZT55Document14 paginiAtlas Copco ZT55benlineyÎncă nu există evaluări

- Domnick Hunter: OIL-XplusDocument6 paginiDomnick Hunter: OIL-XplusAriep RachmanÎncă nu există evaluări

- Blade 1 3 PDFDocument8 paginiBlade 1 3 PDFYohan JanantoÎncă nu există evaluări

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityDe la EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityEvaluare: 3 din 5 stele3/5 (4)

- 3Document1 pagină3k_arindam1Încă nu există evaluări

- 16Document1 pagină16k_arindam1Încă nu există evaluări

- 2Document1 pagină2k_arindam1Încă nu există evaluări

- 14Document1 pagină14k_arindam1Încă nu există evaluări

- 6Document1 pagină6k_arindam1Încă nu există evaluări

- Tech RDocument5 paginiTech Rk_arindam1Încă nu există evaluări

- Paragraph Jumbles PDFDocument5 paginiParagraph Jumbles PDFBabuLalSainiÎncă nu există evaluări

- 4Document1 pagină4k_arindam1Încă nu există evaluări

- Section: General Technical Requirements: Annexure-D: List of SpecificationsDocument5 paginiSection: General Technical Requirements: Annexure-D: List of Specificationsk_arindam1Încă nu există evaluări

- 7Document1 pagină7k_arindam1Încă nu există evaluări

- ConductorDocument4 paginiConductork_arindam1Încă nu există evaluări

- Dry-Type Transformer SpecificationDocument2 paginiDry-Type Transformer Specificationk_arindam1Încă nu există evaluări

- From Narendrapur Sub Station: BhubaneswarDocument1 paginăFrom Narendrapur Sub Station: Bhubaneswark_arindam1Încă nu există evaluări

- 3) List of Raw Mateial SupplierDocument1 pagină3) List of Raw Mateial Supplierk_arindam1Încă nu există evaluări

- 102 - 220kv - Drainage Layout of Switchyard-ModelDocument1 pagină102 - 220kv - Drainage Layout of Switchyard-Modelk_arindam1Încă nu există evaluări

- Transformer CAHORS Transfix-India-2014 BDDocument20 paginiTransformer CAHORS Transfix-India-2014 BDk_arindam1Încă nu există evaluări

- 5 QapDocument3 pagini5 Qapk_arindam1Încă nu există evaluări

- Title Model - PDF FDNDocument1 paginăTitle Model - PDF FDNk_arindam1Încă nu există evaluări

- Air IndiaDocument1 paginăAir Indiak_arindam1Încă nu există evaluări

- Enquiry For SurveyDocument3 paginiEnquiry For Surveyk_arindam1Încă nu există evaluări

- Insulator FittingsDocument14 paginiInsulator Fittingsk_arindam1Încă nu există evaluări

- 3.5C Flat StripDocument1 pagină3.5C Flat Stripk_arindam1Încă nu există evaluări

- 5709E SeptemberDocument16 pagini5709E Septemberk_arindam1Încă nu există evaluări

- RefDocument4 paginiRefk_arindam1100% (1)

- Triumph HP VRLA - Product LeafletDocument4 paginiTriumph HP VRLA - Product Leafletk_arindam1Încă nu există evaluări

- 3.5C Flat StripDocument1 pagină3.5C Flat Stripk_arindam1Încă nu există evaluări

- 220kV Beam - 1Document3 pagini220kV Beam - 1k_arindam1Încă nu există evaluări

- Sl. No. Regarding Item Description Qty: PMT - 100 kVA PMT - 250 kVADocument2 paginiSl. No. Regarding Item Description Qty: PMT - 100 kVA PMT - 250 kVAk_arindam1Încă nu există evaluări

- Non-Segregated Phase Bus Duct BR en 6 2012Document8 paginiNon-Segregated Phase Bus Duct BR en 6 2012Aziddin GadingÎncă nu există evaluări

- Energy Modeling GuidelinesDocument32 paginiEnergy Modeling GuidelinesBrian MayÎncă nu există evaluări

- 2009 Greentech Annual DOE Solyndra GE and MoreDocument15 pagini2009 Greentech Annual DOE Solyndra GE and MoreKim HedumÎncă nu există evaluări

- GAIKINDO - Mr. Kukuh KUMARA - The Future of Indonesia's Auto PDFDocument13 paginiGAIKINDO - Mr. Kukuh KUMARA - The Future of Indonesia's Auto PDFPirhot NababanÎncă nu există evaluări

- B 815 DFC EeDocument17 paginiB 815 DFC EeBasman GeorgeÎncă nu există evaluări

- 18V46-60TS Brochure 1Document12 pagini18V46-60TS Brochure 1Mohamed FahemÎncă nu există evaluări

- Salami Catalog Group3 Zupcaste PumpeDocument32 paginiSalami Catalog Group3 Zupcaste Pumpeado_22Încă nu există evaluări

- Roquette Activity and Sustainable Development Report 2016Document52 paginiRoquette Activity and Sustainable Development Report 2016Khushi ChadhaÎncă nu există evaluări

- Cleaning As An Engineered ProcessDocument105 paginiCleaning As An Engineered ProcessThe Cleaning Library100% (5)

- P2 TAMBAHAN APRIL 2022-DigabungkanDocument8 paginiP2 TAMBAHAN APRIL 2022-DigabungkanRidho Dias KusumoÎncă nu există evaluări

- Presentation On The Cane IndustryDocument16 paginiPresentation On The Cane IndustryBashir Ahmed MujahidÎncă nu există evaluări

- 3D Printer : A Report OnDocument51 pagini3D Printer : A Report Ongoutham k.sÎncă nu există evaluări

- New Automatic Test Bench for Pumps Streamlines Inspections Up to 75 Pumps DailyDocument6 paginiNew Automatic Test Bench for Pumps Streamlines Inspections Up to 75 Pumps Dailysturbine100% (1)

- Energy Audit and Energy SavingDocument21 paginiEnergy Audit and Energy SavingPrafulla Mandlekar100% (2)

- Coffee Life CycleDocument6 paginiCoffee Life CycleSaransiri WongsiriÎncă nu există evaluări

- MPR January 2019Document23 paginiMPR January 2019Anonymous MKT2rZVkNÎncă nu există evaluări

- Gasification Process ModelingDocument6 paginiGasification Process ModelingRebeca Santamaria MedelÎncă nu există evaluări

- Tugas 2Document14 paginiTugas 2Tri Sunanda FathanahÎncă nu există evaluări

- Volvo Group KPMG True Value Case StudyDocument8 paginiVolvo Group KPMG True Value Case Studyaa1122Încă nu există evaluări

- Week 34 09092019 PDFDocument5 paginiWeek 34 09092019 PDFDasmamotor VenturesÎncă nu există evaluări

- LIST MoUs signed for steel projects in Orissa and JharkhandDocument3 paginiLIST MoUs signed for steel projects in Orissa and JharkhandAnimeshChowdhury19Încă nu există evaluări

- Medium Voltage Devices - Range ProductsDocument17 paginiMedium Voltage Devices - Range Productsfelipe1501Încă nu există evaluări

- 9053 Sonadih Cement Plant (Technical Offer)Document6 pagini9053 Sonadih Cement Plant (Technical Offer)Nitesh KhamariÎncă nu există evaluări

- Chapter 12 ITDocument22 paginiChapter 12 ITFarhanah MansorÎncă nu există evaluări

- 112.pwo - Water Oil Coolers, Emdc. Hy10-6010.UkDocument12 pagini112.pwo - Water Oil Coolers, Emdc. Hy10-6010.UkHuong TruongthuÎncă nu există evaluări

- Welkin Solutions - Profile PDFDocument36 paginiWelkin Solutions - Profile PDFZeshan HaydarÎncă nu există evaluări

- Fail-safe power supply solutionsDocument24 paginiFail-safe power supply solutionsparas99Încă nu există evaluări

- Electrical Interview GuideDocument9 paginiElectrical Interview GuideKrishnamoorthi VenkatesanÎncă nu există evaluări

- Bell Dredging Pumps GuideDocument24 paginiBell Dredging Pumps GuidelucarsoÎncă nu există evaluări

- Unit 2: Standards, Certification and Marking: ObjectivesDocument15 paginiUnit 2: Standards, Certification and Marking: ObjectivesHaianh PhamÎncă nu există evaluări